In the Pipeline Issue 1 2012

-

Upload

mark-anthony -

Category

Documents

-

view

224 -

download

0

description

Transcript of In the Pipeline Issue 1 2012

The fastest emergency hose replacement service there is

In the pipelineQuarter 1 2012

Special Irish supplement

The Right Way Contents

Published by Pirtek (UK) Limited35 Acton Park Estate, The Vale, Acton, London W3 7QETel 020 8749 8444 Fax 020 8749 8333 E-mail [email protected]

This edition is mainly about Pirtek’sIrish centres, though other greatstories have bounced in, on Irishlinks. There is one contributionfrom Ireland’s Celtic cousins inWales, one from a UK centre at thefar end of the Dublin ferry lines innear Liverpool at Ellesmere Port,and others on the Rosslare-Fishguard-London ferry and railroute at Reading and Westbury.Ireland was the first of theEurozone countries to need helpfrom the European Central Bank asthe recession bit. Under verydifficult conditions, the countryhas won praise for meeting itsnational economic targets.

Climb Every Mountain 3Green Machine 4Class of Their Own 5Very Hush Hush 6Black Gold 7Digging In 8Secure in the Knowledge 8Forking Out 9Bin and Gone 9Hands Across the Water 10Life Saver 10Right on Track 11In the Pink 12Tiger Tiger 12Ship Shape 13Tight Ship 14Lifting the Sprits 15It’s a Rollover 16Doing the Can Can 17Walking on Air 18Breathe Easy 19BTCC Preview 20

Through the MillA specialist animal feed companyis bringing the business into the21st Century with a little helpfrom Pirtek Redditch.Midland Feed Services (MFS) wasformed in 1987 from the defunctMill Feed Company when sixemployees took over themanagement of the company. MFSnow provides a mobile animal feedservice throughout the Midlandsand Wales using seven mobile millsand a straw processor.Last year MFS took delivery offirst of two state-of-the-artTropper mobile mixer feed vehicle,to provide more capacity forcustomers requiring largerquantities. The mobile mills can millor roll all cereals, peas and beansand then mix minerals andconcentrates with molasses(carried on board) to make acomplete balanced feed producton site, using the farmers’ ownproduce.The MFS mills can also addground straw to stretch out anyshort supply of silage and increasedry matter intake by breaking downthe lignum in the straw. They cangrind straw through smallerscreens for use as cubicle beddingand for use in automated slurrysystems as a cheaper alternativeto wood shavings. The use ofchopped straw in a clamp alsohelps reduce effluent loss.

Father and son directors, Greg andRobert Brookes sold the companyto Harbro in Scotland but continueto run MFS from premises basedclose to Stratford. "Thetechnology of a mobile milling androlling feed vehicle isn't new, it'sabout 40 years old, but it's amechanical process. The newhydraulically controlled vehiclesput the older vehicles to shame sowe soon thought about conversion.What we have done is introducehydraulics into one of the existing18 tonne Volvo mills andredesigned the mechanical sideincluding altering the augers,”Robert Brookes says. “It wasoriginally done to reducemaintenance work, particularly onthe vehicle allocated to Pembroke,which will be miles from the depot.But the new system has increasedproduction on site by as much as30%, so it looks as if we are at thestart of a conversion process now."Robert reports that this conversionprocess has removed all the wearparts such as the drive belts, cogs,bearings and sprocketsand replaced them withhydraulics, with a little helpfrom the team at PirtekRedditch. “We have beenusing Pirtek Redditch foremergency hose replacements andparts for the past two years and we

trust their hydraulic expertise sowe called them in to design thesystem. We had no drawings togive them, which is probably notthe most professional way ofmodifying such an importantvehicle. But they came down andmeasured up, went away andcustom- made the blocks and thefitted all the pumps, control gearand hoses," he says. "It took a bitlonger than expected because wealtered the workings on a regularbasis to make sure it worked theway we wanted it to. But twoweeks to build a prototype fromscratch wasn't bad and our regularMSST Ian Cockrane reckons thenext conversion could becompleted in just two days.”

So Ireland is compared favourablyby international economiccommentators with Portugal, Italy,Greece and Spain, who have notmet theirs. This process has notbeen comfortable for anyone inIreland. The Pirtek centres haverisen to the challenge and thisedition has encouraging reports ofinnovation and service; fromBelfast in the North, to Dublin,Galway, Cork and Limerick in theRepublic. This is not surprising,really. Every European Pirtekcentre has dedicated, focussedteams who, every day, night andweekend, solve problems whichothers think of as difficult.

These problems are normallylogistical, technical andenvironmental. But teams who areused to confronting difficulties andovercoming them every hour ofevery day will not be stopped bydifficulties which are externallyimposed, even economic ones.The stories here are excellentexamples of Pirtek helping itscustomers by excellent service,outstanding quality and a creativeapproach to problem solving. It is THE way to fight a recession.

Best regards

Kelvin Roberts, Chairman, Pirtek Europe

In the pipeline 3

The term 'wonderful but completely bonkers' was a description onceapplied to Morgan cars. And the majority of these 'eccentric' retro-styled auto masterpieces seem to originate from Reading based RichardThorne Classic Cars (RTCC).Celebrating 30 years as one of the top Morgan dealerships, RTCC alsohave interests in Lancia, Jaguar replica manufacturer Proteus, and theGerman Carver company who build a curious car/bike hybrid that broughtRTCC and Pirtek into contact.Always interested in the unusual, RTCCagreed to look after the Carver concern in the UK. This grew intomaintenance and servicing, which meant that RTCC had to source parts forthe vehicles. "For sheer convenience we decided to locally source thegearbox DVT hydraulic pipes that control the body tilting mechanism,"explains sales manager Helen Thorpe. "We approached Pirtek Readingand were delighted to find they could not only supply the hoses but thequality was better than the OEM product. At that point we started toseriously look at other hosecomponents, particularly on theMorgans. The Aero has steel braidhoses which Pirtek have also beenable to duplicate, and a lot quickerthan Morgan can."

Mix of Old & New According to Helen, few peoplerealise just how popular the Morgan range actually is. “Morgan’s annualproduction is now over 1,000 a year, and the introduction of a new three-wheel edition has taken the auto world by complete surprise. Based on theclassic 30s Moggie design, there are over 700 advance orders for the newversion, and that's before it's even been demonstrated,” she says.“Morgans may look retro but they are registered as a new design and notonly comply with the latest Euro NCAP crash requirements but they arefitted with state of the art technology disguised under that retro body.But they are cars to be nurtured and cared for. We have excellentworkshops with the latest diagnostic equipment, and it's good to knowthat whilst we look after the routine maintenance, we canquickly sort out any fuel or hydraulic hoserequirements with Pirtek, who provide afast and efficient service."

Old School

Quarter 1 2012

Sales manager Helen Thorpe and ReadingCentre manager, Martin Cogdell

The Carver car /motorbike hybrid that makes theMorgans look positively sane

Climb EveryMountain

Government austerity measures have left many local authorities seekingnew ways to provide an outstanding service whilst maintaining tightbudget controls.Neath and Port Talbot Council's workshop manager, Danny Prosser is oneof the people at the sharp end of council operations. Very much thelogistics expert and problem solver, Prosser manages a crew of 13 fitters,who maintain 480+ vehicles from the two workshops in Neath andTregelles.Split across five depots, vehicles range from recycling trucks, refuselorries, cranes, gully cleaners and sweepers on one hand to tarmachotboxes, gritting lorries, jetters and tractors on the other. "We also cover a very large geographical area, up to Swansea, the Breconmountains and all the valleys. So the last thing I need is to find that arefuse truck, miles away from the depot, has split a hydraulic hose and isspilling oil down the road,” he asserts. “As a consequence, we keep a veryclose eye on all the vehicles and carry out a constant preventivemaintenance programme. However with so many vehicles in constant use,there is always the danger of an unforeseen part failure, so it's reassuringto have Pirtek working for us in the background."Pirtek Swansea has served Neath council in excess of ten years andretains the business through a variety of reasons, as Prosser explains,"Pirtek have plenty of competition, so it would be easy for the council tochange to a new supplier if Pirtek didn't provide the right service at theright price. However, they have strategically placed two of their mobileworkshops near to our workshops so that callout times are easily withinthe 1 hour ETA promise period. Their service is exemplary, and their ratesare competitive so we get a reallygood deal for the ratepayers,” heconcludes. “They also provide anout-of-hours service, which is vitalif we are operating a 24/7 servicewith something like the wintergritting service.”

