insight Kia Motors sustainability report 2008 execution · thinKing about Since 2003, Kia Motors...

Transcript of insight Kia Motors sustainability report 2008 execution · thinKing about Since 2003, Kia Motors...

Kia

Motors s

usta

inabil

ity r

eport 2

008

thin

Kin

g a

bout t

oM

orrow

Kia Motors sustainability report 2008insight execution

231, Yang

jae-do

ng

Seoch

o-g

u, Seo

ul, 137-938, K

orea

Kia M

oto

rs _ Sustain

ability M

anag

emen

t Team

TEL: +82.2.3464.5166 E-M

ail: ecoK

IA@

kia.co.kr / p

rince@

kia.co.kr

ww

w.kia.co

.kr

ww

w.kiam

oto

rs.com

Kia Motors

sustainability

report

2008

002 I Sustainability Report Framework

004 I Message from the CEO

006 I Stakeholder Participation

007 I Materiality Analysis

012 I Corporate Overview

012 I Global Network

014 I Management Philosophy and Vision

016 I Sustainability Management

020 I Corporate Governance and Board

intro

econoMic value024 I Disclosure on Management Approach

025 I Operating Performance

032 I Financial Highlights

033 I Special Story: Design Management, Global Management

environMental value038 I Disclosure on Management Approach

039 I Environmental Management

040 I Eco-Friendly Product Development

054 I Eco-Friendly Workplace

063 I Environmental Management System

065 I Eco-Friendly Supply Chain Management

069 I Environmental Management Costs

070 I Eco-Friendly Achievements in Domestic Workplace

074 I Special Story: Countering Climate Change

social value078 I Disclosure on Management Approach

079 I Employees

092 I Business Partners

097 I Customers

104 I Community

111 I Special Story: Communicating with Stakeholders

outro112 I Third Party Verification

114 I GRI (G3) / BEST Index

117 I Sustainability Report Committee

thinKing about Since 2003, Kia Motors has published its Sustainability Report for stakeholders annually. With this report, Kia aims to

demonstrate its on-going effort to better its sustainable management practices and report performance in sustainable

development initiatives to stakeholders. Kia Motors strives to fulfill its responsibilities to stakeholders who demand a

company that builds safer and more reliable vehicles while being mindful of the environment and minimizing the impact

of its automobiles. Sustainability Report 2008 provides a thorough analysis of the magnitude of the sustainability

development impact encompassing the areas of economics, the environment and society. With stakeholders’

participation, the sustainability report focuses on the subjects that address their particular interests.

This report outlines major achievements in sustainable development in 2007 with an aim to deliver a clear and accurate

picture of one year’s progress towards being a more sustainable company. Incorporating environmental consciousness

into all facets of product development, from production to logistics to supply chain management, Kia Motors continues

to grow as a socially conscious organization as detailed in this report.

RepoRting guidelines

Kia Motors Sustainability Report 2008 is based on the GRI’s* Sustainability Reporting Guidelines

2006 (G3) and BEST Sustainability Reporting Guidelines** from IPS. GRI’s criteria for the contents can

be found in the Outro of Kia Motors Sustainability Report under section “GRI (G3) / BEST Index.”

* GRI: Global Reporting Initiative (www.globalreporting.org)

** The BEST Guideline (BEST Sustainability Reporting Guideline) was jointly developed by the

Ministry of Knowledge Economy(MKE), the Korea Chamber of Commerce and Industry (KCCI),

and the Institute for Industrial Policy Studies (IPS) and provides for five levels of reporting

rigor (Level 1 ~ 5).

RepoRt outline

PuRPOSE _ This report aims to inform stakeholders of the results of sustainability management

from a balanced perspective while providing a thorough internal review of sustainability

management activities over the year. This report also serves to reexamine Kia’s current position and

evaluate future directions.

ACCOuNTING STANDARDS _ Investment and expenditure of environmental and social costs are

approved by the Board of Directors, audit committee and external audit committee according to

financial accounting standards. The report reflects an investment rating system 2004 based on the

investment breakdown by investment type.

CHANGES _ There are no significant changes in standards for reported data from previous reports,

unless otherwise specified.

DOCuMENT VERIFICATION _ This published report is based on the information provided by the

Sustainability Report Committee of Kia Motors and is created to impartially monitor the progress of

sustainable management within the company. This report is also verified by IPS in its report review,

onsite inspection and review of the Materiality Test according to the verification criterion outlined

by the GRI (G3) guideline and BEST guideline.

toMorrowKia Motors is an entity continually evolving to better serve sustainable efforts. During the evolution of this report, there

are bound to be some growing pains such as the lack of thorough overseas business information in last year’s report.

Thus, extensive information has been added about our overseas business to better meet G3 guidelines. To grow

properly, Kia will create certain rules to which it will strictly adhere. At Kia Motors, full disclosure of sustainable

development in a transparent manner is a top priority.

By publishing the Sustainability Report, Kia Motors reflects on its current sustainability management status, looks back

to find ways in which to improve and looks forward to identify innovative solutions to better serve sustainable efforts as

a responsible corporate citizen.

scope of the RepoRt

THE REPORTING PERIOD AND SCOPE _ The report covers the period between 2005 and 2007. To

accurately depict the quantitative performance, the past three years of data were collected

(environmental data in year zero (2003) + every three years). Qualitative results from the 2007

achievements in this report have also been assessed. The reporting year coincides with the

company’s fiscal year that ends on December 31st of each year. This report’s monetary denomination

is based on Korean currency, the Korean won. All quantitative data is based on ton (t), kilogram (kg),

kilometer (km), square meter (m2), kilowatt (kW), and all other units are listed with their numerical

values.

REPORT TARGETS _ This report covers Kia Motors, subsidiaries of Kia Motors and joint overseas

corporations. Domestic facilities covered include Kia headquarters, Sohari, Hwaseong and Gwangju

plants, R&D Headquarters and Customer Service Centers. Additionally, overseas facilities covered

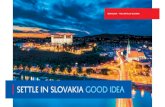

include Dongfeng Yueda Kia Motors, Kia Motors Slovakia plant, overseas technology research

centers and other overseas subsidiaries.

The 2008 report improved upon last year’s report by improving data collection methods and

filling in data gaps of overseas business activity.

REPORT PuBlICATION SCHEDulE _ The English version of the Sustainability Report 2008 was

published on June 5th of 2008, and The Korean version was published on March 21st of 2008 and

distributed at the general shareholders meeting. The Sustainability Report is published yearly, and

this is its 6th edition.

foR moRe infoRmation

Additional information can be found through the Internet and the Sustainability Management

Team of Kia Motors.

FOR MORE INFORMATION ABOuT KIA MOTORS, VISIT www.kia.co.kr or www.kmcir.com/eng/index.

aspx

TO VIEW THIS REPORT ONlINE, SEE englishdart.fss.or.kr (Repository of Korea’s Corporate Filing) or

www.kmcir.com/eng/index.aspx (Kia Motors website)

CONTACT: Sustainability Management Team, Planning Division of Kia Motors

TEL: +82. 2. 3464. 5166 E-Mail: [email protected] / [email protected]

Despite the unstable domestic and foreign business environment last year,

Kia Motors continued strengthening its business foundation to prepare for

future growth.

Business that adds economic value

2007 started with the long-term goal of establishing a brand identity unique to Kia

Motors. To that end, a design team was created in 2007 to build a brand identity

that stood above the rest and reflected a coherent design philosophy. Kia also

focused on improving profitability through cost saving measures to build a strong

stable economic foundation for the future. The recently erected production plant in

Slovakia, the second plant in China and new building in European facility allow Kia

to challenge the rapidly changing global market by increasing global production

and sales capacity. These pro-active steps also aid in the efforts to establish a strong

brand presence throughout the world. Kia Motors will leap onto the global stage

while solidly prepared for the future.

