Impact of the B2 ordering behavior on the mechanical properties of a ...

Transcript of Impact of the B2 ordering behavior on the mechanical properties of a ...

Materials Science & Engineering A 662 (2016) 511–518

Contents lists available at ScienceDirect

Materials Science & Engineering A

http://d0921-50

n CorrE-m1 Pr

New So

journal homepage: www.elsevier.com/locate/msea

Impact of the B2 ordering behavior on the mechanical properties of aFeCoMo alloy

C. Turk a,n, H. Leitner b, G. Kellezi b, H. Clemens a, W.M. Gan c, P. Staron c, S. Primig a,1

a Montanuniversität Leoben, Department of Physical Metallurgy and Materials Testing, Franz-Josef Straße 18, 8700 Leoben, Austriab Böhler Edelstahl GmbH & Co KG, Mariazellerstraße 25, 8605 Kapfenberg, Austriac German Engineering Materials Science Centre, Helmholtz-Zentrum Geesthacht, D-21502 Geesthacht, Germany

a r t i c l e i n f o

Article history:Received 29 February 2016Received in revised form16 March 2016Accepted 17 March 2016Available online 18 March 2016

Keywords:Mechanical characterizationIntermetallicsPowder metallurgyOrdering

x.doi.org/10.1016/j.msea.2016.03.08393/& 2016 Elsevier B.V. All rights reserved.

esponding author.ail address: [email protected] (C. Turesent address: School of Materials Science anuth Wales, Sydney, NSW 2052, Australia.

a b s t r a c t

A Fe - 25 at% Co - 9 at% Mo alloy can be hardened by nm-sized (Fe, Co)7Mo6 m-phase precipitates which isaccomplished by solution annealing in the austenite region followed by rapid quenching to room tem-perature and subsequent aging below the austenite transition temperature. In overaged condition theMo-content in the remaining matrix drops towards zero and, therefore, the matrix consist of 71 at% Feand 29 at% Co. The binary Fe-Co system shows a disorder-order, A22B2 transition at a critical orderingtemperature between 25 at% and 72 at% Co. It is expected that the remaining matrix of an overaged Fe -25 at% Co - 9 at% Mo alloy also exhibits such an ordering reaction. It will be demonstrated that theformation of a B2 ordered FeCo phase can be delayed or completely prevented by rapid quenching fromtemperatures above the critical ordering temperature. This has a strong impact on the mechanicalproperties of this alloy which have been studied by means of tensile, impact toughness and hardnesstesting. The evidence for a disorder-order transition in this alloy has been given by neutron diffraction aswell as high resolution transmission electron microscopy.

& 2016 Elsevier B.V. All rights reserved.

1. Introduction

The first investigations of the ternary system Fe-Co-Mo werecarried out by Köster and Tonn [1] in the early 1930s. Their fun-damental work showed that this alloy exhibits a precipitationhardening mechanism comparable to that of aluminum alloys,whereby hardness level up to values of 70 HRC were attained. Thiscan be achieved by solution annealing in the austenite regionfollowed by fast quenching and subsequent aging of the marten-sitic Fe-Co-Mo matrix at lower temperatures to form nm-sizedprecipitates. It was later revealed that this strengthening is causedby intermetallic m-phase (Fe, Co)7Mo6 precipitates [2,3]. Severaltheoretical and experimental investigations [4–8] were carried outto describe the precipitation behavior in detail. Moreover, Gierland Danninger [9] studied the mechanical properties and heattreatment conditions of this material focusing on solution an-nealing and the achievable hardness levels. All these investigationsled to profound understanding of the m-phase precipitation be-havior, but the matrix properties of this alloy are still far frombeing well understood. Leitner et al. [4] showed by means of atom

k).d Engineering, University of

probe tomography (APT) that the remaining Mo-content in thematrix drops towards zero when the alloy is overaged. In this case,the remaining matrix consists of Fe - 29 at% Co - 1 at% Mo. How-ever, the binary Fe-Co phase diagram in Fig. 1 [10] indicates that abinary Fe - 29 at% Co alloy undergoes a reversible ordering tran-sition around 590 °C, where the disordered bcc (A2) Fe-Co-matrix(α) transforms into a long-range-ordered Fe-Co-matrix (α2) ex-hibiting a CsCl (B2) structure [11,12]. This order transition can bedelayed or prevented by rapid quenching from temperaturesabove the critical ordering temperature leading to a disordered orpartially ordered matrix [13]. The degree of order has great impacton the mechanical properties. Ordered stoichiometric Fe - 50 at-% Co alloys are quite brittle both in the ordered and disorderedcondition, although Zhao et al. [14,15] reported that Fe-rich Fe- 30 at% Co alloys were also brittle in the ordered state, but theyexhibited a ductile behavior in the disordered condition. Moreover,Fe - 30 at% Co alloys show very slow ordering kinetics compared toFe - 50 at% Co alloys, and, therefore, water quenching leads to acompletely disordered matrix [16].

A recent work [17] showed that different cooling operationsfrom the disordered bcc region indeed have an influence on thehardness behavior of an soft-annealed Fe - 25 at% Co - 9 at-% Mo alloy. In order to understand fundamentally the micro-structure property relationship of this alloy in the soft-annealedcondition, additional investigations were conducted in this work.

Fig. 1. Binary Fe-Co phase diagram in at% [18]. For a Fe - 29 at% Co alloy the or-dering temperature is at approximately 590 °C.

