M02御城池 OL - Imabari...Title M02御城池_OL Created Date 2/2/2014 3:10:04 PM

IMABARI Office 09

Transcript of IMABARI Office 09

New

s | 1

6

MEET NEWS 9th Issue

NEW-0006E(16-4)

190 EmployeesA propeller manufacturing capacity of 6,000 tons per year

Changzhou Zhonghai Marine Propeller Co., Ltd

OPERATING BASE

News from MHI-MME Offices Abroad

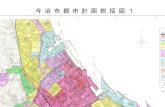

Head, Imabari Office-Tetsuya Yamamoto The Imabari Office was established in 2012 to provide customer support for our products, and we are now entering our fifth year. We are located in Imabari, Ehime Prefecture, within the Hirobishi Sangyo Y.K. Imabari office and directly opposite Oshinden Park. Imabari is famous throughout Japan for its Imabari towels, yakitori (grilled chicken served on skewers), and Barysan, the local mascot character. However, Imabari is also famous as one of the largest maritime cities in Japan and even on a worldwide level, where maritime related industries such as the shipping industry, shipbuilding industry, and the ship machinery industry have gathered. Imabari boasts approximately 65 compa-nies in the ocean-going shipping business while the number of ocean-go-ing vessels belonging to ship-owners in Imabari is said to amount to more than 30% of the total number of such vessels in Japan. Imabari is also one of Japan’s leading shipbuilding hubs and altogether

the group companies with bases in Imabari build more than 30% of the ships made in Japan. With so many ship-owners and shipbuilding yards here in Imabari, we are able to take advantage of sharing the same location as so many of our clients. We engage with them directly, face-to-face, and take care to be thorough in our dealings with them. Every year we hold the Imabari User Conference and use it as an opportuni-ty to exchange information with many clients. We intend to continue to support our clients by being a familiar presence to them.

Imabari City Hall (Propeller made by MHI-MME)

Imabari Castle

Oshinden Park

G l o b a l N e t w o r k

Changzhou Zhonghai Marine Propel-ler Co., Ltd (CZZH) is a company in Changzhou in China’s coastal province of Jiangsu that started up as an ingot manufacturer in 1992. CZZH began making propellers from 2006. Seizing on the expansion of China’s shipbuilding industry as an opportunity to grow, CZZH began operation of its new factory in 2014. Currently the company has 190 employees and a propeller manufacturing capacity of 6,000 tons per year. For MHI-MME, propellers are the product with the longest history. In 1904 we became the first company in Japan to start the manufacture of propellers and since then we have produced and delivered more than 5,000 propellers to our clients. In October 2014, MHI-MME and

concluded a licensing agreement for the manufacture and selling of propel-lers. Through the combined effect of our company’s technology and CZZH’s competitive edge in manufac-turing, orders in China have been piling up since just after the agreement was concluded. We have succeeded in expanding sales of the Mitsubishi Heavy Industries Marine Machinery and Engines brand. We intend to aim for further expanding sales of propeller products and strengthening our brand power in the Chinese market through our excellent partner-ship with CZZH.

IMABARI Office

(Left) Mr. Yamamoto, head of the Imabari Office

LICENSEE PRODUCING PROPELLERSIN CHINA

For inquiries, contact:Mitsubishi Heavy Industries Marine Machinery & Engine Co., Ltd.16-5 Konan 2-chome, Minato-ku, Tokyo 108-0075(Mitsubishi Heavy Industries Building)E-mail: [email protected] URL: www.mhi-mme.com

Mitsubishi Marine Energy & Environment Technical Solution-System

Only One to the Seas of the World

099th IssueApril 2016

Hybrid MET TurbochargerReceives an Award of Excellencefor Energy-EfficiencyJMF President’s Award of the Energy Efficient Machinery AwardsHosted by the Japan Machinery Federation

TOPICS

SPECIAL FEATURES 1

MHI Products Celebrating AnniversariesSPECIAL FEATURES 2

Interview

Technology Supporting IMOTier III NOx Emission RequirementsLow-Pressure EGR / Low-Pressure SCR

Electro-Hydraulic Steering Gears (80th Anniversary)UE Engines (60th Anniversary)MET Turbochargers (50th Anniversary)

Clarksons Research (U.K.)