Business that pRomotes enviRonmental soundness

Environmental sustainability emerged as a global challenge for 2007. This challenge

fueled the need for eco-friendly cars that not only bolster increased performance

and safety but also feature eco-friendly designs. 2007 also became a year that

accelerated the development of an eco-friendly lineup of cars with technological

features like high fuel efficiency and low greenhouse gas emissions. Kia is especially

pleased to be acknowledged for its untiring effort in bridging automobile

development with environmental sustainability. Last year, Kia Motors was selected

as the third “most environmentally friendly automobile manufacturer” in the

United States, the world’s largest automobile market. Kia Motors was also voted

into the top tier of brands in terms of new car quality in the U.S. and European

markets as well as the domestic market. As an environmentally responsible

company, Kia is combating climate change through the reduction of greenhouse

emissions and hazardous waste material in the production process. Kia Motors

strives to minimize the environmental footprint of its products.

We continue in our pursuit to become

a highly competitive company built on a foundation of trust

with an exemplary track record of sustainable management.

Message froM the ceo04

05

socially ResponsiBle Business

Under the banner “Moving Together with the World,” Kia Motors actively

participates in community outreach and service activities. In 2007, Kia ran social

projects that promoted a culture of motor safety and provided aid to persons with

disabilities. Kia also expanded its employee volunteer service program with

emphasis on community service. The company implemented a structured social

contribution system to materialize the principles of corporate social responsibility. It

also devoted its energies to revitalizing the local business community by providing

tailored help to meet their needs. To bridge the disparity between small- and

medium-sized businesses (SMBs) and large conglomerates, Kia actively partnered

with them to provide support to foster healthy relationships. For example, Kia

ventured into overseas markets as equal partners, provided early business

stabilization support, and conducted technology seminars and R&D Tech days to

bridge the technology gap.

Economic value, environmental soundness, and social responsibility serve as Kia

Motors’ underpinnings of its sustainability efforts. To bring stakeholders’ happiness

and ensure a sustainable future for all, Kia Motors will always treat these three

issues equally and attentively.

As a company founded on trust, Kia Motors will play a crucial role in society as a

model corporate citizen fulfilling its responsibilities. As a highly competitive

company, Kia Motors will emerge as a model of sustainable management for others

to emulate.

We continue in our pursuit to become

a highly competitive company built on a foundation of trust

with an exemplary track record of sustainable management.

nam-hong cho

Kia Motors President and CEO

March 2008

Sustainable management begins with a belief that everyone is part of a community. Kia

Motors is a corporation that is part of a larger business community in which it operates and

shares its responsibility within the community. As such, sustainable management must always

consider the stakeholders in all matters of corporate activity. As the corporation’s size

increases, it becomes easier to lose focus on the people who matter. Through a variety of

communication channels, Kia is able to collect feedback and determine the needs of its

stakeholders. The means by which Kia can keep an open channel of communication with its

stakeholders is demonstrated below.

communication channel with stakeholdeRs

stakeholdeRs’ opinion suRvey on sustainaBility RepoRt 2007

Stakeholder opinions on Kia Motors Sustainability Report 2007, published on March 16th of

2007, helped identify key areas of improvement for the 2008 report. The 2007 report was

divided into six parts consisting of interesting parts, excellent parts, weakest parts, contents,

communication, and overall opinion. After, a sample of 67 stakeholders participated in a

survey to detail opinions expressed in each of those parts.

staKeholder participation

Reader survey Results and 2008 Report improvements

kia motors

shareholders & investors

customers

employees

Business partners

ngos & academia

government

Annual shareholders meeting

Customer satisfaction surveys

Addressing customer complaints

Report committee

Report survey

Seminars, forums, survey participation

Analyzing issues and reaction

Mutual business cooperation

Business partners’ feedback channel

Policymaking participation

sampling of stakeholder survey

• employees: 69%• Business partners: 4%• Customers:6%• sustainability management experts: 19%• miscellaneous: 2%

weak contents

50%

40%

30%

20%

10%

22%

14%

46%

18%

0%

economy environment society product

excellent contents

50%

40%

30%

20%

10%16%

43%

15%

26%

0%

economy environment society product

06

I 1 I Writing a report from a stakeholder’s perspective (with

footnotes to explain jargon)

Technical terms and internal jargon can be often confusing

and misunderstood. Confusion was minimized with the

addition of footnotes and detailed explanations of technical

terms and internal jargon used in the report.

I 2 I Sustainable management vision and objectives

The Materiality Test was applied to evaluate the future

direction of Kia’s sustainable management efforts. Contents

of sustainable management activities were expanded at the

beginning of the report. Also, the company's strategy,

performance status and business management goals in each

section of the report were expounded.

I 3 I labor relations-related issues

An in-depth report of social performance in the social value

section of the sustainability report was also included.

Information related to labor issues will gradually be added.

I 4 I Corporate governance

More detailed information on business ethics and corporate

governance were included.

I 5 I Report contents

The 2008 report cites corporate performance and plans based

on the principle of sustainable management while meeting

the guideline requirements.

I 6 I More balanced report (relatively insufficient data in

sections beside environmental value)

Entries on product development (including environmental

value) and social value that were insufficient in last year’s

report according to the stakeholder survey were also

strengthened.

I 7 I Visually aided report (including graph)

Graphs, information in Tp form and a special story to improve

readability were added.

I 8 I Supplementary information in comparison with other

industries

A report with a more balanced view was produced by adding

external evaluations of the company’s and industry’s

activities.

07

The Sustainability Report must incorporate relevant issues from both the company and its

stakeholders. Kia believes that management activity centered around stakeholders’ interests

is the key to becoming a company that opens the doors to a sustainable future. The

Materiality Test allowed key issues to be identified, which were then used to create strategies

to improve sustainability development. In addition, Kia clearly reported current plans and

activities in response to the Materiality Test in the Kia Motors Sustainability Report 2008.

mateRial issues (2008)

Materiality analysis

• employees: 69%• Business partners: 4%• Customers:6%• sustainability management experts: 19%• miscellaneous: 2%

+– (medium) (high)inteRnal conceRns

sustainaBle management

• StakeholderFeedback

economy

• DomesticandForeignMarketExpansion

• StrengtheningOverseasSales

pRoduct development

• Reusability(Recycling)•EmissionReduction

socially ResponsiBle management

• StableEmployment

• Discrimination-FreeWorkplace(HumanRights)

• WorkplaceSafetyandHealth

• ContributiontotheCommunity

enviRonmental management

• EnvironmentalLawCompliance

• ReductionofHarmfulGasEmissionsintotheEnvironment

• CleanerProductionTechnology

• EnvironmentalCosts(Accounting)

sustainaBle management

• SustainableManagementPlanning(Results&Goals)

economy

• FinancialPerformance

• BrandValue

pRoduct development

• AlternativeFuelVehicleDevelopment

• ProductSafety

socially ResponsiBle management

• LaborRelations

• CommunityServiceProjects

• PartnershipSupport

• FairTrade

enviRonmental management

• ClimateChangeCountermeasures

• EnvironmentalManagementSystem

economic achievement

• ExecutiveLeadership•CorporateGovernance

• BusinessProcessInnovation(Reorganization)

economy

• IndirectEconomicImpact

pRoduct development

• ProductDevelopmentStrategy

socially ResponsiBle management

• WorkandLifeBalance•EmployeeVolunteerWork

• LeadershipTraining

enviRonmental management

• EnvironmentalProtection•Eco-friendlyProductAcquisition

• ManagementofTransportationandLogisticsImpact

on Environment

sustainaBle management

• ManagementPhilosophyandVision

• BusinessEthics

economy

• RiskManagement

pRoduct development

• BetterFuelEconomy

socially ResponsiBle management

• CustomerSatisfaction(CustomerService)

• WorkandLifeBalance

• EmployeeTraining

• EmployeeWell-being

enviRonmental management

• ConservationofEnergyandResources

+

–

(med

ium

)(h

igh

)e

xte

Rn

al c

on

ce

Rn

s

what is the materiality test?

