Incorporation of parameter prediction models of different ... · The most common approach of...

Transcript of Incorporation of parameter prediction models of different ... · The most common approach of...

This is an electronic reprint of the original article.This reprint may differ from the original in pagination and typographic detail.

Powered by TCPDF (www.tcpdf.org)

This material is protected by copyright and other intellectual property rights, and duplication or sale of all or part of any of the repository collections is not permitted, except that material may be duplicated by you for your research use or educational purposes in electronic or print form. You must obtain permission for any other use. Electronic or print copies may not be offered, whether for sale or otherwise to anyone who is not an authorised user.

Ikonen, Teemu; Harjunkoski, IiroIncorporation of parameter prediction models of different fidelity into job shop scheduling

Published in:IFAC-PapersOnLine

DOI:10.1016/j.ifacol.2019.06.051

Published: 01/01/2019

Document VersionPublisher's PDF, also known as Version of record

Please cite the original version:Ikonen, T., & Harjunkoski, I. (2019). Incorporation of parameter prediction models of different fidelity into jobshop scheduling. IFAC-PapersOnLine, 52(1), 142-147. https://doi.org/10.1016/j.ifacol.2019.06.051

IFAC PapersOnLine 52-1 (2019) 142–147

ScienceDirect

Available online at www.sciencedirect.com

2405-8963 © 2019, IFAC (International Federation of Automatic Control) Hosting by Elsevier Ltd. All rights reserved.Peer review under responsibility of International Federation of Automatic Control.10.1016/j.ifacol.2019.06.051

© 2019, IFAC (International Federation of Automatic Control) Hosting by Elsevier Ltd. All rights reserved.

10.1016/j.ifacol.2019.06.051 2405-8963

Incorporation of parameter predictionmodels of different fidelity into job shop

scheduling

Teemu J. Ikonen ∗ Iiro Harjunkoski ∗,∗∗

∗ Aalto University, School of Chemical Engineering, Kemistintie 1,02150 Espoo, Finland (e-mail:

{teemu.ikonen,iiro.harjunkoski}@aalto.fi).∗∗ ABB Corporate Research, Wallstadter Str. 59, 68526 Ladenburg,

Germany

AbstractScheduling of industrial job shop processes is normally conducted using estimates of parameters(e.g. processing times) defining the optimization problem. Inaccuracy in these estimatedparameters can significantly affect the optimality, or even feasibility, of the scheduling solution.In this work, we incorporate data-driven parameter prediction models of different fidelity into aunit-specific continuous time scheduling model, and investigate the dependency of the solutionquality on the prediction model fidelity. Our high-fidelity prediction model is based on Gaussianprocesses (GP); more specifically we use the maximum a posteriori probability (MAP) estimate.The low and medium-fidelity prediction models rely on determining the average processing timeor average processing rate, respectively, from the dataset. In our test case, involving prediction oftaxi durations in New York City, the use of GP prediction model yielded, on average, 5.8% and1.8% shorter realized make spans in comparison to using the low and medium-fidelity predictionmodels, respectively.

Keywords: Scheduling Algorithms, Optimization, Parameter Estimation, Machine Learning,Gaussian Processes

1. INTRODUCTION

Industrial job shop processes are inherently stochastic.The optimal scheduling of these processes is dependent onthe realization of scheduling parameters (e.g. processingtimes, customer demand and raw material consumptions).As the information of future realizations is not available,scheduling decisions are typically made based on statictables of estimated scheduling parameters, which containboth inaccuracies and uncertainty.

Modern industrial job shop processes are monitored with asignificantly large number of sensors; the number of thesesensors being in the order of hundreds or even thousands(Gungor and Hancke, 2009). Useful information on theprocesses can be extracted from the historical data of thesesensors by using machine learning algorithms.

The most common approach of applying machine learningalgorithms to job shop scheduling is to learn dispatchingrules from historical data. Li and Olafsson (2005) appliedan inductive learning algorithm (C4.5) to train a decisiontree model using historical data. Later, Olafsson andLi (2010) improved the performance of the model bytraining it only with a subset of the historical data,representing the best decisions, which were chosen using agenetic algorithm. Mouelhi-Chibani and Pierreval (2010)

� Financial support is gratefully acknowledged from the Academyof Finland project “SINGPRO”, Decision No. 313466.

proposed a neural network-based approach to select, inreal time, the best job for a resource, once it becomesavailable. Instead of using historical data, they trainedtheir model using simulated scheduling data, generatedby simulated annealing. For a more extensive review oflearning dispatching rules from historical data, the readermay wish to consult the review article by Priore et al.(2014).

Another approach of applying machine learning algorithmsto job shop scheduling is to improve the accuracy of thescheduling parameters based on the historical data. Berralet al. (2010) predicted power consumption levels, centralprocessing unit loads and service-level agreement timingsof a data center using linear regression and the M5Palgorithm. They used these predictions in the schedulingof computing tasks, with an objective of reducing thetotal power consumption of the data center. Verbovenet al. (2008) predicted the runtimes of computing tasks,belonging to the same parameter sweep experiment, usingvarious machine learning tools, in order to assign them todesktop grids with suitable availability windows.

Jiang et al. (2016) applied Gaussian process regression todynamic scheduling of continuous casting of steel in orderto predict slack ratios of jobs. A slack ratio describes thetrade-off between the low production time and increasedrisk of a cast-break. Related to the same application, Zhaoet al. (2014) predicted the relationship between adjustable

12th IFAC Symposium on Dynamics and Control ofProcess Systems, including BiosystemsFlorianópolis - SC, Brazil, April 23-26, 2019

Copyright © 2019 IFAC 142

Incorporation of parameter predictionmodels of different fidelity into job shop

scheduling

Teemu J. Ikonen ∗ Iiro Harjunkoski ∗,∗∗

∗ Aalto University, School of Chemical Engineering, Kemistintie 1,02150 Espoo, Finland (e-mail:

{teemu.ikonen,iiro.harjunkoski}@aalto.fi).∗∗ ABB Corporate Research, Wallstadter Str. 59, 68526 Ladenburg,

Germany

AbstractScheduling of industrial job shop processes is normally conducted using estimates of parameters(e.g. processing times) defining the optimization problem. Inaccuracy in these estimatedparameters can significantly affect the optimality, or even feasibility, of the scheduling solution.In this work, we incorporate data-driven parameter prediction models of different fidelity into aunit-specific continuous time scheduling model, and investigate the dependency of the solutionquality on the prediction model fidelity. Our high-fidelity prediction model is based on Gaussianprocesses (GP); more specifically we use the maximum a posteriori probability (MAP) estimate.The low and medium-fidelity prediction models rely on determining the average processing timeor average processing rate, respectively, from the dataset. In our test case, involving prediction oftaxi durations in New York City, the use of GP prediction model yielded, on average, 5.8% and1.8% shorter realized make spans in comparison to using the low and medium-fidelity predictionmodels, respectively.

Keywords: Scheduling Algorithms, Optimization, Parameter Estimation, Machine Learning,Gaussian Processes

1. INTRODUCTION

Industrial job shop processes are inherently stochastic.The optimal scheduling of these processes is dependent onthe realization of scheduling parameters (e.g. processingtimes, customer demand and raw material consumptions).As the information of future realizations is not available,scheduling decisions are typically made based on statictables of estimated scheduling parameters, which containboth inaccuracies and uncertainty.

Modern industrial job shop processes are monitored with asignificantly large number of sensors; the number of thesesensors being in the order of hundreds or even thousands(Gungor and Hancke, 2009). Useful information on theprocesses can be extracted from the historical data of thesesensors by using machine learning algorithms.

The most common approach of applying machine learningalgorithms to job shop scheduling is to learn dispatchingrules from historical data. Li and Olafsson (2005) appliedan inductive learning algorithm (C4.5) to train a decisiontree model using historical data. Later, Olafsson andLi (2010) improved the performance of the model bytraining it only with a subset of the historical data,representing the best decisions, which were chosen using agenetic algorithm. Mouelhi-Chibani and Pierreval (2010)

� Financial support is gratefully acknowledged from the Academyof Finland project “SINGPRO”, Decision No. 313466.

proposed a neural network-based approach to select, inreal time, the best job for a resource, once it becomesavailable. Instead of using historical data, they trainedtheir model using simulated scheduling data, generatedby simulated annealing. For a more extensive review oflearning dispatching rules from historical data, the readermay wish to consult the review article by Priore et al.(2014).