Mr. Stephen Gordon

LaunchingChallenges.

TOP

MES

SAG

E | 0

3

P10 - 13

C O N T E N T S TOP MESSAGE

P03Message from the President & CEO

TOPICS

It is because the market is unstable thatwe will make sure to give attention to the basics.

Hybrid MET Turbocharger Receives an Award ofExcellence for Energy-EfficiencyJMF President’s Award of the Energy Efficient Machinery AwardsHosted by the Japan Machinery Federation

MET 37 SRC Electro-Assist Turbocharger CompletedRemote Monitoring of the Condition of Engines by LC-A“Passengers’ reactions have definitely changed.”Shipowner Interview of Vessel Retrofitted with a Retractable Fin Stabilizer Mr. Panagiotakis, Owner, Theologos P., Fast Ferries (Greece)

FY2016 Planned Exhibition ListSEA JAPAN 2016/CIMAC/Posidonia/SMM Hamburg

User Conference Held in Imabari

P04 - 05SPECIAL FEATURES 1

Technology Supporting IMOTier III NOx EmissionRequirementsLow-pressure EGR / Low-pressure SCR

P14 - 15SPECIAL FEATURES 2

Changzhou Zhonghai Marine Propeller Co.,Ltd.

P16MHI-MME Licensees

Imabari Office

P16News from MHI-MME Offices in JapanMitsubishi Marine Energy & Environment Technical Solution-System

VOL.09April 2016, MEET News 9th IssueMitsubishi Heavy Industries Marine Machinery &Engine Co., Ltd.16-5 Konan 2-chome, Minato-ku, Tokyo108-0075 (Mitsubishi Heavy Industries Building)

APRIL

Innovationin Hybrids.Our mission was to develop hybrid tu rbochargers̶which generate electricity using exhaust gas̶ for large ships. In essence, this meant overcoming issues related to speed, power and size. In other words, i t meant the development of an efficient p o w e r g e n e r a t o r c a p a b l e o f high-speed rotation and a large power output in a compact design. The unprecedented challenge was realized by downsizing the power generator and changing the structural design of the turbocharger. It was innovative technology in which the generator was built into the turbocharger. The world’s first practical hybrid turbocharger, MET83MAG, is currently installed on s e v e n b u l k c a r r i e r s . T h e MET66MAG-VTI, our latest hybrid turbocharger wi th e lect ro -assist function and variable turbine inlet ( V T I ) , i s i n o p e r a t i o n o n s i x state -of- the -ar t car carr iers. The innovat ion in hybrids began with challenging the unknown.

MHI Products Celebrating AnniversariesElectro-Hydraulic Steering Gears (80th Anniversary)UE Engines (60th Anniversary)MET Turbochargers (50th Anniversary)

P06 - 09Interview

Mr. Stephen GordonManaging DirectorClarksons Research (U.K.)

Messagefrom the President and CEO

The shipbuilding market is expected to experience a

slowdown in new orders for the near term. This is an

adverse effect of the last-minute demand that was created

before the enforcement of Tier III NOx emission limits in

January this year as well as the slowdown of the Chinese

economy. There are also concerns that international

political and economic upheavals may occur, such as a euro

crisis, refugee crisis or terrorism.

It is because the market is unstable that we will make sure

to give attention to the basics this year.

First, there is customer-centricity. It is the customer that is

the most important to us, and we will make sure that

sufficient follow-up will be carried out to ensure that the

products and services we delivered to our customers are

proving useful. We will also visit our customers more than

ever to hear their comments and opinions, which we will

feed promptly back into our operations.

Then, there are our technological capabilities. The value of

our existence is to continually stay one step ahead of our

competitors in terms of the performance and reliability of

our products. We will share technological capabilities with

the comprehensive machinery manufacturer, Mitsubishi

Heavy Industries, and commit to new product and

technology development as well as the further boost of the

performance and reliability of our products.