First, materiality should be defined. According to the GRI’s

Sustainability Reporting Guideline, materiality is defined as “the

threshold at which an issue or indicator becomes sufficiently

important that it should be reported.” Simply, the materiality test is

a test to see if an issue or indicator is relevant enough for this report.

Kia Motors defines the relevant issues which must take priority and

identified as high risk and/or high interest to stakeholders. In

addition, Kia Motors employed the IPS Materiality Test ModelTM to

determine the material issues. The IPS Materiality Test ModelTM is a

5-step test model subdivided into internal policies, norms and laws,

stakeholder feedback, industry benchmarks and media research. IPS*

created the IPS Materiality Test ModelTM in December 2006 to test

and derive material issues that match characteristics and present the

condition of each industry.

* One of the functions of IPS is to help form strategies for sustainable development.

test 2 norms and lawstest 3 stakeholder feedbacktest 4 industry Benchmarkstest 5 media Research

high Reporting priority2

4

1

3

ex

teR

na

l c

on

ceR

ns

inteRnal conceRnstest 1 internal policiestest 3 stakeholder feedback

as part of the journey, weathering both the good and bad is expected. sometimes, the journey

requires driving through the rain while hoping for clear skies ahead. kia motors has made it its goal to

not look for short-term gain, but instead focus on steady long-term gain. even in harsh weather, kia

continues to raise brand awareness and make its way towards a brighter future through continuous

investment.

08

continuance

Reaching the destination is not necessarily the goal. sometimes, it’s best to move aside to let others

pass. Because the road is shared, it is only courteous to share with others. these little acts of kindness

gather and are then “paid forward.” in the end, the journey goes faster in the right direction.

kia motors remembers that in all its activities, stakeholder happiness precedes all other priorities.

coexistence

09

along the road, there are a number of other creations that share the same journey. as such, it is im-

portant to clear obstacles for others on the way. when choosing a path wisely, looking back on the

road just traveled provides insight into how their journey is just as precious as one’s own. the dream

of a peaceful relationship between the automobile and the earth is what drives kia motors forward.

10

conservation

ahead of the tunnel there is a light but it does not symbolize the end. the journey continues on and

there are often rainy days. when traveling with others, the journey can slow so as to admire the beau-

ty of the land along the way. kia motors’ aim is not to travel the fastest or the furthest, but rather, it

is to ensure an enjoyable journey for everyone.

11

aspiration

conservation

company intRoduction

Since its establishment in 1944, Kia Motors has led the development of the then infant Korean auto industry and contributed to

building a strong national economy over the past 63 years. In 1975, Kia Motors’ first passenger car, the Brisa, became the first

Korean vehicle to be exported, which opened the floodgates to Korean exports. By 2000, through the establishment of a global

sales network, Kia has laid the groundwork to expand to every corner of the global market.

Domestically, Kia revitalized the local business community by creating employment, purchasing properties and partnering with

businesses to open overseas markets. In addition, Kia worked with local residents to find tailored solutions to each of the local

community’s problems. Through community service, Kia continually seeks ways to co-exist and cooperate with the community.

Kia Motors communicates tirelessly with the community to fulfill its duty as a corporate citizen. With concern for the

environment, Kia dedicates its energies and resources to becoming a part of the sustainable solution. Kia will build an unshakable

trust with customers by creating more value for customers who in turn will help the company grow. Ultimately, Kia Motors will

usher in a brighter sustainable future with its dynamic line-up of vehicles.

company status (as of december 31, 2007)

company Kia Motors

key executives Mong-Koo Chung / Eui-Sun Chung / Nam-Hong Cho

industry Cars and trailer manufacturing

product Cars and auto parts

headquarter 231, Yangjae-dong, Seocho-gu, Seoul, Republic of Korea

established December 11, 1944

total asset 12 trillion and 853.8 billion won

capital 1 trillion and 848.7 billion won

employees 32,977*AdditionalinformationisavailableontheweborEconomicValuesectionofthisreport.

coMpany overview

12

Kia Motors Japan

China Manufacturing Plant (Yancheng, Plant one & two with 3,367 employees)

Dongfeng Yueda Kia

Asia Regional Headquarters (Kuala lumpur, Malaysia)

South Africa Office

Middle East & Africa Regional Headquarters (Dubai, uAE)

Kia Motors Spain

Kia Motors Hungary

Kia Motors Czech s.r.o

Kia Motors Poland

Kia Motors Deutschland (Frankfurt)Kia Motors Ireland

Kia Motors uK ltd.Kia Motors Belgium

Kia Motors France

Kia Motors Austria

Kia Motors Central Europe

Kia Motors Sweden AB

Eastern Europe / CIS Regional Headquarters (Moscow, Russia)

Kia Motors Europe / Kia Motors European R&D Center / Kia Motors European Design Center (Frankfurt, Germany)

Slovakia Manufacturing Plant / Kia Motors Slovakia(Zilina, 300,000 units annual capacity, 2,601 employees)

Kia Motors Australia / Pacific Regional Headquarters

Kia Motors New Zealand

Headquarters – Seoul (32,977 employees, three manufacturing plants, two research facilities,

20 service centers, 340 sales offices)

13

majoR facilities

domestic

R&d Namyang R&D Center, Mabuk R&D Center

production •Sohari Manufacturing Plant: Annual Output 350,000 cars

(Carnival/Sedona and Pride/Rio models)

•Hwaseong Manufacturing Plant: Annual Output 600,000 cars (Sorento, Mohave/

Borrego, Cerato/Spectra, Opirus/Amanti, and Lotze/Optima/Magentis models)

•Gwangju Manufacturing Plant: Annual Output 420,000 cars

(Carens/Rondo and Sportage models, trucks, buses and military vehicles)

sales 17 Regional Offices, 340 Regional Sales Office, 424 Dealerships, 13 Shipping Offices

service 20RegionalServiceCenters,811ServicePartners,252VariousServiceProviders

overseas

R&d U.S. Technical Center, U.S. Design Center, Japan R&D Center, Europe R&D Center and

Europe Design Center

production • China Manufacturing Plant 1 & 2: Annual Capacity 440,000 cars (Rio, Sorento, Optima/

Magentis, Carnival/Sedona, Cerato/Spectra and Sportage models)

• Slovakia Manufacturing Plant: Annual Capacity 300,000 cars

(cee’d and Sportage models)

• Georgia Manufacturing Plant: Annual Capacity 300,000 cars (Under construction)

sales 165 Countries, 17 Subsidiaries, 148 Dealerships, 3,864 Dealers

service Located at Dealerships

Kia Motors Canada (Toronto, Canada)

Kia Motors Technical Center (Ann Arbor, Michigan)

Kia Motors America (Irvine, California)

Kia Motors Design Center (California)

Central & South America Regional Headquarters (Miami, Florida)

u.S. Manufacturing Plant / Kia Motors Manufacturing Georgia(West Point, Georgia / under construction / expected annual capacity of 300,000 cars)

China Manufacturing Plant (Yancheng, Plant one & two with 3,367 employees)

coRpoRate pRoduction

coRpoRate sales

Regional headquaRteRs

Regional offices

otheRs

global networK

innovation for

humanity

aim for the apex of the world

pursuing customer satisfaction

Reforms and challenges

aim for the apex of the world

Kia Motors will become a world-class

brand and overtake the position as the

apex of the global automotive industry.

In addition, Kia will build an ideal

structure that entwines both qualitative

and quantitative growth.

pursuing customer satisfaction

Customer satisfaction is the final goal of

Kia Motors. Trust and confidence is

earned by providing the best

technology, exemplary product quality

and excellent customer service.

Reforms and challenges

Kia will abandon preconceived notions

and practices. The company will find

creative and innovative ideas to pursue

its long-term vision of creating a society

that respects the environment and

humanity. Kia will work to advance a

corporate culture that contributes to the

prosperity of humankind.