Another approach of applying machine learning algorithmsto job shop scheduling is to improve the accuracy of thescheduling parameters based on the historical data. Berralet al. (2010) predicted power consumption levels, centralprocessing unit loads and service-level agreement timingsof a data center using linear regression and the M5Palgorithm. They used these predictions in the schedulingof computing tasks, with an objective of reducing thetotal power consumption of the data center. Verbovenet al. (2008) predicted the runtimes of computing tasks,belonging to the same parameter sweep experiment, usingvarious machine learning tools, in order to assign them todesktop grids with suitable availability windows.

Jiang et al. (2016) applied Gaussian process regression todynamic scheduling of continuous casting of steel in orderto predict slack ratios of jobs. A slack ratio describes thetrade-off between the low production time and increasedrisk of a cast-break. Related to the same application, Zhaoet al. (2014) predicted the relationship between adjustable

12th IFAC Symposium on Dynamics and Control ofProcess Systems, including BiosystemsFlorianópolis - SC, Brazil, April 23-26, 2019

Copyright © 2019 IFAC 142

Incorporation of parameter predictionmodels of different fidelity into job shop

scheduling

Teemu J. Ikonen ∗ Iiro Harjunkoski ∗,∗∗

∗ Aalto University, School of Chemical Engineering, Kemistintie 1,02150 Espoo, Finland (e-mail:

{teemu.ikonen,iiro.harjunkoski}@aalto.fi).∗∗ ABB Corporate Research, Wallstadter Str. 59, 68526 Ladenburg,

Germany

AbstractScheduling of industrial job shop processes is normally conducted using estimates of parameters(e.g. processing times) defining the optimization problem. Inaccuracy in these estimatedparameters can significantly affect the optimality, or even feasibility, of the scheduling solution.In this work, we incorporate data-driven parameter prediction models of different fidelity into aunit-specific continuous time scheduling model, and investigate the dependency of the solutionquality on the prediction model fidelity. Our high-fidelity prediction model is based on Gaussianprocesses (GP); more specifically we use the maximum a posteriori probability (MAP) estimate.The low and medium-fidelity prediction models rely on determining the average processing timeor average processing rate, respectively, from the dataset. In our test case, involving prediction oftaxi durations in New York City, the use of GP prediction model yielded, on average, 5.8% and1.8% shorter realized make spans in comparison to using the low and medium-fidelity predictionmodels, respectively.

Keywords: Scheduling Algorithms, Optimization, Parameter Estimation, Machine Learning,Gaussian Processes

1. INTRODUCTION

Industrial job shop processes are inherently stochastic.The optimal scheduling of these processes is dependent onthe realization of scheduling parameters (e.g. processingtimes, customer demand and raw material consumptions).As the information of future realizations is not available,scheduling decisions are typically made based on statictables of estimated scheduling parameters, which containboth inaccuracies and uncertainty.

Modern industrial job shop processes are monitored with asignificantly large number of sensors; the number of thesesensors being in the order of hundreds or even thousands(Gungor and Hancke, 2009). Useful information on theprocesses can be extracted from the historical data of thesesensors by using machine learning algorithms.

The most common approach of applying machine learningalgorithms to job shop scheduling is to learn dispatchingrules from historical data. Li and Olafsson (2005) appliedan inductive learning algorithm (C4.5) to train a decisiontree model using historical data. Later, Olafsson andLi (2010) improved the performance of the model bytraining it only with a subset of the historical data,representing the best decisions, which were chosen using agenetic algorithm. Mouelhi-Chibani and Pierreval (2010)

� Financial support is gratefully acknowledged from the Academyof Finland project “SINGPRO”, Decision No. 313466.

proposed a neural network-based approach to select, inreal time, the best job for a resource, once it becomesavailable. Instead of using historical data, they trainedtheir model using simulated scheduling data, generatedby simulated annealing. For a more extensive review oflearning dispatching rules from historical data, the readermay wish to consult the review article by Priore et al.(2014).

Another approach of applying machine learning algorithmsto job shop scheduling is to improve the accuracy of thescheduling parameters based on the historical data. Berralet al. (2010) predicted power consumption levels, centralprocessing unit loads and service-level agreement timingsof a data center using linear regression and the M5Palgorithm. They used these predictions in the schedulingof computing tasks, with an objective of reducing thetotal power consumption of the data center. Verbovenet al. (2008) predicted the runtimes of computing tasks,belonging to the same parameter sweep experiment, usingvarious machine learning tools, in order to assign them todesktop grids with suitable availability windows.

Jiang et al. (2016) applied Gaussian process regression todynamic scheduling of continuous casting of steel in orderto predict slack ratios of jobs. A slack ratio describes thetrade-off between the low production time and increasedrisk of a cast-break. Related to the same application, Zhaoet al. (2014) predicted the relationship between adjustable

12th IFAC Symposium on Dynamics and Control ofProcess Systems, including BiosystemsFlorianópolis - SC, Brazil, April 23-26, 2019

Copyright © 2019 IFAC 142

Incorporation of parameter predictionmodels of different fidelity into job shop

scheduling

Teemu J. Ikonen ∗ Iiro Harjunkoski ∗,∗∗

∗ Aalto University, School of Chemical Engineering, Kemistintie 1,02150 Espoo, Finland (e-mail:

{teemu.ikonen,iiro.harjunkoski}@aalto.fi).∗∗ ABB Corporate Research, Wallstadter Str. 59, 68526 Ladenburg,

Germany

AbstractScheduling of industrial job shop processes is normally conducted using estimates of parameters(e.g. processing times) defining the optimization problem. Inaccuracy in these estimatedparameters can significantly affect the optimality, or even feasibility, of the scheduling solution.In this work, we incorporate data-driven parameter prediction models of different fidelity into aunit-specific continuous time scheduling model, and investigate the dependency of the solutionquality on the prediction model fidelity. Our high-fidelity prediction model is based on Gaussianprocesses (GP); more specifically we use the maximum a posteriori probability (MAP) estimate.The low and medium-fidelity prediction models rely on determining the average processing timeor average processing rate, respectively, from the dataset. In our test case, involving prediction oftaxi durations in New York City, the use of GP prediction model yielded, on average, 5.8% and1.8% shorter realized make spans in comparison to using the low and medium-fidelity predictionmodels, respectively.

Keywords: Scheduling Algorithms, Optimization, Parameter Estimation, Machine Learning,Gaussian Processes

1. INTRODUCTION

Industrial job shop processes are inherently stochastic.The optimal scheduling of these processes is dependent onthe realization of scheduling parameters (e.g. processingtimes, customer demand and raw material consumptions).As the information of future realizations is not available,scheduling decisions are typically made based on statictables of estimated scheduling parameters, which containboth inaccuracies and uncertainty.

Modern industrial job shop processes are monitored with asignificantly large number of sensors; the number of thesesensors being in the order of hundreds or even thousands(Gungor and Hancke, 2009). Useful information on theprocesses can be extracted from the historical data of thesesensors by using machine learning algorithms.

The most common approach of applying machine learningalgorithms to job shop scheduling is to learn dispatchingrules from historical data. Li and Olafsson (2005) appliedan inductive learning algorithm (C4.5) to train a decisiontree model using historical data. Later, Olafsson andLi (2010) improved the performance of the model bytraining it only with a subset of the historical data,representing the best decisions, which were chosen using agenetic algorithm. Mouelhi-Chibani and Pierreval (2010)

� Financial support is gratefully acknowledged from the Academyof Finland project “SINGPRO”, Decision No. 313466.

proposed a neural network-based approach to select, inreal time, the best job for a resource, once it becomesavailable. Instead of using historical data, they trainedtheir model using simulated scheduling data, generatedby simulated annealing. For a more extensive review oflearning dispatching rules from historical data, the readermay wish to consult the review article by Priore et al.(2014).

Another approach of applying machine learning algorithmsto job shop scheduling is to improve the accuracy of thescheduling parameters based on the historical data. Berralet al. (2010) predicted power consumption levels, centralprocessing unit loads and service-level agreement timingsof a data center using linear regression and the M5Palgorithm. They used these predictions in the schedulingof computing tasks, with an objective of reducing thetotal power consumption of the data center. Verbovenet al. (2008) predicted the runtimes of computing tasks,belonging to the same parameter sweep experiment, usingvarious machine learning tools, in order to assign them todesktop grids with suitable availability windows.

