INDUSTRIAL ETHERNETam.cc-link.org/en/downloads/CLPA-A/Documents/CC... · THE ADVANTAGES OF...

Transcript of INDUSTRIAL ETHERNETam.cc-link.org/en/downloads/CLPA-A/Documents/CC... · THE ADVANTAGES OF...

I N D U S T R I A L E T H E R N E TEnd User Solution Guide

INDUSTRY 4.0 & IIOT READY Industrial Ethernet

network linking field level devices to controllers

at an ultra-fast 1 Gigabit. CC-Link IE Field provides

the bandwidth necessary for all of your Industry

4.0 requirements while maintaining absolute

deterministic communications.

CC-Link IE Field is the world’s first open gigabit

Ethernet Industrial Automation network.

THE ADVANTAGES OF CC‑LINK IE FIELD

■■ Ultra-fast 1 Gigabit speed providing a large bandwidth for all of your IIoT and Industry 4.0 requirements

■■ Powerful network diagnostic functions

■■ Delivers deterministic control communications on an Ethernet platform

■■ Automatic Transmission Control Manager (TCM) Backup

■■ One network to manage all of your Information = Control, Motion, Energy and Safety [IEC61508 SIL3 and IEC61784-3]

CC‑Link IE Field delivers industry 4.0 & IIOT Ready Industrial Ethernet network capabilities. Seamlessly providing control data transmissions between controllers [PLCs, computers, etc.] and field devices [such as digital and analog I/O, pneumatic valve manifolds, RFID readers, VFDs, inverters, motion controllers and other factory assets].

Safety

Design and create systems that are SIMPLE AND HIGHLY FLEXIBLE. Achieve a high performance regardless of the equipment performance or operator’s knowledge & experience. Keep costs low and increase reliability with the flexible system configuration. Implement various connection methods and network topologies to achieve reliability and suit your application requirements – all without sacrificing any performance. Combine the star and line type wiring to achieve a variety of wiring styles, or configure the network in a Ring – whatever is necessary for the application.

Here’s what you can do with CC‑Link IE Field■■ Provide a SINGLE NETWORK FAMILY SOLUTION for your entire application setup reducing the need to know multiple technologies and network schemes [saving engineering resources]. Different networks operate seamlessly as one network – therefore no need to pay attention to the network hierarchy. Data can be collected from field devices and maintenance duties can be completed [Increasing productivity].

■■ NETWORK ARCHITECTURE IS MEMORY MAPPED – not Object Oriented. It is not necessary to have Engineering or IT degrees to understand or implement CC-Link network technologies. This reduces the burden on your setup and maintenance staff, without sacrificing network performance – again saving engineering resources

■■ SEAMLESS COMMUNICATION provides a single network family solution for your entire application; reducing the need to know multiple technologies and network schemes – this resulting in a reduction in system complexity and improved reliability.

■■ NATURAL SECURITY BEHAVIOR with the Token based communication scheme; since only devices registered and recognized by the TCM and in the Token path may transmit & communicate on the network; increasing reliability and decreasing the possibility of a security breach.

■■ DETERMINISTIC BEHAVIOR is built-in allowing for the control of very time-sensitive processes and applications providing consistent and predictable Network throughput within a narrow time bandwidth; this provides for a highly sophisticated application with less engineering and cost.

■■ DIAGNOSTICS TO MONITOR & DETECT ISSUES to avoid system crashes and make quick repairs when trouble occurs. Easily identify the location of the trouble and thus shorten recovery times. You can build a network resistant to faults, and one that avoids system crashes, improving productivity.

AUTOMATIC TRANSMISSION CONTROL MANAGER (TCM) BACKUP can provide a ‘Sub-TCM’ Station to automatically take over control of the Token setup and parameter operations if the primary Transmission Control Manager (TCM) station stops functioning normally. The network architecture provides for the automatic reconnection / restart of off-line or replaced devices; allowing the “Hot Swapping” of network devices; thus increasing the availability of the network by allowing the network to operate while repairing & replacing defective devices – reducing the amount of time the application is unavailable, therefore increasing the productivity & reliability of the control system.

