Industrial I/O Solutions - Control & Protection · Isolation None None None Galvonic Isolation DI,...

Transcript of Industrial I/O Solutions - Control & Protection · Isolation None None None Galvonic Isolation DI,...

-

GEIndustrial Solutions

Factors such as performance requirements, environmental constraints, space limitations and cost can be a real challenge when connecting control systems to real-world sensors and actuators. Most industrial applications require a mix of I/O connectivity for basic control functions as well as robust, harsh-environment connectivity that can be deployed seamlessly and cost-effectively.

Smarter ArchitectureFrom compact slice I/O to triple-redundant solutions, GE's Automation & Controls flexible I/O portfolio encompasses a wide range of form factors, feature sets, and price points to fit any industrial application. Common features like hot swap capability, real-time health monitoring and diagnostics, Ethernet connectivity, and built-in configuration support with GE Automation & Controls programming packages deliver the right solution to meet application requirements and maximize productivity in today's connected industrial environments.

Wide ranging of communication options provide productivity and performance advantages needed for virtually any type of control application. Specialty I/O provide scalability without complexity.

GE's innovative I/O solutions combine a clean layout and outstanding response time while providing powerful redundancy, high density, and small footprint options. Intuitive I/O mapping options simplify installation and maintenance.

Flexible Redundancy

Configure a flexible, easy-to-use system to accommodate the unique uptime requirements of any operation. Open architecture allows for a mix of redundant I/O to meet application requirements for footprint, performance, environment, node distances, and price point. Connect to local devices like operator interfaces using other Ethernet protocols without adding extra hardware or impacting the determinism and integrity of your control network.

Customize your level of redundancy to meet and running reliability needs for both safety and process control.

Better InsightUnlock the continuity, connectivity, and collaboration potential in your control system by incorporating GE I/O solutions.

Take your control system to the next level with advanced capabilities like remote monitoring and diagnostics, asset optimization, and predictive analytics. The freedom to place application-specific I/O in the right spot in a control design enables the design flexibility needed to unlock the full potential of connected control system solutions. Support for common communication options, modularity, simple scalability, improved availability, and simplified maintenance makes GE I/O solutions an ideal choice for enabling powerful performance improvements and Industrial Internet connectivity.

• Remote, real-time diagnostics

• Wide ranging communication options

• Modularity; simple scalability

• Improved availability

• Simplified maintenance

• Integrated safety

Industrial I/O Solutions

-

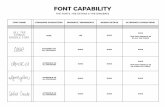

Product PACSystems RSTi

PACSystems RSTi-EP

VersaPoint/ VersaSafe

VersaMax Modular

VersaMax/IP PACSystems RX3i

PAC8000 Mark VIe

Mounting Format DIN Rail DIN Rail DIN Rail DIN Rail On Panel/Machine On Panel/DIN Rail DIN Rail DIN Rail

Network Interfaces PROFINET, PROFIBUS DPModbus/TCPModbus/RTUDeviceNet

PROFINETPROFIBUS DPModbus/TCPEtherCAT

PROFINETPROFIBUS DPModbus/TCPDeviceNET

PROFINETPROFIBUS DPModbus/TCPEGD, DeviceNet

PROFINETPROFIBUS DP

PROFINETPROFIBUS DPModbus/TCPEGD, CMX

PROFINETPROFIBUS DPModbus/TCP

IONET

Network Redundancy None MRP MRP MRP MRP MRP, Dual LAN MRP, Dual LAN Dual or Triple LAN

System Redundancy

None PNSR* None PNSR, EGD or GENIUS

None PNSR, EGD or GENIUS

PROFIBUS or Modbus/TCP

Dual or Triple IONET

IO Redundancy None None None None None None Dual Dual or Triple

Gateways Serial Communications

Serial Communications* Modbus/RTU* Modbus/RTU*

Serial Communications

Modbus/RTU PROFIBUS Master

None Serial CommunicationsPROFIBUS/MasterCANOpenModbus/RTUModbus/TCPHART, GENIUSDNP3 Serial/TCPIEC-61850, IEC-104, Re ective Memory

HART PROFINETPROFIBUS DPCANOpenFoundation FieldbusModbus/RTUModbus/TCPHART

Media Support Copper Copper Copper & MM Fiber

Copper & MM Fiber

Copper Copper, MM & SM Fiber

Copper & MM Fiber

Copper

Media Connector 2x RJ45 2x RJ45 2x RJ45 or 2x SCRJ 2x RJ45 or 2x ST 2x M12 2x RJ45 + 2x SFP 2x RJ45 or 2x ST 2x RJ45