Jiang et al. (2016) applied Gaussian process regression todynamic scheduling of continuous casting of steel in orderto predict slack ratios of jobs. A slack ratio describes thetrade-off between the low production time and increasedrisk of a cast-break. Related to the same application, Zhaoet al. (2014) predicted the relationship between adjustable

12th IFAC Symposium on Dynamics and Control ofProcess Systems, including BiosystemsFlorianópolis - SC, Brazil, April 23-26, 2019

Copyright © 2019 IFAC 142

Incorporation of parameter predictionmodels of different fidelity into job shop

scheduling

Teemu J. Ikonen ∗ Iiro Harjunkoski ∗,∗∗

∗ Aalto University, School of Chemical Engineering, Kemistintie 1,02150 Espoo, Finland (e-mail:

{teemu.ikonen,iiro.harjunkoski}@aalto.fi).∗∗ ABB Corporate Research, Wallstadter Str. 59, 68526 Ladenburg,

Germany

AbstractScheduling of industrial job shop processes is normally conducted using estimates of parameters(e.g. processing times) defining the optimization problem. Inaccuracy in these estimatedparameters can significantly affect the optimality, or even feasibility, of the scheduling solution.In this work, we incorporate data-driven parameter prediction models of different fidelity into aunit-specific continuous time scheduling model, and investigate the dependency of the solutionquality on the prediction model fidelity. Our high-fidelity prediction model is based on Gaussianprocesses (GP); more specifically we use the maximum a posteriori probability (MAP) estimate.The low and medium-fidelity prediction models rely on determining the average processing timeor average processing rate, respectively, from the dataset. In our test case, involving prediction oftaxi durations in New York City, the use of GP prediction model yielded, on average, 5.8% and1.8% shorter realized make spans in comparison to using the low and medium-fidelity predictionmodels, respectively.

Keywords: Scheduling Algorithms, Optimization, Parameter Estimation, Machine Learning,Gaussian Processes

1. INTRODUCTION

Industrial job shop processes are inherently stochastic.The optimal scheduling of these processes is dependent onthe realization of scheduling parameters (e.g. processingtimes, customer demand and raw material consumptions).As the information of future realizations is not available,scheduling decisions are typically made based on statictables of estimated scheduling parameters, which containboth inaccuracies and uncertainty.

Modern industrial job shop processes are monitored with asignificantly large number of sensors; the number of thesesensors being in the order of hundreds or even thousands(Gungor and Hancke, 2009). Useful information on theprocesses can be extracted from the historical data of thesesensors by using machine learning algorithms.

The most common approach of applying machine learningalgorithms to job shop scheduling is to learn dispatchingrules from historical data. Li and Olafsson (2005) appliedan inductive learning algorithm (C4.5) to train a decisiontree model using historical data. Later, Olafsson andLi (2010) improved the performance of the model bytraining it only with a subset of the historical data,representing the best decisions, which were chosen using agenetic algorithm. Mouelhi-Chibani and Pierreval (2010)

� Financial support is gratefully acknowledged from the Academyof Finland project “SINGPRO”, Decision No. 313466.

proposed a neural network-based approach to select, inreal time, the best job for a resource, once it becomesavailable. Instead of using historical data, they trainedtheir model using simulated scheduling data, generatedby simulated annealing. For a more extensive review oflearning dispatching rules from historical data, the readermay wish to consult the review article by Priore et al.(2014).

Another approach of applying machine learning algorithmsto job shop scheduling is to improve the accuracy of thescheduling parameters based on the historical data. Berralet al. (2010) predicted power consumption levels, centralprocessing unit loads and service-level agreement timingsof a data center using linear regression and the M5Palgorithm. They used these predictions in the schedulingof computing tasks, with an objective of reducing thetotal power consumption of the data center. Verbovenet al. (2008) predicted the runtimes of computing tasks,belonging to the same parameter sweep experiment, usingvarious machine learning tools, in order to assign them todesktop grids with suitable availability windows.

Jiang et al. (2016) applied Gaussian process regression todynamic scheduling of continuous casting of steel in orderto predict slack ratios of jobs. A slack ratio describes thetrade-off between the low production time and increasedrisk of a cast-break. Related to the same application, Zhaoet al. (2014) predicted the relationship between adjustable

12th IFAC Symposium on Dynamics and Control ofProcess Systems, including BiosystemsFlorianópolis - SC, Brazil, April 23-26, 2019

Copyright © 2019 IFAC 142

Incorporation of parameter predictionmodels of different fidelity into job shop

scheduling

Teemu J. Ikonen ∗ Iiro Harjunkoski ∗,∗∗

∗ Aalto University, School of Chemical Engineering, Kemistintie 1,02150 Espoo, Finland (e-mail:

{teemu.ikonen,iiro.harjunkoski}@aalto.fi).∗∗ ABB Corporate Research, Wallstadter Str. 59, 68526 Ladenburg,

Germany

AbstractScheduling of industrial job shop processes is normally conducted using estimates of parameters(e.g. processing times) defining the optimization problem. Inaccuracy in these estimatedparameters can significantly affect the optimality, or even feasibility, of the scheduling solution.In this work, we incorporate data-driven parameter prediction models of different fidelity into aunit-specific continuous time scheduling model, and investigate the dependency of the solutionquality on the prediction model fidelity. Our high-fidelity prediction model is based on Gaussianprocesses (GP); more specifically we use the maximum a posteriori probability (MAP) estimate.The low and medium-fidelity prediction models rely on determining the average processing timeor average processing rate, respectively, from the dataset. In our test case, involving prediction oftaxi durations in New York City, the use of GP prediction model yielded, on average, 5.8% and1.8% shorter realized make spans in comparison to using the low and medium-fidelity predictionmodels, respectively.

Keywords: Scheduling Algorithms, Optimization, Parameter Estimation, Machine Learning,Gaussian Processes

1. INTRODUCTION

Industrial job shop processes are inherently stochastic.The optimal scheduling of these processes is dependent onthe realization of scheduling parameters (e.g. processingtimes, customer demand and raw material consumptions).As the information of future realizations is not available,scheduling decisions are typically made based on statictables of estimated scheduling parameters, which containboth inaccuracies and uncertainty.

Modern industrial job shop processes are monitored with asignificantly large number of sensors; the number of thesesensors being in the order of hundreds or even thousands(Gungor and Hancke, 2009). Useful information on theprocesses can be extracted from the historical data of thesesensors by using machine learning algorithms.

The most common approach of applying machine learningalgorithms to job shop scheduling is to learn dispatchingrules from historical data. Li and Olafsson (2005) appliedan inductive learning algorithm (C4.5) to train a decisiontree model using historical data. Later, Olafsson andLi (2010) improved the performance of the model bytraining it only with a subset of the historical data,representing the best decisions, which were chosen using agenetic algorithm. Mouelhi-Chibani and Pierreval (2010)

� Financial support is gratefully acknowledged from the Academyof Finland project “SINGPRO”, Decision No. 313466.

proposed a neural network-based approach to select, inreal time, the best job for a resource, once it becomesavailable. Instead of using historical data, they trainedtheir model using simulated scheduling data, generatedby simulated annealing. For a more extensive review oflearning dispatching rules from historical data, the readermay wish to consult the review article by Priore et al.(2014).

Another approach of applying machine learning algorithmsto job shop scheduling is to improve the accuracy of thescheduling parameters based on the historical data. Berralet al. (2010) predicted power consumption levels, centralprocessing unit loads and service-level agreement timingsof a data center using linear regression and the M5Palgorithm. They used these predictions in the schedulingof computing tasks, with an objective of reducing thetotal power consumption of the data center. Verbovenet al. (2008) predicted the runtimes of computing tasks,belonging to the same parameter sweep experiment, usingvarious machine learning tools, in order to assign them todesktop grids with suitable availability windows.

Jiang et al. (2016) applied Gaussian process regression todynamic scheduling of continuous casting of steel in orderto predict slack ratios of jobs. A slack ratio describes thetrade-off between the low production time and increasedrisk of a cast-break. Related to the same application, Zhaoet al. (2014) predicted the relationship between adjustable

12th IFAC Symposium on Dynamics and Control ofProcess Systems, including BiosystemsFlorianópolis - SC, Brazil, April 23-26, 2019

Copyright © 2019 IFAC 142

gas users and gas tank levels based on a historical datasetusing Bayesian Networks. The information was used toensure safe operating level of the gas tanks.

