Implement A newsletter from C B Norwood Distributors Ltd’s …€¦ · mx_222_bdist_farmec.qxd...

Transcript of Implement A newsletter from C B Norwood Distributors Ltd’s …€¦ · mx_222_bdist_farmec.qxd...

Imple

menta

tion

A ne

wsl

ette

r fro

m C

B N

orw

ood

Dist

ribut

ors

Ltd’

s Eq

uipm

ent D

ivis

ion

Issu

e No

. 15

S

prin

g 20

09

PR

OF

ES

SIO

NA

LS

IN

EV

ER

Y F

IE

LD

With the

compliments of your local

specialist equipment dealer

To find your local dealer

visitwww.equipnz.co.nz

Have we got your postal address and postcode correct?

If not please phone 0800 667-9663

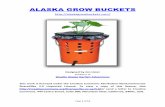

MX Feeding Buckets

Right or left handside feeding...also available with double trap door

www.m-x.co.nz

mx_222_bdist_farmec.qxd 17/10/07 8:37 Page 1

MS

1037

> Full range of heavy duty, reliable MX Feeding Buckets with models and options tailored to individual needs.

> Perfect for precision chopped grass silage, maize, beet and palm kernel etc.

> Suitable for fitting to front loaders, material handlers and tractor linkage mounting.

> Face rotor option for optimum forage conservation.

> Root chopper assembly option.

Phone 0800 667 9663 to find your nearest MX dealer

Standard Equipment:• Automatic “drive in” loader hitching• Pro-Pilot cable control joystick• Electric 3rd Function• MX quick attach implement hitching• High strength sub-frame tractor bracket• Mechanical self levelling on U8// and U10//

Optional equipment:• MACH2 multi-coupler implement to loader• Shock Eliminator• EURO quick attach implement hitching

For more information contact your local MX dealer or visit www.mx.co.nz

MX Feeding BucketsRight or left handside feeding...

also available with double trap door

The all new MX Utility loaders are the ideal solution to meet everyday handling requirements with a practical and cost effective design while retaining a high level of performance, user comfort and versatility.

NEW RELEASE

Utility Loaders

C U S T O M E R P R O F I L E

Tough Fella handles the high country

Neil Sinclair might be relatively new to central North Island contracting but he’s kicked his business off to a good start with the purchase of a range of top-quality Fella machinery. Neil operates N A Sinclair Contracting from his home 7km south of Waiouru, where he is primarily focused on round hay and baleage, as well as helping a few lo-cal contractors out with their agricultural work during spring. Neil has only been contracting for two years and has purchased a number of new pieces of machi-nery, including a Fella TH680 tedder, a Fella SM310 mower-conditioner and a Fella TS670 twin rotor rake. Neil chose the TH680 tedder due to a number of its features, including the fact it can be offset. “It has a telescopic head so it follows the ground well. You don’t smash any tynes and it folds up pretty good,” he says. “I tedder everything and I’ve used it a lot. It’s been awesome. I haven’t had to touch it for maintenance. I haven’t even had one tyne smashed and I’ve done some pretty rough paddocks.” Neil says the Fella SM310 mower-conditioner also does a nice job. The machine features six cutting discs and a 3m

working width. “I did a gearbox when I first had it but C B Norwood replaced that straight away, no questions asked. It’s great for the rough paddocks we do around Taihape and it seems to follow the contours of the ground pretty well,” he

says. “It’s a well-built strong mower compared to some of the others. The subframe is pretty good on it and it’s heavy duty.” Neil also has trouble faulting his Fella TS670 twin rotor rake. “It’s been like the tedder – good con-tour following and it does a nice clean job. It’s easy to adjust the width or the tyne height. I’ve put a drawbar on the end of it so we can tow other gear behind it. I tow it with my ute or hook the baler or wrapper up

behind it. It works well and it saves a lot of running around with vehicles and gear. I’ve put a tow bar on the mower as well.” Neil says the TS670 twin-rotor rake is a simple machine to operate, making a neat job of the grass. “We wanted to be able to provide a professional service to the farmer and have used the best gear available.”