Table 2Cooling media and non-linear cooling parameters of the samples which weresubjected to impact toughness and tensile testing. There are differences in thecooling speed between the impact and tensile samples due to the different samplevolumes, which leads to slower cooling rates in the case of the tensile samples.

Sample Cooling treatment λ - impact λ - tensile

WQ Water quenched 0.01 0.01OQ Oil quenched 0.06 0.07AC Air cooled 1.73 3.00FC Furnace cooled 7.30 14.60AR As-received 10.00 10.00

C. Turk et al. / Materials Science & Engineering A 662 (2016) 511–518512

The mechanical properties were characterized by means of hard-ness, tensile and impact toughness testing on disorder-annealedsamples, which were subjected to different cooling operations.Using high resolution techniques as transmission electron micro-scopy (TEM), atom probe tomography (APT) and neutron diffrac-tion it was possible to confirm that the structural order of Fe andCo atoms within the matrix is responsible for the observed changein mechanical properties.

2. Materials and methods

All experiments were carried out with a powder metallurgically(PM) manufactured Fe-Co-Mo alloy provided by Böhler EdelstahlGmbH & Co KG. The nominal composition of the PM-alloy is givenin Table 1.

After atomizing and hot isostatic pressing (HIP), the materialwas hot-rolled and soft-annealed. This material condition does notexhibit precipitation of nm-sized m-phase particles or grain growthwhen it is annealed at 800 °C for 30 min [4] and, thus, is the idealstarting microstructure to study the impact of order on the me-chanical properties. In the following, this material condition willbe referred to as-received (AR). Disorder annealing was performedin a Carbolite heat treatment furnace under Argon atmosphere at atemperature of 800 °C. In order to gain a constant isothermaldwell time of 30 min, the sample temperatures were monitoredwith a K-type thermocouple. Afterwards, different cooling opera-tions were applied as listed in Table 2 together with the corre-sponding abbreviations that will be used in the following. Theindividual quenching parameters λ were calculated for each non-linear cooling condition. The value λ describes the time for coolingfrom 800 °C to 500 °C divided by a factor of 100. The λ-value of 10of the AR condition represents the heat treatment condition usedin production. Moreover, a controlled linear slow cooling (SC)treatment was carried out to achieve a higher degree of order inthe material, since according to [16] the ordering kinetic in Fe -30 at% Co alloys is very sluggish. Therefore, the cooling after the

Table 1Nominal composition in mass-% (m%) and atomic-% (at%) of the alloy as determinedby wet-chemical analysis.

Fe Co Mo Si Mn Cr Ni V

m% 59.07 24.90 15.20 0.41 0.31 0.03 0.06 0.02at% 63.66 25.50 9.50 0.88 0.34 0.03 0.06 0.03

solution treatment was done with a cooling rate of 0.5 °C/minfrom 800 to 600 °C followed by a cooling rate of 0.083 °C/min from600 °C to 500 °C and 0.5 °C/min from 500 °C to room temperature.

The mechanical properties were studied by means of impacttoughness, tensile and hardness testing. To evaluate the impacttoughness, impact tests were performed with a 300J Zwick impactpendulum. For every quenching condition five unnotched speci-mens with dimensions of 7�10�55 mm3 were used. The direc-tion of impact testing was along the 7 mm specimen dimension.The tensile tests were carried out on an Instron 8803 tensile testmachine at room temperature with a constant testing speed of1 mm/s on 3 samples per quenching condition. Due to the highbrittleness of this material, a specimen geometry similar to lowcycle fatigue testing was used. The tensile samples had an initialdiameter of Ø 9 mm and an initial measuring length of 12 mm.Due to the fact, that this is a non-proportional sample geometry,the elongation after fracture values can only be taken for internalcomparison. HRC150 hardness measurements were performed onan Emco M4R-075 hardness tester. The hardness values werecalculated from 3 valid hardness indentations on the cut, groundand polished cross-sections of the impact and tensile specimens.

The microstructural characterization was carried out by meansof scanning electron microscopy (SEM), TEM and APT. The SEM-experiments were done with a Zeiss EVO 50 in secondary electron-(SE) and backscatter electron- (BSE) mode. Additionally, chemicalanalyses were carried out using energy dispersive X-ray spectro-scopy (EDS). The sample preparation for the SEM analysis was astandard grinding and polishing procedure for steels. In order toimprove the image quality in the SEM, an additional polishing stepwith an oxide polishing suspension was applied. The APT mea-surements were carried out on the AR, WQ and SC condition. Thinslices with a thickness of 0.3 mmwere taken from impact samplesand cut into rods with a cross-section of 0.35�0.35 mm2 and alength of 10 mm. The needle-shaped specimens were preparedusing a standard electro-polishing two-step method [19] with anadditional final step applying 2% perchloric acid in 2-butox-yethanol at room temperature. Due to the fact that the tips wereelectro-polished, no information of the sample site within the bulkmaterial was available. Therefore, three measurements of eachsample were used to calculate an average chemical composition.The APT measurements were carried out in voltage mode in aLEAP 3000X-HR from Cameca. The measurements were performedat a temperature of 30 K, a pulse frequency of 200 kHz, a targetevaporation of 1%, and with a pulse fraction of 20%. The detectionefficiency was assumed to be 37%. The reconstruction and analysisof the datasets was done with the software IVAS 3.6.6 from Ca-meca. The reconstruction was done by the evolution of the voltagecurve, whereby a k-factor of 3.3 and an evaporation field of Fe with33 V/nm [19] was assumed. TEM-experiments were done in a FEITecnai F20 with an acceleration voltage of 200 kV. The TEM sam-ples were cut to a thickness of 200 mm, prepared with a dimplinggrinder and a precision ion polishing system (PIPS).