Regardless of the used estimation model, and the size andquality of the historical dataset, the estimated schedul-ing parameters contain uncertainty, which is mainly dueto stochasticity of the process, measurement errors andmodel imperfections. The deviations in the realized andestimated scheduling parameters can significantly affectthe optimality, or even the feasibility, of the solution.

The purpose of this paper is to accurately predict the pro-cessing times from a historical dataset using the Gaussianprocess (GP) regression, and to use these predictions injob shop scheduling. We benchmark the prediction methodagainst simple average duration and average rate models(see Section 3) by examining the realized make spans ofa set of 30 scheduling problems. As the scheduling model,we use the unit-specific continuous-time model by Shaikand Floudas (2009).

2. SCHEDULING PROBLEM

We use the New York City (NYC) taxi duration dataset(Kaggle Inc, 2017) 1 , in order to devise a simple schedulingproblem that can facilitate the evaluation of parameterprediction models. The dataset contains information ofover 1.4 million taxi trips in NYC, including the durationof the trip, passenger count, as well as pick-up and drop-offdate, time and coordinates.

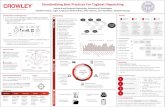

We now define a scheduling problem that is based on thedataset but has features that are transferable to industrialjob shop scheduling. Let us consider a company, whichhead quarter is at Wall Street 2 , located at the SouthWest tip of Manhattan. The company performs surveysat remote sites located around NYC. In order to performa survey, an employee of the company travels to the siteby taxi, performs the survey and travels back to the headquarter. We refer to this combination of the outbound taxitrip, the survey and the inbound taxi trip as a task (Fig. 1).When performing a survey, an employee relies on a surveyteam that is based at the head quarter. We consider bothtaxis and survey teams as processing units, and define thenumber of both types of units to be two. The number oftraveling employees is not restricted. In addition, a taxithat drops off an employee to location A is defined tobe instantly available to pick up another employee fromlocation B. The objective of the scheduling optimizationis to minimize the make span ms of performing surveys atsix different sites located in NYC (see Fig. 2 for an exampleset of sites). The durations of outbound and inbound taxitrips are predicted (see Section 3), whereas the durationof conducting a survey is fixed to 1800 s.

From an industrial point of view, the taxis and surveyingteams are equivalent to machinery or processing units,and the procedure of performing a task to a recipe toproduce a product. Alternatively, the inbound and out-bound taxi trips can be considered as preparation and

1 We have amended the dataset with the corresponding fastestroutes (in kilometers) from another openly available dataset (Os-carleo, 2017).2 The coordinates of which are 40.70729◦N, 74.01095◦W.

survey 2

survey 1

taxi 2

taxi 1start

finish

or or

Figure 1. The procedure of performing a task from startto finish. Two parallel units exist for both taxis andsurveying teams.

1

2

3

4

5

6

74.08°W 74.02°W 73.96°W 73.9°W 73.84°W 73.78°W

40.66°N

40.72°N

40.78°N

40.84°N

Figure 2. The example scheduling problem, consisting ofsix survey sites. The grey point indicates the locationof Wall Street. Continuous red and dashed blue linesindicate the start and end points of the outbound andinbound trips, respectively, from the test set.

cleaning, respectively, of a processing unit, and the surveyas performing the actual job in the unit.

In order to extract the most relevant information from thedataset for our purpose, we create a filtered dataset, inwhich either the pick-up or drop-off location lies within500 m from Wall Street (indicated by the red oval in Fig.3(b)). In addition, we filter trips with unrealistically longdurations (>20 000 s). Figure 3(a) shows the histogramof trip durations in the filtered dataset. Further, Figure3(b) presents a scatter plot of trip durations, in which thelocation of a point is the pick-up or drop-off location thatlies further away from Wall Street, and the color of thepoint indicates the duration of the trip.

Further, we divide the filtered dataset into training andtesting sets, using a ratio of 67-33%. The training set isused to train the prediction model, and the test set toevaluate its accuracy (see the next section). In scheduling,the realization of outbound and inbound trip durationscorresponds to the trip in the training set with the closestmatch to Wall Street and the site coordinates. Figure 2shows the pick-up and drop-off coordinates (connected byred and blue lines) of these trips for the example set of sixsites.

3. DURATION PREDICTION

In the next three sections, we describe our models topredict the duration of a taxi trip, starting from the lowestfidelity. Finally, in Section 3.4, we compare the predictionaccuracy of the models.

2019 IFAC DYCOPSFlorianópolis - SC, Brazil, April 23-26, 2019

143

Teemu J. Ikonen et al. / IFAC PapersOnLine 52-1 (2019) 142–147 143

Incorporation of parameter predictionmodels of different fidelity into job shop

scheduling

Teemu J. Ikonen ∗ Iiro Harjunkoski ∗,∗∗

∗ Aalto University, School of Chemical Engineering, Kemistintie 1,02150 Espoo, Finland (e-mail:

{teemu.ikonen,iiro.harjunkoski}@aalto.fi).∗∗ ABB Corporate Research, Wallstadter Str. 59, 68526 Ladenburg,

Germany

AbstractScheduling of industrial job shop processes is normally conducted using estimates of parameters(e.g. processing times) defining the optimization problem. Inaccuracy in these estimatedparameters can significantly affect the optimality, or even feasibility, of the scheduling solution.In this work, we incorporate data-driven parameter prediction models of different fidelity into aunit-specific continuous time scheduling model, and investigate the dependency of the solutionquality on the prediction model fidelity. Our high-fidelity prediction model is based on Gaussianprocesses (GP); more specifically we use the maximum a posteriori probability (MAP) estimate.The low and medium-fidelity prediction models rely on determining the average processing timeor average processing rate, respectively, from the dataset. In our test case, involving prediction oftaxi durations in New York City, the use of GP prediction model yielded, on average, 5.8% and1.8% shorter realized make spans in comparison to using the low and medium-fidelity predictionmodels, respectively.

Keywords: Scheduling Algorithms, Optimization, Parameter Estimation, Machine Learning,Gaussian Processes

1. INTRODUCTION

Industrial job shop processes are inherently stochastic.The optimal scheduling of these processes is dependent onthe realization of scheduling parameters (e.g. processingtimes, customer demand and raw material consumptions).As the information of future realizations is not available,scheduling decisions are typically made based on statictables of estimated scheduling parameters, which containboth inaccuracies and uncertainty.

Modern industrial job shop processes are monitored with asignificantly large number of sensors; the number of thesesensors being in the order of hundreds or even thousands(Gungor and Hancke, 2009). Useful information on theprocesses can be extracted from the historical data of thesesensors by using machine learning algorithms.

The most common approach of applying machine learningalgorithms to job shop scheduling is to learn dispatchingrules from historical data. Li and Olafsson (2005) appliedan inductive learning algorithm (C4.5) to train a decisiontree model using historical data. Later, Olafsson andLi (2010) improved the performance of the model bytraining it only with a subset of the historical data,representing the best decisions, which were chosen using agenetic algorithm. Mouelhi-Chibani and Pierreval (2010)

� Financial support is gratefully acknowledged from the Academyof Finland project “SINGPRO”, Decision No. 313466.

proposed a neural network-based approach to select, inreal time, the best job for a resource, once it becomesavailable. Instead of using historical data, they trainedtheir model using simulated scheduling data, generatedby simulated annealing. For a more extensive review oflearning dispatching rules from historical data, the readermay wish to consult the review article by Priore et al.(2014).

Another approach of applying machine learning algorithmsto job shop scheduling is to improve the accuracy of thescheduling parameters based on the historical data. Berralet al. (2010) predicted power consumption levels, centralprocessing unit loads and service-level agreement timingsof a data center using linear regression and the M5Palgorithm. They used these predictions in the schedulingof computing tasks, with an objective of reducing thetotal power consumption of the data center. Verbovenet al. (2008) predicted the runtimes of computing tasks,belonging to the same parameter sweep experiment, usingvarious machine learning tools, in order to assign them todesktop grids with suitable availability windows.