Left Snow plough being readied in September!Above Mike & Jason avoiding a brush off

Pirtek Swindon is playing a key role in supporting the development of aprocess capable of producing a carbon neutral and sustainable fuelsource.It sounds like every environmentalist’s dream: A state-of-the-art plant,manufacturing a carbon neutral fuel from natural sustainable sources, witha waste ash content of less than 0.7 percent. Too good to be true?Absolutely not, but the manufacturing process has required a little helpfrom Pirtek Swindon.

Bio Mass EffectAlthough there was an existing and growing bio mass market in the UK, thegovernment's announcement on the Renewable Heat Incentive (RHI) inMarch was welcomed by Verdo Renewables as a step in the right directionfor green energy. Already better in price than oil and coal and comparableto gas, the RHI policy will make bio mass products considerably bettervalue for industry, schools and hospitals. And it is hoped that the RHI willbe extended to the general public in the near future.Verdo Renewables - part of the Danish Verdo Holdings Group which hasmanufactured bio mass products in Europe for 25 years - expanded itsoperations into Scotland with a plant in Grangemouth. And in April 2010, asecond plant was opened in Andover. Both plants manufacture 55,000 tonnes of wood pellets and 15,000tonnes of briquettes each year from locally-sourced virgin timber withinthe UK, mainly Kent, the New Forest and Frome in Somerset.The system has been of great interest to the energy companies, with ninebio mass projects being instigated this year alone. This will rise to 20 in2012 and to more than 500 over the next few years.

The company manufactures three products: Grade 1, 6 mm premiumpellets that conform to the latest European Standard EN Plus (CertificateUK001) used in commercial premises; domestic briquettes suitable forburning in multi-fuel stoves, log burners and open fireplaces; and, as a bi-product of the process, quality wood pellets for horse bedding.Seen as a clean, green alternative to other fuels, the briquettes aremanufactured from virgin timber that is debarked on site with the aid of aJCB JS200W armed with an orange peel grab. Once inside the plant, thewood is chipped, dried and compressed into the various products. "They are much more efficient to burn than traditional timber because thewater content has been greatly reduced," explains plant manager PeterPollard. "They have a calorific value of 4,800 KWhr/tonne, because themoisture content has been reduced to less than 10%. The end product isalso very clean to handle with less than one percent dust and fines,because the products have also been compressed. The heat output of asingle pallet of briquettes is the equivalent of 10m³of seasoned logs. Andbecause they are made from virgin not recycled material, the end productproduces no toxic gases.”

Aggravating ProblemsEven though the governmental and legislative stars aligned in thecompany’s favour, the Andover plant has not been without its challenges,according to Peter. "Although the plant has been in full swing since Aprillast year, we have had a number of aggravating production problems thatPirtek Swindon has helped us overcome. We have used them for all theusual hydraulic maintenance work, they have even built us a drum pumptrolley, and they have started to repair damaged rams. To cap it all, they

have just rebuilt the control panel for the hopper ram switch gear.” Petercontinues. "The hoppers feeding the manufacturing line use two powerfulrams. Unfortunately they are a bit too powerful for the rest of the fixturesand fittings. "To rectify this, Pirtek lowered the system pressure andchanged the control logic to put the rams on alternating strokes. Thisreduces the shock onto the welded parts and has greatly reduced the strainon the rest of the system. They have rewelded, resealed and refitted eightrams to date. The hydraulic hoses have been respecified and are now of ahigher specification than the OEM product. The original hydraulic controlvalves were not up to the job either due to being over pressurised, and at£700 a time to replace, they were expensive. A redesigned hydraulic systemand the new control panels have resolved this situation. I have used Pirtekbefore at other companies, and they were the obvious choice for anyhydraulic maintenance work at this plant. But they have proved to beexcellent problem solvers as well. We are very pleased with their work.There is a great future for this business and we need to be geared up for it.With Pirtek we can guarantee we will be working at maximum efficiency."

(L-R) The control room at Andover, briquettes ready for dispatch The rebuilt control panel for the hopper rams, and a thank you from Verdo Plant Manager Peter Pollard to MSST Matt Home

Green Machine

www.pirtek-europe.com

In the pipeline 5

Quarter 1 2012

Above, the award winning Bullnosed Scania

(L-R) Sons Barry, Garth , Clive,Howard,, & founder Roy with PirtekNewport MSST Kyle Water

You know when you when you have found a company that takes a realpride in its business when even their work vehicles consistently win the'best of' in the All Wales Truck & Transport Show.Originally established in 1968 as Thomas Plant Hire, the company, nowbased in Brynmawr, Blaenau Gwent, has evolved into Thomas WasteManagement Limited (TWM). During the past 10 years, the company hasdiversified into skip hire, crushing, aggregates, recycling and asbestosdisposal.Far from his sole trader days, founder Royden (Roy) Thomas now has hisfour sons to help oversee the 40 employees, 27 Scania trucks, and amyriad of recycling, crushing and screening equipment operated by thecompany today. These are in addition to literally thousands of skips that

Class of Their Ownrange in size from 4 to 40 m3, and of course, the treasured and prize-winning, bull-nosed Scania that is used to pull the 40 m3 ro-ro artic trailers."We take a pride in what we do and the service we provide," says directorBarry Thomas. "That’s why we have survived when all of our smallercompetitors have been swallowed up, or gone to the wall. We take a verypersonal approach to our customers and provide the service that theywant. We are also the only licensed asbestos transporter in the area.That's very important as there are no longer any sites in Wales that willdeal with it.”

Recycling RatesTWM prides itself on its environmental credentials. “We recycle in excessof 80 percent of the commercial and domestic waste brought on to thesite. That figure would be higher but we don't have incinerator facilities inthis part of Wales, so unfortunately the rest goes to landfill,” Thomascontinues. “However, we do process odd products such as tyres and willrecycle all wood, which goes to Swansea for fibreboard, metal which istaken to Port Talbot, construction and demolition waste, which is crushedand used as a 30 mm sub base material, green waste, which is turned intocompost, plastics, paper, stone, cardboard and glass."In order to maintain the fleet of equipment required to keep pace withthese waste throughputs, TWM operates an extensive maintenanceprogramme of its own. "We have our own fitters and run a six-weekpreventive maintenance programme, but you can't foresee everycontingency, so it's vital to have provision for the unexpected as well asmaintaining the scheduled work. Pirtek Newport does that. We have alocal MSST - Kyle Water - who will often call in to make sure everything isrunning OK. Our engineers have a very good rapport with him and we knowhe will provide a good service that's on time, especially as they will need hisservices at least a couple of times a week.”Barry Thomas says that TWM is loyal to its suppliers but expects them toshare his own company’s work ethic. “It's always good to find anothercompany that demonstrates the same amount of customer care as us,” heconcludes. “We have used Pirtek Newport for close on 15 years now forone simple reason: they do what we need done, and they do it without fuss,at the right price, and when they say they will."

Up for GrabsUnloading 20, seventyfive tonne rail wagons,each carrying 8,000tonnes of rail ballast,in two hours is adaunting enough task.When it has to be doneby just two operatorsusing two excavators,the need to keep bothmachines operationalis paramount. Railfreight, operatingout of sidings inWestbury use twoCase 9046 excavatorsarmed with Verachert2500 litre grabs to dothe work. Recentlyone of the grabs was

refurbished and refitted. In the process it was decided that thehydraulic hoses operating the grab rams should be replaced as well. Pirtek Westbury stepped into the breach and manufactured the fourreplacement hoses and MSST Daniel Spencer was despatched tocarry out the installation. "Unfortunately, when the hoses were fittedand the grab tested just about everything leaked, except my hoses. Iended up retightening just about everything on the grab before testingit again, and it still leaked,” Spencer says. “I took all the fittings apart,identified a few worn washers, which I replaced and again the grab wasreassembled and tested, producing just one small leak. It turned outto be paint ingress on the pipe thread. It was almost impossible to see,but once cleaned and reassembled, the grab worked perfectly."And not a moment too soon. With another ballast train en route fromLeicester, it was vital that the excavator was returned to service which,thankfully, it was. "We do a lot of hydraulic work on the rail side at Westbury because ofour proximity to the sidings. We offer a fast and efficient servicebecause time is very much of the essence there. Even though that wasa somewhat longer maintenance job than scheduled, we were on sitefor less than an hour and ensured the grab was fully operationalbefore leaving,” Daniel Spencer concludes. “And theoperators were relieved that they had twomachines to work with again."