Neutron diffraction was carried out at the FRM II using the

C. Turk et al. / Materials Science & Engineering A 662 (2016) 511–518 513

STRESS-SPEC diffractometer operated by Helmholtz ZentrumGeesthacht (HZG) and Technical University of Munich at the HeinzMaier-Leibnitz Zentrum (MLZ), Garching, Germany. The usedneutron wavelength is 1.603 Å produced by a Ge 311 mono-chromator and a 25″ in-pile collimation was applied [20]. Theexposure time was 10 min at each detector (2θ) position. Thediffraction patterns were extracted from the measured 2D imagesusing the program SteCa [21]. The software tool PowderCell v2.3was then used to fit the measured diffraction patterns. For thefitting of the ordered Fe - 29 at% Co system, the Fe-sublattice oc-cupation was assumed to be completely occupied by Fe atoms andthe Co-sublattice by 58% Co and 42% Fe atoms.

3. Results

3.1. Mechanical properties

The mechanical tests were performed on the as-received soft-annealed material condition AR as well as on the disorder-an-nealed and subsequently differently cooled samples, i.e. waterquenched WQ, oil quenched OQ, air cooled AC, furnace cooled FCand slowly cooled SC. The microstructure and their details arecomprehensively described in Section 3.2. The impact toughnessand hardness values as a function of cooling rate are plotted inFig. 2. The slowly cooled samples SC exhibit the highest hardnessof 42 HRC, which is 1 HRC higher when compared to the ARcondition with 41.2 HRC. As the cooling rate increases, the hard-ness drops continuously until the lowest hardness value of sampleWQ with 37.7 HRC is achieved. In contrast to this, the impacttoughness reaches the lowest value with 7.3 J/cm2 for the SCcondition and increases with faster quenching rates. The condi-tions AR, FC, AC, and OQ have an impact toughness ranging from20 J/cm2 for the AR and 28 J/cm2 for the OQ condition. Althoughboth the oil and water quenching are relatively effective coolingoperations, there is a strong increase in impact toughness with51.6 J/cm2 for the WQ condition.

As the WQ and OQ conditions show a considerably higherductility, the fracture surfaces of these samples were analyzed inthe SEM in SE and BSE mode. Fig. 3 shows characteristic SEM-images of the fracture surface of a WQ impact toughness sample.

The images were taken at distance of 20 mm from the surfaceand the fracture area belongs to the tension region of the impacttoughness sample. In Fig. 3a, there are two different fracturemodes visible. The white dashed line depicts the change fromductile fracture to brittle transgranular fracture. The ductile area in

Fig. 2. Impact toughness and hardness values of the unnotched specimen aftertesting. The hardness drops as the impact toughness increases with increasingquenching rates.

the lower part of the image exhibits a width of 30 mm and is si-tuated �30 mm below the surface. After this small ductile region,the brittle transgranular fracture becomes the dominant fracturemechanism. Fig. 3b and c shows the same region of the fracturetransition area in SE and BSE mode with higher magnification. Inthe SE mode image in Fig. 3b, there are crystallographic cleavageplanes visible. This feature is an indicator for a transgranularbrittle fracture. Fig. 3c is a SEM image in BSE mode of the samefracture surface position as in Fig. 3b. In the BSE-contrast, them-phase appears light grey and the Fe-Co matrix dark grey. Thisimage additionally reveals that the transgranular cleavage planespropagate homogenously through the m-phase particles and alsothrough the matrix grains. Although the lower right region inFig. 3b apparently exhibits intergranular fracture, Fig. 3c revealsthat this is a fracture area which shows ductile features. Thisductile behavior can be explained by the formation of voids in thesoft Fe-Co-matrix which are typical for a ductile fracture. More-over, it can be seen that the voids indicated in Fig. 3c nucleated atm-phase particles. Most of the m-phase particles seem not to sufferfrom cleavage during loading; however, there are a few crackedm-phase particles within the voids as marked with arrows inFig. 3c. The change from ductile to transgranular brittle fracturecan also be observed in the OQ condition, but the fraction ofductile fracture is less compared to the WQ condition. All othercooling operations resulted in an entirely transgranular brittlefracture of the impact toughness samples. In addition, the impacttesting showed that higher quenching rates lead to improvedtoughness.

The impact of the cooling operation on the mechanical prop-erties where additionally studied with static tensile testing, asshown in Fig. 4. Two types of stress-strain curves were obtained inthe tensile tests of the differently cooled samples. The SC samplesexhibit a small region after the elastic rise in stress, where a dis-continuous yielding (Lüders type) can be observed, whereas allother conditions show a continuous yielding behavior. As in caseof impact toughness testing (Fig. 2), similar cooling rate de-pendencies can be seen in Fig. 4. With increasing cooling rate thehardness as well as the strength values start to decrease and theelongation after fracture rises. A hardness of 38 HRC can beachieved with the WQ cooling operation. Furthermore, the WQconditions exhibit a yield strength Rp0.2 of 763 MPa and a tensilestrength Rm of 1179 MPa. In addition to this, OQ and WQ condi-tions show the highest elongation after fracture with 7.6% and8.0%, respectively. With decreasing cooling rates the hardness aswell as the strength reaches the highest values for the FC condi-tion, with a yield strength Rp0.2 of 882 MPa and a tensile strengthRm of 1297 MPa, whereas the elongation after fracture is quite lowwith 4.3%. The highest hardness values of 42.1 HRC can beachieved with the SC condition. However, the yield and tensilestrength of this cooling condition are lower compared to the ARand FC condition, but the elongation after fracture drops to 1.2%.

