Img

-

Upload

cuchuflina -

Category

Documents

-

view

4 -

download

0

Transcript of Img

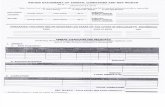

CLASS.No. l2O54OsuB No l o o 61 z(t/S)

MODELDRAWNG

No.

UNIVERSAL JOINTS INSTRUCTION MANUAL

3r.¡\*9'tv)e 4 y hm+&-=rfr,EE*

crlrcs BJ

Ref No. UJ No.

41AGU 89230072A415G90 892 30073A410&95 892300744415G95 892300774413G97 892 30081A

MARK REVISION APPROVED REVIEWED DRA!ryN DATE

NIIGATA POWER SYSIEMS CO. . LTD,

ENGINEER/AIG & TECHNOLOGY CENTER

APPROVED S.Ehata

REVIEWED Y.Oshb

DRA\^/NI T. To kito u/H. H a sh i m oto

DATE 16 / Sep./ 2004

KFRM.2O78 (9802)

G€lU€S

TE CHMCAL DE S CRIPTIOIY Edition 2002

the mounting, maintenance andconcernrngrepair of propshafts with flanged joints

1. General hints

Assembly, disassembly, maintenance and repair of propshafts should be performed only by qualified personnel. ln addition,for repair work we recommend our own service to ensure professional workmanship, the use of original spare parts, technicalequipment, guarantee etc.

The propshafts lve manufacture are supplied ready for installation and operation. All are lubricated, base painted and the

surf-ace ofthe fianges are protected against corrosion.The propshafts have been dynamically balanced to ensure perfect smooth running. The balance plates attached to the driveshaft tubes or thejoint drivers must not be removed as they are essential for the vibration-free running ofthe propshaft. Forthe same reason. the joints must not be exchanged with one another. When a propshafl is being installed care must be taken toensure that the engraved indicating arrows coincide so that the two joints are located within one plane, as required lbr perfectmotion.

Fig. I

The propshaft should be set-up according to the installation instmctions issued by the final manulacturer. For safety reasons,

propshafis used in hazardous environments should be suitably guarded. High-speed propshafts should be guarded by saf'ety

bands to avoid damage in the event ofshaft release or fracture. The relevant national regulations concerning industrial safety

and protective efficiency are to be observed. During transport and storage, the propshafts should be handed caref'ull¡' and be

protected against impacts and shocks in order to guarantee the balance quality. Propshafts should preferably be transportedand stored horizontally. An¡i neglect of these instructions may lead to an impairment of functional reliability.

2. Assembly Before the propshaft is installed, the faces ofthe two flanges (shaft flange and connecting flange) are to becleaned, i.e. the faces and centring surface must be tiee ofburrs, dirt, paint and grease. The axial and radlal run out tolerancesadmissible for the connecting flange are to be maintained. otherwise the correct running of the propshaft may be affected (Fig2 and Table l).

r1g. IRadial run out

inner forks ofjoint

arking arrows

,lfit'ft

il.'t

t:', li'ii

,l

'*l

".t,l i--iProp-Shafttpm

.-lmln

tolerancefor d

RadialRun out

KR

axialRun out

KS

Up to500

h8 0, l5 0. I 8/t 00

500 to3.000

h] 0,08 0, I 0/r 00

Morethan

3.000h6 0.05 0,071 100

axial run out

Table I

Gelenkwellenwerk Stadtllm GmbH Weimarische Strasse

DRW.No. 20540-00612 (215 |

[email protected] Pagetof456 D- 99326 Stadlilm Tel +49 3629 640 0 Fax +49 3629 800002

g€tu€sBoth flanges are connected by means ofhexagon bolts according or similar to ISO 4014 ofproperfy class 10.9 and hexagonnuts according to ISO 7042-V ofproperty class 10.