ManageMent philosophy

and vision

14

15

management philosophy

The spirit of creative challenge is the underlying mentality and principle at Kia Motors. It is

the driving force behind the continued success of Kia Motors today and is what will allow an

active response to the changing business environment. With this spirit of creative challenge,

Kia hopes to create a rich and bountiful experience for its shareholders, customers,

employees, partners and the community.

Business policy

management confidence

Kia Motors facilitates business activities and increases the effectiveness of management by

fostering a mutual trust between employees and management. Kia believes that strong

confidence formed within the company will strengthen the company’s competitiveness and

organizational culture.

In turn, strong competitiveness and culture will boost operational efficiency, product

quality and customer service. Through strong management confidence, Kia insures worker

productivity, superior products and service, and stronger stakeholder confidence in the

company. In 2007, with the strong backing of its stakeholders, Kia took giant steps toward

becoming a world-class brand and competitor.

worksite management

Kia Motors enhances employee satisfaction and product quality through rapid decision-

making and immediate response to issues or suggestions that may arise in the field.

In 2007, through management of a global network, including regional sales headquarters

and overseas factories, Kia was able to provide early stabilization support and increase sales

capability. As a result, Kia’s ranking in IQS by JD Power and Associates jumped 12 spots from

2006 to 12th place with 125 points.

transparent management

In an effort to achieve sound governance and transparent management, Kia created a Board

of Directors, where the major corporate decisions are made, and established “checks and

balances” of management. To secure transparency of the decision-making process, corporate

governance was institutionalized. Kia Motors’ corporate governance is made up of the Board

of Directors, Audit Committee, Ethics Committee, and the Board Nominating Committee.

In 2006, Kia Motors received public attention due to a lawsuit against its executives for

their dealings with the management of company’s funds. Using this as an opportunity to

reflect, Kia Motors placed stronger re-emphasis on the fairness and transparency of decision-

making processes and proper business ethics.

sustainaBle management

Kia Motors began sustainability management based on the pressing need for accountibility

for the environment, now and in the future. In the past, the need for a more convenient

mode of transportation was the primary focus that shaped the automobile industry. However,

recent trends reveal the need for eco-friendly alternatives. In the 21st century, expectations

have changed and demand from the automotive industry to develop vehicles that maximize

convenience while minimizing their environmental impact is rising. All companies, regardless

of the industry, must exercise responsibility in generating profit and fairly distributing

revenue while keeping stakeholder interests in mind.

As part of the global automotive industry, Kia Motors proactively practices Environment-

ally Sound & Sustainable Development (ESSD) to fulfill its responsibility as a corporate citizen.

As such, Kia Motors hopes to grow with the community in a responsible manner. To help

achieve this goal, Kia created three models of sustainable development: environmental

management, community outreach and service, and business ethics.

All divisions of Kia Motors recognize the importance of sustainability management. Every

year, each department selects personnel to give a briefing on the current status of Kia in

improving the system one step at a time.

sustainability ManageMent16

sustainaBle development model

Sustainable Management

-Materialization

of Love for Humanity through

Automobiles

Business Ethics

Environmental Management Community Engagement

committee oRganization chaRt

economy

• PlanningOffice•FinanceCenter

pRoduct enviRonment

• Environmental Technology Institute

• Namyang R&D Center

pRoduction enviRonment

• Sohari Manufacturing Plant

• HwaseongManufacturingPlant

• GwangjuManufacturingPlant

• ChinaManufacturingPlant

• SlovakiaManufacturingPlant

• A/SDivision

• Production&DevelopmentDivision

community

• Management Support Division

• Procurement Division

• Domestic Sales Division

• Overseas Sales Division

social ResponsiBility

• Office of Planning & Coordination

• Management Support Division

• Regional Offices

Business ethics

• AuditOffice

Sustainable Management Supervision

-Sustainability

Management Team

sustainaBle development model

environmental management

Kia Motors’ environmental management aims to improve economic value and environmental

sustainability simultaneously. Kia sets environmental management as top priority for

sustainable management and seeks to expand the program. In June 2003, Kia Motors

unveiled a global eco-friendly management initiative called “ECO-GT5 2010”(Top 5 Global

Environmental Automobile Manufacturer by 2010). This initiative has laid a solid foundation

for creating sustainable values as Kia Motors fulfills its economic, environmental and social

responsibilities. ECO-GT5 2010 consists of environmental policy, environmental activity

guidelines, environmental goals, specific objectives, and implementation plans. The

Environmental Activity Guideline is comprised of the three-stage roadmap as shown below.

17

environmental activity

guideline

goals of enviRonmental management

Environmental Management Business Environment (Marketing, A/S, Sales)

Production Environment (Production, Procurement)

Product Environment (R&D)

enviRonmental declaRation

1. Share responsibility for the present

and future.

2. Make efforts in meeting environmental,

economic and social demands.

3. Strive to preserve life, diversity and the

Earth’s beauty.

4. Respect nature, and economic and

social justice.

enviRonmental policies

Concern for the environment is at the core of

Kia’s business management activity. As a global

stakeholder, Kia will do all it can to fulfill its social

and economic responsibilities.

Kia will actively lead the efforts in developing a

strong economy and protecting the environment.

Respect for the environment, present and future, is

what motivates the company.

enviRonmental management opeRation system

Environmental Management Plan Implementation

Environmental Management Strategy and Goals

Environmental Analysis and Performance Evaluation

PlAN DO

CHEC

K

A

CT

Kia MotorsImprovement and Application

Kia Motor's Long-term

Environmental Management

Strategies

Environmental Action Plan;

Three Rounds in Three Years

FIRST ROUND

2003-2005establishment stage

for environmental

management(Introductory Stage of Sustainability Management)

Building environmental management bases focused on domestic business sites

SECOND ROUND

2006-2008extension stage for

environmental management(Establishment Stage for Sustainability Management)

Reinforcing organizational competencies through extending environmental management of all business sites at home and abroad

THIRD ROUND

2009-2011growth stage for

environmental management(Extension Stage for Sustainability Management)

Pursuit of sustainable growth through environmental management

Business ethics

Working towards a more sustainable future is one of the responsibilities of corporate ethics.

Using a corporate responsibility model of fair distribution of earnings, Kia Motors adopted

the principle of fairness and impartiality as a model for sustainable management. Kia has

combined two corporate principles, building a trustworthy and transparent business, and

incorporates them into its corporate ethics code as a guideline for sustainable development.

Kia Motors’ ethical practices will serve as a medium to correct and improve faulty corporate

customsandcoststructuretoincreaseoverallcompetitivenessandEconomicValueAdded

(EVA®). The ultimate goal is to pursue business ethics that value stakeholders.

In an effort to become a trustworthy and transparent company, Kia adopted its code of

ethics in 2001 and issued a code of conduct for all employees. To ensure ethics compliance,

Kia conducts mandatory online education for employees and created a Cyber Audit Office to

enforce and oversee compliance.(1)

(1) MoreinformationontheCyberAuditOfficecanbefoundintheSocialValuesectionofthisreport.

By raising its competitiveness to world-class levels, Kia has been given the great responsibility to guide the growth of its national economy for the 21st century.

• Contribution to Society and

Country

• Promotion of Shareholder and

Customer Interests

• Respecting Human Rights and

Fostering Future Talent

• Establishing Respectable

Partnerships between Partners

• Establishing Transparent

Management

Code of Ethics Adoption

Strict Ethical Compliance

in Acquisitions Department

Adoption of Code of Ethics

Regulation of Workplace Ethics

Regulation of Gifts and Bribes

18

structure of Business ethics

Sections

Institutionalized Code Kia Motors’ Code of Ethics

Regulation of Workplace Ethics

Employee Ethics Compliance

Cyber Audit Office Cyber Call-in Center

Production and Distribution of Employee Ethics Guidelines

Ethical Guideline Publication and Cyber Ethics Education

19

community engagement

Kia Motors believes that community involvement is a natural extension of corporate social

responsibility as an active member of the community. Community service demonstrates the

company’s appreciation for its stakeholders and the community who have supported its

growth and made it possible for Kia’s current success. Kia Motors believes that the community

must be healthy in order for sustainable development to be successful. For this reason, Kia

adopted community outreach and service as its third criterion in its sustainable management

policy and continues to expand the scope and scale of the activity.