I/O Type TTL, 12, 24, 48, 125 VDC120, 240 VAC, relay, analog, RTD, Thermocouple

24, 125 VDC

120, 240 VAC†, relay, analog, RTD, Thermocouple

24 VDCRelay analog, RTD, Thermocouple

TTL, 12, 24, 48, 125 VDC120, 240 VAC, relay, analog, RTD, Thermocouple

24 VDC analog

TTL, 12, 24, 48, 125 VDC120, 240 VAC, relay, analog, RTD, Thermocouple

24 VDC, 115, 230 VAC in2-60 VDC, 20 - 265 VAC out, analog, RTD, Thermocouple,

24, 48, 125 VDC in relay (24, 48, 125 VDC, 120/240VAC)analog (I out only), RTD

Speciality Modules

High Speed CountersSSI InterfacePWM and Pulse Output

High Speed CountersSSI Interface†PWM and Pulse OutputPower Measurement†SIL3 Power Feed

High Speed CountersSSI InterfaceAbsolute EncoderMotor StartersSIL3 Logic ProcessorSIL3 24 VDC, SIL3 relay

High Speed CountersPWM and Pulse Output

None Pulse Test 24, 125 VDC, High Speed Counters, PWM and Pulse OutputPower Sync & Measure, Strain Gauge, SoE Inputs (application)

Pulse Test 24 VDCPulse InputSoE InputsASH Detector

Pulse Test 24, 125VDC, Universal I/O†, Servo/LVDT Control Vibration MonitoringSIL3 Overspeed Monitor, SIL3 24, 125 VDC, SIL3 relay, SoE Inputs

Isolation None None None Galvonic IsolationDI, DO, AI, AO

None Galvonic IsolationDI, DO, AI, AO

Galvonic Isolation

DI, DO, AI, AO

Galvonic IsolationDI, Line surge suppressionDI, DO, AI, AO

Channel Density 1 - 16 points 4 - 16 points 1 - 8 points 4-32 points 4,8 points 2-32 points 2-32 points 8-36 points

Hot Swap No Yes No Yes No Yes Yes Yes

Environmentals IP20 0° to 55C° (UL)

IP20 -20° to 60C°

IP20 -20° to 55C°

IP20 0° to 60C°

IP67 -20° to 60C°

IP20 0° to 60C°

IP20 -40° to 70C°

IP20 -40° to 70C°

Agency Approvals

UL, UL HAZLOC Zone 2CE, ATEX C1D2

UL, UL HAZLOC Zone 2CE, ATEX C1D2TUV SIL3GL†

UL, UL HAZLOC Zone 2CE, ATEX C1D2TUV SIL3

UL, UL HAZLOC Zone 2CE, ATEX C1D2ABS, BV, DNV, GL, LR

UL, UL HAZLOC Zone 2CE

UL, UL HAZLOC Zone 2CE, ATEX C1D2ABS, BV, DNV, GL, KRS, LR

UL, UL HAZLOC Zone 1CE, ATEX C1D1, ISTUV SIL2LR, G3

UL, UL HAZLOC Zone2‡CE, ATEX C1D2‡Exida SIL3‡G3†

I/O Module Size 12mm W x 99mm H x 70 mm D

11.5mm W x 120mm H x 76mm D

12mm W x 120mm H x 70 mm D

66.8mm W x 163.5mm H x 70 mm D

70 mm W x 178 mm H x 49.3 mm D

34mm W x 145mm H x 140 mm D

42mm W x 110mm H x 106 mm D

SIMPLEX: 178mm W x 159mm H x 130mm D

REDUNDANT: 178mm W x 330mm H x 130mm D"

GE's Industrial Solutions business is a subsidiary of General Electric. The GE brand and logo are trademarks of General Electric. © 2016 General Electric. * Trademark of General Electric. All other trademarks are the property of their respective owners. Speci cations are subject to change without notice.

3.16 GFA2109

GE Industrial Solutions 2500 Austin Dr Charlottesville, VA, 22911 1-800-433-2682 or 1-434-978-5100 www.geautomation.com

† Targeted for 2016 release. ‡ Currently certi y, not at a component level.