Implementation Of 2000 L Sub And Disposable Clarification System

description

Transcript of Implementation Of 2000 L Sub And Disposable Clarification System

Implementation of 2000L SUB and

Disposable Clarification System in

Existing cGMP Facility

Dave Wolton

CMC Biologics

2011-10-25

Overview

• CMC Biologics

• Why is the 2000L a game changer?

• Integration into Existing Facility

• Defining the Bioreactor Process

• Facility Design Challenges

• Disposable Harvest System

• Lessons Learnt

2

CMC Biologics

Contract Manufacturer of Biological Therapeutics utilizing

MAMMALIAN & MICROBIAL CELL CULTURE TECHNOLOGIES

• Cell-line Development – CHEF1™ technology • Upstream/Downstream – process development and manufacture • Analysis, Characterization, Formulation, Quality and Regulatory

Target

& Lead

ID

Pre-

tox Tox Phase I Phase II Phase III

Commercial

Production

CMC Biologics

Background to why I believe the

2000L is a game changer

• 13 years at contract manufacturer in Slough 2000L

scale

• 6 years producing Enbrel in a 6 x 12,000L plant

• 1 year designing 12 x 1000L SUB plant

• Approximately 1 million Euros spent on basis of design

• Moved to CMC 2 years ago

CONFIDENTIAL 4

– Plant runs for 300 days per year

– Protein A Cycles per batch approx. 4

– Harvest two reactors every 2 days

– Assumed product campaigns are the norm

– Cell culture only work days

= 2 x 12,000L stainless plant

5

Blockbuster ‘in market supply’

potential of the 2000L SUB factory

Output from model

Plants of the future

6

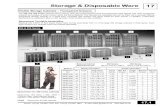

6 x 12,000L stainless

12 x 2,000L Disposable Conventional design

12 x 2,000L Disposable Lean design

Plants of the future

7

Reactor hall 15M x 15M

Copenhagen 2000L SUB

Implementation and proof of

concept

2000L SUB

• 2000L capacity retrofitted to a 100L stainless

steel suite

9

Aim of the project

• Increase US/DS capacity to match launch/commercial

production (MAB): 2000L

• Integrate into existing facility without affecting current

clinical manufacturing

• Minimize limited company recourses

• Project used 1 Engineer and two validation resources

• Meet cGMP requirements – EMEA, FDA

10

2000L SUB in 100L SS facility

11

Microbial 2x 1500L

CCI 2x 750L

CCII 100L

CCIII 300L

Stainless Steel

12

SIP

CIP

HPW

Automatic valves

DCS

70 elastomers

Disposable Bioreactor

• Minimize limited

company recourses

• Low level of

atomization

• Off the shelf

• High flexibility

• Waste – Supported by

existing infra-structure

at CMC Biologics

13

SIP

CIP

HPW

DCS

Waste

Defining the Bioreactor Process

14

Project Plan

15

7 months from start to finish

Right. On time.

Vendor:

• Security of supply

• Market leader in number of units sold

• Back up in both USA and Europe

• We already use their single use mixers,

100L, and 500L SUBs

• Willingness to negotiate a bag supply

agreement

• Track record in supplying disposables

• Conventional design

• Compact storage

• Wide choice of control systems

16

Vendor: EZ controller

• Wheel in wheel out seed reactor concept

• Simple

• Robust

• Large number of units sold

• Fast to set up, train on and validate

• Compact (can be mounted on the SUB)

• Cost effective to have multiple units on

multiple SUB’s

17

Factory Acceptance Testing

18

Installation

19

Installation

20

Reception as

it was

Installation

21

Installation

22

Reception as

it looks now….

Engineering Run - Inoculation

23

XG2Cb

2000L SUB data

24

• The light blue

datapoints

represent the

2000L SUB

• The other data is

from 500L SUB

runs of the same

product

Disposable Harvst System

25

26

Integrated 2000L depth filter system

Lessons Learnt

27

• Decide on controller early – This will impact timelines

and complexity

• Agree who mounts the control system and where it will

be mounted

• Do a cost benefit analysis on the seed strategy

• Take into account fabrication and shipping costs/time

• Be careful in regards vessel orientation and hose

location

28

Summary

• Slide from Johannes R. Roebers, PhD

Thanks to…

• Andreas Mark Arnung, CMC Biologics

• Christian Skjødt, CMC Biologics

• Esben Eggertsen, CMC Biologics

• Gustavo Mahler, CMC Biologics

• Henrik Knudsen, CMC Biologics

• Jakob Ravnsborg, CMC Biologics

• Johannes R. Roebers PhD, Elan

• Mads Laustsen, CMC Biologics

• Martin Oscar Miret Hattel , CMC Biologics

• Martin Kelly, Thermo Scientific

• Ronni Glenn Refstrup Hansen , CMC Biologics

29

CONFIDENTIAL 30

31