Quietly tucked away in a newly redeveloped part of Liverpool docks is themodest home of Marine Specialised Technology (MST). But inside beatsthe heart of one of the forerunners of commercial and military RIBs andhigh-speed workboats.With a long history in naval architecture, the three directors of MSTrealised in 2001 that they had more than enough pooled experience andknowledge to form their own manufacturing facility when a Europeanagent approached them with a marine contract to complete. MSTeffectively project managed the work and admit they traded on theirreputation for the next three years whilst they established their own brandname. It wasn't until 2005 that the company had designs of its own tomarket.

Discarding the RulebookThrowing away the rulebook, MST designed a series of vessels based ontheir own templates but with parts commonality playing a major role in thedesigns. The company set out to maximise the interchangability of thefittings, which would dramatically reduce the need for a huge range ofspares and parts, and facilitate easy customisation without compromisingthe basic design.

It also allowed for "all the clever bits' as sales director Philip Hibbertmodestly described them, to be combined in single units. It was a conceptthat was instantly adopted by navies around the world and in 2009 MSTlanded the biggest RIB contract outside of North America. The Royal Dutch Navy has a current order for 48, 12 metre vessels inproduction. These boats carry two crew and 10 fully equipped embarkedpersonnel. The order was won on the adaptability of the boats and theparts commonality of the design. MST has also become the preferredsupplier for a Dutch company specialising in high-speed stern ramplaunched RIBs for frigates. One of MST's specialities is their military RIB, especially its Subskimmer550 special operations submersible diver delivery craft. An adaptableRIB that can be used as a surface vehicle, semi submerged for stealthapproach or submersed by deflating the collars.

Specialist as StandardObviously in a saltwater environment and with such customisedequipment, specialised fixtures, fittings and hoses would be required asstandard. Sourcing a suitable supplier wasn't that difficult a task for MSTas one of the directors had previously used Pirtek with Jungheinrich. PirtekLiverpool was subsequently contacted in 2008 with a list of requirementsfor highly specialised power steering and fuel hoses. "Pirtek now supplies all the power steering hydraulic lines which have to beto ISO standards as well as MCA specification for military use. Fromdelivery of the hull, MST will have the vessel in the water in three weeks, sowe have to be efficient. It’s no good having a half a million pound vesseldelayed for the sake of a £6 part. And that’s where Pirtek win,” Hibbertasserts. “They will come out when we want, fully equipped and supply allthe odd bits we need. Their ability to arrive on site with a mobile workshopmakes a lot of our work viable, as they can make the hose assemblies onsite and on demand. That saves a lot of investment in stock and capitalexpenditure for the company."

Above left, Phillip Hibbert with one of the SBS Subskimmer RIBs, above, in normal naval dutyrig and just to prove you can submerge the boat for stealth operations. Below one of the highspeed patrol boats in action with the Kystvakt (Norwegian Coast Guard).

All VeryHush-Hush

www.pirtek-europe.com

In the pipeline 7

Quarter 1 2012

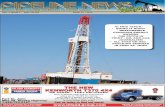

Black Gold“They have helped a great deal with hoses for our tanker bay and areworking on a spare set to be kept in the stores to save time when they getdamaged or worn. Pirtek Waterford has a good rapport with our serviceengineers and I know we are in good hands to keep the export of ourfamous product right on track."

The Guinness site at Waterford is a wonderful mix of the old andtraditional with the ultra modern and efficient. However behind thebeautiful facade lies a far darker secret - they don't make Guinness here!Guinness has seen many changes since it first started brewing in 1759, butnone more interesting than how they brew at Waterford. The Waterfordsite has had a brewery since 1792 and was purchased by Guinness in1955. In recent years the plant has been totally modernised as part of a€34 million refurbishment programme, and the end product changed tosuit the export market. The Waterford site makes a Guinness concentratethat is shipped to 50 countries (mostly in Africa, Australia, and America) ingiant containers where it is used as the basis of overseas beers. Apartfrom the giant plastic containers, the company also has inflatable vesselsinside standard sea containers that can be filled directly and shipped as astandard container. The site is so automated that the 30 employees on site use just two oftheir number to control the brewing process from a high-tech control roomthat produces sufficient concentrate to brew 550 million pints every year."This is one of the most modern plants of its type with all of the traditionalbrewing methods geared to make a unique product. Everything is forexport, which obviously helps the country's balance of payments in thesestrange economic times," says site manager Paul McCusper. "Obviouslythere is a huge demand for the product and Guinness has found aprofitable niche in the overseas market. But to make sure we keep up thegood work on exports the plant must run very efficiently. After eachbrewing process the system is cleaned and flushed with water and causticacid, which sounds drastic but it makes sure there is no contaminationfrom a previous session. This requires a huge amount of piping and Pirtekhas a natural role to play on site. We have used them for over 10 yearsbecause they provide the sort of innovative response we need.”Although Pirtek Waterford’s remit began as an emergency hosereplacement provider, the relationship has evolved and grown, as Paulexplains. “They do all the usual repairs and maintenance work, on time andin budget, which I would expect. But because of their specialist knowledgethey have become part of our approved suppliers list. As a result, we aremore than happy to listen to their ideas. “

Waterford MSST Larry McGrathoutside the Guinness Waterfordbrewery which is a juxtapositionof the new and the old, even ifthey do paint a mural on the side.

Above one of the many Pirtek stainless steel hoses in the brewery

Larry with Paul McCusper with some of the palleted concentrate awaiting dispatch

Inside the sea container, an inflatable plastic container that can be filled direct

All-Plant based in Clonard, County Meath has diversified its plant hirefleet to meet the changing needs of local customers and to buck theregion’s construction recession trend. Partners Martin Barry and Dermot Ennis started their professionalcareers 16 years ago as electricians. It was when they were rewiring afarmhouse that they realised the excavator operator was makingconsiderably more than they were, by just digging the ducting trenches. "Looking back it seems incredible that we just hopped on a plane, flew toEngland and bought a Case excavator to enable us to do the same thing,”recalls Dermot Ennis. “That was the start of our plant hire fleet. This was

also just as mini excavators came onto the market. We recognised thepossibilities and bought into the concept. We've never looked back."Martin Barry says that the company also offered a unique service thatfound favour among their local rivals. "We've always maintained our ownequipment fleet and we started to offer a repairs and a spares service toother companies. This kept their overheads down, but provided a lot ofwork for us,” he explains. “This is where we first came across Pirtek. Theyprovided specialist services, which in turn kept our overheads down. And,as the local construction industry has retracted in the past few years, wehave invested in a new workshop to cope with the additional maintenancework. As a result we can find work for all our machines as well as offeringlight engineering, welding, repairs, fabrication work and haulage."“ We have also diversified into lots of other industry sectors includingUtility work, pipe laying, remedial building work, demolition, railways,green recycling, drainage trenches, canal restoration, water pipeinstallation, farming, housing, ground stabilisation, National Trust sites,generator installation and industrial site buildings. Not bad for an industrythat has supposedly died," says Dermot Ennis with a wry smile. "As thebuilding developers have disappeared, we have also used the machinery onagricultural and environmental projects. As people have returned to theland, we have the equipment already in place to make farming pay foritself. "Despite the diversification and continued success, both Dermot andMartin are constantly aware of the current economic climate facing theirfellow countrymen "These are not the easiest of times. We've done dealsmerely to help keep companies afloat, and we've looked at our pricingstructures to give even better value for money. If we can do that for ourcustomers, then we expect our suppliers to play the same game, andPirtek does. But they don’t do so to the detriment of efficiency,” DermotEnnis concludes. "They are punctual, have the right equipment to repairwhatever customers have done to our machines, anywhere in Ireland. Wehave used every Pirtek depot in the region now, and they are all good.Logistically they are far better than any of their competitors. We've usedthem for ram repairs, hydraulic and diesel hoses. Pirtek is very much ourpreferred one-stop-shop for hose replacements now.”