SEM investigations in SE and BSE mode of the fracture surfaceof all tested tensile samples revealed a fully transgranular brittlefracture, with non-metallic inclusions acting as crack initiationsites (see Section 3.3). Although the hardness, tensile and impacttesting results showed that different cooling operations changedthe mechanical properties, further investigations were necessaryto identify the effect responsible for the change. Therefore, furthermicrostructural investigations with SEM, TEM and APT were car-ried out, as described in the next section.

3.2. Microstructural analysis

The microstructure consists of m-phase particles (light grey)embedded in a ferritic matrix (dark grey), whereas the matrixshows contrast variations arising from different crystallographic

Fig. 3. SEM images of the fracture surface of a WQ impact sample. (a) Overview of the fracture transition area in SE-contrast with ductile and transgranular brittle fractureregions. (b) SE and (c) BSE images with higher magnification of the transition area from ductile to transgranular brittle fracture.

Fig. 4. Yield strength, Rp0,1 and Rp0,2, tensile strength Rm, elongation after frac-ture A and hardness HRC 150 of the Fe - 25 at% Co - 9 at% Mo alloy in different heattreatment conditions. Higher quenching rates lead to a more ductile material be-havior as the elongation increases and the strength decreases. In contrast to thisthe slowly cooled conditions AR, FC and SC show a very low ductility as well as alow strength but a high hardness.

Fig. 5. (a) SEM image in BSE mode of Fe - 25 at% Co - 9 at% Mo alloy in the AR condition. Tregions, whereas some contrast variations arising from different crystallographic orienm-phase appears dark, due to the high Mo-content and the matrix appears as bright re

C. Turk et al. / Materials Science & Engineering A 662 (2016) 511–518514

grain orientations (Fig. 5).There are two populations of coarse m-phase particles. The

dominating fraction has a size of 1–3 mmwhich arises from the HIPprocess. The second population, which is formed during the an-nealing treatment, are below 1 mm. A combined SEM and surfacefraction analysis revealed an overall m-phase fraction of 23 vol%.The TEM bright field image in Fig. 5b shows the grain structure ofthe matrix as bright regions while the m-phase appears as darkregions. In addition to this, an average grain size of about 1 mm canbe estimated. Moreover, the microstructure as well as the m-phasecontent and the grain size of the disorder annealed and differentlycooled samples were examined in the SEM. All the investigationsrevealed that the disorder-annealing and different cooling opera-tions did not affect the microstructure in terms of grain growth,change in m-phase content or its morphology. In order to cross-check that the heat treatments did not change the chemicalcomposition of the matrix, APT measurements were performed onthe AR, WQ and SC condition. If the heat treatment did affect thechemical composition of the matrix, the WQ and SC conditionsshould provide evidence, since these samples exhibit the largestdifferences in the mechanical properties.

Exemplary for the APT evaluation, Fig. 6 shows 2D elementalmaps of Fe and Co atoms in the reconstructed volume of a SC tip,

he coarse m-phase particles appear in light grey and the matrix appears in dark greytations can be seen. (b) TEM image in bright field mode of the AR condition. Thegions.

Fig. 6. Reconstruction of an APT measurement with 3D elemental maps of Fe andCo atoms in the matrix in the AR condition. The homogenous distribution of bothelements is visible.

Table 3Average chemical composition of the matrix and standard deviation (std. dev.) fromthree different heat treatments (AR, WQ and SC).

As received AR Water quenched WQ Slowly cooled SC

Element Content[at%]

Std. dev.[at%]

Content[at%]

Std. dev.[at%]

Content[at%]

Std. dev.[at%]

Fe 70.21 0.08 69.64 0.12 70.04 0.19Co 29.15 0.08 28.88 0.14 29.28 0.18Mo 0.24 0.02 0.94 0.02 0.25 0.06Mn 0.18 0.01 0.27 0.01 0.20 0.01Cu 0.10 0.002 0.10 0.001 0.11 0.002Si 0.029 0.002 0.103 0.003 0.034 0.002Ni 0.020 0.001 0.018 0.001 0.018 0.001Cr 0.015 0.001 0.023 0.001 0.016 0.001V 0.011 0.001 0.012 0.001 0.012 0.001

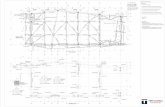

Fig. 7. Measured neutron diffraction patterns conducted at SC and WQ samplesand as well as simulated neutron diffraction patterns of ordered and disorderedbinary FeCo alloys. The simulated ordered systems and the SC condition showsuperlattice reflections arising from the structural order of Fe and Co atoms (seetext).

C. Turk et al. / Materials Science & Engineering A 662 (2016) 511–518 515

exemplary for all conditions. The elemental mappings in Fig. 6reveal that both elements are homogenously distributed. Addi-tional analyses of the decomposition of those elements, such asfrequency distribution analysis of the matrix [22] also shows noevidence of any segregation or clustering. An average chemicalcomposition of the matrix was calculated for every single heattreatment condition, which is given in Table 3. From three differ-ent matrix measurements a homogenous distribution of elementswas also proved for the AR and the WQ tips.

