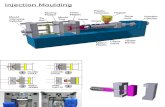

Injection Moulding

description

Transcript of Injection Moulding

PLASTICS PROCESSING

Plastics have become a part of our day today life from toys to trucks From buttons to buckets

Plastics are every were around us…

And plastic processing gives shape to plastics

The shaping of Plastics is nothing but various plastics processing methods

There are number of plastics forming processes like blow molding, extrusion, injection molding, thermoforming, rotational molding, casting, etc.

but the first three processes are very widely used.

Injection Molding Process

This is the process of shaping of plastics byinjecting molten material into the closedmould and remove it after it has solidified.This is very widely used, since this is the onlyprocess by which one can form plastics partswith complicated geometry ranging fromsmall ball pen parts to large bumpers used incars.

Blow Moulding Process

It is the process of shaping the melted plasticsby forming a tube called parison, enclosing itin a mould of the shape of the product andblowing air into the tube which forces the hotmelt to stick to the mould surface and thefinal product is formed. This is normally usedfor hollow products like bottles, air ducts etc.

Extrusion Process

It is the process of forcing the melted plasticsthrough a die of the shape of the product andcooled. Some applications require reshapingof the forced melt by blowing (as in films) oraddition of metals as inserts (as in cables).This process is normally used for productswhich are continuous in length like pipe,sheets, films, section profile etc.

INJECTION MOULDING CYCLE • The Injection Moulding Cycle is an

intermittent cycle. The Injection MouldingProcess can be performed in Cycles which would be as follows

• 1 Mould close • 2 Tonnage • 3 Injection - Pack and Hold • 4 Cooling (Refilling) • 5 Mould open • 6 Ejection

MOULD CLOSING - When a machine cycle begins, oil is directed tothe cap end of the clamp cylinder. This causes the cylinder rodto extend. The cylinder rod pushes on the cross-head, and theforce of this push is transferred through the toggle linkage tothe moving platen. Therefore, the moving platen is forced tomove toward the stationary platen

TONNAGE - After the mould halves touch, the pressure in theclamp circuit is increased to provide the force necessary to lockthe toggle linkage. When the linkage is locked over, maximumtonnage is built. (Maximum tonnage is dependent on theposition of the die height adjust platen.) This tonnage ismaintained until the injection sequence is completed and theparts produced have been allowed to cool.

INJECTION - Once the mould has been closed and the tonnage isbuilt, the next stage would be to ensure that the nozzle is incontact with the mould, and that sufficient nozzle contact forcehas been built up so as not to allow any plastics material droolout from the nozzle contact area during the injection. This mayrequire the injection unit (sled) to move forward, if it is in backposition. Once the unit is in forward position, the Injection phasestarts.

COOLING (REFILLING) – The injected part should be allowed tosufficiently cooled before it is ejected. This portion of the cycleconsumes most of the time. To control the cycle time, this periodgets maximum focus.

MOULD OPENING - The clamp opening movement begins when oil is directed to the rod end of the clamp cylinder. This creates a pulling force on the crosshead. As the crosshead is pulled downward, the moving platen is pulled away from the stationary platen. This opens the mould.

EJECTION – The moulded part is pushed out from the mould by the ejector mechanism