Digging In

Secure in the Knowledge...After successful rollouts in the UK and the Irish Republic, PirtekBelfast is pioneering the use of the Cesar Datatag system to reduceplant and equipment theft in Northern Ireland. During 2010, it is estimated that more than £4 million worth of farmequipment was stolen from Ulster alone. Little wonder that the CesarDatatag system from Pirtek Belfast has started to find favour amongthe farming and construction equipment communities alike.“It’s time for the rural community to fight back against the thieves,” saysUlster Farming Union deputy president Harry Sinclair. “We are offeringdiscounts on security products to help our members improve theirfarm theft prevention”. "The installation consists of two highly visible tamper proof markersthat are intended to act as a deterrent. One of these hides atransponder, but even if these are removed, there is another hiddentransponder as well as millions of microdots hidden all over the vehicle.Even if a tractor, excavator or quadbike were dismantled to componentparts, we could still identify the original vehicle. Police haveinstructions to scan any suspect vehicle they come across and thehidden transponder will soon reveal the true identity of the vehicle,”says Pirtek Belfast’s Cathy Doyle. “Couple that with Datatag's 100%prosecution record and you are looking at affordable protection."

www.pirtek-europe.com

Dermot Ennis & Martin Barry with one of thelow ground pressure Morooka tipper trucks

UFU deputy president Harry Sinclairwith Pirtek Belfast’s Cathy Doyle,demonstrating the Cesar kit, with tamperproof ID labels, transponders andmicrodots

In the pipeline 9

Forking Out

Co. Galway based lift truckspecialist Reddilift has placedcustomer care at the heart of itsbusiness; and it’s a philosophy thathas paid handsome dividends inturbulent economic times.Founded in 2004, the family-run business operates from a fully equipped370 m2 custom-built workshop deep in the Galway countryside. Reddilifthas built a client base of large national companies as well as a plethora ofsmall local companies. The majority of the machines it supplies are Toyotaand Yale together with more specialised narrow aisle and warehousemachines. The company’s forklifts range in size from 1-10 tonnes, with agood cross section of gas, electric and diesel vehicles.According to managing director Mike Reddington, the company has had tomove with the economic times. " Customers are more inclined to hire thanbuy so we have made sure there are enough forks available in the fleet toremain flexible enough to cope with customer needs. Where customershave struggled with payments, we have bought the trucks back and hiredthem out on terms the customer can cope with. If we didn't help andprovide a flexible response, we could have put some customers under a lotof financial strain. This way we all benefit and the customer has one lessworry,” he says. “We also provide a lot of fuel options on the trucks simplybecause LPG is expensive and hard to find in rural areas.”Mike applies the same “keep the customer satisfied credo to his repair andmaintenance operation. "Even the best forks go wrong or get damagedfrom time to time. We provide a replacement truck if it's something thatcan't be fixed on the spot. But it often makes more sense to call out Pirtek

when we have a hydraulic problem.They can often get to a customerbefore we can, and it's generallycheaper to use their MSSTs ratherthan taking one of our own fitters offother vital work,” Mike Reddingtonconcludes. “We know times could bebetter out there, but I'm sure thingswill bounce back. It's in the Irishnature to work hard on one hand andhelp out on the other. I'm pleased tosay Pirtek enable us to do just that."

Quarter 1 2012

Bin and GoneIreland has a proud tradition of entrepreneurship. And nowhere isthis more evident than in the business of refuse collection. With recycling in Ireland in private rather than corporate hands, refusecollections are run by highly individual and competitive localcompanies, with customers benefitting by frequent, low-costcollections due to the fierce competition. Many of the companiesinvolved are small local enterprises with limited resources, so if a keycomponent fails, it puts a real strain on the service offered.One such company is Tom Cassidy Bin Collections in Limerick, a familybusiness with brothers Tom and Jimmy running a collection service inthe Limerick and Shannon district. They operate two refusecollection vehicles and run a very effective but lean and mean service,which has proved very popular in the area.Returning from a regular preventive maintenance call-out, PirtekLimerick licensee Michael Fogerty received an urgent phone call tosay there was an anxious customer waiting outside the LimerickCentre. The vehicle in distress turned out to be a Seddon refuse truckdriven by Jimmy Cassidy. Halfway through a collection round, the ramhydraulic hose had blown, preventing the collections beingcompressed and effectively ending his round.Jimmy Cassidy says he was far more worried about letting hiscustomers down than the damage to the truck. "We provide a fast,reliable service to our customers and they don't like to be let down," heconcludes. "Refuse trucks are notorious for hose failures, even whenwe keep a close eye on the fixtures and carry out regular scheduledmaintenance work to make sure they work to maximumefficiency. But we are lucky to have the likes ofPirtek on our doorstep when things don'tgo to plan."

Galway MSST Dave Murray, founder MikeReddington and the engineering crew

A happy Jimmy Cassidy, because he is just about to get his Seddon refuse truck back.What you can’t see, is franchisee Michael Fogerty underneath completing the repair!

With a little help from Pirtek Cork , ferriesMV Carrigaloe and sister ship Glenbrookprovides the city with a vital cross-harbourferry service at Cobh. Built in Newport, Wales in 1970, the 240 ton,45 metre long, Class 5 open car ferries havebeen operating the Irish route for the past 18 years, after years in theScottish highlands. These two vessels make the cross river journey up to180 times per day, in a 16-hour period, carrying up to 3000 vehicles. Both ferries have now undergone major refits with Marine TransportServices Ltd at Cobh that has seen the installation of new 223 kW VolvoPenta marine diesel engines and all the associated hydraulic, fuel andcooling lines. Glenbrook is currently being used whilst Carrigaloeundergoes a regular monthly maintenance work, under the watch ofmaintenance fitter Billy Frahill. "Pirtek Cork has done a lot of work on the two ferries. They havereinstated the diesel returns, fuel and pressure lines. In the wheelhousesthey have fitted the oil pressure lines, and provided new gauges as well asnumerous hydraulic hoses. They have recently refitted the barrier hosesas well. We now have the boats on a two-weeks-on, two-weeks-offschedule, which allows us to keep the regular maintenance work in hand.We do a lot of preventative maintenance work at the Cobh dock where thebiggest problem is salt water corrosion which will affect everything,including the hoses, so there is always something to repair or replace,” Billyexplains. “We use the Pirtek Cork counter service a lot but we also have

regular visits fromtheir MSSTs withparts. Pirtek Corkhave provided us witha superb 24 hour a day,seven days a weekservice for the past 12years, all backed withexcellent productquality. They are veryfast to respond andalways on hand 24/7 ifwe have anemergency.”

Hands Acrossthe Water

www.pirtek-europe.com

A chance encounter with a surveyor from the Royal National LifeboatInstitute (RNLI) was to change the fortunes of a local boat builder basedat Waterford Harbour. "Carrolls Botyard was started by my father in 1968, and it was verysuccessful until the EU fisheries fishing quota policy came into force in the1980s," says managing director John Carroll. "Boat building stoppedalmost overnight. Since then, marine work has taken a real battering in thearea. Obviously we had a skilled workforce that we didn't want to lose, sowe switched to boat repairs and conversions, and even turned our hand tobar design at one point to keep the company afloat."But all that was set to change. Carrolls was lucky to be visited by asurveyor from the RNLI who had heard about their work. "I'm pleased tosay he liked what he saw and we started to get small jobs from the RNLI in1995 and our first full refit in 1996,” John recalls. “They tried us out onboarding boats then we were offered the chance to work on a steel-hulledTyne-class lifeboat. We came up to the expected level of workmanship andwere consequently offered two more Tyne boats. "However the real break came 18 months later when the first Trent lifeboatcame into the yard for a complete refit. "These were a completelydifferent concept for us but we did three complete refits in the first year.We have now refitted 40 Trent lifeboats to date and by making changes atthe yard, we hope to become even more productive in the new year," Johnsays. "Because the RNLI is a charity, we have to be very competitive andkeep things as tight as possible. We endeavour to give real value formoney, but always work to a standard that can't be questioned."Carrolls Boatyard applies the same cost-effective quality demands uponits own suppliers, including Pirtek Waterford. "We have used PirtekWaterford for the past eight years because they give such good serviceand their response time is second to none. They make a very good productbacked by complete traceability. All hoses are tagged, so we can quicklyidentify everything for reordering," John Carroll concludes. "It's a greatsystem and allows us to certificate everything for the RNLI, a key part oftheir supplier criterion.”

