Ink Jet Printing and Spin-coating of Electrically ... · Peter C. Wilson, Constantina Lekakou, John...

-

Upload

truongtruc -

Category

Documents

-

view

223 -

download

0

Transcript of Ink Jet Printing and Spin-coating of Electrically ... · Peter C. Wilson, Constantina Lekakou, John...

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

Presentation Outline

• PhD Outline

• Background

• Custom Ink Jet Printing Equipment

• Electro-impedance Model

• Charge Transport Method

• Microscale Comparison

• Mobility & Morphology

• Ongoing & Future Work

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

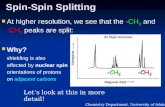

PEDOT Useage

Simple organic device structure displaying PEDOT:PSS as a

high work function anode

Figure 8 - Comparative assessment of

PEDOT:PSS films compared to ITO

layers.

Device life-time is omitted ~ 7x ITO

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

Gas Line

Motors

Control Cards

JetServer

Camera

Reservoir

Heat Pad

Substrate Temp Control

Jetter

Strobe

Control Program

Monitor

Inkjet Printer Setup

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

InkJet Printer OverviewControllable Parameters

• Drop size

• Ejection wave guide architecture

• Drop velocity

• Drop / substrate Temperature

• Drop placing / overlap

• Print rate

• Print layering

• Ejection angle

• Drop chemistry

Rig Specification

250dpi @ Ts = 50deg C

Position accuracy < 2μm (at 1/8th step)

Position repeatability < 10 μm

Print rate from 0 – 100mm s-1

Print acceleration 0 – 100m s-2Transmission Optical Microscopy Of

Printed PEDOT:PSS Tracks - 100um orifice jetter, 5% drop overlap

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

PEDOT:PSS Surface Tension As A Function Of DMSO DMSO & Surfynol 2502

Concentration

0

0.01

0.02

0.03

0.04

0.05

0.06

0.07

0.08

0 1 2 3 4 5 6

DMSO %wt

Surf

ace T

ensio

n (

N/m

)

0% Surfynol

1% Surfynol

Linear (0% Surfynol)

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

Electro-impedance Spectroscopy

Nyquist plot for Inkjet Printed PEDOT:PSS (5%wt DMSO, 0%Surfynol) at 93K

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

Electro-impedance Spectroscopy

|REL| Bode plot for Inkjet Printed PEDOT:PSS (5%wt DMSO, 0%Surfynol) at 93K

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

Electro-impedance Spectroscopy

Zplot model fitting for Inkjet Printed PEDOT:PSS (5%wt DMSO, 0%Surfynol) at 93K

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

Electro-impedance Spectroscopy

Zplot equivalent circuitry for Inkjet Printed PEDOT:PSS (5%wt DMSO, 0%Surfynol) at 93K

Series Resistance

Surface capacitive region

Bulk PEDOT:PSS film

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

Surface Resistivity For 0-1% Surfynol, 0-5% DMSO InkJet Printed Films

1.00E+02

1.00E+03

1.00E+04

1.00E+05

1.00E+06

1.00E+07

0 1 2 3 4 5

DMSO %wt

Res

isti

vit

y W

/sq

Surface Resistivity (0%wt Surfynol)

Surface Resistivity (1%wt Surfynol)

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

4-Point Hall Probe demonstrate the effect on carrier mobility in inkjet printed PEDOT:PSS thin films

• 0% DMSO, 1% Surfynol,

•

• 1.164x 105 W sq-1 ~ 11 W cm-1 (0.09 S cm-1)

• Carrier Mobility 1.43 cm-2 v-1s-1

• Carrier Concentration ~ 3.74 x1013 cm-2

• 5% DMSO, 1% Surfynol,

• 633 W sq-1 ~ 6.33 x10-2 W cm-1 (16 S cm-1)

• Carrier Mobility 397 cm-2 v-1s-1

• Carrier Concentration ~ 2.48 x1013 cm-2

Printed samples displayed ohmic contacts and excellent film uniformity

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

Surface Resistivity For 0-1% Surfynol, 0-5% DMSO Spin Coated Films

1.00E+03

1.00E+04

1.00E+05

1.00E+06

1.00E+07

1.00E+08

0 1 2 3 4 5

DMSO %wt

Re

sist

ivit

y W

/sq

Surface Resistivity (0% Surfynol)

Surface Resistivity (1% Surfynol)

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

x

e

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

T

TEXP 0

0

Mott Variable Range Hopping Law,

denote the recipical dimensionality of conduction

the conductivity

o & T0 are material constants

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

Reproduced from - A. M. Nardes, M. Kemerink, R. A. J. Janssen,

“Anisotropic hopping conduction in spin coated PEDOT:PSS thin films”,

Phys. Rev. B 2007, 76, 085208-1.