As Table 3 evidences, the matrix of the AR and SC samplesconsists mainly of 70 at% Fe and 29 at% Co. All other elements canbe regarded as trace elements in the matrix, due to the fact thattheir corresponding sum is below 0.7 at%. The matrix of the WQsample exhibits a lower Co-content, but an amount of 0.9 at% Mo.However, the APT data shows that the disorder annealing followedby WQ and SC operations did not lead to a significant change inthe chemical composition of the matrix. To verify that the matrixis responsible for the observed change in ductility and strength-ening behavior further TEM and neutron diffraction experimentswere carried out on both SC and WQ samples as reported in Sec-tion 3.3.

3.3. Neutron diffraction and TEM investigations

Neutron diffraction patterns of fully ordered and disorderedFeCo systems were calculated and compared with measured pat-tern (Fig. 7.) All measured and calculated diffraction patterns havebeen normalized to the maximum of the corresponding (200)

peak. The measured patterns of the WQ and SC samples indicatethat the characteristic (110) and (200) peaks of the disordered bccFeCo-matrix are dominant in the spectra (Fig. 7). Additionally,there are several rhombohedral FeCo7Mo6 m-phase peaks and onesmall peak from face-centered-cubic β-MnS impurities. Due to thefact that the WQ sample exhibits only bcc-FeCo peaks, it is as-sumed that quenching led to a completely disordered matrix witha long range order parameter of S¼0 and, therefore, to the muchhigher ductility of the material. However, the neutron diffractionpattern of the SC sample shows additional peaks (marked with thearrows) arising from an ordered FeCo phase in the matrix. Thesesuperlattice reflections can be found at 32.5° (100) and 53° (111)2θ diffraction angle. Since the (100) and (111) reflections are for-bidden for a disordered bcc-structure, this observation is a clearevidence for ordering activity in the Fe - 29 at% Co matrix. Thesuperlattice peaks exhibit a quite strong broadening, hence, it issupposed that the ordered domains in the matrix are very small.

The calculated patterns of the binary Fe - 29 at% Co systems inthe ordered and disordered condition show a quite similar beha-vior when compared to the measured diffraction patterns of the SCand WQ samples. In all simulated patterns, the bcc peaks from the(110) and (200) lattice planes have the highest intensities. Theordered Fe - 29 at% Co and Fe - 50 at% Co system exhibits super-lattice reflections from the (100) and (111) lattice planes. More-over, it can be seen that an equiatomic ordered Fe - 50 at% Co alloyexhibits a higher (100) peak compared to the ordered Fe - 29 at%Co system.

The degree of order in the matrix of the SC sample has beenestimated by calculations using the relationship given by Cleggand Buckley [13] with S2¼R*I(100)/I(200), where R stands for theLorentz and Polarization factors and I(100) and I(200) representsthe integrated intensity of the reflection (hkl). With this calcula-tion, a long-range order parameter of 0.4670.08 has been calcu-lated for the SC condition. In addition to this, the (100) peakbroadening can be used to rate the domain size of the orderedregions in the same manner as diffraction methods can be usedcalculate the crystallite size. The domain size of the ordered re-gions has been approximated using the Scherrer formula [23] withthe volume weighted domain size Dv¼Kλ/(γ cosθ), where K is ageometric factor and can set as 1, λ is the neutron wavelength, andγ is the integral breadth defined by γ¼[π/(4ln2)]1/2 times fullwidth half maximum for the analysis of the (100) peak with an

Fig. 8. (a) TEM bright field image of the SC sample. The matrix grain has a [001] orientation. (b) Selected area diffraction of the matrix. The (100)-superlattice reflections ofthe ordered FeCo-Matrix are clearly visible. (c) Dark field image of the (100) superlattice reflections. (d) HRTEM image of a matrix grain in [112] direction showing ordereddomains.

C. Turk et al. / Materials Science & Engineering A 662 (2016) 511–518516

Gaussian peak profile. With this expression, a domain size of8.770.8 nm can be estimated for the SC condition.

To validate the neutron diffraction results, complementary TEMinvestigations on the SC sample were carried out. Fig. 8a shows abright field TEM image of a matrix grain orientated in [001] di-rection. The image shows dark spots within the matrix, but thematrix structure appears to be homogeneous. The selected areadiffraction in this matrix grain resulted in the diffraction patternshown in Fig. 8b. The diffraction image reveals also (100) super-lattice reflections from an ordered structure within the Fe - 29 at%Co matrix. In addition to this, a dark field mode image has beentaken from the regions which featured these (100) superlatticereflections. The corresponding dark field image is shown in Fig. 8c.Comparing the bright field (Fig. 8a) and the dark field (Fig. 8c)images, it becomes obvious that the dark spots in the bright fieldimage overlap with the bright spots in the dark field image asindicated by the circles in both images. Therefore, it is believedthat these regions are ordered domains in the Fe - 29 at% Co ma-trix. In addition to this, a high resolution TEM (HRTEM) image of a[112]-orientated matrix is shown in Fig. 8d. In the HRTEM imagethere are distinct regions, where the atomic structure appearssharper. These regions are domains where an ordered atomicstructure of Fe and Co atoms is present. The domain size can beestimated to be in the range of 5–10 nm.

4. Discussion

Binary FeCo alloys in the compositional range of 25–70 at% Coexhibit an A22B2 disorder-order transition. The critical orderingtemperature depends on the Co content. This order transition af-fects strongly the mechanical properties of FeCo alloys [12]. In thisstudy the influence of an order transition on mechanical proper-ties of a soft-annealed Fe - 25 at% Co - 9 at% Mo alloy has beeninvestigated. Recent work by Turk et al. [17] has shown, that thematrix of this soft-annealed alloy consists of 71 at% Fe and 29 at-% Co, and, therefore, should show an order transition. Further-more, it was reported that the hardness of this alloy changes withdifferent cooling operations after annealing at temperatures of800 °C. Consequently, the influence of the cooling rate after an-nealing at 800 °C on the mechanical properties was further eval-uated by means of impact toughness, tensile and additionalhardness testing, although in this study special interest was laid onthe ductility of the material.