LifeSaver

Director Pat Carroll, brother of MD John , puttingthe finishing touches to the latest Trent lifeboat

Waterford MSST Larry McGrath waitingfor the ferry to Carrolls boatyard

The RNLI is an independentcharity and depends entirely onpublic support.If you would like to know more, please visitwww.rnli.org.uk/how_to_support_us

In the pipeline 11

Quarter 1 2012

Right on Track

For the past 55 years, Unilokomotive Limited has been building specialistroad/rail wagons that are probably the most efficient, versatile and cost-effective machines on the market.The company manufactures the Unilok Road/Rail Wagon Mover orShunting Locomotive used for moving railway wagons, carriages orlocomotives. Unlike many of the vehicles manufactured by competitors,these are not truck or excavator conversions, but purpose built rail yardworkhorses that travel as easily on road as on rail. The company has aninteresting history, having been purchased by Toyota, sold again in the 80s

and finally resold as part of a management buy out in 2001. Thecompany is one of only two in the world that manufacture a trueroad/rail shunter as a fully-flanged rail unit. Today, there are more than 2,000 Uniloks at work in over 60 countries,from port terminals in the Russian Arctic, through cement plants in theMalaysian tropics, to train and carriage repair facilities in the UK. Although there are a further seven Unilocks on order for the New Year,general manager Ulick Egan says the company needs to diversify andlook at other niche markets in the present economic conditions. "All ofthe rail products are for export and we can't rely on rail products alone,"he says. "We have a huge amount of manufacturing experience andfabrication capability available on site. We also have our own designteam, we do our own electronics and don't sub anything out. So it made alot of sense to look at the home market this time."

Mother of InventionAccording to Ulick, one of the fast growing sectors of the Irish market isrecycling, with a lot of companies coming into the market place in recentyears. “We looked at this market and realised immediately there was aproblem with the standard method of refuse collection, that ofseparating dry recyclable material and wet landfill material. At present,you need two vehicles or two collections, when one vehicle could do bothjobs,” he continues. "So we designed one. At the moment we areconverting a standard refuse truck so that it will have two separatecompartments, each with its own sealed container, rams and hydraulics.This will be used as a test vehicle before we fabricate a new custom-builttruck. We are currently installing the 170 bar ram control gear into thisvehicle. We believe the concept will be extremely popular and arealready looking at the UK market where a similar problem of separatecollection exists."At the heart of this “necessity is the mother of invention” innovation liesa close working relationship with PirtekGalway. "We have used Pirtekfor years to fabricate all the weird and wonderful hoses we need. One ofour shunters has 102 hoses on the hydrostatic drive unit alone. We haveour shunters all over the UK with customers as diverse as Rio Tinto andAlstrom, and rely on Pirtek to come out for repairs at any time of the dayor night - and they do. We've even called upon them in the US. Theirreliability is 100%,” Ulick Egan concludes. “When our refuse truck takesoff, I'm sure PirtekGalway will be at the forefront of supplies."

Top of the PopsThe recent MTV awards in Belfast wouldn't have gone with such a bangwithout some last minute help from Pirtek Belfast. Having spent 10 years lobbying to bring the prestigious awards to thecity, the show arrived only to hit an unexpected production problemduring the set up. Despite arriving with an truckload of equipment, Devizes-basedQuantum Special Effects – which produces all the stage special effects -found it needed additional connectors to make anything work."We had an air gap in the system that needed extra connectors, this wasonly discovered at 9.30pm on the Friday night before the show on theSaturday! But we needed have worried," says special effects andpyrotechnics designer and supervisor, Sean Barnett. "We regularly usePirtek in England and realised we could use their emergency call outservice in Belfast sort this out.”That call took Pirtek Belfast by surprise. "I certainly didn't expect tohave a callout on a Friday night concerning MTV," recalls Pirtek Belfastlicensee, David Adams. "After explaining the problem, I arrived armedwith the right parts and the show went ahead as planned. We connected

up the trademark flame thrower bars, made sure everything workedbefore heading home. The biggest problem was concentrating ongetting the job done while ignoring all the celebrities milling about. But it was very satisfying to hear Gary Lightbody of Snow Patrolstand on stage the next night and say how MTV had throwna spotlight on the city, and know we had played a small part in that."

Unilokomotive general managerUlick Egan with the prototype dualfeed refuse truck

You can't miss a Metro Translink bus in Belfast, well not since theychanged the traditional red and cream livery to a startling Barbie pinkand white. However it does have its downside because the buses are evenmore noticeable if they don't turn up.After spending 32 years with the company, Belfast's Short Strand depotengineer Colin Bennett knows pretty much everything there is to know

In thePink

www.pirtek-europe.com

about keeping his fleet of 125 buses on the road. The diverse fleet rangesin age from three to 15 years with an average age of eight years. ShortStrand runs the largest depot fleet in Ulster - half of the Translink fleet -with 70 more based at the Falls depot, 25 at Great Victoria and theremainder at Newton Abbey.The majority of the fleet are Volvo B10BLE single-deckers with B7 and thenewer B9 double deckers, although there is also a number of Wright orAlexander bodied Scanias running alongside. "At £150,000 a bus youcan't expect to replace too many vehicles in this economic climate. So wehave to ensure that the current fleet operates to its maximum efficiency.We do all the bus maintenance in-house, with scheduled monthlyinspections, and daily visual checks that soon pick up any likely faults. Butwe’re still likely to have two or three in for testing, the same number in forscheduled maintenance and several in for mechanical failures or repairs atany given time. That doesn't leave me with much of a contingency ifsomething fails unexpectedly."Colin reports that buses are notoriously tough on hydraulic hoses used tooperate the steering, compressor, gearbox or brakes. “To keep a full rangeof hoses in stock for all these eventualities would be prohibitivelyexpensive. So we use Pirtek for that service. It not only makes goodeconomic sense - they can provide a hydraulic hose far cheaper than Volvo- but also logistical sense. They can do it within the hour."Having helped to conquer many of Metro Translink’s ongoing repair issues,Pirtek has now taken an even more proactive approach. "Pirtek’sengineers have worked with our workshop to help cure persistent faults.We have an ongoing programme to replace inflexible steel pipes that areprone to breakage, with flexible hoses that move with the bus. Where wehave common parts that need regular replacement, Pirtek have madespare complete sets of hoses we can keep in stock and avoid a call out.That does them out of business but it suits us,” Colin Bennett concludes."We have used Pirtek for 10 years, simply because they fulfil theirpromises. They come on time, armed with all the right parts, hoses andfittings. They make the hoses on the spot, and if we need anything reallyspecial they will go back to their workshop and return within half an hour.The bus is back in service really quickly and we get no complaints from thepassengers - how good is that?"

The company prides itself on being able to transport just about anyvehicle anywhere, whether it's the last of the Beetles from Mexico toIreland, or a high value export to Switzerland. Green Tiger alsospecialises in moving construction equipment between the UK andIreland.The company’s trucks are not just green in colour. They are alsoequipped with engine "Hush Kits" to ensure minimal noise levels andwhere available, they run on Pure Plant Oil, with all used maintenanceoils recovered for recycling. "Anti spray" equipment is used throughoutthe fleet to allow for better visibility for other road users. The Green Tiger fleet has some of the most up-to-date cartransportation equipment available in Europe. But as Jerry Kiersey, manager at the Dublin HQexplained, that does not preclude them fromproblems. "We quickly learnt of the many thingsthat can go wrong on a transporter, a large majorityof them seeming to be hydraulic leaks," he says."We discovered Pirtek Dublin when we entered thetransporter business in 1999 and since then theyhave always been there whenever we’ve neededthem. As we have expanded into the UK, so has ourrelationship with Pirtek. Our call outs are generallyoutside normal working hours and are often in poorweather, but the Pirtek lads never demure, they justget on with the job quietly and efficiently.”