We are happy to report that the first 6UEC 50LSH, a new

engine that was launched last year, is operating extremely

well in service. Onboard testing of the low-pressure EGR

that meets Tier III requirements is also going well, and the

low-pressure EGR is awaiting the arrival of future business

opportunities.

It is because the market environment is unstable that we

will give attention to the basics, listen to the opinions of

our customers and work tirelessly to improve and enhance

our technological capabilities. This is the course that

MHI-MME should follow at this time.

It is because the market is unstablethat we will make sure to giveattention to the basics.

President & CEO

Kazuo Soma

SPEC

IAL-

FEAT

URES

1 | 0

5

SPEC

IAL-

FEAT

URES

1 | 0

4Technology for IMO NOx TierⅢSPECIAL FEATURES 1

Technology Supporting IMO Tier III NOx Emission Requirements

In a low-pressure EGR system, a portion of the exhaust from an engine is recirculated to the engine. It suppresses the genera-tion of thermal NOx by changing the engine’s internal combus-tion conditions.MHI-MME’s EGR system was developed with support from ClassNK’s Joint R&D with Industries and Academic Partners scheme. It recirculates low-pressure exhaust from an engine turbocharger outlet to the turbocharger intake gas. It has a simpler system configuration and is more compact than a high-pressure EGR system, which utilizes the high-tempera-ture, high-pressure exhaust that has not passed through a turbocharger. Other advantages are that it keeps both initial and running costs lower.Reduction of NOx emissions to Tier III levels were thought extremely difficult to achieve using only an EGR system. However, it has been confirmed possible during development using a test engine. In April 2015, the MHI-MME EGR system was installed on a 6UEC 45LSE-Eco-B2 engine at Kobe Diesel Co., Ltd. for shop testing. Confirmation was made that the desired performance could be achieved as planned. This included NOx emission levels and a less-than 1% loss of fuel efficiency as compared with the Tier II version. The engine received a certificate of conformity to Tier III requirements.In August 2015, test installation was made on the 6UEC 45LSE-Eco-B2 engine of the 34,000 DWT bulk carrier Dream Island (shipowner: Shikishima Kisen K.K.) built by The Hakodate Dock Co., Ltd. Confirmation was made in onboard testing that the desired performance could also be achieved as planned.This is the first time worldwide that a Tier III-certified low-pres-

sure EGR system for low-speed marine diesel engines was installed on a ship. In regards to the long-term durability testing currently taking place, verification is also being made of the system’s actual operability (e.g. logistics and operation) with the cooperation of Shikishima Kisen K.K., NYK Bulk & Projects Carriers Ltd.—which operates the ship—and Nippon Yusen Kabushiki Kaisha. Overall optimization of the system will be carried out in preparation of future business talks.

IMO NOx Tier III is a set of emissions requirements applied to vessels whose keels are laid on or after January 1, 2016, that has taken effect in Emission Control Areas (ECAs). NOx ECAs have so far been established only in North America and parts of the Caribbean Sea. However, Europe and other areas where Sox ECAs are established are being considered for future addition. It is an extremely major environmental regulation that may also become a requirement for ships operating outside of North America. It requires the reduction of NOx emissions by approximately 76% in comparison to Tier II requirements.MHI-MME has been developing two solutions to deal with IMO NOx Tier III: low-pressure EGR and low-pressure SCR. The following is an introduction of our efforts in regards to these two technologies supporting IMO NOx Tier III emission requirements.

The low-pressure EGR and low-pressure SCR systems introduced here can, of course, be installed on the UE engines developed by MHI-MME. What is more, the simplicity of the systems enables installation on the brand engines manufactured by other companies.MHI-MME will contribute to the preservation of the global environment by widely popularizing the excellent performance of the low-pressure EGR and low-pressure SCR systems. We will also continue to work towards further enhancement of the performance and reliability of the systems as well as expand sales. Our commitment is to ensure that MHI-MME will meet the expectations of customers around the world.