Charge transport asymmetry in spin coated

PEDOT:PSS films due to oblate spheroid-type

conducting grain morphology

- 3d variable range hopping in the parallel plane

- Space Charge limited tunnelling in the normal plane

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

Processing Dynamics

The deposit, spin, spread & evaporate

process for spin coated films

Fluid flow in drying droplets displaying

surface & interface evaporation and

redistributive flow

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

Parallel plane conductivity displaying Nearest Neighbour Hopping (nn-H)

conduction mode.

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

R² = 0.9855

0.001

0.01

0.1

0.25 0.26 0.27 0.28 0.29 0.3 0.31

D

C (

S/cm

)

T-0.25 (K-0.25)

(DC) As A Function Of Temperature For InkJet PEDOT:PSS (4%wt DMSO) - Fitting T-0.25

Parallel plane conductivity displaying 3d Variable Range Hopping

behaviour

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

Drop Observation

303K

323K

353K

SEM Images For Identical Inks At 3 Substrate Temperatures

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

Drop Profilometry

303K

323K

353K

Single Drop Profilometry For Identical Inks At 3 Substrate Temperatures

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

Drop Profile As A Function Of Substrate Temperature

-0.05

0.05

0.15

0.25

0.35

0.45

0 20 40 60 80 100 120 140 160 180 200

Displacment (mm)

Hei

gh

t ( m

m)

Ts = 30

Ts = 40

Ts = 50

Ts = 60

Ts = 70

Drop Shape Evolution For Identical InkJet Printed PEDOT:PSS Drops At Varying Substrate Temperatures

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

Droplet Diameter As A Function Of Substrate To Liquid

Temperature Ratio

0

20

40

60

80

100

120

140

160

180

303 313 323 333 343

Substrate Temperature (K)

Dro

ple

t D

iam

ete

r (u

m)

0.9

0.95

1

1.05

1.1

1.15

1.2

Sub

stra

te T

o L

iqu

id

Te

mp

era

ture

Rat

io

Droplet Diameter

Liquid To Substrate

Temperature Ratio

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

Peak To Trough Ratio As A Function Of Substrate To Liquid

Temperature Ratio

0

1

2

3

4

5

6

7

8

303 313 323 333 343

Substrate Temperature (K)

Pe

ak T

o T

rou

gh

Rat

io

0.9

0.95

1

1.05

1.1

1.15

1.2

Sub

stra

te T

o L

iqu

id

Te

mp

era

ture

Rat

io

Peak To Trough Ratio

Liquid To Substrate

Temperature Ratio

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

Electrostatic Force Microscopy

Electrostatic Force Microscopy (EFM) Displaying sub-surface concentric ring charge

concentration in InkJet Printed PEDOT:PSS films

AFM Phase AFM TopographyEFM Phase

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

5um x 5um topographic

Spin Coated (1% DMSO, 0% Surfynol)

5um x 5um topographic

Spin Coated (1% DMSO, 1% Surfynol)

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

2um x 2um topographic

InkJet (1% DMSO, 0%Surfynol)

2um x 2um topographic

InkJet (1% DMSO, 1%Surfynol)

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

Film Roughness

RMS Roughness For 0-1% Surfynol, 0-5% DMSO Spin Coated Films

0

5

10

15

20

25

0 1 2 3 4 5

DMSO %wt

1% S

urf

yn

ol

RM

S R

ou

gh

ne

ss

0

0.5

1

1.5

2

2.5

0% S

urf

yn

ol

RM

S R

ou

gh

ne

ss

1%wt Surfynol Height RMS Roughness

0%wt Surfynol Height RMS Roughness

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

Film Roughness

RMS Roughness For 0-1% Surfynol, 0-5% DMSO InkJet Films

0

5

10

15

20

25

30

35

0 1 2 3 4 5

DMSO %wt

1% S

urf

yn

ol R

MS

Ro

ug

hn

ess

0

0.5

1

1.5

2

2.5

0% S

urf

yn

ol R

MS

Ro

ug

hn

ess

1%wt Surfynol Height RMS Roughness

0%wt Surfynol Height RMS Roughness

Peter C. Wilson, Constantina Lekakou, John F. Watts

Ink Jet Printing and Spin-coating

of Electrically Conductive Polymers

On Going & Future Work

>> Normal direction charge conduction as a function of printing parameters.

Variable electric field measurements for characteristic hopping length.

T0 and 0 comparison.

>> In plane and cryogenically cleaved Electrostatic Force Microscopy to view grain morphology.

>> Scanning Kevlin Probe Force Microscopy to observe work-function changes as a function of chemistry &

processing.

>> Characterisation of the effects of annealing on in-plane and normal direction charge conduction.

>> Validating the role of Electro-Impedance Spectroscopy as an analytical method for characterisation of multiple

thin-film properties.