Jiang et al. (2016) applied Gaussian process regression todynamic scheduling of continuous casting of steel in orderto predict slack ratios of jobs. A slack ratio describes thetrade-off between the low production time and increasedrisk of a cast-break. Related to the same application, Zhaoet al. (2014) predicted the relationship between adjustable

12th IFAC Symposium on Dynamics and Control ofProcess Systems, including BiosystemsFlorianópolis - SC, Brazil, April 23-26, 2019

Copyright © 2019 IFAC 142

Incorporation of parameter predictionmodels of different fidelity into job shop

scheduling

Teemu J. Ikonen ∗ Iiro Harjunkoski ∗,∗∗

∗ Aalto University, School of Chemical Engineering, Kemistintie 1,02150 Espoo, Finland (e-mail:

{teemu.ikonen,iiro.harjunkoski}@aalto.fi).∗∗ ABB Corporate Research, Wallstadter Str. 59, 68526 Ladenburg,

Germany

AbstractScheduling of industrial job shop processes is normally conducted using estimates of parameters(e.g. processing times) defining the optimization problem. Inaccuracy in these estimatedparameters can significantly affect the optimality, or even feasibility, of the scheduling solution.In this work, we incorporate data-driven parameter prediction models of different fidelity into aunit-specific continuous time scheduling model, and investigate the dependency of the solutionquality on the prediction model fidelity. Our high-fidelity prediction model is based on Gaussianprocesses (GP); more specifically we use the maximum a posteriori probability (MAP) estimate.The low and medium-fidelity prediction models rely on determining the average processing timeor average processing rate, respectively, from the dataset. In our test case, involving prediction oftaxi durations in New York City, the use of GP prediction model yielded, on average, 5.8% and1.8% shorter realized make spans in comparison to using the low and medium-fidelity predictionmodels, respectively.

Keywords: Scheduling Algorithms, Optimization, Parameter Estimation, Machine Learning,Gaussian Processes

1. INTRODUCTION

Industrial job shop processes are inherently stochastic.The optimal scheduling of these processes is dependent onthe realization of scheduling parameters (e.g. processingtimes, customer demand and raw material consumptions).As the information of future realizations is not available,scheduling decisions are typically made based on statictables of estimated scheduling parameters, which containboth inaccuracies and uncertainty.

Modern industrial job shop processes are monitored with asignificantly large number of sensors; the number of thesesensors being in the order of hundreds or even thousands(Gungor and Hancke, 2009). Useful information on theprocesses can be extracted from the historical data of thesesensors by using machine learning algorithms.

The most common approach of applying machine learningalgorithms to job shop scheduling is to learn dispatchingrules from historical data. Li and Olafsson (2005) appliedan inductive learning algorithm (C4.5) to train a decisiontree model using historical data. Later, Olafsson andLi (2010) improved the performance of the model bytraining it only with a subset of the historical data,representing the best decisions, which were chosen using agenetic algorithm. Mouelhi-Chibani and Pierreval (2010)

� Financial support is gratefully acknowledged from the Academyof Finland project “SINGPRO”, Decision No. 313466.

proposed a neural network-based approach to select, inreal time, the best job for a resource, once it becomesavailable. Instead of using historical data, they trainedtheir model using simulated scheduling data, generatedby simulated annealing. For a more extensive review oflearning dispatching rules from historical data, the readermay wish to consult the review article by Priore et al.(2014).

Another approach of applying machine learning algorithmsto job shop scheduling is to improve the accuracy of thescheduling parameters based on the historical data. Berralet al. (2010) predicted power consumption levels, centralprocessing unit loads and service-level agreement timingsof a data center using linear regression and the M5Palgorithm. They used these predictions in the schedulingof computing tasks, with an objective of reducing thetotal power consumption of the data center. Verbovenet al. (2008) predicted the runtimes of computing tasks,belonging to the same parameter sweep experiment, usingvarious machine learning tools, in order to assign them todesktop grids with suitable availability windows.

Jiang et al. (2016) applied Gaussian process regression todynamic scheduling of continuous casting of steel in orderto predict slack ratios of jobs. A slack ratio describes thetrade-off between the low production time and increasedrisk of a cast-break. Related to the same application, Zhaoet al. (2014) predicted the relationship between adjustable

12th IFAC Symposium on Dynamics and Control ofProcess Systems, including BiosystemsFlorianópolis - SC, Brazil, April 23-26, 2019

Copyright © 2019 IFAC 142

Incorporation of parameter predictionmodels of different fidelity into job shop

scheduling

Teemu J. Ikonen ∗ Iiro Harjunkoski ∗,∗∗

∗ Aalto University, School of Chemical Engineering, Kemistintie 1,02150 Espoo, Finland (e-mail:

{teemu.ikonen,iiro.harjunkoski}@aalto.fi).∗∗ ABB Corporate Research, Wallstadter Str. 59, 68526 Ladenburg,

Germany

AbstractScheduling of industrial job shop processes is normally conducted using estimates of parameters(e.g. processing times) defining the optimization problem. Inaccuracy in these estimatedparameters can significantly affect the optimality, or even feasibility, of the scheduling solution.In this work, we incorporate data-driven parameter prediction models of different fidelity into aunit-specific continuous time scheduling model, and investigate the dependency of the solutionquality on the prediction model fidelity. Our high-fidelity prediction model is based on Gaussianprocesses (GP); more specifically we use the maximum a posteriori probability (MAP) estimate.The low and medium-fidelity prediction models rely on determining the average processing timeor average processing rate, respectively, from the dataset. In our test case, involving prediction oftaxi durations in New York City, the use of GP prediction model yielded, on average, 5.8% and1.8% shorter realized make spans in comparison to using the low and medium-fidelity predictionmodels, respectively.

Keywords: Scheduling Algorithms, Optimization, Parameter Estimation, Machine Learning,Gaussian Processes

1. INTRODUCTION

Industrial job shop processes are inherently stochastic.The optimal scheduling of these processes is dependent onthe realization of scheduling parameters (e.g. processingtimes, customer demand and raw material consumptions).As the information of future realizations is not available,scheduling decisions are typically made based on statictables of estimated scheduling parameters, which containboth inaccuracies and uncertainty.

Modern industrial job shop processes are monitored with asignificantly large number of sensors; the number of thesesensors being in the order of hundreds or even thousands(Gungor and Hancke, 2009). Useful information on theprocesses can be extracted from the historical data of thesesensors by using machine learning algorithms.

The most common approach of applying machine learningalgorithms to job shop scheduling is to learn dispatchingrules from historical data. Li and Olafsson (2005) appliedan inductive learning algorithm (C4.5) to train a decisiontree model using historical data. Later, Olafsson andLi (2010) improved the performance of the model bytraining it only with a subset of the historical data,representing the best decisions, which were chosen using agenetic algorithm. Mouelhi-Chibani and Pierreval (2010)

� Financial support is gratefully acknowledged from the Academyof Finland project “SINGPRO”, Decision No. 313466.

proposed a neural network-based approach to select, inreal time, the best job for a resource, once it becomesavailable. Instead of using historical data, they trainedtheir model using simulated scheduling data, generatedby simulated annealing. For a more extensive review oflearning dispatching rules from historical data, the readermay wish to consult the review article by Priore et al.(2014).

Another approach of applying machine learning algorithmsto job shop scheduling is to improve the accuracy of thescheduling parameters based on the historical data. Berralet al. (2010) predicted power consumption levels, centralprocessing unit loads and service-level agreement timingsof a data center using linear regression and the M5Palgorithm. They used these predictions in the schedulingof computing tasks, with an objective of reducing thetotal power consumption of the data center. Verbovenet al. (2008) predicted the runtimes of computing tasks,belonging to the same parameter sweep experiment, usingvarious machine learning tools, in order to assign them todesktop grids with suitable availability windows.

Jiang et al. (2016) applied Gaussian process regression todynamic scheduling of continuous casting of steel in orderto predict slack ratios of jobs. A slack ratio describes thetrade-off between the low production time and increasedrisk of a cast-break. Related to the same application, Zhaoet al. (2014) predicted the relationship between adjustable

12th IFAC Symposium on Dynamics and Control ofProcess Systems, including BiosystemsFlorianópolis - SC, Brazil, April 23-26, 2019

Copyright © 2019 IFAC 142

Incorporation of parameter predictionmodels of different fidelity into job shop

scheduling

Teemu J. Ikonen ∗ Iiro Harjunkoski ∗,∗∗

∗ Aalto University, School of Chemical Engineering, Kemistintie 1,02150 Espoo, Finland (e-mail:

{teemu.ikonen,iiro.harjunkoski}@aalto.fi).∗∗ ABB Corporate Research, Wallstadter Str. 59, 68526 Ladenburg,

Germany

AbstractScheduling of industrial job shop processes is normally conducted using estimates of parameters(e.g. processing times) defining the optimization problem. Inaccuracy in these estimatedparameters can significantly affect the optimality, or even feasibility, of the scheduling solution.In this work, we incorporate data-driven parameter prediction models of different fidelity into aunit-specific continuous time scheduling model, and investigate the dependency of the solutionquality on the prediction model fidelity. Our high-fidelity prediction model is based on Gaussianprocesses (GP); more specifically we use the maximum a posteriori probability (MAP) estimate.The low and medium-fidelity prediction models rely on determining the average processing timeor average processing rate, respectively, from the dataset. In our test case, involving prediction oftaxi durations in New York City, the use of GP prediction model yielded, on average, 5.8% and1.8% shorter realized make spans in comparison to using the low and medium-fidelity predictionmodels, respectively.