The World’s First Low-Pressure EGR SystemInstalled in a Bulk Carrier Built by Hakodate Dock;Currently Undergoing Durability Testing

Low-pressure EGR system (concept diagram) Onboard installation during SCMD development

Unlike the EGR system, which suppresses the generation of NOx by changing an engine’s internal combust ion conditions, the low-pressure SCR system uses a catalyst to carry out after-treatment (denitration) of NOx in engine exhaust.Since 2007, MHI-MME participated from the beginning in the Super Clean Marine Diesel (SCMD) R&D Project, until the conclusion of onboard testing in 2012. The Project was initiated and overseen by the Japan Ship Machinery & Equipment Assoc iat ion , promoted by The Nippon Foundation and led by the Ministry of Land, Infrastructure, Transportation and Tourism. MHI-MME fully incorporated the denitration technology cultivated by Mitsubishi Heavy Industries in its land-based plants, etc., and installed a low-pressure SCR system, which carried out denitration of all exhaust gas, on an 88,000 DWT coal carrier (main engine: 6UEC 60LS II) built by Oshima Shipbuilding. A denitration rate of over 80% under full-load conditions in E3 mode was confirmed through the onboard testing.Long-term operation of the system, comparable to actual onboard operation, was later carried out using a land-based test plant to carry out quantitative development related to durability and catalyst life. The low-pressure SCR system for low-speed, two-stroke marine engines was completed by integrating the results of such development.A certificate of conformity to Tier III requirements has not been obtained because the IMO requirements were still u

nder discussion and being formulated during the SCR system’s development under the SCMD R&D Project. However, it was the first time in the world that a low-pressure SCR system was installed on an onboard low-speed engine.As for the UE engine, application on small engines with relatively high exhaust gas temperature is intended, and we are primarily dealing with inquiries in China.

<Glossary>IMO: International Maritime OrganizationNOx: Nitrogen OxidesECA: Emission Control Area

EGR: Exhaust Gas RecirculationSCR: Selective Catalytic ReductionSOx: Sulfuric Oxides

Development Concept・To develop an unrivalled low-pressure EGR system・To recirculate low temperature, low-pressure exhaust gas exiting the turbocharger; to recommend gas branch on the rear flow side of the exhaust gas economizer・To realize the simple configuration and control enabled by a low-pressure system; to attain maximum downsizing・To achieve overwhelming superiority over other systems through the low initial costs and running costs that a simple system makes possible・To realize low costs in the water treatment system for purifying scrubber water through maximum utilization of conventional technology・To enable installation in not only UE engines but also engines manufactured by other companies

As installed on the bulk carrier Installed water treatment system

A NOx Removal Efficiency of 80% of all ExhaustEmissions AchievedOnboard Testing for Low-Speed Two-StrokeMarine Engines Completed

I n t e r v i e w

INTE

RVIE

W | 0

7

INTE

RVIE

W | 0

6I n t e r v i e wINSIGHT & FORESIGHT

— Today, we would like to ask you several quest ions about market status. We understand that year 2015 was historical tough market for new sh ipbui ld ing contracts. Could you tell us statistics easily showing the status of the year 2015?

Mr. Stephen GORDON: In 2015, there

was 37 million CGT of deliveries, up

marginally from 35.1 million CGT in

2014 but down 30% from a peak of 53.1

million CGT in 2010. China (35.1%)

re-took top position in CGT terms from

Korea (34.6%) followed Japan (18%).

In terms of ordering, we had a total of

1,306 vessels, 98 million DWT and 33.8

million CGT down from 121 million

DWT in 2014 and 178 million DWT in

2013. From my perspective, last year was

the lowest ordering year since 2009 and

quite a challenging year.

Particularly, it was a very challenging

year for bulk carriers. The bulk carrier

market has shown a strong slowdown

because of the continued delivery of ships

following orders booming in 2014 and

also because of the slowdown in the

trade, specifically China. In China, coal

imports were down around 30%. More

interesting statistics which have just been

re l eased show that Chinese s tee l

production in the last year fell for the

first time since 1981.

The conta iner sh ip market a l so

experienced a significant slowdown,

particularly in the second half of the year.