In 2005, Kia started a community service slogan, “Moving Together with the World,” to

move towards a better future with neighbors and the greater community. Kia’s community

activities encouraged comprehensive future-oriented activities as social welfare,

environmental preservation, next-generation growth support, cultural arts, healthy living

promotion and international exchange. Of those, Kia further focuses on motor safety and

convenient motor use within its community service activities. For example, Kia Motors started

the “School Zone Keeper Campaign” and other traffic safety campaigns to raise public motor

safety awareness. Also, the “Easy Move” vehicle development and accessibility campaign

creates a friendly transportation environment for persons with disabilities. Through these and

other programs, Kia employees have volunteered their time and energy to reach out and

serve the community. With the launch of overseas production facilities in 2007, overseas

headquarters and production facilities conducted community service in each of their

respective communities to reach the greater global community. Every part of the

organization, internally and externally, has taken active part in the effort to make sustainable

development successful.

Expansion of Motor Safety Culture

• Child Safety Motor Education

• School Zone Keeper Campaign

• Support Program for Traffic Accident

Victims and Surviving Children

Improving Motor Environment for the

Disabled

• Easy Move Vehicle Development and

Accessibility

• Improving Accessibility

• Supporting Disabled with Special Shoes

and Safeguards

Regional Social Projects

• Cultivation of the Environment and

Young Talent

• Development of Local Community

Employee Volunteer Work

• Social Volunteer Groups

• Volunteer Work by Affiliates

Kia Motors and Its Affiliates

Expansion of Motor Safety

Culture

Regional Social Projects

Employee Volunteer Work

Improving Motor

Environment for the Disabled

corporate governance

and board

Kia Motors’ corporate governance is a system created to insure soundness and transparency

of the corporation and manage the interest of Kia executives, shareholders and employees.

Kia Motors’ governance structure consists of the Board of Directors, the Board Committee

who voices the opinion of the external stakeholders, Audit Committee who closely watches

over the corporate management, the Board Nominating Committee, and the Ethics

Committee.

Board of directors

The Board of Directors is responsible for oversight and supervision of the overall affairs of the

company. More specifically, the Board of Directors not only undertakes the duties of the

articles of association as well as the duties entrusted by general meeting of shareholders, but

also oversees the company’s overall policy and management of the business. Additionally, the

board will appoint one of its members to be the chairperson of the Board to supervise

management. The Board of Directors consists of four inside directors and five outside

directors. The Board will meet regularly at appointed times and more meetings will be held as

needed.

Performance-oriented Compensation _ Kia Motors CEO, executives and senior managers

receive annual salaries which are determined by both personal achievement and

performance.

committee

Audit Committee _ The Audit Committee consists of four outside directors. The Audit

Committee’s role includes monitoring the fairness and transparency of business practices,

auditing the company’s operations, and investigating the company’s assets to assess business

performance. The Audit Committee also discusses the minutes of the annual shareholders and

Board of Directors meetings.

Board Nominating Committee _ The Board Nominating Committee consists of two outside

directors and two inside directors. The two outside directors are chosen at the annual

shareholders meeting.

20

the BoaRd of diRectoRs and committees

Board of Directors Ethics Committee

Board Nominating Committee

Audit Committee

21

Ethics Committee _ The Ethics Committee consists of five outside directors. The main goal of

the Ethics Committee is to maintain fair and transparent business practices. To achieve that

goal, the Ethics Committee reviews the "Monopoly Regulations and Fair Trade Law," enforces

the stipulation on favoritism in personal relationships in the "Securities Exchange Act," and

checksforcompliancewiththeFairTradeVoluntaryInspection.ThesocialfrontoftheAudit

Committee’s responsibilities also includes reviewing and evaluating community engagements.

Lastly, the Ethics Committee reviews the Code of Ethics and Code of Conduct within the

company and makes amendments to the Codes when deemed necessary.

Board structure as of December 31, 2007

Composition

Internal

External

Name

Mong-Koo Chung

Eui-Sun Chung

Nam-Hong Cho

Hee-Bong An

Jong-Chang Kim

Jong-Am Chung

Yul Choi

Dong-Sung Cho

Gun-Soo Shin

Position

Member of Board Nominating Committee

Member of Board Nominating Committee

-

-

Member of Board Nominating Committee,

Chairperson of Audit Committee, Member

of Ethics Committee

Member of Board Nominating Committee,

Auditor, Chairperson of Ethics Committee

Auditor, Member of Ethics Committee

Auditor, Member of Ethics Committee

Member of Ethics Committee

Remarks

Chairperson of Board

shareholders’ Rank as of december 31, 2007 (over 5% ownership)

Rank

1

2

3

Shareholder

Hyundai Motors

Credit Suise Financial

Treasury Stock Union

Number of Shares

134,285,491

29,583,586

24,719,219

Ratio of Shares

38.7%

8.5%

7.1%

2007 membership status of corporate associations

NO Association Membership Grounds

01 Federation of Korean Industries Mandatory

02 Korea Automobile Manufacturers Mandatory

Association

03 Korea International Trade Association Mandatory

04 Korea Economic Organization Council Mandatory

05 Korea Chamber of Commerce & Mandatory

Industry

06 Korean Federation of Science and Mandatory

Technology Societies

07 Korea Industrial Technology Mandatory

Association

08 Korea Management Association Necessary

NO Association Membership Grounds

09 Fair Trade Commission Necessary

10 Korean American Friendship Necessary

Association

11 Korea Association of Machinery Necessary

Industry

12 Ethical Management Forum Necessary

13 Korean Standards Association Necessary

14 Korea Logistics Association Necessary

15 Korea Association of Industrial Necessary

Designers

16 Korea Council for Sustainable Necessary

Development

For a car, the road is where it will find its true existence.

For a business, sustainable growth is the path that will add meaning to its existence.

When 20,000 moving parts come together, life of the automobile

begins. The power that moves the world comes from those that

gathered under the name of Kia Motors from all corners of the world.

The first mission of the company is generating profits. But Kia is not

only looking to add growth in the few sparks of visible performance.

Instead, Kia sets its goal in tune with long-term sustainable

development. Korea, China, Slovakia, the United States, Europe and

Asia all gather to create the Kia Motors that is known around the world

today and are paving the way for the future.

econom

ic v

alue

Kia Motors is focusing on enhancing profitability, strengthening global management,

introducing flexible manufacturing systems and innovating corporate culture to realize

its goal of creating sustainable economic value. 2007 was an especially important year as

Kia announced the launch of its design management system, through which Kia will

enhance its brand value and aggressively roll out a differentiated Kia Motors design

identity.

KEy AChIEvEMEnTS And plAnS

CrITICAl ISSUES

Financial performance

In 2007, Kia Motors recorded operational losses due to a worsening business environment

that included high oil prices and a strengthening Korean currency. However, the business

loss contingency buffer created in 2006 and operating profit from the fourth quarter of

2007 allowed Kia to fortify the company’s financial health to respond to any changes in

the volatile business environment. A variety of new cars announced for 2008 will further

improve Kia’s financial performance.

Brand Equity

In 2007, the domestic and international communities recognized Kia Motors’ highly

competitive product quality by bestowing high marks in product quality and safety

evaluations. Kia has strengthened its design competitiveness and continuously improves

quality, which will ultimately translate into stronger brand recognition.