NEW RELEASE

Arable farmers must ensure post-cultivation consolidation is sufficient to press the seedbed to its full depth and break the ‘horizons’ between different sized aggregates that often occur in cultivated soil. That advice comes from Philip Wright, Technical Consultant to Simba and author of the company’s new guide to “Culti-vations and Soil Structure”. He says these ‘horizons’ – along with both unconsolidated and compacted layers – can inhibit water, air and root movement through the soil and inhibit crop performance: This new guide summarises much of the data and technical information Simba has collected during field-testing of new equipment and collaborative research projects completed with a range of partners in the arable farming industry. It builds on the information previously presented in its “Oil-seeds Establishment” and “Cereals Establishment” publica-tions, both of which have been acclaimed by both farmers and agronomists alike: “In natural conditions crumb size tends to get bigger the deeper you go, but sudden changes in size – or the presence of looser, un-consolidated layers – can be a barrier to water movement. They must be disrupted by effective pressing so they do not prevent water moving both up and down through the soil profile. “To do this, farmers need to apply sufficient force to con-solidate the whole seed-bed, combined with sufficient ‘point loading’ on the edge of the press rings to disrupt the ‘horizons’ so they no longer prevent moisture movement.

Simba publishes new guide to soil management

“Single or double presses do this primary job best because they press the seed-bed intermittently. A Cambridge roll or any similar flat surface-acting roller can help consolidate the seed-bed and close up some of the pores that – if left open – reduce effective soil to seed/root contact, but may lack the subtlety required to do a really effective job through to depth”. The guide also highlights the different characteristics of he-avy and light soils and discusses the many factors that interact to affect both types: “You cannot change the soil type on your farm, but how you work it has a huge impact on structure and workability. If you cultivate at the right time and in the right way you can enhance the soil’s structure and workability; do it in the wrong conditions or do it badly and you risk damaging them”, says Philip. As a result, the guide includes a quick practical guide to testing whether any particular soil type is workable: “Farmers must know the lower plastic limit of their soil to determine the optimum time to cultivate, and the guide provides advice on how to do this for a range of different soil types”, says Philip. “This is one of the arable farmer’s permanent dilemmas – choosing the right time between the conditions being too dry and risking creating clods, and being too wet and risking smearing the soil”.

For your free copy of “Cultivations and Soil Structure” send an e-mail giving your full postal address to: [email protected] or phone 0800 667 9663

Bigger Simba and Vaderstad gear keeps contractor humming

C U S T O M E R P R O F I L E

Central Hawkes Bay contractor Rob Foley’s new Simba and Vaderstad machinery is improving the speed of his operation and providing his clients with a more professional finish. Rob’s family has been contracting in the region since the 1940s, when Rob’s grandfather Bill Foley started the family contracting business. Today Rob operates Foley Agrisystems Limited from his home in Takapau. He offers a range of servi-ces: sowing barley, brassica and grass, hay and baleage (round, medium-square and conventional bales), and combine harve-sting of maize, cereals and grass seed. A month ago Rob purchased a 6.0m Simba Horsch Pronto drill to replace the 4.0m Pronto drill he had owned for four years. “It was just time for an upgrade. We were very happy with the 4.0m drill – it went very well and the establishment of crops was good.” However, Rob wanted a larger drill with the option to apply fertiliser while drilling. His new 6.0m Simba Horsch Pronto drill comes with a fertiliser tank as standard. “We’ve used the fertiliser box and it’s very good. At this time of the year we’re doing cereals and we’ve started doing brassicas as well. In the autumn we’ll do grass and winter oats,” Rob says. “The 6.0m Pronto drill is a similar machine to the 4.0m model but it has better disc brakes and a new computer. I like the placement of seed and the evenness of the strikes. It’s very consistent.” Rob is a fan of Simba gear, having owned a set of 4.5m Simba discs for more than two years. “We also had a set be-fore this one for about five years. We’ve been very happy with them. They’ve done what we required them to do with mini-mum costs. They’re robust and we’ve had no structural issues

with them,” he says. “We use them all season. We virtually plough nothing, it’s all discs. We go from lighter soils to heavier soils and it handles them all, as well as roughness. We break in a bit of