The start of the year was quite busy and

a lot of large post-Panamax container

ships were ordered. So, actually, the

annual total of ordering in tonnage terms

was up quite significantly for the first

half of the year. However, it did slow

down towards end of the year. This

slowdown was caused by concerns from

the demand s ide about the world

economy such as a decelerating in

international trade, and a declining

charter and freight rate.

Tanker ordering was steady. In fact, the

tanker market was up by around 70% in

dead weight terms and in numeric terms

up by around 70 orders to just over 450.

Th i s was d r i v en by the g rowing

international oil trade because of low oil

prices, and so the tanker market had its

best year since 2008 with a significant

amount of cash coming to ship owners.

Offshore markets which had been good

business for shipyards in the previous 3

or 4 years took a significant hit because

of the slump in the price of oil. That

resulted in utilization of rigs globally

dropping from around 95% to 73% of

the end of the last year and very limited

number of ordering in offshore markets.

Ro-Ro ferry/Cruise Business had a

positive year, particularly for the cruise

section. We had a record order book both

in terms of tonnage and value for cruise

markets.

Gas related markets were both tough

and good depending on the vessel type.

As for LNG, although there were some

projects, the volume was smaller than the

previous year. LPG gas also experienced a

slowdown in ordering. However, VLGC

is still performing very well, and had a

very large order book. So, in terms of

contracting, I think that it was quite a

challenging year over all.

One point we would make is that there

was a lot of addi t ional order ing,

particularly in the second half of the year,

in response to the Tier III standards to

meet the deadline. Moreover, we expect

that there some more orders were made

before the Tier III deadline which have

not yet been reported. However, this is

one of the reasons why we expect that

this year wil l be quiet in terms of

ordering, particularly the first half.

— I think that Japanese yards are doing well securing their contracts in 2015. What is your overall forecast for new shipbuilding contracts for 2016/17?

Mr. Stephen GORDON: For 2016, we

would expect probably a lower volume

than 2015. We think the first half of

2016 will be very quiet and overall

volume for the year will be below 2015.

Of course sh ipbui ld ing i s a lways

unpredictable, but that seems to be the

consensus at the moment. We do expect a

recovery in demand in the long term but

the timing is very uncertain. It will take

t ime fo r th e sh ipp ing marke t to

recuperate, and also to adjust global

shipping capacity, which is the challenge

for the industry.

In 2015, Japan was the only one of the

'big three' shipbuilding nations to see

ordering volumes increase year-on-year, up

10% million GT terms to 19.7 million

GT. Japan was the largest ordering nation

from an owner perspective, particularly

for bulk carriers, and of course they have

many loyal clients both internationally

and domestically. Also, the currency rate

changes were helpful for Japanese yards

last year.

— Regarding the fuel oil price, we are experiencing very low prices and it is affecting the new shipbuilding market and offshore markets so much. Do you think that the current situation will continue for several more years?

Mr. Stephen GORDON: We expect the

oil price to recover in the medium to long

term. However, in terms of offshore

cycle, we do not expect a bounce in terms

of the recovery. It seems that it may take

several years to recover because of the oil

price and also there is global surplus

capacity. These are our main challenges.

— Regarding oil prices, some people say that $60/Barrel or $70/Barrel will be the break even point.

Do you think it will be recovering in that area?

Mr. Stephen GORDON: I think the oil

price is inherently volatile. We would

expect the recovery to a level significantly

above today’s price, but the timing and

scale are very difficult to anticipate. It is a

very complicated issue, considering shale

oil production in US, Saudi Arabian

product ion output l eve l , I ran ian

sanctions, and the global demand. So I

think that an accurate forecast of oil prices

is not possible, but certainly we would

expect recovery from the current level.

— Regarding Tier III regulations, I think some ship owners seem very reluctant for higher CAPEX and OPEX as result of this regulation. What do you feel for this regulation?

Mr. Stephen GORDON: CAPEX should

be considered of course, particularly in

the current challenging market.

In today’s market, CAPEX is always an

issue; ship owners and shipyards will

need to discuss and move forward with

the correct solutions.

— Do you think that this additional cost from Tier III should be reflected in freight rates?

