In The Groove AD Article

-

Upload

will-bacon -

Category

Documents

-

view

71 -

download

1

Transcript of In The Groove AD Article

How can a manufacturer prioritize the manage ment

of A, B & C-class items to save money?

Inventory classification is typically based on cost

from delivery programs that shift focus from C-class

items that represent a low value spend in terms of

overall inventory purchases but often a high level of

programs create a shift in resources so the focus can

be on more effective management of high value

What are the differences between a transaction-

based supply chain model and a modern advanced

delivery model?

Improved process efficiencies have evolved from

the traditional transaction-based supply chain to the

a win-win situation where inventory and operating

costs can be significantly reduced, cycle times

How can a supplier help component manufacturers

optimize resources through an Advanced Delivery

Program?

Typically resources can be optimized by focusing on:

reducing inventory

lessening time spent in purchasing and order

planning activities

decreasing the amount of operations

lowering the number of times parts are handled

improving part availability

implementing visual signals to ensure the

necessary size and number of parts are available

This kind of focus can help consolidate vendors,

reducing the stress and cost associated with

What approach or model can be used to manage

C-class items?

Advanced delivery programs should be flexible,

programs, such as, forward stocking location, delegated

inspection authority/dock-to-stock, SealScan™, Kanban,

direct line feed, vendor managed inventory, (pull

system bin stocking) and vendor consolidation/C-class

34 35Trelleborg Sealing Solutions

in the groove

in the groove EDITION 29

in the groove

SERVICESSERVICES

Will Bacon, Advanced Delivery Program Manager at Trelleborg

Sealing Solutions answers questions on how specialized

delivery services can enhance customers’ businesses by better

management of inventoried items. By Valerie Harding

TRANSACTION-BASED

SUPPLY CHAIN

OPTIMIZED

SUPPLY CHAIN

Enter into MRP System

MRP output to purchasing

Forecasts and Revised

Forecasts, Sales &

Marketing Crystal Ball

Purchasing places orders

MRP Planner adjustment

Supplier or Manufacturer

Expeditor

Receiving

Warehouse

Packaging and assembly

Customer

Warehouse Ships Parts

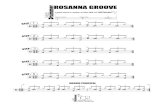

Electronic Kanban sent to Supplier

Parts Received and Demand Fullfilled

Part Usage

Capture Usage

LEVERAGING ADVANCED DELIVERY

Comparison of traditional transaction-based supply chain

model with an optimized supply chain process

As usage increases, the replenishment cycle quickens and as

Do you have actual examples of where costs have been

lowered through the use of an Advanced Delivery Program?

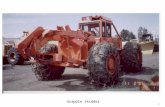

Let’s look at the fictitious ACME Inc that is representative of a

By applying Advanced Delivery principles, we are able to reduce

their inventory levels from three to four months of inventory down

Can advanced delivery systems reduce total annual cost?

Absolutely! As we mentioned, the gains realized in reducing

Another way to look at it is to consider the total cost of

This factors in the costs of acquiring, receiving and storing

Trelleborg Sealing Solutions offers strategic sourcing services

that leverage our centralized purchasing resources to consolidate

using forecasts while also providing value-added handling and

packaging services, including single/bulk bag and tag, kitting,

What should a manufacturer deliver to the supplier to support

the implementation of an Advanced Delivery Program?

A manufacturer should expect a supplier to meet and discuss

contributed should be assessed and a delivery plan customized

customer’s planning system to manage the flow of parts and

of the flow of product into the manufacturing facility and floor will

What are the areas involved in special handling and packaging?

Special handling & packaging incorporates a wide range

of services including custom labeling, barcoding, cluster

packaging, kitting and assembly, direct bag printing and mil

spec packaging as well as surface treatment marking, assembly

inbound product inspection, production part approvals, quality

inspections, process improvement recommendations and

What kind of Kanban system would you recommend?

The two-bin SealScan™ Kanban system is very simple and

information and transmits the information to our logistics

automatically sends a replenishment pack to replace the used

ABC Analysis, or Selective Inventory Control, is a

provides a mechanism for identifying items that will

while also providing a mechanism for identifying

different categories of stock that will require different

The ABC analysis suggests that inventories of an

is grouped into three categories (A, B, and C) in order of

- ITEMS

the high value of these ‘A’ items, frequent value analysis is

- ITEMS are important, but of course less important than

- ITEMS

WHAT IS ABC INVENTORY

MANAGEMENT?

MORE INFORMATION

Interested in finding out more about an Advanced Delivery

Program? Contact your local Trelleborg Sealing Solutions

marketing company to find out more!

A

B

C

WILL BACON, Advanced Delivery

Program Manager at Trelleborg

Sealing Solutions Americas

Sealscan gives significant

benefits in inventory control of

C-Class items

36 37Trelleborg Sealing Solutions

in the groove

in the groove EDITION 29

in the groove

SERVICESSERVICES

http://en.wikipedia.org/wiki/ABC_analysis