country with them and they handle that extremely well too.” Another new piece of machinery for Foley Agrisystems is its Vaderstad NZA800 8.0m cultivator, which Rob bought a month ago. The NZA was designed specifically for New Zealand con-ditions. Rob never had a cultivator of this type before but he does have a 5.0m Vaderstad Carrier, which he still owns. “We changed to the cultivator for the width and the low horsepower required to pull that width. We looked at one-pass machines but they required high horsepower for the width,” Rob says. “We like the new 8.0m cultivator a lot. We thought it might replace the Carrier but we still use the Carrier for turfier grass. The cultivator is doing a good job and it’s covering the ground quickly. “Having the extra three metres makes a difference. It’s doing nine or 10 hectares an hour and in the future we might have to put a roller behind it. It’s got a couple of levelling boards in it too and it’s leaving the paddocks very level. If you have to you can do the paddocks twice. It doesn’t take long.”

Easy, efficient, lightweight –JF-Stoll mixer wagon has it all

C U S T O M E R P R O F I L E

A new JF-Stoll mixer wagon has taken all the guess work out of feeding cows for the Shepherd family of Northland. Mark Shepherd says prior to purchasing the VM18 mixer wagon in May from Dave Boyt Farm Machinery Centre in Northland, feeding their cows the correct balance of food and nutrients was a bit hit-and-miss. Mark farms 400 hectares with his parents, Owen and Gail Shepherd, and other family members, at Matauri Bay an hour and-a-half north of Whangarei. They run 550 dairy cows and dry stock. “This is the first mixer wagon we’ve had. Before we just fed out silage in one lot and then went back and got some maize and hay. It was kind of guess work without having any scales to calculate the feed,” Mark says. “We wanted to have more accurate feeding. We were keen to get a more palatable feed in front of the cows and they seem to clean it up quicker if it’s mixed with something else.” The Shepherd family tried three different mixer wagons before settling on the JF-Stoll VM18, which they believe mixed the feed more effectively. “The JF-Stoll mixer wagon was a lot more user friendly,” Mark says. “You can chuck the bales in whole and it chops them up. It’s mainly myself and my brother who use it but if we nee-ded someone else to use it it’s easy. It’s got a feed programme on it – you push the buttons and it comes up with the dairy milkers’ mix. You tell it how many cows you’re feeding on that day and it calculates it all for you. It’s very easy to operate. “We used to feed palm kernel in between feeds but we lost two or three cows to acidosis because they overdid it. Now we can mix palm kernel with baleage, mai-ze and molasses for the dairy cows. The other good thing

for the dairy milkers is we can mix it in with triple mix – sodium, calcium and magnesium – and we know our cows are getting it.” Mark says the dry cows that have been living in the farm’s three ‘herd homes’ have also been benefiting from the ma-gnesium oxide he has been able to add to their feed with the JF-Stoll mixer wagon. “The other thing we’ve noticed is that when the mixture is fed to the cows and they eat it they seem to digest the maize better. We’re doing just under two milk solids a day, with 200 of our 500 cows milking through the winter. This time last year we were doing 1.5 milk solids.” A significant feature is that the VM18 is considerably lighter than the other wagons the Shepherds tried, making it more efficient to tow. “It has hydraulic brakes as standard – you don’t have to fit them on as an extra. It’s quite handy if you have to cart downhill like we do and the other thing is that it doesn’t seem to take a lot of power to drive it. Our 90hp tractor can handle it,” Mark says. The feed weight and calculations are transmitted to the display inside your tractor by radio transmission, meaning there are no cables to connect, with the Shepherds having a second display inside their loader, so they can receive all the weight details while loading. The VM18 mixer wagon is also easy to hook up and disconnect, with the drive shaft being easy to handle, Mark says.