Mr. Stephen GORDON: That is a

difficult question, because there are a lot

of issues. There are many factors for

setting freight rates, such as the market

cycle from the demand side, circumstances

around the negotiation, commercial terms

as well as technical competitiveness. Since

there are so many issues which need to be

taken into consideration, it is very

difficult to anticipate freight rates in a

very specific element of commercial

framework.

— It’s a very difficult issue as to who should absorb this additional cost. So, this is challenging in any sector such as ship owner, as well as shipyard, machinery side. Do you think that there might be some kind of answer for this issue?

Mr. Stephen GORDON: Historically,

things are changing all the time. Currency

price, market cycle, supply demand, steel

prices, interest rates, all of the factors for

price are changing all the time. I think

that the price will recuperate accordingly

over time in relation to those factors and

it is difficult to predict the price by those

specific issues.

— I would like to change the topic. Iranian sanctions will be released. What could you imagine as the impact on new shipbuilding orders from this?

Mr. Stephen GORDON: There are

ranges of forecast regarding the Iranian

oil production, from additional output in

the short medium terms 2-300,000

barrel/day up to close to a million/barrel.

Also, there are a number of large shipping

companies in Iran which will require new

building. Although it is still relatively early

to quantify the potential of the Iranian

impact, generally speaking, there are

clearly opportunities for marine and oil

& gas business internationally.

— Could we expect some more orders in tankers sector?

Mr. Stephen GORDON: Certainly the

fleet strategy of large shipping companies

in Iran will go forward and we would

expect that there will be some new

building activities.

— If we include Iranian crude oil, the quantity will be increased. Considering current low price of oil and new Tier III regulations, what do you imagine for the scenario of fuel oil for the large vessels?

Mr. Stephen GORDON: The low oil

price makes LNG as fuel less persuasive.

However, in a long term view such as the

next 10 years, or in the case of ships,

over 20 to 25 years, oil and gas price may

settle down. LNG as a fuel has a number

of advantages and also has a number of

disadvantages. Firstly I think it is

important to take a long term view when

we talk about fuel prices.

Secondly, I think regulation regarding

emissions globally is something that will

be on the political agenda over the next

10 to 20 years, and we feel that regulations

inc luding emiss ions wi l l increase

significantly in the long term.

— You mentioned that steel production in China is very low. The recession in China including steel production is having a large impact on this market. Could you tell me some key factors or key words to recover the market from this situation?

Mr. Stephen GORDON: I think China is

moving to a more mature phase of its

economy. Rather than talking about the

recession, we should be thinking that

China is moving into a more mature

economy, having gone through its

developing phase.

In a more mature economy, new

commodities and cargos will be needed,

for example, the cruise sector in China is

doing very well at the moment.

So, I think as China matures into a

different type of economy, then that will

create new opportunities for shipping

although it might not be such aggressive

growth for cargo.

I think there is still potential for growth

in the market in the long term view,

considering that 85% of all international

trade is carried by ships and that there is

totaled 10.8 billion tonnage which is

equivalent to 1.5 tonnes of trade per

single person on the planet. The world

trade has grown quite consistently and

steadily for nearly 50 years, experiencing

only one or two interruptions, such as the

financial crisis.

However, of course in the short term,

we have a business cycle to deal with,

some surplus capacity and the Chinese

economy maturing. These are causing a

decl ine in growth rates in certain

economies or certain trades and making

the markets challenging.

I think that shipbuilding surplus

capacity is a problem both in China,

Korea and Japan and I think that is

something challenging for the marine

industry for this next couple of years.

— From a broking or funding point of view, can you find some good signs for the future?

Mr. Stephen GORDON: I think that

there are a lot of challenges across the

markets.

However, we are seeing a lot of buying

interests in capesize at the moment, a lot

of well established and successful ship

owners are investigating capesizes today.

We have seen 15 to 20 more capesize sold

in last 4 or 5 weeks.

This is because those owners believe

that this is an attractive point in the cycle

to acquire ships and they feel the market

will recover in the long term, and I think

that is a good signal.