The results of the mechanical testing revealed that the sampleswith higher quenching rates (WQ and OQ) exhibit a higher duc-tility in terms of impact toughness, elongation after fracture and

lower hardness compared to the slower cooled samples AC, FC, AR,and SC (Figs. 2 and 4). The improved elongation after fracture(Fig. 4) with increasing quenching rates are in good agreementwith the results from tensile tests at room temperature performedon binary Fe - 30 at% Co alloys by Zhao et al. [14,15]. The elonga-tion after fracture of the WQ condition in (Fig. 6) is in the samerange as Zhao et al. [14] have reported for disordered Fe - 30 at%Co model alloys. Also the higher impact toughness in the dis-ordered condition WQ (Fig. 2) is in good agreement with the re-sults of Johnston et al. [24]. They showed that the ductile brittletransition temperature starts to decrease from 400 °C to �100 °Cas the Fe - 48 at% Co - 2 at% V alloy becomes disordered and,therefore for this reason shows a higher ductility. The fracturemechanism of all tested impact toughness and tensile samples inthis study is transgranular brittle fracture, although the work ofZhao et al. [14,15] reported for Fe - 30 at% Co alloys mainly inter-granular fracture with some transgranular cleavage regions, in-dependent on the state of order. In addition to this, they also ob-served plastic deformation before transgranular and intergranularfracture occurred [15]. This behavior is consistent with the frac-tography results of the WQ impact toughness sample shown inFig. 3, where ductile fracture prior to the transgranular brittlefracture was observed. Transgranular brittle fracture in FeCo alloysin the ordered as well in the disordered condition was only foundin Fe - 48 at% Co - 2 at% V alloys [12,24]. It is assumed that Va-nadium prevents grain boundary embrittlement and thus sup-presses the intergranular fracture. Furthermore, it is known [12,14]that a grain size below 1 mm enhances the ductility of FeCo alloysand that additional phases [20,21] improve the ductility via grainrefinement. The transgranular fracture in the present study mightbe a combined result from the grain size o1 mm and the existenceof 1–2 mm-sized homogenously distributed m-phase particles. Ac-cordingly, the effect of the primary m-phase particles on the frac-ture behavior should be further investigated.

In addition to this, the lower hardness and yield strength of therapidly cooled samples WQ and OQ are consistent with the workof Zhao et al. [14]. The room temperature yielding of fully orderedand disordered FeCo alloys showed that disordered binary Fe -30 at% Co alloys have a lower yield strength compared to the or-dered conditions. It is well established for Fe - 50 at% Co alloys thatdisorder increases the yield strength [25]. The higher yieldstrength of disordered Fe - 50 at% Co alloys has been attributed tothe presence of short range order (SRO) [26]. Fisher [26] proposedthat the degree of SRO depends on the temperature, and, there-fore, the degree of SRO increases as the critical ordering tem-perature increases. An Fe - 30 at% Co alloy has a critical orderingtemperature of 620 °C [11], whereas the stoichiometric Fe - 50 at%

C. Turk et al. / Materials Science & Engineering A 662 (2016) 511–518 517

Co has an ordering temperature of 730 °C [11,12]. Accordingly, Fe- 30 at% Co alloys exhibit a lower degree of SRO and a muchweaker SRO strengthening. Consequently, the yield strength ofdisordered Fe - 30 at% Co alloys is lower compared to the orderedconditions. This continuous increase in the strength with a higherdegree of order is consistent with the results from the tensile testsshown in Fig. 4. As the quenching rate decreases the hardness andthe strength increases continuously from WQ to FC, while theelongation after fracture as well as the impact toughness de-creases. However, it appears, that the SC samples with the slowestcooling rate do not exhibit a similar strengthening behavior, whilethe elongation after fracture and impact toughness are low asexpected for this cooling condition, since it should show a higherdegree of ordering. The SC samples show a discontinuous yielding(Lüders type) behavior. The discontinuous yielding of the SCcondition has also been observed by Zhao et al. [14] at the testedordered FeCo alloys. It was proposed, that in B2-ordered FeCo al-loys this type of yielding is promoted by the small grain size. If thegrain size increases the Lüders region cannot be observed on thestress strain curve since it becomes very small. Furthermore thediscontinuous yielding was not observed for disordered FeCo al-loys [14], which is consistent with the results of this work. Due tothis discontinuous yielding behavior, the lower yield stress Rp0.1

and Rp0.2 of the SC conditions could be explained. The decrease ofthe stress while discontinuous yielding is occurring leads to lowerstrength values when the yield strength of all samples is de-termined by the given strength at a defined strain of 0.1% and 0.2%.To conclude, due to the different stress-strain behavior, the de-termination of the yield strength in case of continuous or dis-continuous yielding behavior is strongly affected by the chosenstrain values. In addition to this, the low tensile strength of the SCsamples can be attributed to the low fracture elongation.