NEW RELEASE

JF-Stoll recently introduced a wireless weighing system, Feed Manager, as standard on complete diet mixers. With the di-splay placed in the loader tractor, the driver always has the weight information right at hand. Thereby the diet feeder can be loaded from all sides which increases the flexibility and reduces the time consumption and the loss of feed. The weighing system is prepared for upgrade with the new-ly developed ProFeed+ package which is the professional so-lution for registration and comparison of feed data. With the display placed in the loader you can not only load the feeder from all sides but also read the weight during the inloading of feed. Therefore the loading is optimised since you always have an overview of the remaining amount to be taken out. In addition to the display in the loader a mobile display is placed in the tractor driving the diet feeder. The mobi-le display can, as the word indicates, be brought along where the “traditional” display cannot be seen. This is an advantage when loading straits and other minerals from other locations, where the loader tractor is not present. The weighing system can be extended with ProFeed+ which for instance contains load plans and registration of data. The enclosed PC software is the platform for programming of loading and un-loading plans, data processing, including e.g. comparison of load plan and consumption. New adjustments made on the PC are synchronised with the display in the trac-tor - this takes place without the display in the tractor being switched on. The synchronisation takes place wirelessly. User friendliness had a high priority during the develop-ment of the weighing system. The functions of the weighing

New weighing system increases the flexibility during loading of the diet feeder

system can be controlled from the tractor seat. The display in the tractor creates a unique overview of decisive information (weight, load plan, number of cows, name of ingredient and amount planned and actually loaded). With the display placed in the tractor you have the best preconditions for receipt of the information, visually and acoustically. This unique overview reduces loading errors and makes the whole feeding process more efficient. Operation of the displays and the PC programme is so user-friendly that registration of ingredients will be a natural part of feeding. Exact registration is the precondition for optimising the pro-duction and obtaining a better result.

One or more mobile displays make weight information independent of the feeder possible. Can for instance be placed in the tractor, at the silo or be brought along.

The large display is typically placed in the loader. Thereby the person has all the information right at hand and can load the diet feeder from all sides.

Switch to minimum tillage cuts tractor time by two-thirds

C U S T O M E R P R O F I L E

South Canterbury farmer Warren Darling’s Simba Horsch Pron-to drill and Simba Genesis SL500 cultivator have helped him transform his farming practices and make significant financial gains. Warren and his wife Joy own a 280-hectare cropping property at Kingsdown, south of Timaru. They grow a rotation of wheat, barley, beans and seed brassica crops. “We moved into minimum tillage gear three years ago, coming from a conventional cultivation system,” Warren says. “Because of where we’re located – bounding Timaru city with a major road going through the property –we had to look at some other means than burning off our residues. That’s why we moved into dealing with the residues by cultivation methods.” Four years ago Warren took part in a Norwood tour lead by Paul Collins, to Europe and the UK, where they looked at minimum tillage machinery. He saw Simba gear operating and liked the look of the cultivators and Pronto drill. “From there we converted over to minimum tillage and have benefited from the cost savings,” Warren says. He and Joy purchased a 3.0m Simba Horsch Pronto drill initially but have since upgraded it to a 4.0m model. They bought the Simba Genesis SL500 cultivator three years ago from Johnson Gluyas Tractors Ltd in Washdyke. “To spread the capital outlay we operate the two pieces of equipment in separate partnerships. With a neighbour, the drill covers 800 hectares a year and the cultivator covers 1500 hectares a year with another partner.” Warren chose the Genesis SL500 cultivator because the action of the front discs result in faster breakdown of residue with good soil contact. The subsoiling legs incorporated in the machine free the soil up to 200mm deep, resulting in better root penetration for the following crop and it’s all done in one pass.

“Drilling commences three weeks later using the Simba Horsch Pronto drill. We tried other makes of minimum tillage gear but to suit our rotation and soil types, Simba had the best equipment,” Warren says. “The cultivator is simple to operate, it does the job required and it suits our system completely because everything here is straightforward.” Warren says. “It’s a two-pass system and the cost savings we’re getting are definitely showing up in our balance sheet. Also, with the minimum tillage system the earlier sowing is resulting in improved yields.” Warren also likes the 4m Simba Horsch Pronto drill for its easy calibration and accuracy. “It makes a level job, and even in relatively strawy conditions it still makes a good seed bed, giving even germination.” Under his conventional tillage system, Warren was spen-ding 450 hours a year on the tractor, a figure which has been cut back to 140 hours (which he says equates to 30 minutes per hectare) using the minimum tillage method, with a total fuel usage of 17 litres per hectare.