The hexagon bolts cannot be inserled from thejoint end on all types ofpropshafts.Particular attention should be given to tighten the flange connecting bolts in order to achieve the necessary frictional torquetransfer. Suitable spanners are to be used, but in every case the torque is to be checked with a torque wrench. The specifiedtightening torques given in table 2 are to be followed.Fis. 3

:Thread

Tighteningtorque

Th¡eadTightening

torque

mm Nm mm Nm

M5 9 M16 300

M6 15 Mr8 410

M8 35 M20 600

Ml0 l0 M22 800

Mt2 t2a

Ml4 200

Table 2

Maintenance interval50,000 km or I year

30,000 km or I year

3,000 hours or t/2 yeaÍ500 operating hours

Shaft flange connecting flange

3. Maintenance

Propshafts without grease nipples are greased fbr 1if-e and therefore require no fufiher lubrication. Ilhigh pressurc equipmentis used for cleaning, it is important not to direct thejet directly onto the seal.For propshafts fitted with a tape red grease nipple (acc. to DIN 71412) or flat grease nipple (acc. to DIN 3404) it is possibleto lubricate thejoints rvith a grease gun (see Fig. 4),

The grease nipples must be cleaned before a grease gun is applied. The 4 bearings ofeachjoint are lubricated by one centralgrease nipple.Complete lubrication is achieved when grease can be obsen¡ed coming from the bearing seals. For shafts with regreaseable

shaft length compensation, l0 - 30 g ofgrease should be sufficient depending on shaft size.

Grease guns must be operated smoothly. at pressures not exceeding 2 MPa to prevent any damage to the seals.

The maintenance intervals ofthe propshafts in special areas ofapplication (mass produced parts), are to be agreed with the

final customer. For general applications, the following directions are recommended:

Propshafts employed in:- road motor vehicles- off'-road motor vehicles- rail vehicles- stationary plant

Regreasing is necessary after cleaning with high pressure equipment. It is important not to direct thejet directly onto the seal.

Shorter maintenance intervals will be required where the propshafis are operated in extremely adverse conditions. Propshafts

taken out ofpro-longed storage (6 months and more) should be lubricated before being installed.Suitable lubricants recommended:

Lithium-saponified lubricating greases of penetration class 2 with epoxy additives.No greases containing Mo52 to be used for the joint bearings.

When the application temperature limits exceed the normal range of +80 oC to -25 "C. special-purpose greases of the above-

mentioned specilication should be used.

DRW.No. 20540-00612 ( 315Gelenkwellenwerk Stadtilm GmbH Weimansche Strasse 56 D- 99326 Stadtilm Tel +49 3629 640 0 Fax *49 3629 800002 [email protected] ivww.qewes de Page: ofa

g€tu€s,1. Reconditioning

The propshafts can be reconditioned with the aid of simple auxiliary tools, as the joints can be completely disassembled and

the length-compensating attachment can be exchanged. The principal points ofwear are:

Joint bearr'ng: Perceptible play in the bearings; damaged sealings or bearing housings; wear marks and indicationsofpitting on the bearing surfaces.

Profile length-compensating joint: Perceptible play permitting twisting and/or tilting; indications of pitting at

profile flanks and at the head periphery; damaged seals.

DISASSEMBLY of the propshaft starts with the dismantling of the two half shafts, with the profile length-compensatingjoint being pulled apart.For disassembly of the joints, the locking rings placed in the drivers are to be removed flrst, with the aid of a special

pliers. The bearing bushes can then be dismantled, according to Fig. 5.

Ifthe bearing bush cannot be removed by hand after the push out operation, the release from the bore can be affectedtapping against the yoke driver.

tsro l

Flansch

Auxiliary tool

The other bearing bushes are to be dismantled in similar manner(Fig. 6).

pair of

by light

Fig. 6

Flange yokeCross

Fig.7

Sleeve

Bearing bushes

protective cap

Auxiliary tool

On.loints rvith split bearing eye bores the bearing Gap balls should be slackened to allor.v removal of the cap. After all 4

bearing ca ps have been removed, the spider. including the bearing sleeves. can be separated tram the flange yokes.

Note! Bearing Gaps and flange yokes are in pairs and must not therefore be interchanged or mounted in a difTerent positionduring reassembly .

