impellers;fadol naamani.pptx

-

Upload

mohammad-ammar -

Category

Documents

-

view

221 -

download

0

Transcript of impellers;fadol naamani.pptx

-

8/9/2019 impellers;fadol naamani.pptx

1/22

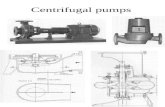

RADIAL

PUMP

IMPELLERS

-

8/9/2019 impellers;fadol naamani.pptx

2/22

I n t r o d u c t i o n

The blades of the rotating impeller transfer energy to the fluid there by

increasing pressure and velocity. The fluid is sucked into the impeller at theimpeller eye and flows through the impeller channels formed by the blades

between the shroud and hub. The impeller is the primary component

determining the pump performance.

-

8/9/2019 impellers;fadol naamani.pptx

3/22

-

8/9/2019 impellers;fadol naamani.pptx

4/22

SEMI-OPEN IMPELLERS

The Function of the pump-out vanes to reduce the pressure at the back hub of

the impeller! to prevent foreign matter from lodging in the back of the impeller

and interfering with the proper operation of the pump and the stuffing bo".

They have shroud plate on eye side of impeller. This shroud may or

may not have pump-out vanes# which are located at the back of the

impeller shroud.

-

8/9/2019 impellers;fadol naamani.pptx

5/22

ENCLOSED IMPELLERS

$nclosed impeller% &ave shroud plates or hub plate 'hub side(. )sed

for clear liquids.

-

8/9/2019 impellers;fadol naamani.pptx

6/22

Direct ion and o re lat i!e l" toimpel ler :

SuctionE"e

Discharge #o$$le

%olute&asing

Impeller

'lades

-

8/9/2019 impellers;fadol naamani.pptx

7/22

Direct ion and o re lat i!e l" toimpel ler :

-

8/9/2019 impellers;fadol naamani.pptx

8/22

I N L E T

O U T L E T

U: the impellers tangential velocity

C: the absolute velocity of the uid (compared to the surrounding)W: the relative velocity of the uid (compared to the rotatingimpeller ): is the fluid absolute flow angle: is the fluid relative flow angle

-

8/9/2019 impellers;fadol naamani.pptx

9/22

Taking the inlet velocity triangle

!he ow is assumed non"rotational atthe impeller (i#e# $%&')

!he area of the inlet by taing a radialimpeller isA()*+,+r(+b(

r$: is the radial position of the impellersinletb$: is the blades height at the inlet

: is the ow rate through the inlet of theimpellerC$m: is the absolute inlet velocity

*: angular fre+uency,: revolution of the impeller (rpm)U$: is the impeller inlet tangentialvelocity

-rom the triangle:

-

8/9/2019 impellers;fadol naamani.pptx

10/22

Taking the outlet velocity triangle

A*)*+,+r*+b*

: is the ow rate through the outlet ofthe impellerC.m: is the absolute outlet velocity

*: angular fre+uency,: revolution of the impeller (rpm)U.: is the impeller outlet tangential velocity

/n the design phase0 .is assumed to have the same

value as the blade angle#

Then#

-

8/9/2019 impellers;fadol naamani.pptx

11/22

From the previous relations obtained# we can use

EULERS PUMP EQUATION

* control volume is an imaginary limited volume which isused for setting up equilibrium equations. The equilibrium

equation can be set up for torques# energy and other flow

quantities which are of interest.

The moment of momentum equation is one such

equilibrium equation# linking mass flow and velocities

with impeller diameter.

The balance which we are interested in is a torque

balance. The torque 'T( from the drive shaft corresponds

to the torque originating from the fluid+s flow through the

impeller with mass flow m1,2%

-

8/9/2019 impellers;fadol naamani.pptx

12/22

-

8/9/2019 impellers;fadol naamani.pptx

13/22

Then#

/f the flow is assumed to be loss free# then the hydraulic and mechanical

power can be equated%

This is the equation known as $uler+s equation# and it e"presses the

impeller+s head at tangential and absolute velocities in inlet and outlet.

/f the cosine relations are applied to the velocity triangles# $uler+s pump

equation can be written as the sum of the three contributions%

0 1tatic head as consequence of the centrifugal force

0 1tatic head as consequence of the velocity change through the impeller

0 2ynamic head

-

8/9/2019 impellers;fadol naamani.pptx

14/22

-

8/9/2019 impellers;fadol naamani.pptx

15/22

The graph shows an e"ample of the

changed head and power curves for a

pump where the impeller diameter is

machined to different radii in orderto match different motor si3es at the

same speed.

&igher impeller tip speeds increase

kinetic energy/mpeller diameter

/mpeller speed

&igher flows through impellerdecrease kinetic energy

-

8/9/2019 impellers;fadol naamani.pptx

16/22

-

8/9/2019 impellers;fadol naamani.pptx

17/22

4avitations may occur when the local static pressure in a fluid reach a

level below the vapor pressure of the liquid at the actual temperature.

/f at any point the vapor pressure is reached0 the li+uid boils andsmall bubbles of vapor form in large numbers

bubbles are carried along by the ow0 reaching a point where the

pressure is higher they suddenly collapse6 cavity results and the surrounding li+uid rushes in to 8ll it#

!he li+uid moving from all directions collides at the centre of thecavity0 thus giving rise to very high local pressures

the surface becomes badly scored and pitted

9ow Cavitations occur

&a!itations are li-el" to occur on theinlet side o. a pump particularl"

-

8/9/2019 impellers;fadol naamani.pptx

18/22

&a!itations due topitting .rom bubblecollapsing

-

8/9/2019 impellers;fadol naamani.pptx

19/22

-

8/9/2019 impellers;fadol naamani.pptx

20/22

NPS&! Net 'o#itive #uction head availa$le

/s a function of your system and must be calculated. /t depend on the

fittings and the frictional losses at the inlet side of the pump.

NPS&R Net 'o#itive #uction head re(uired

/s a function of the pump and must be provided by the pump

manufacturer.

TO !"OID C!"IT!TIONS

#PS/a!ailable0#PS/re1uired

-

8/9/2019 impellers;fadol naamani.pptx

21/22

voiding Cavitations:7. 8educe friction losses in the pump suction line as much

as possible.

9. /ncrease the height of the suction tank fluid surface with

respect to the pump suction.

:. /ncrease the pressure in the suction tank. 'for pressuri3ed

suction tanks(

;. The atmospheric pressure. 'depends on sea level(

-

8/9/2019 impellers;fadol naamani.pptx

22/22

T & ! N ) S

-adel l",aamani