Hunt for reliable equipment leads contractor to Norwood Ag Equipment

C U S T O M E R P R O F I L E

Hauraki Plains contractor Ian Troughton selects machinery that is strong and reliable and he operates a range of top gear from Norwood Farm Machinery Centre in Pukekohe. Ian has been contracting for 25 years and runs ID and SN Troughton Limited from his home at Turua. He offers a full range of services in-cluding cultivation of small seeds through to maize, forage har-vesting, round and square bales, undersowing and transport. He purchased a 6.0m Lemken Zirkon power harrow six years ago and bought a second 3.0m machine three years ago. Both power harrows have been gre-at value to the operation. “They’ve been excellent machines. They are robust and the life we’ve had out of the blades has been exceptional,” Ian says. “The quality of the machines is great and I haven’t had anything else that compares to them – they are so reliable.” The 6.0m Zirkon power harrow has been fitted with a small seed system for planting seeds, which makes it a one-pass machine.” Six years ago Ian also purchased a variable width Lemken plough, which is an auto reset model. Its spring mechanism allows it to operate without any shear bolts. “It’s a good featu-re, in fact all of its features mean it works extremely well,” he says. “You can vary the width you’re ploughing on the move – you don’t have to stop. It means if you’re going down the paddock and it’s getting narrower, you can adjust the width on the move. “Another big advantage of it is that we’re in extremely he-avy clay country here and it’s all hard work. The plough is wor-king in hard conditions all the time and it’s strong and robust under those conditions.”

A significant piece of machinery in Ian’s fleet is his Kinze eight-row maize planter, which he has modified to suit his pur-poses. “We took the planter and added it to a large fertiliser tank and spray system and we’re more than happy with it. The Kinze machine works very well. It’s the first time I’ve had a Kinze and I chose it because of its reliability. It’s simple and reliable. This is its second season” Ian has run Fella mowers for many ye-ars and today operates several, along with four MX loaders, which includes three MX T12 loaders. “They are extremely good. I’m impressed by them and we’ve never had an issue with them,” says Ian. “One of the things I’ve looked for is reliable gear and I’ve run a couple of Fella swathers as well, which have also been really marvel-lous.”

“The loaders do everything from feeding out to stacking our forage grass silage. They are

used for general purpose loading from fertiliser to metal. They do more than they are designed to do and are extremely good and easy to operate.” In addition, Ian has a set of 4.5m-wide Simba discs, which fold up for transport. “They’ve been brilliant. They’ve done a lot of work and they are good. I’ve had them about six years and there’s been just about nothing on them that has needed fixing. Anything that I’ve done to them hasn’t been the discs’ fault, it’s been rocks or so-mething,” he says.

Canterbury farmer says Simba disc-drill combo saves time, money

C U S T O M E R P R O F I L E

The purchase of a new Simba Horsch Pronto DC4 drill and Simba X-Press from Gluyas Motor Group has enabled Mid Can-terbury farmer Leicester Wilson to streamline his agricultural practice and create huge time and cost savings. Leicester and his wife Lidka own a 300-hectare farm at Riverside, east of Ashburton, on which they grow a variety of crops, including ryegrass, clover, small brassica seeds, peas, wheat and barley. They also finish between 3000 and 5000 store lambs. Leicester began trialling a Simba Horsch Pronto DC4 drill back in early 2006, when he was drilling ryecorn for winter feed direct into stubble. “I was reasonably impressed with the stri-ke. We did half the paddock with the direct drill and the other half my conventional way of burning the stubble, followed by quick cultivation and drill,” he says. “Then we moved on and planted some wheat in au-tumn 2006 with the trial drill. We had a paddock that was ex-peas. We went straight into it with the drill in the April, and in one pass we drilled out. The next exercise was a pass with the X-Press and then the drill. The rest of the paddock we did our conventional way of plough and cultivation and then drilled the rest with the Pronto.” The trial indicated to Leicester the time saving he could experience using the X-Press and the Simba Horsch system. “When we added it up the time and fuel saving was amazing, although we did feel we needed the cultivation before the drill. It’s not a one-pass system. We can do it in one or two passes with the X-Press.” The Wilsons pur-chased their own