2007 performance• Promotion of Total Cost Innovation (TCI) • Quality improvement: IQS rises 12 spots• Erected a solid foundation for future growth

2008 plans• Secured successful entry into the new car market• Focused on strengthening total sales capacity

2007 performance• Established production plant in Slovakia• Established second production plant in China• Established new Kia Motors Europe headquarters

2008 plans• Strengthen global capability• Raise overseas subsidiaries’ profitability

2007 performance• Early operational stabilization and met mass-production schedule deadline • Secured engine and transmission production flexibility

2008 plans• Improve operating capacity, HPV (1) and organizational efficiency (2)

• Secure cost competitiveness

2007 performance• Fostered active corporate culture through bulletin board encouragements• Established and spread Kia Motors vision

2008 plans• Revitalize organization and improve corporate culture

Business profitability as

top priority

Build a flexible manufacturing system

Innovate corporate culture

Laid foundations for global

management

+ + +

Innovation for humanity (Innovation for Customers)

(1) HPV (Hour per Vehicle): The time it takes to build one car

(2) Organizational efficiency: the effectiveness of human resources management

(For example: if efficiency is below 60%, then 1.67 workers will do the work of 1 worker)

24

Disclosure on

management approach

25

The automotive industry’s activities have a wide ripple effect on other industries, ranging from

materials and equipment, to parts and manufacturing, transportation, sales and maintenance, oil,

insurance, and banking industries. The automotive industry has potential for high economic

growth and job creation as a leading labor-intensive national industry based on economies of

scale. In 2007, the domestic automotive industry and related industries employed an estimated 1.5

million persons, which represented 10% of total national employment. Last year alone, the

domestic automotive industry accounted for 14% of total national exports, amounting to

approximately 17% of the national tax revenue.

Hyundai and Kia Motors comprise Korea’s largest national automotive group and together

hold 75% of the domestic automobile market. As the leader of the Korean automotive industry,

the Hyundai-Kia Automotive Group is the driving force behind the nation’s economic

development. As a convenient mode of transportation for goods and people, the automobile

sustains modern life and economic activities. Kia Motors is Korea's second largest automobile

manufacturer with a sales network and production bases spanning 165 countries. As a global

company, Kia Motors has played a major role in the sustainable growth of national and

international economies by raising transportation convenience while minimizing its impact on the

environment. Through responsible corporate management at the national and international

levels, Kia will grow together with its stakeholders.

KEy MAnAgEMEnT ACTIvITIES And AChIEvEMEnTS In 2007

Kia Motors faced many difficulties in 2007 amidst a harsh business environment that was plagued

by high oil prices, currency exchange volatility, and the sub-prime crisis in the U.S. Even during this

difficult time, Kia maintained its focus on long-term sustainable growth and strengthened its

foundation for the future.

Kia Motors’ business activities in 2007 can be summarized into two parts: enhancing

profitability and laying the groundwork for future growth. Last year, Kia Motors addressed its goal

of enhancing profitability by improving product quality, boosting productivity and reducing costs.

Kia’s focus on product quality resulted in receiving top marks in quality surveys conducted by

independent research firms in the United States and Europe, thereby placing Kia’s quality in the

top tier among the world’s automakers. On the service front, Kia placed utmost attention on

operating performance

securing “customer satisfaction” as a top priority. As a result, the Korean Standards Association’s

'Korean Call Center Service Quality Index' survey ranked Kia’s customer service in first place, while

the 'Korean Service Quality Index' survey ranked Kia’s overall customer service in first place for the

fourth consecutive year. (1) Kia is becoming a company known for its customer service and

satisfaction. In addition, Kia introduced a design management system in order to secure

competitiveness and differentiate Kia Motors’ vehicles from the rest of the pack.

With the core business objective of strengthening international competitiveness, Kia erected

the Slovakia plant, a new European headquarters complex and a second production plant in China.

These facilities have secured the base for stable global production and sales capability for the

future.

Efforts made in 2007 have become a stepping-stone for 2008. Kia has laid out the key

challenges of “establishing a sales-oriented management system,” “securing profitability,” and

“strengthening core competencies” in 2008. The company’s goals for 2008 are the delivery of 1.69

million vehicles at home and abroad while achieving 23 trillion won in sales and operating margin

of 3%. With the release of the Borrego (Mohave) in January 2008, Kia is set to launch its restyled

Lotze (Optima/Magentis), next generation Spectra (Cerato), and all-new Soul for 2008. Two new

models are further planned for release in 2009. Enhancing its product lineup with the launch of

new models, Kia has orchestrated a turning point for sales recovery.

Kia will innovate management to ensure sustainable growth regardless of the business

environment. In 2008, the design management system will be leveraged to raise brand equity. In

order to establish an excellent workplace for employees,(2) the Great Work Place (GWP) program

was initiated to form close personal relationships among employees, the company’s first corporate

customer. In addition to building efficient overseas networks, Kia plans to conduct various

employee-training programs to strengthen global capacity in every sector of its business.

26

(1) More information on customer services can be found in the social value section of this report.

(2) Great Work Place refers to a workplace with three essential elements: a place where mutual trust between labor and management exists,

a place where employees are proud of their work, and a place where employees enjoy working together.

AnnUAl prodUCTIon Unit: Vehicles 2007 prodUCTIon By plAnTS Unit: Vehicles

total Domestic plants Overseas plants

236,628

387,579345,806

105,538148,569 145,158

Sohari Hwaseong Gwangju Seosan China Slovakia Total

500,000

600,000

700,000

800,000

900,000

1,000,000

1,100,000

1,200,000

1,300,000

1,400,000

400,000

300,000

200,000

100,000

0

2005 2006 2007

1,105,431

1,215,502

110,071 120,480

250,696

1,150,397

1,270,877

1,118,582

1,369,278 1,369,278

500,000

600,000

700,000

800,000

900,000

1,000,000

1,100,000

1,200,000

1,300,000

1,400,000

400,000

300,000

200,000

100,000

0

24

2532

33

Disclosure on Management Approach

operating performanceFinancial Highlights

Special Story: Design Management, Global Management

goAlS And AChIEvEMEnTS By SECTor

production and Sales

Despite high oil prices and unfavorable exchange rates in 2007, Kia Motors succeeded in boosting

production and sales. The production plant in Slovakia, for example, exceeded its first year sales

target. Although domestic production fell slightly, Kia Motors enjoyed an increase of 7.7% in total

production and doubled overseas production capacities from 2006 thanks to overseas production

achieving full operational capacity along with strong sales generated in Europe.

Although domestic sales rose only slightly, exports significantly increased. Since the first-ever

export of 10 Brisa pickup trucks to Qatar 32 years ago, annual exports totaled more than one

million vehicles for the first time. Kia’s continual effort to nourish the company’s growth produced

fruits of success as operating losses in 2006 were minimized and there was a return to operating

profit in the fourth quarter of 2007.

Key production performance and plan _ Although domestic manufacturing production fell

slightly, overseas production grew by 7.7% from last year with total production of 1,369,278

vehicles. Notable achievements in the manufacturing sector include creating an efficient logistics

system and Global Maintenance Management System (GMMS).(3) In 2006, Kia became the first

Korean company to utilize an advanced logistics system with Radio Frequency Identification (RFID) (4) during the manufacturing process. In 2007, Kia established the UCLIP system(5) to improve

reliability of its logistics system, share information with business partners in real time, and manage

inventories efficiently. With the UCLIP system in place, Kia Motors achieved cost reduction and a

competitive edge in the marketplace. Additionally, by using GMMS, it ensured increased capacity

and productivity while reducing costs through efficient management. Currently, Seosan and

Gwangju Plants utilize RFID, but the RFID system will be expanded to all Kia Motors facilities in the

future.

