In situ permeability testing in boreholes

-

Upload

martin-preene -

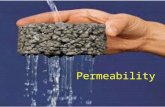

Category

Technology

-

view

7.505 -

download

10

description

Transcript of In situ permeability testing in boreholes

- 1. www.preene.com IN-SITU HYDRAULIC TESTING OF LOW PERMEABILITY MATERIALS Dr Martin Preene, Preene Groundwater Consulting, UK Stephan Rohs, Golder Associates, Germany

2. www.preene.com Definitions and current UK practice Specialist applications Test equipment Test interpretation Conclusion SYNOPSIS 3. www.preene.com PRACTICE PROFILE Preene Groundwater Consulting is the Professional Practice of Dr Martin Preene and provides specialist advice and design services in the fields of dewatering, groundwater engineering and hydrogeology to clients worldwide Dr Martin Preene has more than 25 years experience on projects worldwide in the investigation, design, installation and operation of groundwater control and dewatering systems. He is widely published on dewatering and groundwater control and is the author of the UK industry guidance on dewatering (CIRIA Report C515 Groundwater Control Design and Practice) as well as a dewatering text book (Groundwater Lowering in Construction: A Practical Guide to Dewatering) 4. www.preene.com Hydraulic conductivity is a measure of how easily water can pass through soil or rock. Also known as coefficient of permeability or permeability Symbol k Units of velocity metres/sec, metres/day Very wide range of values in natural soils and rocks,10-2 to 10-11 m/s Hydraulic conductivity depends on the properties of the soil/rock and the properties of water. The viscosity of water varies with temperature, so hydraulic conductivity will vary with temperature DEFINITION OF PERMEABILITY 5. www.preene.com The goal of hydraulic testing is to characterize the hydraulic properties of the system composed of the borehole and geological formation DEFINITION OF HYDRAULIC TESTING Formation properties: Permeability Static formation pressure Flow model Borehole properties: Wellbore storage coefficient Near wellbore properties: Skin 6. www.preene.com Hydraulic properties (including permeability) cannot be measured directly They are derived from the hydraulic reaction (variation of pressure and/or flow) of the system: Pressure (P) in the test interval as function of time P = f1(t) Flow rate (q) of the test interval as function of time q = f2(t) DEFINITION OF HYDRAULIC TESTING 7. www.preene.com DEFINITION OF HYDRAULIC TESTINGFLOWRATE ZEIT CONSTANT PRESSURE TESTS Pressure recovery CONSTANT RATE TESTS SLUG- AND PULSE-TESTS Pressure recovery PRESSURE 8. www.preene.com Current (and historic) UK practice is defined in BS5930:1999 (amended 2010) CURRENT UK GEOTECHNICAL PRACTICE Packer injection tests (sometimes referred to as Lugeon tests) Variable and constant head tests in boreholes, typically analysed by the methods of Hvorslev (1951) Falling head Rising head 9. www.preene.com Analysis methods are based on references from the 1950s and 1960s CURRENT UK GEOTECHNICAL PRACTICE New standards (related to Eurocode 7) have being developed for permeability testing for geotechnical purposes BS EN ISO 22282 Geohydraulic Tests Part 1. General rules Part 2. Water permeability test in borehole without packer Part 3. Water pressure test in rock Part 4. Pumping tests Part 5. Infiltrometer tests Part 6. Closed packer systems The new standards use similar methods of analysis to BS5930 More sophisticated methods of testing and analysis have been developed outside the geotechnical industry 10. www.preene.com The specialist testing and interpretation methods described in this presentation are derived from methods used in reservoir engineering in the oil and gas industries Potential applications related to construction and geotechnics include: Nuclear repository engineering High specification cut-off walls Critical consolidation analyses Unconventional gas (shale gas) development Gas storage caverns Deep geothermal systems APPLICATIONS FOR SPECIALIST TESTING 11. www.preene.com In moderate to high permeability environments constant rate tests and/or slug tests are appropriate In low permeability environments the choice of viable test methods is limited: Very low flow rates involved Large wellbore storage effect Time constraints TEST DESIGN 12. www.preene.com Pulse tests are an appropriate hydraulic test method for very low permeabilities For a pulse test a defined volume of test fluid is injected or extracted from the test interval, which results in a pressure decrease or increase. The subsequent pressure recovery is used in the analysis TEST DESIGN 2250 2500 2750 3000 3250 3500 3750 4000 4250 4500 0 5 10 15 20 25 30 35 40 45 50 Elapsed Time [hrs] Pressure[kPa] 15 16 17 18 19 20 Temperature[C] P2 (Interval) T2 (Interval) PW DEF INF + COM PSR 13. www.preene.com A typical pulse test consists of the following steps: 1. Packer Inflation (INF) and Packer Compliance (COM) 2. Pressure Static Recovery (PSR) 3. Pulse Injection (PI) or Pulse Withdrawal (PW) 4. Packer Deflation (DEF) TEST DESIGN 14. www.preene.com TEST EQUIPMENT Control lines Pressure gauges Shut-in tool Upper Packer Test interval Lower Packer Main parts of the downhole equipment 1. Packer to isolate the section of interest 2. Pressure gauges 3. Shut-in tool (SIT) 15. www.preene.com Volume change of test interval due to: 1. Packer compliance 2. Borehole convergence Temperature change Borehole history effects INFLUENCES ON TEST RESPONSE 16. www.preene.com Traditional geotechnical methods of analysis are based on the analysis of pressure (or head) vs time (e.g. Hvorslev analysis) More sophisticated analyses use the first derivative (the rate of change of fluid pressure with time) as well as pressure vs. time Furthermore, tests are interpretated against the wider geological context and conceptual model Suitable flow regime (porous media, multiple fissures, single fissure) Borehole history Strata type and hydrogeological conceptual model The desired outcome is to test interpretation rather than simply analysing the test data ANALYSIS METHODS 17. www.preene.com Pulse test analysis method is based on a signal processing technique known as deconvolution, which: 1. Increases the ability to identify an appropiate flow model 2. Improves the sensitivity of the analysis with regard to permeability Analysis is normally done by numerical modelling using proprietary software packages Multiple analyses allow better interpretation of test results The numerical analysis allows a full test simulation TEST INTERPRETATION 18. www.preene.com Parameter correlation e.g. influence of different borehole histories on parameters, including formation permeability and static formation pressure Relationship between different parameters (e.g. static formation pressure and permeability) TEST INTERPRETATION 19. www.preene.com More sophisticated methods of permeability testing and analysis have been developed in other industries and may have applications in geotechnical engineering Pulse tests are an appropriate method to measure the hydraulic properties of very low permeable formations The deconvolution method of analysis allows a reliable flow model identification and permeability estimation and, in combination with statistical methods, the reliability of the derived parameters and connected uncertainties can be quantified These methods are likely to be used in any future investigations for nuclear repository engineering CONCLUSION 20. www.preene.com IN-SITU HYDRAULIC TESTING OF LOW PERMEABILITY MATERIALS Dr Martin Preene, Preene Groundwater Consulting, UK Stephan Rohs, Golder Associates, Germany

![Development of a new in situ test method to measure the ......excellent parameter for in situ quality control [3,5,8]. Using the established Autoclam air permeability method, a preliminary](https://static.fdocuments.in/doc/165x107/5f0f8ff47e708231d444c714/development-of-a-new-in-situ-test-method-to-measure-the-excellent-parameter.jpg)