Keywords: Scheduling Algorithms, Optimization, Parameter Estimation, Machine Learning,Gaussian Processes

1. INTRODUCTION

Industrial job shop processes are inherently stochastic.The optimal scheduling of these processes is dependent onthe realization of scheduling parameters (e.g. processingtimes, customer demand and raw material consumptions).As the information of future realizations is not available,scheduling decisions are typically made based on statictables of estimated scheduling parameters, which containboth inaccuracies and uncertainty.

Modern industrial job shop processes are monitored with asignificantly large number of sensors; the number of thesesensors being in the order of hundreds or even thousands(Gungor and Hancke, 2009). Useful information on theprocesses can be extracted from the historical data of thesesensors by using machine learning algorithms.

The most common approach of applying machine learningalgorithms to job shop scheduling is to learn dispatchingrules from historical data. Li and Olafsson (2005) appliedan inductive learning algorithm (C4.5) to train a decisiontree model using historical data. Later, Olafsson andLi (2010) improved the performance of the model bytraining it only with a subset of the historical data,representing the best decisions, which were chosen using agenetic algorithm. Mouelhi-Chibani and Pierreval (2010)

� Financial support is gratefully acknowledged from the Academyof Finland project “SINGPRO”, Decision No. 313466.

proposed a neural network-based approach to select, inreal time, the best job for a resource, once it becomesavailable. Instead of using historical data, they trainedtheir model using simulated scheduling data, generatedby simulated annealing. For a more extensive review oflearning dispatching rules from historical data, the readermay wish to consult the review article by Priore et al.(2014).

Another approach of applying machine learning algorithmsto job shop scheduling is to improve the accuracy of thescheduling parameters based on the historical data. Berralet al. (2010) predicted power consumption levels, centralprocessing unit loads and service-level agreement timingsof a data center using linear regression and the M5Palgorithm. They used these predictions in the schedulingof computing tasks, with an objective of reducing thetotal power consumption of the data center. Verbovenet al. (2008) predicted the runtimes of computing tasks,belonging to the same parameter sweep experiment, usingvarious machine learning tools, in order to assign them todesktop grids with suitable availability windows.

Jiang et al. (2016) applied Gaussian process regression todynamic scheduling of continuous casting of steel in orderto predict slack ratios of jobs. A slack ratio describes thetrade-off between the low production time and increasedrisk of a cast-break. Related to the same application, Zhaoet al. (2014) predicted the relationship between adjustable

12th IFAC Symposium on Dynamics and Control ofProcess Systems, including BiosystemsFlorianópolis - SC, Brazil, April 23-26, 2019

Copyright © 2019 IFAC 142

Incorporation of parameter predictionmodels of different fidelity into job shop

scheduling

Teemu J. Ikonen ∗ Iiro Harjunkoski ∗,∗∗

∗ Aalto University, School of Chemical Engineering, Kemistintie 1,02150 Espoo, Finland (e-mail:

{teemu.ikonen,iiro.harjunkoski}@aalto.fi).∗∗ ABB Corporate Research, Wallstadter Str. 59, 68526 Ladenburg,

Germany

AbstractScheduling of industrial job shop processes is normally conducted using estimates of parameters(e.g. processing times) defining the optimization problem. Inaccuracy in these estimatedparameters can significantly affect the optimality, or even feasibility, of the scheduling solution.In this work, we incorporate data-driven parameter prediction models of different fidelity into aunit-specific continuous time scheduling model, and investigate the dependency of the solutionquality on the prediction model fidelity. Our high-fidelity prediction model is based on Gaussianprocesses (GP); more specifically we use the maximum a posteriori probability (MAP) estimate.The low and medium-fidelity prediction models rely on determining the average processing timeor average processing rate, respectively, from the dataset. In our test case, involving prediction oftaxi durations in New York City, the use of GP prediction model yielded, on average, 5.8% and1.8% shorter realized make spans in comparison to using the low and medium-fidelity predictionmodels, respectively.

Keywords: Scheduling Algorithms, Optimization, Parameter Estimation, Machine Learning,Gaussian Processes

1. INTRODUCTION

Industrial job shop processes are inherently stochastic.The optimal scheduling of these processes is dependent onthe realization of scheduling parameters (e.g. processingtimes, customer demand and raw material consumptions).As the information of future realizations is not available,scheduling decisions are typically made based on statictables of estimated scheduling parameters, which containboth inaccuracies and uncertainty.

Modern industrial job shop processes are monitored with asignificantly large number of sensors; the number of thesesensors being in the order of hundreds or even thousands(Gungor and Hancke, 2009). Useful information on theprocesses can be extracted from the historical data of thesesensors by using machine learning algorithms.

The most common approach of applying machine learningalgorithms to job shop scheduling is to learn dispatchingrules from historical data. Li and Olafsson (2005) appliedan inductive learning algorithm (C4.5) to train a decisiontree model using historical data. Later, Olafsson andLi (2010) improved the performance of the model bytraining it only with a subset of the historical data,representing the best decisions, which were chosen using agenetic algorithm. Mouelhi-Chibani and Pierreval (2010)

� Financial support is gratefully acknowledged from the Academyof Finland project “SINGPRO”, Decision No. 313466.

proposed a neural network-based approach to select, inreal time, the best job for a resource, once it becomesavailable. Instead of using historical data, they trainedtheir model using simulated scheduling data, generatedby simulated annealing. For a more extensive review oflearning dispatching rules from historical data, the readermay wish to consult the review article by Priore et al.(2014).

Another approach of applying machine learning algorithmsto job shop scheduling is to improve the accuracy of thescheduling parameters based on the historical data. Berralet al. (2010) predicted power consumption levels, centralprocessing unit loads and service-level agreement timingsof a data center using linear regression and the M5Palgorithm. They used these predictions in the schedulingof computing tasks, with an objective of reducing thetotal power consumption of the data center. Verbovenet al. (2008) predicted the runtimes of computing tasks,belonging to the same parameter sweep experiment, usingvarious machine learning tools, in order to assign them todesktop grids with suitable availability windows.

Jiang et al. (2016) applied Gaussian process regression todynamic scheduling of continuous casting of steel in orderto predict slack ratios of jobs. A slack ratio describes thetrade-off between the low production time and increasedrisk of a cast-break. Related to the same application, Zhaoet al. (2014) predicted the relationship between adjustable

12th IFAC Symposium on Dynamics and Control ofProcess Systems, including BiosystemsFlorianópolis - SC, Brazil, April 23-26, 2019

Copyright © 2019 IFAC 142

Incorporation of parameter predictionmodels of different fidelity into job shop

scheduling

Teemu J. Ikonen ∗ Iiro Harjunkoski ∗,∗∗

∗ Aalto University, School of Chemical Engineering, Kemistintie 1,02150 Espoo, Finland (e-mail:

{teemu.ikonen,iiro.harjunkoski}@aalto.fi).∗∗ ABB Corporate Research, Wallstadter Str. 59, 68526 Ladenburg,

Germany

AbstractScheduling of industrial job shop processes is normally conducted using estimates of parameters(e.g. processing times) defining the optimization problem. Inaccuracy in these estimatedparameters can significantly affect the optimality, or even feasibility, of the scheduling solution.In this work, we incorporate data-driven parameter prediction models of different fidelity into aunit-specific continuous time scheduling model, and investigate the dependency of the solutionquality on the prediction model fidelity. Our high-fidelity prediction model is based on Gaussianprocesses (GP); more specifically we use the maximum a posteriori probability (MAP) estimate.The low and medium-fidelity prediction models rely on determining the average processing timeor average processing rate, respectively, from the dataset. In our test case, involving prediction oftaxi durations in New York City, the use of GP prediction model yielded, on average, 5.8% and1.8% shorter realized make spans in comparison to using the low and medium-fidelity predictionmodels, respectively.