Also, the financial landscape in the

shipping world is very different today

from pre-financial crisis. It is very

different in terms of the number and

types of banks involved, and terms and

nature of lending are different from pre-

financial crisis.

— What is the biggest difference between today and pre-financial crisis?

Mr. Stephen GORDON: I think we have

s m a l l e r n u m b e r o f b a n k s , m o r e

conservative terms, more regulations,

more focus on certain top tier owners,

more export credits, and less private

equity which was very active in 2013 and

2014.

— My last question is about the current over-capacity situation. Do you think this can be regulated in 2 or 3 years?

Mr. Stephen GORDON: Clearly the

market i s very chal lenging today,

however, marine industry plays an

incredibly important role in the world

economy. If you believe in long term

development of world economy and

globalization, then the marine industry

will continue to have an important role

to play. However, the cycle of timing is

very difficult.

Apart from that, I think there are a lot

of exciting opportunities in the marine

industry, particularly from technology, IT,

au tomat ion , and the innova t ion

perspective, such as the advancement

seen in IT and satellite connections. We

feel that there are a lot of exciting

opportunities for innovation that can be

driven by the marine equipment sector as

well as other parts of the shipping

industry. Those are exciting opportunities

in the short term when the fleet market is

challenging.

MHI-MME has a great potential as one

of the worldwide technology provider,

and we believe that you have a great

opportunity in this field, too.

— Thank you, Steve san.

[CLARKSONS RESEARCH]

Interviewee: Mr. Stephen GORDON

Managing Director, Offshore and Energy, Shipping and Trade, Valuations at CLARKSONS RESEARCH. Clarksons Research is the part of the Clarksons Group, the world's largest provider of shipbroking and banking services through Clarksons Platou.

Managing Director

Mr. Stephen GORDON

2015 saw the slowdown in the bulk carrier, container ship, and offshoremarkets due to China's trade decrease and the fall of the fuel oil price.

A severe outlook in the markets continues overall in 2016-2017.

With 85% of all international trade being carried by ships,The innovation perspective in technology, IT, and automation forecaststhere are a lot of opportunities in the marine industrywhich will activate the currently severe new shipbuilding market.

I n t e r v i e w

INTE

RVIE

W | 0

9

I n t e r v i e wINSIGHT & FORESIGHTIN

TERV

IEW

| 08

The issue of Tier III is to be solved by ship owners and shipyards together.China is moving into a more mature economy, rather than the recession,after the development. Such economy will create new opportunities,such as in the cruise sector.

— Today, we would like to ask you several quest ions about market status. We understand that year 2015 was historical tough market for new sh ipbui ld ing contracts. Could you tell us statistics easily showing the status of the year 2015?

Mr. Stephen GORDON: In 2015, there

was 37 million CGT of deliveries, up

marginally from 35.1 million CGT in

2014 but down 30% from a peak of 53.1

million CGT in 2010. China (35.1%)

re-took top position in CGT terms from

Korea (34.6%) followed Japan (18%).

In terms of ordering, we had a total of

1,306 vessels, 98 million DWT and 33.8

million CGT down from 121 million

DWT in 2014 and 178 million DWT in

2013. From my perspective, last year was

the lowest ordering year since 2009 and

quite a challenging year.

Particularly, it was a very challenging

year for bulk carriers. The bulk carrier

market has shown a strong slowdown

because of the continued delivery of ships

following orders booming in 2014 and

also because of the slowdown in the

trade, specifically China. In China, coal

imports were down around 30%. More

interesting statistics which have just been

re l eased show that Chinese s tee l

production in the last year fell for the

first time since 1981.

The conta iner sh ip market a l so

experienced a significant slowdown,

particularly in the second half of the year.

The start of the year was quite busy and

a lot of large post-Panamax container

ships were ordered. So, actually, the

annual total of ordering in tonnage terms

was up quite significantly for the first

half of the year. However, it did slow

down towards end of the year. This

slowdown was caused by concerns from

the demand s ide about the world

economy such as a decelerating in

international trade, and a declining

charter and freight rate.