The 4 bearing bushes, and protective Gaps if fitted, are to be removed prior to assembly of the new complete spider to allowspider to be placed in flange yoke. The protective caps are then tapped on to the cap scat provided on the bearing spigot: a

hollow mandrel is to be used forthe purpose. Subsequently, the bearing bushes should be pressed into the bores ofthe flangeyoke, rvith the inserted spider being guided by hand.'lhe bearing bush must not be canted while it is being pressed in. it should be seated firmly in the bore of the flange yoke.The locking rings must fit snugly into the ring grooves provided. To avoid any deformation" the flange yoke should be

supported during the push-in operation, ifpossible. Any adiustment necessary to take-up any play in thejoints or lack ofconcentricity should be carried out at the same time (permissible tolerance +/- 0.05 mm). Play and press lit. are compensatedfbr by using locking rings ofdifferent thickness.

DRW.No. 20540-00612 ( 415 |GelenkwellenwerkStadtilmGmbH WeimanscheStrasse56 D-99326StadtilmTel +4936296400Fax*493629800002 [email protected] Pageiof4

G€TU€SOn propshafts with split bearing eye the spider should be inserted in the flange yokes complete and bolted together with thecorresponding bearing caps. The bolts should be tightened to the recommended torque depending on the dimension and

st¡ength ofthe bolt. Play is adjusted by using endjoumal bearing disks or distance-rings ofdifferent thickness rvithin thebearing sleeve.

Ifthe profile length-compensatingioint is to be replaced, the connecting weld betrveen tube and proflle part has to be

separated. The separation should preferably be performed on a lathe, with the welding seam to be recessed completelythrough (Fig.).In every case, the replacement should involve both hubs and splined shafts, as these parts are manufactured in pairs. Duringassembly, the splined shaft should be ioined to the tube; a fit of 0, I ... 0,3 mm to be provided to avoid any tack welds. Therotational inaccuracy should not exceed 0,5 mm after the push-in operation.At the same time. care must be taken in the assembling process that the inner yoke drivers lie within one plane and thatmisalignment does not exceed the admissible angle of 3".

Fig. 8 , lathe tool

t/,/ centenngSplined section

For a perfect weld to be ensured there are ceftain technological prerequisites to be met, concerning weld preparation and thewelding operation itself -

It is essential. in order to comply with welding classilication DIN 8563 -85 I f l, that we are consulted prior to any weldingbeing carried out on propshafts, or have the rvelding done in a workshop, qualified and having the certification fbr such

rve lding.Once the trvo half sha11s have been completed, they should be assembled in the profile length-compensating joint. resulting inthe complete propshaft. Subsequently, the propshaft should be aligned; admissible run out must not exceed 0,5 mm. Anyrepair of propshafts (replacement of complete spiders and profile length-compensating.joint) rvill usually require subsequentbalancing.Inadequatelv balanced propshafts may cause harmiul vibrations and excessive stresses af'f'ecting their proper operation.D-vnamic balancing is therefore essential for propshafts at speeds in excess of 500 rpm. The test speed should exceed themaximum operating speed. Balancing to be in accordance with DIN ISO 1940:

balance quality level G 40 - propshafts used fbr general applicationbalance quality level G 16 - propshafts used for special applications.

CIn the flnal visual inspection, particular attention should be given to the all-round smooth movement ofioints, axialmovement of the length-compensating joint. and the perfect seating of the locking rings.

lf local workshop f-acilities are unsuitable lbr proper repairs (lacking the balancing equipment, for example, or theauthorísation for weldingjobs) users should contact one ofour service workshops or our after-sa1es service department, whor.vill be pleased to assist you.

Gelenkwellenwerk Stadtilm GmbHWeimarische Stra8e 56D-99326 StadtilmGermany/ DeutschlandPhone: ++49 3629 640 0Fax: ++49 3629 80 00 02http : //wu,'rv. qerves. de

DRW.No. 20540-00612 ( 515 |-Mail: [email protected] WeimarischeStrasse56 D-99326StadtilmTel *4936296400Fax+493629800002 [email protected] Pageroi+