The results of the mechanical properties fortified the assump-tion that higher quenching rates produce a disordered matrix and,therefore, a higher ductility of the alloy. Furthermore it is ex-pected, that ordering of the matrix is responsible for the change inmechanical properties. In order to reveal the mechanism re-sponsible for the observed change of the mechanical propertiesthe microstructure of all differently cooled conditions was ana-lyzed to find evidence for an order transformation. The micro-structural characterization of the Fe - 25 at% Co - 9 at% Mo alloys,including SEM and APT, revealed a two-phase microstructureconsisting of a Fe - 29 at% Co ferritic matrix and coarse m-phaseparticles (Fig. 2). The soft annealing heat treatment led to a Mo-depleted Fe - 29 at% Co matrix (Table 1), which is consistent withprevious work of Leitner et al. [4] and Turk et al. [17]. Additionalheat treatments in the disordered bcc region at 800 °C and sub-sequent different cooling operations did change neither the overallchemical composition of the matrix, nor the grain size or them-phase fraction of the alloy. However, different cooling operationshad an influence on the mechanical properties of the two phasemicrostructure. Therefore, neutron diffraction and further TEMinvestigations were used to evidence the ordering of the matrix.For this purpose, the WQ and the SC sample were examined, sincethese samples showed the largest difference in the mechanicalproperties and accordingly should show different scattering be-havior of the Fe - 29 at% Co matrix. The ideal ordered FeCo B2-structure consists of an Fe- and a Co-sublattice. In case of dif-fraction with electrons, neutrons or X-rays, these sublattices pro-duce superlattice-reflections, which are forbidden for the dis-ordered bcc structure, e.g. (100), (111), (210), (221), (300), and(311) reflexes [27]. The neutron diffraction pattern of the WQcondition (Fig. 7) indicated no superlattice reflections from or-dered domains and, hence, it is thought that this cooling treatmentled to a completely disordered Fe - 29 at% Co matrix. Also, thesimulated disordered Fe - 29 at% Co pattern gave no evidence of

additional peaks. Usually, a completely disordered bcc phase in abinary Fe - 50 at% Co alloy can only be achieved by rapidquenching faster than 4000 K/s from temperatures above the cri-tical ordering temperature [13]. In other words, only very thinsamples can reach complete disorder. However, off-stoichiometricFe-rich FeCo alloys show a slower ordering kinetic compared to Fe- 50 at% Co alloys and, thus, water quenching can also produce acomplete disorder [13]. This was also proven by Gilles et al.[28,29], since their water quenched Fe - 30 at%Co - 3 at% Pt and Fe- 30 at%Co - 3 at% Pd alloys did not exhibit ordered domains and,therefore, the long range order parameter is zero. The neutrondiffraction pattern of the SC condition (Fig. 7) depicts that ordereddomains can be found in the matrix, because of the appearance ofthe (100) and (111) superlattice reflections. These superlattice re-flections were also verified by the TEM analysis and the corre-sponding selected area diffraction (Fig. 8). Galimberti et al. [30,31]revealed by means of TEM and selected area diffraction in age-hardened FeCoMo/W systems that ordered domains are present inthe Fe-rich FeCo matrix. In the present study the first estimation ofthe long range order parameter of S¼0.46 could be obtained fromthe neutron diffraction pattern of the SC sample. This result is ingood agreement with calculated long-range order parameter ofthe furnace cooled samples of the Fe - 30 at% Co - 3 at% Pt and Fe -30 at% Co - 3 at% Pt alloys [28] with S¼0.5 and S¼0.6, respectively.It is known for Fe - 30 at% Co alloys that the maximum achievabledegree of order is below S o0.6 [16,29]. This effect is also visiblein the simulated neutron diffraction patterns of the Fe - 29 at% Coand Fe - 50 at% Co alloys (Fig. 7). The higher Co-content leads to ahigher possible degree of order and the intensities of the super-lattice reflections (100) and (111) increase. The comparison of theintensity of the (100) superlattice reflections shows that in thecase of the Fe - 50 at% Co the (100) peak is as high as the (200)peak which results in a completely ordered Fe - 50 at% Co phasewith a degree of order of S¼1. However, the (100) peak in themeasured SC sample exhibits a very pronounced broadening and aquite low intensity. This behavior could be explained by the low(100)/(200) intensity relationship of Fe - 29 at% Co alloys of 1:40.Moreover, the peak broadening of the (100) reflections of the SCsample compared to the (100) peak of the simulated ordered Fe -29 at% Co phase leads to the assumption that in the SC sample theordered domains are very small. As a first estimation, the domainsize was calculated to be 8.7 nm. This estimation is in the samesize range as the HRTEM investigations, where the domain size isbetween 5 nm and 10 nm. These ordered FeCo domains within thedisordered matrix are responsible for the higher strength andlower ductility of an Fe - 25 at% Co - 9 at% Mo alloy that is slowlycooled from temperatures above the critical ordering temperature.

5. Summary

In this study we have shown that an overaged Fe - 25 at% Co -9 at% Mo alloy consists of m-phase particles and a Mo-depleted Fe -29 at% Co matrix. Solution annealing in the disordered bcc regionand a variation of the cooling parameters to room temperature ledto significant differences in the mechanical properties. Theachieved results can be summarized as follows:

� Water quenched (WQ) samples exhibit a higher ductility, alower strength and a lower hardness value, whereby additionalductile fracture surfaces were found at the impact toughnesssamples.

� The rapid quenching (WQ, OQ) prevents the order-disordertransformation, which promotes a ductile disordered Fe -29 at% Co matrix.

� Evidence for the occurrence of ordered regions in slowly cooled

C. Turk et al. / Materials Science & Engineering A 662 (2016) 511–518518

samples in the Fe - 29 at% Co matrix was given by neutrondiffraction experiments with a calculated long range orderparameter of S¼0.46 and a domain size of 8.7 nm.