Tiger, Tiger

Green Tiger is a vehicle logistics company specialising in themovement, storage and preparation of new, pre-owned and end-of-lease vehicles for the trade, between Ireland and the rest of the world.

Short Strand depot engineer ColinBennett with Belfast MSST Alan Craig and

the pink fleet

One of the car transporter fleet that needs the occassion tweak from Pirtek Dublin

Jerry Kiersey

In the pipeline 13

Quarter 1 2012

Ship Shape

The Shannon Foynes Port Company is Ireland’s second largest portoperator, with statutory jurisdiction over all marine activities on a 500km2area of the Shannon Estuary.

The company provides a variety of services, from controlling navigationand marine safety, to warehousing, logistics and cargo handling, andprocess the largest vessels entering Irish waters, up to 200,000 dwt. Todeal with vessels of this nature, there are some impressive cranes at workat the docks, all of which require the attention of Pirtek Limerick licenseeMichael Fogerty and his team. "It's a very busy port that competes with Cork for business. Everythingdepends on the mobile cranes, a 32 tonne LHM100 Liebherr, purchased in2001 supplemented by two 64 tonne HMK 170 Gottwalds purchased in2008. To give you an idea of scale, the grab on the Gottwald is 18 m3," saysFoynes Terminal Operations Supervisor John Hayes. "We import oil, coal,and even offshore wind turbines, which are a growing business in Ireland.Last year we had 10 ships in port each carrying six complete turbines, andwe've had a further six this year. With such a large volume of trafficcoming through the port, we can't afford to have the cranes out of action,so we carry out an extensive preventative maintenance programme whichis where Pirtek comes in.”

According to Joh, the port places veryspecific demands upon both equipmentand suppliers. Salt water is highlycorrosive and can play havoc withcomponents, particularly thehydraulics. With one of the cranesdating back to 1986, obtaining sparesis a constant challenge and, onoccasions, lead times have beenridiculous. “We were compelled to lookat alternative sourcing and Pirtek cameup trumps. They come out within thehour and make up the hose on the spot,including a 2" drop flanged pipe,considerably cheaper than the OEM Imight add. We can't keep spares ofeverything the cranes need, so we holda stock of regular wear parts and Pirtekmakes the rest as required," John Hayesconcludes. “When those parts arebeing fitted, the MSST keeps a closelookout for other parts displaying signsof wear. Thanks to that, ourbreakdowns have gone down tovirtually nothing. The service fromPirtek Limerick is simply priceless.”

Operations manager John Hayes with Limerickfrnchisee Michael Fogerty and one of theGottwald cranes in his care

The eponymous Michael O'Brien has been modifying the furniturecompany his father started in 1975, since he took control in the 80s. "Isoon realised that the furniture side wasn't making any money but thekitchen side did. So we switched to just making custom made doors forkitchen companies and became real specialists in this field. The timingwas spot on as there weren't many competitors then. "The products proved extremely popular and the company moved to itscurrent location in Vicarstown, Co.Cork where the 1,100 m2 of workshopfacilities were four times larger than their previous offices in Blackpool,allowing it to produce 700 doors a week. Although the company makeseverything on site, production was limited by the existing machinery where12 separate operations were required to make one door. To increaseproduction, a new machine was required, and subsequently a new SCMrouting machine was purchased. "It was a massive investment and only oneof two similar machines in Ireland. We can programme all of the processesin one go and cut down 12 separate actions to just four. It is so muchquicker,” Michael says.

But the greasing hoses on the SCM failed and trying to find replacementson a near unique machine proved fruitless. After a phone call made toPirtek Cork, Michael O’Brien was amazed to find a Pirtek MSST waiting forhim in the workshop inside the hour. "When the engineer said he would beable to replace the hose within 24 hours, I simply didn't believe him, but hetook it away, and as good as his word he returned with the replacementwhich has worked perfectly ever since," he recalls. “Although the SCM is a wonderful machine, there are parts that need to beredesigned and Pirtek Cork came to the rescue again. They are nowworking on an automatic lubrication system rather than the awkwardmanual system."And Pirtek involvement doesn’t end with a single machine. "They arelooking at the workshop airline at the moment and there is a heavy dutyairline from the main building to the paint shop that was leaking. I wantedit replaced, but Pirtek Cork insisted that it simply needed rerouting, thedamaged part cutting out and rejoined,” he recalls. “What could have beena profitable little job for them, proved to be a real money saver for me.”

Right, Because of long lead times, Micheal O’ Brien Ltd hold over 200 tonnes of

virgin timber on site. Below, the state of the art SCM router now

working perfectly after a little help from PirtekCork.

Below right, Michael and Pirtek Cork MSSTSean O’Shea with some of the 19 basic designs

in a cohice of 9 different woods that can bemanufactured on site

OpenDoorPolicy

www.pirtek-europe.com

Michael O’Brien Ltd’s purchase ofnew equipment to increaseproduction while retaining qualityran into some teething problemsbefore the timely intervention ofPirtek Cork.

The Willingnessof YouthContrary to headlines in the Daily Mail, not all teenagers are hoodie-wearing, pensioner-baiting, work-shy louts, as two new recruits to thePirtek Liverpool team illustrate.Engineering isn't the most glamorous profession in the world, so it ishardly surprising that it's not the career path of choice for many oftoday's teenagers, who'd prefer to sit in front of a computer, in a nicewarm office. Bu then Tom Comer and Jordan Middleton aren’t regularcomfort-first teenagers.The pair, both 17, have joined Pirtek Liverpool on an apprenticeshipscheme. They have already been inducted into the workings of theCentre and have hands on experience in the parts department. Theyhave accompanied the more experienced MSSTs in the mobileworkshops to obtain first hand experience of the types of equipmentthey will be expected to service and repair. And they have both beenenrolled on day release on mechanical engineering courses in localcolleges to gain a City and Guilds certification.When asked why they had chosen Pirtek as a career, they both agreedthat their current education had taken them as far as it could, and theyboth preferred to start work and gain practical skills. Work placementby the school had also helped sway their decisions.

Baggage-FreePirtek Liverpool realised that finding qualified hydraulic engineers isbecoming harder if not impossible and decided to use the apprenticeroute so that the engineers could be taught from fresh, rather thanretraining an engineer with set ideas and bad habit baggage. Pirtek Liverpool took on both lads because they said they had stood outhead and shoulders from the rest of the candidates. They realised thiswas the start of a two year investment for the Centre, before eachapprentice would be allowed out with their own vans. However judgingby the start they had made, it could be money well spent.Both Tom and Jordan have seen the promotion opportunities offered byPirtek and it won't be a surprise to see either or both of them managingor even owning a franchise in the future; they are certainly keen enough.

Jordan Middleton and Tom Comer

In the pipeline 15

Quarter 1 2012

Lifting the Spirits

MD Frank Smith, Left (l-r) EmmaPalmer, ColletteHope, RachaelHancock, BelowStuart Pritchard,service manager

Customers experience a moment of serendipity when they come acrossAvonmouth-based forklift experts, Solution MHE, as they operate in aquite unique fashion.Operating across the UK, Solution MHE sell, service, maintain and hire gas,electric and diesel forklifts and pallet trucks - nothing exceptional aboutthat. But it is the company’s operations side that makes it stand out from the crowd."We know we are experts in the field, and we provide lots of specialistequipment such as narrow isle trucks. We can hire, lease or sell equipmentover just about any time. Where we come up trumps is taking the time totalk to customers to find out what they actually need,” says managingdirector Frank Smith. "This has lead to some interesting conversationswith finance departments who must think I've gone mad when I decline tosell them a piece of equipment. Because we only deal with the bestequipment, we can often supply a better, cheaper and more efficientworking solution, even if that means supplying one good machine when Icould have sold two mediocre replacements.”