Keywords: Scheduling Algorithms, Optimization, Parameter Estimation, Machine Learning,Gaussian Processes

1. INTRODUCTION

Industrial job shop processes are inherently stochastic.The optimal scheduling of these processes is dependent onthe realization of scheduling parameters (e.g. processingtimes, customer demand and raw material consumptions).As the information of future realizations is not available,scheduling decisions are typically made based on statictables of estimated scheduling parameters, which containboth inaccuracies and uncertainty.

Modern industrial job shop processes are monitored with asignificantly large number of sensors; the number of thesesensors being in the order of hundreds or even thousands(Gungor and Hancke, 2009). Useful information on theprocesses can be extracted from the historical data of thesesensors by using machine learning algorithms.

The most common approach of applying machine learningalgorithms to job shop scheduling is to learn dispatchingrules from historical data. Li and Olafsson (2005) appliedan inductive learning algorithm (C4.5) to train a decisiontree model using historical data. Later, Olafsson andLi (2010) improved the performance of the model bytraining it only with a subset of the historical data,representing the best decisions, which were chosen using agenetic algorithm. Mouelhi-Chibani and Pierreval (2010)

� Financial support is gratefully acknowledged from the Academyof Finland project “SINGPRO”, Decision No. 313466.

proposed a neural network-based approach to select, inreal time, the best job for a resource, once it becomesavailable. Instead of using historical data, they trainedtheir model using simulated scheduling data, generatedby simulated annealing. For a more extensive review oflearning dispatching rules from historical data, the readermay wish to consult the review article by Priore et al.(2014).

Another approach of applying machine learning algorithmsto job shop scheduling is to improve the accuracy of thescheduling parameters based on the historical data. Berralet al. (2010) predicted power consumption levels, centralprocessing unit loads and service-level agreement timingsof a data center using linear regression and the M5Palgorithm. They used these predictions in the schedulingof computing tasks, with an objective of reducing thetotal power consumption of the data center. Verbovenet al. (2008) predicted the runtimes of computing tasks,belonging to the same parameter sweep experiment, usingvarious machine learning tools, in order to assign them todesktop grids with suitable availability windows.

Jiang et al. (2016) applied Gaussian process regression todynamic scheduling of continuous casting of steel in orderto predict slack ratios of jobs. A slack ratio describes thetrade-off between the low production time and increasedrisk of a cast-break. Related to the same application, Zhaoet al. (2014) predicted the relationship between adjustable

12th IFAC Symposium on Dynamics and Control ofProcess Systems, including BiosystemsFlorianópolis - SC, Brazil, April 23-26, 2019

Copyright © 2019 IFAC 142

gas users and gas tank levels based on a historical datasetusing Bayesian Networks. The information was used toensure safe operating level of the gas tanks.

Regardless of the used estimation model, and the size andquality of the historical dataset, the estimated schedul-ing parameters contain uncertainty, which is mainly dueto stochasticity of the process, measurement errors andmodel imperfections. The deviations in the realized andestimated scheduling parameters can significantly affectthe optimality, or even the feasibility, of the solution.

The purpose of this paper is to accurately predict the pro-cessing times from a historical dataset using the Gaussianprocess (GP) regression, and to use these predictions injob shop scheduling. We benchmark the prediction methodagainst simple average duration and average rate models(see Section 3) by examining the realized make spans ofa set of 30 scheduling problems. As the scheduling model,we use the unit-specific continuous-time model by Shaikand Floudas (2009).

2. SCHEDULING PROBLEM

We use the New York City (NYC) taxi duration dataset(Kaggle Inc, 2017) 1 , in order to devise a simple schedulingproblem that can facilitate the evaluation of parameterprediction models. The dataset contains information ofover 1.4 million taxi trips in NYC, including the durationof the trip, passenger count, as well as pick-up and drop-offdate, time and coordinates.

We now define a scheduling problem that is based on thedataset but has features that are transferable to industrialjob shop scheduling. Let us consider a company, whichhead quarter is at Wall Street 2 , located at the SouthWest tip of Manhattan. The company performs surveysat remote sites located around NYC. In order to performa survey, an employee of the company travels to the siteby taxi, performs the survey and travels back to the headquarter. We refer to this combination of the outbound taxitrip, the survey and the inbound taxi trip as a task (Fig. 1).When performing a survey, an employee relies on a surveyteam that is based at the head quarter. We consider bothtaxis and survey teams as processing units, and define thenumber of both types of units to be two. The number oftraveling employees is not restricted. In addition, a taxithat drops off an employee to location A is defined tobe instantly available to pick up another employee fromlocation B. The objective of the scheduling optimizationis to minimize the make span ms of performing surveys atsix different sites located in NYC (see Fig. 2 for an exampleset of sites). The durations of outbound and inbound taxitrips are predicted (see Section 3), whereas the durationof conducting a survey is fixed to 1800 s.

From an industrial point of view, the taxis and surveyingteams are equivalent to machinery or processing units,and the procedure of performing a task to a recipe toproduce a product. Alternatively, the inbound and out-bound taxi trips can be considered as preparation and

1 We have amended the dataset with the corresponding fastestroutes (in kilometers) from another openly available dataset (Os-carleo, 2017).2 The coordinates of which are 40.70729◦N, 74.01095◦W.

survey 2

survey 1

taxi 2

taxi 1start

finish

or or

Figure 1. The procedure of performing a task from startto finish. Two parallel units exist for both taxis andsurveying teams.

1

2

3

4

5

6

74.08°W 74.02°W 73.96°W 73.9°W 73.84°W 73.78°W

40.66°N

40.72°N

40.78°N

40.84°N

Figure 2. The example scheduling problem, consisting ofsix survey sites. The grey point indicates the locationof Wall Street. Continuous red and dashed blue linesindicate the start and end points of the outbound andinbound trips, respectively, from the test set.

cleaning, respectively, of a processing unit, and the surveyas performing the actual job in the unit.

In order to extract the most relevant information from thedataset for our purpose, we create a filtered dataset, inwhich either the pick-up or drop-off location lies within500 m from Wall Street (indicated by the red oval in Fig.3(b)). In addition, we filter trips with unrealistically longdurations (>20 000 s). Figure 3(a) shows the histogramof trip durations in the filtered dataset. Further, Figure3(b) presents a scatter plot of trip durations, in which thelocation of a point is the pick-up or drop-off location thatlies further away from Wall Street, and the color of thepoint indicates the duration of the trip.

Further, we divide the filtered dataset into training andtesting sets, using a ratio of 67-33%. The training set isused to train the prediction model, and the test set toevaluate its accuracy (see the next section). In scheduling,the realization of outbound and inbound trip durationscorresponds to the trip in the training set with the closestmatch to Wall Street and the site coordinates. Figure 2shows the pick-up and drop-off coordinates (connected byred and blue lines) of these trips for the example set of sixsites.

3. DURATION PREDICTION

In the next three sections, we describe our models topredict the duration of a taxi trip, starting from the lowestfidelity. Finally, in Section 3.4, we compare the predictionaccuracy of the models.

2019 IFAC DYCOPSFlorianópolis - SC, Brazil, April 23-26, 2019

143

144 Teemu J. Ikonen et al. / IFAC PapersOnLine 52-1 (2019) 142–147

0 1000 2000 3000 4000 5000 6000trip duration [s]

0

1000

2000

3000

4000

occu

rren

ces[

-]

(a) Histogram of trip durations in the filtered dataset.

(b) Trip durations plotted on the map of New York City. Thepoints of the scatter plot are either the pick-up or drop-off locationof the trip, whichever lies further away from Wall Street. Thecluster of points in the South East corner corresponds to JohnF. Kennedy International Airport, and the rectangular area inManhattan without any points to Central Park.

Figure 3. Visualization of the filtered dataset, containingall taxi trips, the start or end point of which lies within500 meters from Wall Street. The region is marked bythe red circle in Subfigure (b).

3.1 Average prediction model

The simplest approach to estimate the duration of a taxitrip is to calculate the average duration in the datasetand assume that all future taxi trips have the sameduration. We refer to the corresponding model as theaverage prediction model. The average taxi duration inthe training set is 1082 s. While the model exploits theground truths of the training set, it naively discards theinformation stored in the features of the training set. Inindustrial job shop scheduling, the values of static tablesare often determined using the average values of relevantjobs in the past.