Pronto DC4 drill soon after, followed by the Simba X-Press. “We’ve now almost moth-balled the plough. We’ve only used it twice since we’ve had the X-Press and the drill, mainly in very trashy conditions. But we’ve done work since then with some more trashy paddocks and it’s been fine just to use the X-Press and the drill. It involves more passes but still a hell of a lot more cost effective than ploughing and doing full cultivation.” For spring cultivation Leicester is now doing three passes with the X-Press, with Cambridge rollers towed behind, follo-wed by a couple of maxi-tills to get a fine seed bed and then the Pronto DC4. Autumn seeding involves one or two passes with the X-Press and then the drill. “It means a lot of time and cost savings. The drill system has discs in front of the seeders, with compaction of the press wheels that go behind the discs resulting in a firm seed bed. The small packer wheels behind the seeder ensure the seed depth is even. We’re very pleased with the results we’re getting – anything from 2kg of Chinese kale seed up to 350kg of peas. It’s the same machine – we just change the seed system. It’s simple to do, the calibration is good and the compact seeding system seems to be very accurate. We also find we’re able to use the drill in wetter situations than the other systems we’ve used,” Leicester says. “The X-Press is very robust and it looks as if it’s going to last very well. We would be doing 500-600 hectares a year with the X-Press and 300-400 hectares with the Pronto drill. There has been more cost and time saving since we’ve had these machines. And we’re pleased with the plant population because of the consistent planting depth. It’s more regular than the other systems I’ve been using, which means better

production.”

NEW RELEASE

Kinze® Manufacturing recently announced that it will offer a more broad selection of planter configurations and an ex-panded array of options on its row-crop planters for the 2010 planting season. “Our goal has always been to provide the planter models and options that allow any row-crop grower to farm the way they want to farm, regardless of the size of their operation,” explained Susanne Veatch, the Vice President and Chief Mar-keting Officer at Kinze. “We conducted extensive marketing research earlier this year, which confirmed that growers want more options and flexibility when it comes to their equipment. So our 2010 product line will answer that desire among gro-wers.”

Some of these key new offerings in the 2010 Kinze product line include: • Offering either mechanical metering or the EdgeVac® vacu-

um metering systems on the 3660 planter line, in both a 12 row and a 16 row unit

• 3660TS two-section configuration with manual shut-off of right and left sections

• The Air Seed Delivery (ASD) system will be available on more planter models, including the 3700 product line

Kinze® Manufacturing rolls out expanded product line for 2010

• Offering either mechanical metering or the EdgeVac® vacu-um metering systems on the 3800 planter with ASD

Proprietary market research conducted by Kinze also showed that advanced planter technology (such as vacuum metering sy-stems, automatic section control and hydraulic drive systems) is becoming more prevalent among all growers. This adoption of new technologies is especially rapid among larger acreage growers. Veatch says the company’s strategy and aggressive product development direction reflects their determination to keep bringing forth the industry’s best new planter and grain cart technologies. “The history of Kinze is filled with innovation, and that’s a trend that will continue,” says Veatch. “We set the standard for producing the industry’s most reliable, durable planter. In the future we will seek innovative ways to enhance these ‘best-in-class’ products with new technologies.”

Do you have a story or something of interest to share?If so, please contact us at: Implementation, C B Norwood Distributors Ltd, Freepost 255, PO Box 1265, Palmerston NorthPhone (0800) 667-9663, Fax (06) 356 4939

