Innovations temporary storage of food grains ciphet

-

Upload

ramabhau-patil -

Category

Technology

-

view

237 -

download

0

Transcript of Innovations temporary storage of food grains ciphet

Innovations in Temporary Storage of

Food Grains

Dr. R.T. Patil

Former Director, CIPHET, Ludhiana

Chairman & ED, Benevole for PHT,

Bhopal

Temporary Grain Storage in India

•FCI and state agencies stored 23.08 lakh

tonnes and 144.97 lakh tonnes, respectively in

2010 and the damaged grain in CAP was 716

metric tonne in 2010

•Storage gap (deficit) to the tune of 12-14

MMT.

•The efficient alternative to CAP is necessary

to meet the growing demand for storage and

reduction of storage losses

Grain Quality in Storage•Optimum storage conditions-moisture less than

12% and temperature less than 30°C will not

deteriorate quality during storage over a season.

Problems due to Higher temperatures:

1) Development of hot-spots,

2) Moisture migration from warmer to cooler grain

causing caking,

3) Mould development in over-moist grain

4) Decrease in seed germination

5) Decrease in malting quality of barley,

6) Decrease in baking and milling quality of wheat,

7) Colour deterioration of pulses and

8) Rancidity in oilseeds

Conditions in Temporary Storage

•Grain entering a temporary storage structure should

be cool and dry.

•Temperatures of grain loads placed into storage

should be within 5 to 10°C of each other to prevent

moisture movement due to temperature gradients.

•The grain should be placed in the storage at less than

14% (w.b.) and preferably 13% for greater safety.

•The average moisture content of the pile should be

0.5 to 1% less than the safe storage moisture content.

•Grain of poor quality should be dried 1% more than

required for good quality grain.

Grain Aeration

•Aeration is necessary, if more than 50 MT grain is

stored for longer than 2 months.

•Aeration rates of at least 0.04 m3 per minute per MT

should be provided.

•Provide two or three smaller fans and ducts to obtain

proper air distribution in flat storage structures.

•Aeration ducts of 30 cm or larger dia. corrugated drain

pipes are used in temporary structures.

•The drainpipe is covered with cloth to prevent grain from

plugging the openings.

•The number of fans and aeration ducts depends on the

grain type and dimensions of the grain pile.

Temporary Storage Structures used

Worldwide

•The CAP storage

•Grain Storage Rings

•Flexible silos

•Underground storage/Bunker storage

•Prefabricated relocatable warehouses

•Cocoons

•Airwarehouses

•Flat Grain Storage

•Large Plastic Membrane Bags

•In CAP 50 kg capacity jute bags

are used

•The most commonly

constructed size is for 1500

tonnes with 3000 bags of 50 kg

•CAP storage are with the length

and breadth of 8.55 and 6.30 m,

respectively.

•The sides and ridge heights are

4.50 and 6.00 m, respectively.

•Regular opening of covers is

necessary to allow some

aeration.

•The advantage of CAP is its low

establishment cost, which is only

25% the cost of godown storage

Cover and Plinth Storage

• Thermal model has been developed based

on solar energy for predicting the wheat grain

temperature while stored in CAP.

• The model showed around 10 to 12°C rise in

grain temperature from the mean monthly

ambient temperature during the year with

black cover.

• A white colour plastic cover simulated result

showed reduction in the grain temperature by

6-8oC compared to black sheet.

Effect of Color of Cover on Quality

Grain Storage Rings

•Corrugated galvanised

panels are rolled and

crimped on a line

•This deep corrugation

are made in 22 SWG.

•The industrial gasket is

also provided on the top

edge of the ring for the

entire diameter

protecting the tarp from

the sharp edges of the

steel panels.

Flexible silos

•Early types employed butyl rubber

sheeting as the membrane and had

capacities of up to 1,000 tonnes.

• Currently available silos use PVC-

coated polyester fabric & have 500 tonne

capacity.

•The silos require little site preparation,

are easy to erect and are relocatable.

•The silos require no mechanical

equipment

Underground storage of grain •The pit is about one and

a half times the width of a

bulldozer blade, length as

per volume.

•The grain must be under

13 per cent moisture

content.

•Polythene sheeting is laid

across the ridged grain for

about 2 m either side of

the pit

•Soil cover of 30 - 100 cm

deep, sloping to ground

level is put on the pit

Prefabricated Relocatable

Warehouses•It has tubular steel frame

covered by PVC-coated

polyester fabric tensioned

over the frame.

•The capacity of structures

varies from 50 to 3000

tonnes.

•Stores require minimal

foundations, and the

integral base frame can be

effectively anchored to the

ground

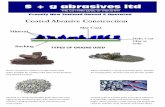

Cocoons•These are tough but flexible

UV-resistant PVC enclosures

sealed with zip fasteners.

•Light in weight when empty

and can be delivered easily to

site.

•Capacity ranges from 5–50

tonnes.

•They prevent insect, water

and water vapour penetration

into the contents.

•The cocoons are modular,

fabricated in 5, 10, 20 and 50

tonnes capacity.

Airwarehouses•Airwarehouses are kept erect by pressure of

forced ventilation.

•Once erected and working satisfactorily, bagged

produce can be moved in and out of the buildings

easily.

•Each warehouse typically has a capacity of 2000–

5000 tonnes.

•Constant flow of air keeps the interior free of

condensation and moisture and the structure's

coated fabric provides protection from ultraviolet

radiation.

•Constant power supply is necessary to keep the

structure inflated and erect.

Flat Grain Storage

•These are modular flat grain storage bunkers.

•These grain bunkers come in up to 5 million

bushels capacity and are very economical for

storage of corn, wheat, canola and other grains.

•Precast exterior concrete walls are erected

from 1.5 m to 6.5 m height.

•The optional aeration system having Z shaped

tubes is connected through the wall flushed with

the floor.

Large Plastic Membrane Bags

•The system is very cost

competitive in

comparison to other

storage options.

•This system of storage

offers a low investment

storage system that can

be quite effective on farm

in several scenarios.

• The polymer bag is

described as a hermetic

type of storage system.

Major Recommendations

•The color of the polyethylene used in

traditional CAP storage should be changed to

white.

•The prefabricated relocatable warehouses

may be installed on the railway platforms

where the grain need to kept for transit

•In grain mandies the harvest bags and rings

may be explored to avoid the damage to the

grain due to sudden rain during harvest

season.

•Investigations may be undertaken to test the

suitability of structures for Indian conditions

Modern Technologies for Food

Storage are essential for

reducing the post harvest

losses and increasing the

profitability of farmers