3.2 Rate prediction model

Considering the current application, a more reasonableprediction model involves determining the average speedof the taxi trips in the training set, and using the streetdistance of the planned trip to predict its duration. We

refer to this prediction model as the rate prediction model.The average taxi speed in the training set is 6.299 m/s.From an industrial point of view, this approach is relevantto estimating the processing time of a job where a givenvolume of a material state is treated (e.g. heated orpurified) 3 .

3.3 Gaussian process prediction model

A Gaussian process (GP) defines a prior distribution in aspace of functions f without parameterizing f . Thus, theyare considered as nonparametric methods. After seeingsome data, the prior distribution over functions is updatedinto a posterior distribution over functions. In this work,we use Gaussian process regression 4 to predict taxi tripdurations. Here, we wish to point out that other nonlinearmachine learning methods, such as neural networks orsupport vector regression, could possibly yield results withsimilar prediction accuracy.

Let us consider a training set D = {xi, yi, i = 1 : N}, inwhich the values of y contain noise in the form of

yi = f(xi) + ε, (1)

where f is the underlying (noise-free) function, and ε ∼N (0, σ2

y) is a normally distributed noise term. Using GPsfor regression, the posterior predictive density is

p(f∗|X∗,X,y) = N (f∗|µ∗,Σ∗), (2)

whereX is the design matrix,X∗ is the test input, µ∗ is themean of multivariate distribution and Σ∗ is the covariancematrix. The latter two are defined as{

µ∗ = KT∗ K

−1y y (3)

Σ∗ = K∗∗ −KT∗ K

−1y K∗, (4)

where, for a chosen kernel κ:

K∗ = κ(X,X∗) (5)

K∗∗ = κ(X∗,X∗) (6)

Ky = κ(X,X) + σ2yIN , (7)

where IN is an identity matrix having dimensions N ×N .For a comprehensive review of GPs, the reader may wishto consult text books by Rasmussen and Williams (2006)and Murphy (2012).

We chose to use the exponential kernel

κ(x, x′) = σ2f exp

(− ||x− x′||

2l2

), (8)

where x and x′ are the two inputs for the kernel, σf is thescaling parameter, and l is the length scale. The reasonis that the kernel enables us to define a priori all taxidurations to be positive.

We include two features from the dataset described inSection 2 in our GP regression model: the latitude andlongitude of the pick-up or drop-off location that liesfurther from the head quarter. Thus, our model predictsthe same taxi durations for trips from location A to B andfrom B to A. In order to enable the relatively memory-intensive training of the model on a laptop, we use arandom subset of 3000 samples from the training set.

3 Assuming that the processing time is linearly dependent on thevolume.4 The GP regression model is implemented using the Python pack-age PyMC3 (Salvatier et al., 2016).

2019 IFAC DYCOPSFlorianópolis - SC, Brazil, April 23-26, 2019

144

Parameters σf , σy and l in Equations 7 and 8 are hy-perparameters θ of the model. We tune them using themaximum a posteriori (MAP) estimate

θMAP = argmaxθ

log p(X|θ)p(θ), (9)

where p(θ) is the prior distribution of the hyperparameters(see for example the text book by Murphy (2012)). Thetuned hyperparameters θMAP are listed in Table 1.

Table 1. Hyperparameters of the GP predic-tion model, estimated using the maximum a

posteriori (MAP) method.

parameter value

σf 1805l 0.8151σy 410.7

3.4 Prediction accuracy

We used the three above described models to predict thedurations of the taxi trips in the test set. In order toquantify the prediction accuracy, we list the root meansquare error (RMSE) and coefficient of determination(r2) of these predictions in Table 2. As expected, thevalues of RMSE decreases and r2 increases with respectto increasing model fidelity. The value of r2 ≈ 0 for theaverage prediction model indicates that the model explainsnone of the variability around the average duration of thetest set. This is also an expected result as the model alwaysreturns the average duration of the trips in the training set.

Table 2. Prediction accuracy, measured usingroot mean square error (RMSE) and coefficientof determination (r2), of the average, rate andGaussian process (GP) prediction models.

prediction model RMSE r2

average 701.8 -2.37e-4rate 556.5 0.371GP 438.4 0.610

Figure 4 visualizes the predicted durations by the GPprediction model against actual durations on the costline drawing of NYC. Predicted durations are shown asa contour plot, and the actual durations of the test setas a scatter plot. In general, the isocurves of the contourare oriented circumferentially around the head quarter.However, the density of the isocurves is the highest inthe longitudinal direction of Manhattan, i.e. roughly NorthEast, while they are the sparsest in the direction East fromthe head quarter.

4. SCHEDULING MODEL

Let us next describe the reasoning for our choice of thescheduling model and how we incorporate the predicteddurations from the three alternative prediction models intothe scheduling optimization.

As the scheduling model, we use the unit-specific conti-nuous-time model by Shaik and Floudas (2009), which isformulated using the state-task network (STN). The modelflexibly facilitates changes in the realized durations, withrespect to those predicted. In contrast, the use of discretetime formulations would expose the realized scheduling

Figure 4. Predicted durations (the contour plot) plottedagainst the actual durations of the test set (scatterpoints). The predictions are obtained by the GPmodel.

models to the risk of being infeasible (in the occurrenceof a job exceeding its allocated time slot).

The scheduling model by Shaik and Floudas (2009) is animproved version of the original model by Ierapetritou andFloudas (1998) – enabling jobs to span over a number ofevent points, ∆n. In this work, we define our model usingequations 1-8, 10-16, 34 and 35 from the paper by Shaikand Floudas (2009), and use the value of ∆n = 1. Wedetermine the total number of event points n iterativelyby starting from n = 3, and increasing it by one until themodel has a feasible solution. We note that shorter makespans could possibly be obtained by increasing the numberof event points, but we have not studied this.

If the durations of inbound and outbound taxi trips wouldbe constant for all tasks, we could formulate the modelby using the following four states only: 1) employee inthe head quarter (survey not performed), 2) employee onsite (survey not performed), 3) employee on site (surveyperformed), and 4) employee in the head quarter (surveyperformed). However, in this work, we wish to assignindividual predictions of inbound and outbound taxi tripdurations to a job. Therefore, we are required to dividethese states into substates, specific to a task in the prob-lem. As we have earlier fixed the number of tasks to besix, the number of states in the problem is 4× 6 = 24.

In the current scheduling problem, we only consider whole-sale jobs, i.e. the amount of material in each job is requiredto equal unity. Therefore, we constrain the initially scalarvariables that determine the amount of material in aspecific job (denoted by symbol b by Shaik and Floudas(2009)) to be equal to the corresponding binary variablesdefining at which event point the job starts and ends(denoted by symbol w by Shaik and Floudas (2009)).

Finally, after solving the scheduling problem with pre-dicted durations, we evaluate the realization of thescheduling solution. This is conducted by updating thedurations of taxi trips with their realized values from thetest set, fixing the binary variables of the model, andsolving the resulting linear programming problem.

The scheduling model is implemented using the Pythonpackage Pyomo (Hart et al., 2011, 2017), and the resulting

2019 IFAC DYCOPSFlorianópolis - SC, Brazil, April 23-26, 2019

145

Teemu J. Ikonen et al. / IFAC PapersOnLine 52-1 (2019) 142–147 145

Parameters σf , σy and l in Equations 7 and 8 are hy-perparameters θ of the model. We tune them using themaximum a posteriori (MAP) estimate

θMAP = argmaxθ

log p(X|θ)p(θ), (9)

where p(θ) is the prior distribution of the hyperparameters(see for example the text book by Murphy (2012)). Thetuned hyperparameters θMAP are listed in Table 1.

Table 1. Hyperparameters of the GP predic-tion model, estimated using the maximum a

posteriori (MAP) method.

parameter value

σf 1805l 0.8151σy 410.7

3.4 Prediction accuracy

We used the three above described models to predict thedurations of the taxi trips in the test set. In order toquantify the prediction accuracy, we list the root meansquare error (RMSE) and coefficient of determination(r2) of these predictions in Table 2. As expected, thevalues of RMSE decreases and r2 increases with respectto increasing model fidelity. The value of r2 ≈ 0 for theaverage prediction model indicates that the model explainsnone of the variability around the average duration of thetest set. This is also an expected result as the model alwaysreturns the average duration of the trips in the training set.

Table 2. Prediction accuracy, measured usingroot mean square error (RMSE) and coefficientof determination (r2), of the average, rate andGaussian process (GP) prediction models.

prediction model RMSE r2

average 701.8 -2.37e-4rate 556.5 0.371GP 438.4 0.610