Your local dealers:Kaikohe DaveBoytFarmMachineryCentre (09)405-2269Whangarei DaveBoytFarmMachineryCentre (09)438-4719Pukekohe NorwoodFarmMachineryCentre (09)238-7189Ngatea CentralMotors(2001)Ltd (07)867-7524Morrinsville NorwoodFarmMachineryCentre (07)889-8505Te Awamutu NorwoodFarmMachineryCentre (07)872-0232Matamata MurrayWilcoxLtd (07)888-7139Putaruru PutaruruTractorServices (07)883-7544Bay of Plenty R&RTractors(TePuke) (07)573-9107Rotorua PSLAgri (07)343-6081Taupo PSLAgri (07)378-2673Hastings/Gisborne NorwoodFarmMachineryCentre (06)873-7300New Plymouth NorwoodFarmMachineryCentre (06)757-5582Hawera NorwoodFarmMachineryCentre (06)278-6159Palmerston North NorwoodFarmMachineryCentre (06)351-2799Masterton NorwoodFarmMachineryCentre (06)377-3184Blenheim WilliamsServiceCentre(1990)Ltd (03)578-1021Nelson NSRogersLtd (03)528-9212Westport WestlandFarmers (03)788-8050Christchurch NorwoodFarmMachineryCentre (03)349-5089Ashburton GluyasMotors (03)307-5800Timaru JohnsonGluyasTractorsLtd (03)688-1133Mosgiel NorwoodFarmMachineryCentre (03)489-7754Southland ThompsonMachineryLtd (03)208-9179

®

POWER HARROWS, MULCHERS & ROTARY HOESwww.breviglieri.co.nz

PRECISION FINGER & VACUUM METERING PLANTERSwww.kinze.co.nz

MOWERS, CONDITIONERS, RAKES & TEDDERSwww.fella.co.nz

PLOUGHS, POWER HARROWS, CULTIVATORS & DRILLSwww.lemken.co.nz

FRONT END LOADERS, FRONT LINKAGES & ATTACHMENTSwww.m-x.co.nz

MIxER/FEEDER WAGONS & FORAGE HARVESTERSwww.jfstoll.co.nz

BALE WRAPPERS & FORAGE CONSERVATIONwww.tanco.co.nz

CULTIVATORS, ROLLERS & SEEDING EQUIPMENTwww.vaderstad.co.nz

PRECISION APPLICATORS & SEEDERSwww.stocksag.co.nz

DISC HARROWS & CULTIVATORSwww.baldan.co.nz

®

®

CULTIVATORS, SEED DRILLS & PRECISION PLANTERSwww.simbahorsch.co.nz

DISC HARROWS, CULTIVATORS & PRESS ROLLERSwww.simba.co.nz

European farming continues to change at an extraordinary rate, with greater volatility in the price of inputs and crops (both have doubled and halved again inside a year) placing ever-greater pressure on business management. 2009’s harvest was smaller, but easier to gather and needed less drying. Subse-quent field conditions have been kind, so crops are getting a good start. Inputs like fertiliser and chemicals are cheaper, which should help the balance sheet and confi-dence. While forward wheat prices are back above £100/tonne, the Nix Pocketbook – an essential guide to the finances of UK farming – estimates it still costs £110/t to grow. This means many farmers rely on the Single Farm Payments to remain profitable, and so are happy that 2010’s payments will be worth about 15% more than 2009. Amazingly just a year ago the national press was reporting food riots around the world, and current papers carry images of starvation in Ethiopia. This uncertainty has subdued the UK machinery market, with tractors sales down 15% and combines 11%, admittedly on last year’s ‘spike’. Cultivation kit sales are steady, but drills

are down about 30%. With little machinery made in the UK – with some honourable exceptions! – the weakening pound has raised the price of imports, and big ticket items like drills have suffered most. How do we see 2010? We agree with the industry view that trade will be “slight-ly worse”. Simba believes it will fare better, becau-se its young machines like the SL and DTX cultivators, and new drills like Horsch’s 3m Pronto EX mounted cultivator drill, which further extends our 3m machinery range, are opening up exciting new market sec-tors. The low pound opens up fresh export opportunities, but how they develop de-pends on different factors – notably the availability of finance and credit to farmers in Eastern Europe.

Guy Leversha23 October 2009

And, finally...

If you would like more information on any of the products featured in this newsletter please contact your local specialist equipment dealer.

®

TRAILED & MOUNTED FERTILISER SPREADERS

®

To keep you up-to-date with trends around the world we have invited our suppliers to comment on the market in their own country. We kick off this issue with a comment from Guy Leversha of Simba in the UK.

®