In 2008, Kia set its sights on improving product quality and achieving stable production

through the extension of domestic and overseas production facilities. Kia is planning to introduce

27

010203

04

01. Breaking Ground for China’s Second Manufacturing Plant

02. European Sales Office and Design Center in Kia Motors’ New European Headquarters

03. Transporting Kia Motors’ Vehicles at the Slovakia Plant

04. Eva Yanashova, Slovakia Plant Employee

(3) GMMS (Global Maintenance Management System)

(4) RFID (Radio Frequency Identification): Through Wireless and IC chips, RFID manages information through a variety of

next-generation object-recognition technologies

(5) UCLIP (Ubiquitous Cooperated Logistics Information Platform System): RFID-Integrated Logistics Information

(auto parts, logistics, finished vehicles) sharing system between small and medium-sized businesses (SMBs) and Kia Motors

zooM In » Kia Motors in Udmurtia, russia

MInI InTErvIEW » Eva yanashova, Kia Motors’ plant in Slovakia

“Kia motors created 10,000 jobs in Udmurtia”

On March 2007, Alexander Alexandrovich Volkov,

President of the Udmurt Republic, expressed his

gratitude for the contribution of Kia Motors to

the economy of Russia. Since 2005, Kia Motors has

manufactured the Cerato (Spectra) in the IshAvto

plant in Izhevsk, the second largest automotive

producer in Russia. Cerato (Spectra) is the best sell-

ing car in the Russian market.

According to Mr. Volkov, “Just one Kia Motors

assembly line created 2,700 jobs. It is supporting

approximately 10,000 citizens as it creates jobs

from affiliated business partners and surrounding

businesses. Introducing a cutting-edge Spectra

(Cerato) assembly line to Udmurtia expanded social

benefits to employees and increased tax revenue to

Udmurtia.” He welcomes a larger Kia Motors pres-

ence in Udmurtia.

“Everyone’s impressed when I tell them I work for

Kia motors.”

Hello, I’m Eva Yanashova of Kia Motors Slovakia.

Working for Kia Motors is a source of pride in

Slovakia. With high pay and great benefits, Kia Mo-

tors is the best place to work. Many friends of mine

want to work for Kia Motors and ask about open-

ings at the plant. Kia Motors has superior benefits

for female workers in comparison to other plants

in Slovakia. Recently, I read in the newspapers that

Kia Motors has created more than 8,000 jobs in

Slovakia along with new infrastructure. Kia Motors

is making our city a better place to live. Thank you,

Kia Motors.

0102

28

01. The refreshed for 2008 Morning (Picanto) has posted high sales figures.

02. Ceremony for the 100,000th cee’d produced at the Slovakia plant in September 2007

(6) More information on overseas facilities can be found on pages 34 to 35.

* ‘Others’ include commercial and specialty vehicles.

AnnUAl SAlES Unit: Vehicles SAlES By CATEgory Unit: Vehicles

total sales Domestic sales Overseas sales total sales passenger car RV Others

2005 20052006 20062007 2007

a Gamma engine facility with annual output of 100,000 units for small- to mid-sized engines in the

Hwaseong plant. The Gwangju plant specializes in bus production, and it is pushing to finish

renovation of production lines to churn out 2,100 buses a year such as the Granbird. As for

overseas manufacturing facilities, Slovakia has been fully operational since last year with an annual

production capacity of 300,000 vehicles, and Kia’s second plant in China came online in December

2007 with an annual production capacity of 300,000 vehicles. The construction of the U.S.

manufacturing facility in Georgia, which began in 2006, is on track for completion in 2009 with an

annual capacity of 300,000 vehicles. Kia is expecting its overseas annual production capacity to

reach 1.03 million vehicles by 2009. This global expansion will contribute to the stabilization of

production and sales while raising Kia’s brand equity.(6) In 2008, Kia Motors is aiming to produce

1.69 million vehicles (1.215 million and 0.475 million vehicles at home and abroad, respectively), an

increase of 23.5 % from last year.

Sales division Key performance and plan _ In 2007, Kia Motors’ domestic sales rose 0.8 %

with 271,809 vehicles. The domestic market shrank approximately 30% last year compared to 2002

due to high oil prices and the falling exchange rate, which devastated the export market and

created a rough year for every domestic automaker. Although no new models were introduced in

the stagnant domestic market, Kia launched restyled models with enhanced marketability and

environmental performance, while expanding customer marketing. These strategies allowed Kia

to weather the worsening market environment and end the year with improved sales and lower

operating losses. In the sedan segment, Opirus (Amanti) recorded first place in sales for 19

consecutive months, and the refreshed super compact Morning (Picanto) posted high sales volume

in the latter half of 2007. The sub-compact Rio (Pride) and Sportage compact SUV maintained top

market share in their respective segments as well. Recovery in the domestic market for 2008 is not

expected. By launching new models and enhancing customer satisfaction, however, Kia will

achieve its target sales goal of 322,000 vehicles and 25% market share in 2008.

265,825

623,151

1,215,849 1,215,849

950,024

481,422

111,27685,592 82,113

989,276

511,167

1,088,147

490,607

269,575

662,092

1,258,851 1,258,851

271,809

787,236

1,359,956 1,359,956

500,000 500,000

600,000 600,000

700,000 700,000

800,000 800,000

900,000 900,000

1,000,000 1,000,000

1,100,000 1,100,000

1,200,000 1,200,000

1,300,000 1,300,000

1,400,000 1,400,000

400,000 400,000

300,000 300,000

200,000 200,000

100,000 100,000

0 0

24

2532

33

Disclosure on Management Approach

operating performanceFinancial Highlights

Special Story: Design Management, Global Management

Kia’s overseas sales division made significant accomplishments through export market

diversification and a stable global production system this year. Kia Motors enjoyed a sales

breakthrough with exports of 1,088,147 vehicles, a 10% increase from the previous year. Kia

focused on Asia, the Middle East, Central and South America, and emerging markets. These

diversified markets allowed Kia to increase exports by 26.3 % from the previous year. In addition,

Kia overcame difficulties and posted a 7% export increase despite high oil prices and the U.S. sub-

prime crisis. With successful operation of the manufacturing plant in Slovakia since last year, Kia

also grew by 10% in the European market.

Right on the tails of US and Europe, China is quickly emerging as one of Kia’s largest markets.

Although sales fell slightly last year in China, as many automakers introduced new models and

fierce price competition ensued, Kia plans to aggressively tackle the Chinese market with increased

production from its second plant in China and new models that satisfy Chinese consumers’ needs.

Kia expects the 2008 overseas market environment to stay unfavorable as oil and raw material

prices continue to increase and the dollar value remains low. Despite the worsening business

environment, Kia has set ambitious goal of exporting 1.363 million vehicles, a 25.2% increase from

2007. Kia plans to meet this goal by strengthening its product line-up, nurturing emerging

markets, taking advantage of its overseas production base, increasing dealer capacity, introducing

a 5-door Cerato (Spectra) designed exclusively for the Chinese market, stabilizing China’s second

plant, and expanding its overseas sales network.

Quality and r&d

In 2007, Kia Motors fortified its design capability, developed advanced technologies, reduced costs

and implemented quality assurance systems. Through these efforts, Kia received glowing reviews

on product quality from independent research firms, thereby raising its brand equity.

Key Quality performance and plan _ In 2007, Kia Motors received accolades from around the

world as its products earned top marks in product quality from various distinguished independent

research firms. More specifically, Kia is proud of its success in the U.S., most notably its results in

J.D. Power and Asociates’ 2007 Initial Quality Study (IQS), in which Kia’s ranking jumped 12 spots

from 2006 to 12th place overall, thus placing Kia in the top tier of automakers. The company’s

subcompact sedan, Pride (Rio), played a major role in enhancing brand value as it took first place

in the subcompact segment in both the 2006 and 2007 studies. Furthermore, the Total Quality

Study (TQS) by Strategic Vision (an American automotive research firm), U.S. Consumer group’s

Consumer Reports, and the European Car of the Year (COTY) jury all gave rave reviews about Kia’s

vehicle quality.