Tracking SystemAnother key differentiator at MHE is its ability to track its equipment, itsengineers and any spare parts that might be required. "We operate a netreporting system that enables the company and customers to trackengineers and spares. All our vans are tracked so we can stop siteduplication and even redirect an engineer for urgent work,” Smith explains.“When you have customers like Cadburys, Betterware, DHL and Honda,you have to be efficient, as well as fast.”It is a policy that clearly works, and one that has earned MHE a loyal bandof blue chip customers. "It is a delight when a customer tells me that theywould never dream of using another forklift company," he says proudly."That is the ultimate proof that they trust us and the way we work. Andthat's really the same reason we use Pirtek Bristol. They supply a reallygood service, they are fast, their admin is spot on, and they do what wewant, when we want it. For such a long-standing supplier we've never had acustomer complaint and consequentially we are very pleased to continuetrading with Pirtek. I'm pleased to say Pirtek do as good a job as we do."

The name CRH Plant will be familiar to anyone with even the mosttenuous connections to the UK construction industry, where it is knownas a market leader in the compaction equipment field. But it takes a lotto keep the company’s fleet rolling.CRH Plant offers a vast range of plant equipment from a 427 kgpedestrian roller to 19 tonne padfoot compactors. The range ofcompaction equipment in between is staggering, as are the number ofspecialist applications they can be used for.The company proudly boasts that its rental fleet is one of the most up-to-date currently available in the UK today, and having established areputation for buying state-of-the-art equipment and ensuring it is alwaysreliable, it is down to the service department to continually maintain andservice that machinery."With eight national depots servicing the UK, and with machineryconstantly on the move between customers, it's almost impossible toaccurately say how many pieces of equipment are based at any one depot,”says works foreman Mike Eaton. “In fact, it's a good job that we achievesuch good utilisation levels. We would never fit it all in this yard if it cameoff hire.”Eaton runs the busy Ashton-in-Makerfield workshop on the outskirts ofWigan, and has the challenging job of keeping the fleet in good runningorder. "Only today we've had a Bomag BW24RH roller returned to us froma six-month contract on the Isle of Man," he says. "This is a specialistroller for the production of ultra smooth tarmac surfaces. It’s popularbecause it is very adaptable and can be ballasted with sand, water or steelweights taking it from a standard 10 tonnes to 24 tonnes to suit thematerial to be rolled. It was new when it went out but, in keeping with ourdetermination to ensure our customers receive only the very best, we willnow put it through a major servicing programme to get it ready for the nexthire."

Unforeseen RepairsThis policy, combined with the numerous unforeseen repairs andmaintenance duties makes caring for the CRH fleet a full time job. "Withmyself and 5 fitters, we carry out extensive preventative maintenanceprogrammes and regular servicing to make sure everything worksperfectly, but we do have to cope with a lot of repairs on top. So it's veryhelpful to have Pirtek Wigan working alongside the company. They do allour hydraulic work,” Eaton says. “Pirtek Wigan started with us here atAshton in 2007 and are regular visitors, but CRH use Pirtek on a nationalbasis. They have direct links for parts with our suppliers Wirtgen andVolvo, which saves a lot of paperwork for the workshops as they will workdirectly with the OEMs, especially on warranty issues."According to Eaton, caring for CRH Plant’s huge compaction equipmentfleet requires considerable teamwork. "Pirtek are very much part of ourmaintenance programme. They turn up on time and come equipped tosort out the problem or repair, regardless of where a particular machinehappens to be working,” Mike Eaton concludes. “We have absolutely nocomplaints about their work. We're very pleased with everything they do."

Right, Works foreman Mike Eaton at the CRH North West depot, Wigan, with Pirtek WiganMSST Tom BarrowAbove the ultra smooth tarmac roller freshly arrived from the Isle of Man works departmentthat morning. Below, some of the huge array of CRH kit.

It's a Rollover!

www.pirtek-europe.com

In the pipeline 17

Quarter 1 2012

Doing the Can Can

A unique machine used to suck molten aluminium from a furnacepresented an unusual challenge for the team at Pirtek Warrington.Travel around the Warrington area and it won't be long before you comeacross a flat bed trailer loaded with aluminium ingots, all bearing thestatement 'made from 1.5 million aluminium drink cans.' Those statisticsprovide an idea of the scale of work undertaken at the Novelis recyclingworks at Latchford. Novelis is the leading producer of rolled aluminiumproducts in Europe and South America, the number two producer in bothNorth America and Asia, and the global leader in aluminium beverage canrecycling, processing approximately 40 billion cans each year—enough tocircle the globe more than 100 times. This recycled aluminium is primarilyutilised in its own rolling facilities to produce new can sheet but is alsoincorporated in the latest Jaguar and Land Rover models. Recyclingaluminium obviously means melting it. That happens at 660 deg C, somachinery working on the factory floor has to be well protected againstthe hostile environment. The Hyster forklifts used on site, for example,have their hydraulic hoses protected by steel sheathing as the standardhoses melt under sustained use in the factory. Each forklift uses two 4.5and 3.5 metre hoses that have been systematically protected by PirtekWarrington.

Glama PussThere are other specialist vehicles in use on the floor. There are three JCB426 wheel loaders equipped with what looks like a huge metal proboscisused to push material into, and to rake waste out of, the furnaces. But theweirdest vehicle at Latchford must be the Glama crucible transporter.This bizarre vehicle sucks molten aluminium out of the furnaces andtransports it in crucibles across the factory floor and into the castingareas. A truly unique vehicle, the Glama mobile forging manipulator is theonly unit of its kind in Europe, and as such, all the fixtures and fittings areequally odd. Pirtek Warrington has replaced and resealed a ram on the

Glama, and replaced numerous hydraulic hoses, as MSST Jamie Harrisverified. "The Glama is the key piece of kit on the site. If it doesn't work,then the whole plant goes quiet. To ensure this doesn't happen, we arelooking at keeping a complete set of hoses on site to reduce anyunscheduled downtime. But the majority of the work here is for Barloworldwhich operates the site’s forklifts." Barloworld has two on-site engineers -Rob Murray and Mark Fillingham - and their overseer Carl Black who hadthis to say about Pirtek, "We use them because of the excellent service. Ifwe call them out, they'll be here in the hour. Their mobile workshops carrya lot of stock, so that any visit will usually cure the problem. They have agood pricing policy, which certainly helps in this economic climate. Butwhere they really score is on out of hours’ service, which we use a lot,” heconcludes. “They have even been known to send a van from Stoke to makesure we get the service on time."Left, armoured steel clad hosesfor the Barloworld forkliftsRight, the nightmare of hoses on the Glama crucible lifter

Pirtek Warrington MSST Jamie Harris, the Glama and thecrucible usually full of molton aluminium

Above, one of the giant ingots of recycledaluminium. Middle, another specialist vehicle,complete with rake for furnace clearing. Bottom, some of the millions of cans waiting to beturned into new cans or even cars

The trouble with being the expert in one particular industry field is thatcustomers often forget all the other services Pirtek can offer. Althoughrenowned for its emergency hose replacement service, Pirtek is also aleader in pneumatics, ram repairs, and – even more surprisingly - airconditioning.This is demonstrated by Pirtek Reading which operates a mobile airconditioning unit under the control of centre manager, Martin Cogdell. Thededicated service vehicle is fully equipped with gas tanks, a sniffer/tester,test system, vacuum and siphon pumps and a tiny crimping rig for work onthe aluminium pipes. Cogdell typically reconditions 400 vehicles a year,along with a plethora of excavators and most of the black cabs inBerkshire. And he is half way through a prototype replacement glycol airconditioning programme on 60 trains based at Reading. Most recently,Cogdell has combined his background in marine engineering with his airconditioning expertise to help vehicle restorers and repairers, SpecialisedPaintwork, undertake some interesting projects.