CC-Link IE Field provides the capacity for a large volume of data, and when combined with its high reliability; any loss of data is prevented while still exchanging large amounts of control an diagnostic data.

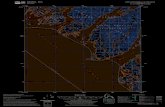

Line Topology Ring Topology

Star Topology

Managed or Unmanaged Switch(Needed only for Star Topology)

1. TCM station is running normally, then problem occurs and TCM stationSTOPS

2.Shift network control rights(TCM operation)

3. Sub-TCM stationcontinues data link

Sub-TCM stationTCM station

PROBLEMOCCURRENCE

PREVENTED A SYSTEM FAILURE

CYCLIC

ONLY

CYCLIC

ONLY

CYCLIC

ONLY

CYCLIC COMMUNICATION

Dedicated lane(s) for I/O control, real-time data, safety messages, etc.…

TRANSIENT (MESSAGE) COMMUNICATION

Large volumes of message comms

[traceability, diagnostics and other non-real-time

or on-demand data], does not affect/impact the cyclic

communications etc.…

With the LARGEST BANDWIDTH AVAILABLE, you can build an entire system from information to production with a single CC-Link IE Field network. Get constant speed and the utmost network reliability – even when the communication data increases due to Industry 4.0 & IIoT requirements (such as diagnostics and analytics). CC-Link IE Field provides the capacity [bandwidth] for a large volume of data. When you combine its capacity and its high reliability, you prevent the loss of any data while maintaining the exchange of control & diagnostic data.

SPEED & TIMING IS STABLE AND CONSISTENT AT 1GBPS

ONE COMPREHENSIVE NETWORK FOR COMPLETE VERTICAL INTEGRATION

CC Link IE Field can manage all of your Information = Equipment I/O Control, Safety Functionality, Motion Control & Energy monitoring. CC Link IE Field provides a solution to optimize the entire production system up to and including the Plant Management Information System [IT].

HERE’S IS HOW CC‑LINK IE FIELD CAN HELP YOU

■■ You can manage your information, control, motion and safety – all in a single Ethernet network. This reduces the complexity of the application which allows you to build an efficient and reliable network

■■ You can link controllers and other field devices such as I/O, inverters, valve blocks, servo drives and many other device types to create a flexible system to meet your automation needs.

■■ Easily set up your network to reduce labor and startup costs.

■■ Effortlessly diagnose the cause of trouble to reduce downtime and diminish engineering costs.

■■ IE Field makes it easy to change, add, or update devices as configurations are updated automatically in real-time. This feature provides a path to upgrade your system; to future proof the application, resulting in a long term reduction in engineering costs and system savings.

■■ The use of commercially-available standard industrial-purpose IEEE 802.3 standard Ethernet equipment; including Cat 5e cable, and RJ-45 or M12 connectors and switches; results in hardware savings and reduced system complexity.

■■ Achieve a suitable performance no matter who builds the system - Expertise Ethernet knowledge is not necessary – reducing engineering costs and increasing ROI

■■ Communicate between CC-Link IE networks and General Purpose Ethernet devices. Achieving seamless communication between applications without awareness of network hierarchy or boundaries. This reduces the necessity for multiple networks, reducing costs and increasing reliability.

®

© 2019 CC-Link Partner Association. CLPA-2902

https://twitter.com/CLPA_News Twitter = #CLPA_News

https://www.facebook.com/CLPANews Facebook = CLPANews

https://www.linkedin.com/company/clpa-americas

CC-Link Partner Association – Americas (847) [email protected] am.CC-Link.org

PLC PLC HMI

PLC

Safety PLC

PLCRobot

Servo Servo Servo

Emergencystop switch

SafetyRemote I/O

Light CurtainRobot

GeneralRemote I/O

Servo

Motion Control Safety ControlEquipment ControlTM TMSafety

TM

TM

PC