Kia works tirelessly to develop top-quality vehicles in order to become consumers’ number one

preference. For example, extensive tests are conducted to match driving performance with

intended usage and environment when designing a new vehicle. Kia has revitalized customer

services, such as the Auto Prosumer Systems, to reflect customer needs and wants. In addition, Kia

29

* ‘Others’ include commercial and specialty vehicles.

01. Kia Motors representative receiving the JD Power and Associates’ IQS award for the Pride (Rio) as a segment winner

02. 2008 Quality Meeting for acquiring top IQS ranking

Sales by region Unit: In million won

Total sales

Korea

overseas

north America

Europe

others

2007

15,948,542

4,852,075

11,096,467

4,879,604

2,860,028

3,356,835

2006

17,439,910

4,867,129

12,572,781

5,144,229

4,295,839

3,132,713

2005

15,999,356

4,471,757

11,527,599

4,297,325

4,492,756

2,737,518

2004

15,257,742

4,241,228

11,016,514

4,989,520

3,655,789

2,371,205

2003

12,839,881

5,126,358

7,713,523

3,731,397

2,145,117

1,837,009

2002

12,158,113

6,304,394

5,853,719

3,344,308

1,071,728

1,437,683

0102

30

0102030405

060708

vehicles rating history

vEhIClE QUAlITy EvAlUATIon In 2007

• Germany, Autobild, C-segment (1st place tie with VW golf)

• Austria, Autotouring, 1st place

• U.K., Practical Caravan, What Car?, and Camping and Caravan Club

eco-friendly vehicle and best hatchback

• Germany, ACE Lenkrad, C-segment 1st place

• Europe, 5 stars front and side impact tests, European New Car

Assessment Programme (Euro NCAP)

• Europe, 1st place in European COTY C-segment (4th place overall)

• Romania, 1st place COTY

• 1st class in offset impact evaluation by Korea Automobile

Technology Center

• U.S., 5 stars in impact tests by National Highway Traffic Safety

Administration (NHTSA)

• U.S., Consumer Reports Recommended model

• U.S., The Car Book “Best Bet”

• U.S., “Highest Ranked sub-compact car in Initial Quality Survey (IQS)”

By J.D. Power and Associates

• U.S., 5 stars in impact tests by the National Highway Traffic Safety

Administration (NHTSA)

• U.S., Best Medium SUV Ownership Experience in Total Quality Award

from Strategic Vision

• U.S., Highest possible rating in rear impact evaluation from Insurance

Institute for Highway Safety (IIHS)

• U.K., < Caravan Club Tow Car awards 2008> 1st place in Full-size 4X4

segment

• U.S., The Car Book “Best Bet”

• U.S., Motor Week “Best Minivan” from 2007 Drivers’ Choice Awards

• 1st place in minivan segment for five consecutive years according to

Korea Management Association Consulting

• U.S., 1st place in Total Quality Award of Strategic Vision for

Best Minivan Ownership Experience

• Australia, Royal Automobile Club of Victoria “Lowest cost of

maintenance”

• U.S., Highest possible rating in rear impact evaluation by Insurance

Institute for Highway Safety (IIHS)

• U.S., 2nd place in Automotive Performance, Execution and Layout

(APEAL) Study by J.D. Power and Associates in 2007

• U.S., Forbes “The safest family car”

• U.S., Highest possible rating in safety evaluation by Insurance Institute

for Highway Safety (IIHS)

• U.S., The Car Book “Best Bet”

• U.S., US News & World Report, Best affordable Compact Wagon

• U.S., The Car Book “Best Bet”

• 1st class in offset impact evaluation by Korea Automobile

Technology Center

• U.S., Consumer Reports Recommended model

• U.S., Highest possible rating in side impact evaluation by Insurance

Institute for Highway Safety (IIHS)

cee’d

sportage

pride (Rio)

sorento

carnival (sedona)

cerato (spectra)

Lotze

(Optima/magentis)

Opirus (Amanti)

01. cee’d

02. Sportage

03. Sorento

04. Cerato (Spectra)

05. Lotze (Optima/Magentis)

06. Pride (Rio)

07. Carnival (Sedona)

08. Opirus (Amanti)

24

2532

33

Disclosure on Management Approach

operating performanceFinancial Highlights

Special Story: Design Management, Global Management

is stabilizing production lines and ensuring that its suppliers deliver high quality parts to gain a

competitive advantage through higher end-product quality. For overseas facilities, the quality

control manual, which consists of 10 categories with 180 checklists, is being prepared to improve

the product quality control system and enable them to perform their own internal quality control.

With a stabilized on-site work management system, Kia is working in overseas manufacturing

facilities to produce new models under strict quality control at an early stage.

Kia is never satisfied with past performances. Thus, despite excellent reviews on product

quality in 2007, Kia will make every effort to surpass 2007’s performance in 2008. According to the

Initial Quality Survey (IQS), Kia’s overall quality has improved by 53% since 2001. Kia’s

improvement is the result of the steadfast belief that product quality is the foundation of

competitiveness. Kia Motors is continuously improving product quality and raising brand value so

that customers will not only acknowledge the brand, but go beyond and recognize the brand as a

product that can be trusted and driven. For this to happen, Kia has taken three measures to insure

product quality. First, Kia comparatively analyzes its products against competitors to improve their

perceived quality. Second, Kia proactively checks quality parts for defects before they enter the

production cycle through careful monitoring of suppliers. Third and lastly, Kia has established a

three-tier quality inspection process to prevent problems in the production cycle to meet the

“Drive Defects to Zero” challenge.

r&d performance and plan _ In 2007, Kia’s R&D efforts concentrated on creating innovative

designs, strengthening technology and improving cost competitiveness through cost innovation.

Kia’s concept cars, based on the "simplicity of a straight line" design concept, captured the

world’s attention at numerous motor shows. The concept car line up included the 'Kue' large CUV,

‘ex_cee'd' convertible coupe, 'KND-4' mid-large size SUV, and ‘Kee’ sports coupe. In terms of cost

innovation activities, Kia came up with 20,000 cost saving ideas centered around streamlining

design and developing new materials with active participation from employees. Kia then

successfully implemented these ideas into its vehicles to improve profitability. Digital development

of automobiles and shared platforms and components are just some of the methods Kia is

exploring in order to save costs. But Kia is always looking for permanent cost saving solutions.

In order to strengthen Kia’s technological competitiveness, the company must focus its

attention on the development of eco-friendly and intelligent cars. To achieve that end, Kia has

formed a close partnership with parts suppliers and affiliated companies to secure electronics,

materials and environmental technolog components critical to the industry.(7) Additionally, the

Namyang R&D Center is the epicenter of support for the Eco-Technology Research Center and

overseas R&D Centers (United States, Europe and Japan) to strengthen its global technological

competitiveness. As a result, Kia received a favorable response from the European market when

launching the cee’d 3-door and wagon models. At the same time, in China and the emerging

markets, Kia strengthened R&D capabilities to respond immediately to local customers with

customized vehicles. For example, Kia has received superb response in China from models like the

Cerato (Spectra), Sportage, and Pride (Rio) with modified colors and body shapes that reflect the

tastes of local customers.

31

01. “ex_cee’d” convertible and “Kee” sports coupe receive worldwide attention at motor shows

(7) More information on the technology for eco-friendly vehicles, strategies for climate change and the technology for

intelligent vehicles can be found in the Environmental Value and Social Value sections, respectively, in this report.

01

Brand Management

Last year, Kia focused more on improving its core

brand values to spur more business activities

for sustainable growth. Kia continues to launch

tailored vehicles to match customer needs. Kia

will focus on today’s growth as well as tomorrow’s

anticipated trends in order to become a top global

brand.

Brand Management

PHASE 1

2005-2007laying a solid foundation for brand management • Brand management plan announced • Execution of the plan by division/region

PHASE 2