Injection Moulding Basics

-

Upload

mrriassaty -

Category

Documents

-

view

247 -

download

0

Transcript of Injection Moulding Basics

-

8/8/2019 Injection Moulding Basics

1/27

InjectionInjectionMouldingMoulding

-

8/8/2019 Injection Moulding Basics

2/27

2

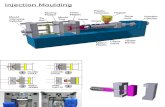

Moulding machineMoulding machine

-

8/8/2019 Injection Moulding Basics

3/27

3

Basics of InjectionBasics of Injection

MouldingMouldingHopper

Screw & Barrel

Nozzle

Clamping unit

-

8/8/2019 Injection Moulding Basics

4/27

4

Calculated by multiplyingtheprojected area of the cavity

(cavities), including runner system by the maximum internalpressure (hold pressure).

Clamping pressureClamping pressure

-

8/8/2019 Injection Moulding Basics

5/27

5

Clamping pressureClamping pressure

POMPOM

PAPA

LCPLCP

PETPPETP

PCPC

PMMAPMMA

PPPP

PEPE

ABSABS

PSPS

3 - 4 T/inch3 - 4 T/inch22

3 - 5 T/inch3 - 5 T/inch22

4 - 6 T/inch4 - 6 T/inch22

4 - 6 T/inch4 - 6 T/inch22

3 - 5 T/inch3 - 5 T/inch22

2 - 4 T/inch2 - 4 T/inch22

1 - 4 T/inch1 - 4 T/inch22

1 - 4 T/inch1 - 4 T/inch22

3 - 4 T/inch3 - 4 T/inch22

2 - 3 T/inch2 - 3 T/inch

22

-

8/8/2019 Injection Moulding Basics

6/27

6

Drying PrinciplesDrying Principles

Non-hygroscopic Polymers :e.g. P/S, P/E, P/P, POM

Drying require only to remove surface moisture.Hygroscopic Polymers :

e.g. P.A., P/C, PBTP, PETP, PET-G

Use Dehumidified air drier or Vacuum oven

-

8/8/2019 Injection Moulding Basics

7/27

-

8/8/2019 Injection Moulding Basics

8/27

8

Water content & lowering of molecular weight:

0

10

20

30

0 0.05 0.1 0.15 0.2 0.25

Water content of pellet (wt%)

Loweringofm

olecular

weight(%)

Moulding temp.300 cMoulding temp.300 c

PolycarbonatePolycarbonate

-

8/8/2019 Injection Moulding Basics

9/27

9

30% GR PET30% GR PET

Influence of Moisture on impact strength

-

8/8/2019 Injection Moulding Basics

10/27

10

Drying time &Drying time &

temperaturestemperaturesMaterial Moisture level Temp (

oC) Time (Hrs)

PA 0.2 80 2 4

PBTP 0.04 120 3 4

PETP 0.02 130 3 4

P/C 0.02 120 4 6

POM 0.2 80 1 2

LCP 0.01 135 2 4PPS 0.04 150 4 6

ABS 0.1 80 2 4

-

8/8/2019 Injection Moulding Basics

11/27

11

Moulding temp. & lowering of molecularMoulding temp. & lowering of molecular

weight:weight:

100

1000

10000

350 340 320 300 280

Moulding temp (deg.C)

L

oweringofm

ol.wt.(Mv)

35 min35 min

20 min20 min

5 min5 minResidencetime

Residencetime

PolycarbonatePolycarbonate

-

8/8/2019 Injection Moulding Basics

12/27

12

Hold-up-timeHold-up-time

Toughened Nylon 6.6

-

8/8/2019 Injection Moulding Basics

13/27

13

Temperature profileTemperature profile

-

8/8/2019 Injection Moulding Basics

14/27

14

Injection and HoldInjection and Hold

PressurePressure

Injection pressureInjection pressure - Dynamic filling phase (under velocity- Dynamic filling phase (under velocitycontrol), moves the screw and push the material intocontrol), moves the screw and push the material into

the mould, (around 95% of the part volume).the mould, (around 95% of the part volume).

Hold pressureHold pressure - Quasi-static feeding phase (under- Quasi-static feeding phase (underpressure control), packing the part to compensate forpressure control), packing the part to compensate for

the change in volume from a liquid to a solid.the change in volume from a liquid to a solid.

V-P switch pointV-P switch point

- In crystalline material, use distance- In crystalline material, use distance

rather than with pressure, as would typically be donerather than with pressure, as would typically be done

for an amorphous materialfor an amorphous material..

-

8/8/2019 Injection Moulding Basics

15/27

15

Hold pressure time Vs

part weight and shrinkageDelrin* 500

-

8/8/2019 Injection Moulding Basics

16/27

16

Hold-on-timeHold-on-time

POMPOM

PAPA GR-PAGR-PA

MR-PAMR-PA

PBTPBT

GR-PBTGR-PBT

PETPET LCPLCP

TEEETEEE

88 secssecs/mm/mm

55 secssecs/mm/mm 33 secssecs/mm/mm

33 secssecs/mm/mm

44 secssecs/mm/mm

33 secssecs/mm/mm

44 secssecs/mm/mm 0.50.5 secssecs/mm/mm

4-84-8 secssecs/mm/mm

-

8/8/2019 Injection Moulding Basics

17/27

17

Tool at 400C Tool at 900C

Influence of ToolInfluence of Tool

TemperatureTemperature

Outer layer insufficientlycrystallised

Optimum structure

-

8/8/2019 Injection Moulding Basics

18/27

18

Shrinkage behaviourShrinkage behaviour

-

8/8/2019 Injection Moulding Basics

19/27

19

Gate PositionsGate Positions

-

8/8/2019 Injection Moulding Basics

20/27

20

Gate Size and DesignGate Size and Design

-

8/8/2019 Injection Moulding Basics

21/27

21

Effect of Gate diameterEffect of Gate diameter

on the qualityon the qualityNylon 6.6

-

8/8/2019 Injection Moulding Basics

22/27

22

Runner Size and Design

-

8/8/2019 Injection Moulding Basics

23/27

23

Venting designVenting design

-

8/8/2019 Injection Moulding Basics

24/27

24

Moulding tolerancesMoulding tolerances

-

8/8/2019 Injection Moulding Basics

25/27

25

RegrindRegrind

-

8/8/2019 Injection Moulding Basics

26/27

26

Forcrystalline materials. (With amorphous materials, the

main differences are shorter hold on time, but much longer

cooling time.)

Moulding cycle-TimeMoulding cycle-Time

-

8/8/2019 Injection Moulding Basics

27/27

A Polymer for Every ApplicationA Polymer for Every Application