� Complementary TEM-investigations gave additional evidencethat ordered domains are present in the matrix. HRTEM-in-vestigations revealed ordered domains with a size between5 nm and 10 nm.

Acknowledgements

The authors would like to thank Gerhard Hawranek for theSEM-investigations, Stefan Marsoner for the tensile testing,Manfred Brabetz and Krystina Spiradek-Hahn for the TEM mea-surements and Emanuel Schwaighofer for helpful discussions.

References

[1] W. Köster, W. Tonn, Arch. Eisenhuttenwes. 12 (1932) 627–630.[2] M. Hansen, K. Anderko, Constitution of Binary Alloys 1, McGraw-Hill,

New York, 1958.[3] E. Houdremont, Handbuch Der Sonderstahlkunde. 3.Aufl, Bände 1–2, Springer-

Verlag Berlin Heidelberg, 1956.[4] H. Leitner, M. Schober, H. Clemens, D. Caliskanoglu, F. Danoix, Int. J. Mater. Res.

99 (2008) 367–374.[5] E. Eidenberger, E. Stergar, H. Leitner, P. Staron, J. Spitaler, C. Ambrosch-Draxl,

H. Clemens, Appl. Phys. A 97 (2009) 331–340.[6] E. Eidenberger, M. Schober, T. Schmoelzer, E. Stergar, P. Staron, H. Leitner,

H. Clemens, Phys. Status Solidi 207 (2010) 2238–2246.[7] E. Eidenberger, M. Schober, P. Staron, D. Caliskanoglu, H. Leitner, H. Clemens,

Intermetallics 18 (2010) 2128–2135.

[8] E. Povoden-Karadeniz, E. Eidenberger, P. Lang, G. Stechauner, H. Leitner,E. Kozeschnik, J. Alloy. Compd. 587 (2014) 158–170.

[9] C. Gierl, F. Rouzbahani, C. Harold, H. Danninger, H. Ponemayr, M. Daxelmüller,in: Proceedings of the 15th IFHTSE, Int. Fed. Heat Treat Surf. Eng. Congr, 2006,2006, pp. 106–111.

[10] T. Nishizawa, K. Ishida, in: T.B. Massalski (Ed.), Bin Alloy Phase Diagrams, 2nded., ASM International, Materials Park, OH, 1990, pp. 1186–1189.

[11] I. Ohnuma, H. Enoki, O. Ikeda, R. Kainuma, H. Ohtani, B. Sundman, K. Ishida,Acta Mater. 50 (2002) 379–393.

[12] T. Sourmail, Prog. Mater. Sci. 50 (2005) 816–880.[13] D.W. Clegg, R.A. Buckley, Met. Sci. 7 (1973) 48–54.[14] L. Zhao, I. Baker, Acta Metall. Mater. 42 (1994) 1953–1958.[15] L. Zhao, I. Baker, E.P. George, in: High Temp. Ordered Intermet. Alloy. V, Proc.

Mater. Res. Soc., 1993, pp. 501–506.[16] Y.I. Mal’tsev, V.I. Gorman’kov, I.M. Puzey, A.D. Skokov, Phys. Met. Met. 43

(1977) 47.[17] C. Turk, G. Kellezi, H. Leitner, P. Staron, W. Gan, H. Clemens, S. Primig, in: B2

Compd. Iron Alum. YY4, Proc. Mater. Res. Soc., 2015, pp. 175–180.[18] K. Nishizawa, T. Ishida, in: ASM Int. 2nd Ed., 1990, pp. 1186–1187.[19] M.K. Miller, A. Cerezo, the late M.G. Hetherington, G.D.W. Smith, Atom Probe

Field Ion Microscopy, Oxford University Press, USA, 1996.[20] M. Hofmann, W.M. Gan, J. Rebelo-Kornmeier, M. Schöbel, Neutron News 24

(2013) 14–17.[21] C. Randau, U. Garbe, H.-G. Brokmeier, J. Appl. Crystallogr. 44 (2011) 641–646.[22] D. Vaumousse, A. Cerezo, P.J. Warren, Ultramicroscopy 95 (2003) 215–221.[23] B.E. Warren, X-Ray Diffraction, Dover Publications, Inc, New York, NY, 1990.[24] T.L. Johnston, R.G. Davies, N.S. Stoloff, Philos. Mag. 12 (1965) 305–317.[25] S.-T. Fong, M. Marcinkowski, K. Sadananda, Acta Metall. 21 (1973) 799–806.[26] J.C. Fisher, Acta Metall. 2 (1954) 9–10.[27] C. Shull, S. Siegel, Phys. Rev. 75 (1949) 1008–1010.[28] R. Gilles, M. Hofmann, F. Johnson, Y. Gao, D. Mukherji, C. Hugenschmidt,

P. Pikart, J. Alloy. Compd. 509 (2011) 195–199.[29] R. Gilles, M. Hofmann, Y. Gao, F. Johnson, L. Iorio, M. Larsen, F. Liang,

M. Hoelzel, B. Barbier, Metall. Mater. Trans. A 41 (2009) 1144–1150.[30] P. Galimberti, S. Lay, A. Antoni-Zdziobek, Intermetallics 22 (2012) 33–40.[31] P. Galimberti, S. Lay, A. Antoni-Zdziobek, S. Coindeau, M. Véron, F. Bley, M. De

Boissieu, Intermetallics 19 (2011) 556–562.