Car CollectionBased in Calcot to the south west of Reading, the company's premiseshold an array of some of the most beautiful and iconic vehicles in variousstates of restoration, including an MGA currently undergoing £15,000worth of restoration. There are several Lotus Elises, Porsches, Morgansand a wonderfully sinister black Mustang parked outside. But the yard isdominated by a restored 1960s S1 Jaguar E type now reported to beworth an eye-watering £92,000. It is a car that is only driven for threeweeks a year when its Australian owner returns to Britain.Specialised Paintwork was formed in 1983 by father and son team Alanand Karl Rigarlesford, after they worked with Mike Spence Racing andLotus cars. The company became Lotus Authorised Repairers and now

deal with a multitude of post production issues as Karl Rigarlesfordexplains. "Lotus are a production facility and are not geared up forpaintwork issues or repairs, so we have taken that work on for them.However there are some issues, such as the air conditioning on the Elise,where we happily pass the problem over to Pirtek Reading,” he says. “Theair conditioning pipes pass through a sealed foam filled sill, through 90degrees and into the engine compartment. Because of the bend, you can'tpull the pipe through the foam, leaving you with the option of cutting outthe sill at a cost of £1,500. Martin Cogdell devised a method of cuttingaway part of the foam through the rear wheel arch with an air saw and thenreplacing the pipework. That was seven years ago, since then we've hadthe faith in Pirtek to use them on a multitude of projects. They now supplyeverything from Esprit cooler hoses to the jet wash reels in our workshop."

Problem SolverAccording to Rigarlesford, this single innovation typifies Pirtek Reading’s“can-do” approach. “Martin Cogdell is one of those engineers who delightin solving a problem, and we've never found a problem he couldn't fix. Hetypifies Pirtek's working practises, he puts himself out, puts in lots ofeffort and nothing is too much trouble." Karl Rigarlesford concludes."When we can spend 800 hours restoring a car, we want the best results,best products and right skills to do the job properly. We are approvedsuppliers for Rolls Royce, Ferrari and Aston Martin, which is as good as itgets. We wouldn't dream of using anyone that would jeopardise that.That’s why we use Pirtek"

Walking on Air

www.pirtek-europe.com

Alan and Karl Rigarlesford with Pirtek Readingcentre manager Martin Cogdell between. Below the regassing unit in the back of the van.Below left, Martin and the mini crimper, thefabulous E Type being drooled over and a smallarray of some of the classic cars being restored

In the pipeline 19

Quarter 1 2012

Hyperbaric oxygen therapy (HBOT) thankfully isn't something that mostpeople come across on a regular basis. However, for those that do, it's areal life-saver.When Pirtek Ellesmere Port provided the original flex pipe fixtures andsteel fittings in 2006 for the eight person decompression/recompressionchamber at the heart of the Hyperbaric Medicine (North Westrecompression unit) situated next to Murrayfield Hospital in the Wirral,little did they know that five years later they would still be providing hosesfor fire engines for the same company.Although hyperbaric treatment is used to treat decompression in divers(28 of them needed treatment last year) it actually has a myriad of otherbeneficial uses on the emergency front, particularly when treating carbonmonoxide poisoning or smoke inhalation. Using HBOT, patients are able tobreathe pure oxygen, instead of the 20 percent normally found in theatmosphere. This increases the oxygen transport capacity of the blood. "We have very seasonal use for the chamber," says facilities manager JohnMills. "In the summer it tends to be divers, in the winter it’s gas poisoning,usually when people turn on the unserviced gas central heating boiler. Butwe get gas poisoning all year, including a case where someone kept a gasfridge in a tent thinking it was safe."Mills reports that Hyperbaric Medicine has also diversified. "We nowoffer a huge range of medical training courses, all provided at the UK’sbest-equipped facility. These are divided into Military pre-hospitaltrauma life support, Clinical Governance, Trauma Management foremergency services and medical personnel, Pre-hospital Management forthe trapped and injured and Advanced Life Support courses, all approvedby the Royal College of Surgeons. We also run IMCA approved diver medictechnician courses and Diver Medicine courses. We have training groupsfrom all over the country and even abroad, including the RAF, police, fireservices, commercial divers, doctors and nurses and paramedics. Theparamedics from the John Moore University in Liverpool are also trainedhere. So it is vital everything works and kept in pristine condition, henceour involvement with Pirtek Ellesmere Port."If Hyperbaric Medicine has diversified, then so too has Pirtek EllesmerePort. “Pirtek did all the initial chamber installation work, so they were theobvious choice for auxiliary hydraulic parts,” John Mills concludes. “Theyhave since supplied all sorts of hydraulic hoses including instantaneousassemblies for the fire engines, hydraulic fittings for a Komatsu excavatorand hoses for a pressure washer.

Breathe Easily

'Big' Paul Johnson, centre managerat Pirtek Ellesmere Port, minus foronce the pink tutu that he is famedfor wearing at charity events John Mills, Facilities manager

The decompression chamber an below right part of the rescue and training training facilities

Jack

Mor

ton

In the pipeline

By any measure the 2011 MSA British Touring Car Championship seasonwas a memorable one for Pirtek Racing and its lead driver Andrew Jordan.

The bare statistics from the season are impressive. In overall BTCC terms,Andrew scored a race win, six more overall podiums and took 15 morepoints’ scoring finishes from 30 races to make it 22 times in the points. Hewas third in the final Independents’ Trophy with four wins and anotherseven Independent podiums. Meanwhile, Andrew’s team mate Jeff Smithhad a very impressive first season in the BTCC in the team’s other VauxhallVectra with seven top ten finishes including a best of fifth overall atDonington Park.But the numbers are only part of the story. The 2011 season was the yearwhen Andrew really established himself as one of the star names in theBTCC. His excellent media profile grew even stronger and he won thehearts of many race fans with his determined performances and fabulouscar control. With huge race day crowds and massive live TV audiences, the BTCCcontinued to ride high at the top of British motor sport and that providedsuperb exposure for the teams and their commercial partners as the BTCCcircus toured the country. The 2011 season was something of a transition year for the BTCC as the

series organisers juggled to equalise three different car specificationswhile encouraging the development of the Next Generation Touring Cars(NGTC). With the performance of the various types of car being regularly adjusted,the Pirtek Racing Vauxhall Vectras went into some race weekends at adisadvantage, but there were still some absolute highlight events for theteam.At Donington Park in April Andrew had sensational pace and bagged a winand two seconds to make it the best weekend of his BTCC career to date.That front-running pace continued through the events at Thruxton, OultonPark and Croft, but after the summer break the Vectra was up against it atSnetterton, Knockhill and Rockingham. The team came back strongly atBrands Hatch in early October when Andrew delivered a mighty qualifyingperformance to put the car second on the 29-car grid. But a computerfault, completely out of the team’s control, struck before the first race andhe was unable to take the start.But those highs and lows are all part of the challenge of competing at thehighest level and plans for 2012 are already well advanced. The newseason promises to be an even more successful season for Pirtek Racingwhen its to field a pair of new NGTC Honda Civics for Andrew and Jeff inthe BTCC. Team principal Mike Jordan confirmed that the squad has ordered twocars from Team Dynamics ahead of the coming season. “This is the start ofa new two-year partnership with Pirtek and that has given us theconfidence and stability to make a major investment,” said Jordan senior. Andrew can’t wait to start running the latest Honda Civic. “I’m very excited,”he said. “We’ve straight away put ourselves in the best car on the grid fornext year. I’d like to think we’ll be consistently near the front in 2012 andconsistency is something I want to concentrate on.”

BTCC season review

Q1 Product

PromotionPirtek branded

Water Displacement Spray l Displaces Water

l Multipurposel Penetrates

l Cleans500ml – List price £3.75

With the British Touring Car Championshipconcluded, In the Pipeline is offering one luckyreader a chance to own a Pirtek RacingHoodie and an Andrew Jordan Baseballcap. To be in with a chance, just answer the following question:According to the Pirtek UK website, when did Pirtek enter the UK market?Please email your answer [email protected]. The winner will bedrawn from the correct entries on27.02.2012. Good luck.And congratulations to Simon Parker from Normenca Limited,in Cheshire, who correctly answered the competition in theprevious edition of In the Pipeline and joined Pirtek Racingfor the final race of the season at Silverstone.

20

www.pirtek-europe.com

Competition