Tanker ordering was steady. In fact, the

tanker market was up by around 70% in

dead weight terms and in numeric terms

up by around 70 orders to just over 450.

Th i s was d r i v en by the g rowing

international oil trade because of low oil

prices, and so the tanker market had its

best year since 2008 with a significant

amount of cash coming to ship owners.

Offshore markets which had been good

business for shipyards in the previous 3

or 4 years took a significant hit because

of the slump in the price of oil. That

resulted in utilization of rigs globally

dropping from around 95% to 73% of

the end of the last year and very limited

number of ordering in offshore markets.

Ro-Ro ferry/Cruise Business had a

positive year, particularly for the cruise

section. We had a record order book both

in terms of tonnage and value for cruise

markets.

Gas related markets were both tough

and good depending on the vessel type.

As for LNG, although there were some

projects, the volume was smaller than the

previous year. LPG gas also experienced a

slowdown in ordering. However, VLGC

is still performing very well, and had a

very large order book. So, in terms of

contracting, I think that it was quite a

challenging year over all.

One point we would make is that there

was a lot of addi t ional order ing,

particularly in the second half of the year,

in response to the Tier III standards to

meet the deadline. Moreover, we expect

that there some more orders were made

before the Tier III deadline which have

not yet been reported. However, this is

one of the reasons why we expect that

this year wil l be quiet in terms of

ordering, particularly the first half.

— I think that Japanese yards are doing well securing their contracts in 2015. What is your overall forecast for new shipbuilding contracts for 2016/17?

Mr. Stephen GORDON: For 2016, we

would expect probably a lower volume

than 2015. We think the first half of

2016 will be very quiet and overall

volume for the year will be below 2015.

Of course sh ipbui ld ing i s a lways

unpredictable, but that seems to be the

consensus at the moment. We do expect a

recovery in demand in the long term but

the timing is very uncertain. It will take

t ime fo r th e sh ipp ing marke t to

recuperate, and also to adjust global

shipping capacity, which is the challenge

for the industry.

In 2015, Japan was the only one of the

'big three' shipbuilding nations to see

ordering volumes increase year-on-year, up

10% million GT terms to 19.7 million

GT. Japan was the largest ordering nation

from an owner perspective, particularly

for bulk carriers, and of course they have

many loyal clients both internationally

and domestically. Also, the currency rate

changes were helpful for Japanese yards

last year.

— Regarding the fuel oil price, we are experiencing very low prices and it is affecting the new shipbuilding market and offshore markets so much. Do you think that the current situation will continue for several more years?

Mr. Stephen GORDON: We expect the

oil price to recover in the medium to long

term. However, in terms of offshore

cycle, we do not expect a bounce in terms

of the recovery. It seems that it may take

several years to recover because of the oil

price and also there is global surplus

capacity. These are our main challenges.

— Regarding oil prices, some people say that $60/Barrel or $70/Barrel will be the break even point.

Do you think it will be recovering in that area?

Mr. Stephen GORDON: I think the oil

price is inherently volatile. We would

expect the recovery to a level significantly

above today’s price, but the timing and

scale are very difficult to anticipate. It is a

very complicated issue, considering shale

oil production in US, Saudi Arabian

product ion output l eve l , I ran ian

sanctions, and the global demand. So I

think that an accurate forecast of oil prices

is not possible, but certainly we would

expect recovery from the current level.

— Regarding Tier III regulations, I think some ship owners seem very reluctant for higher CAPEX and OPEX as result of this regulation. What do you feel for this regulation?

Mr. Stephen GORDON: CAPEX should

be considered of course, particularly in

the current challenging market.

In today’s market, CAPEX is always an

issue; ship owners and shipyards will

need to discuss and move forward with

the correct solutions.

— Do you think that this additional cost from Tier III should be reflected in freight rates?

Mr. Stephen GORDON: That is a

difficult question, because there are a lot

of issues. There are many factors for

setting freight rates, such as the market

cycle from the demand side, circumstances

around the negotiation, commercial terms

as well as technical competitiveness. Since

there are so many issues which need to be

taken into consideration, it is very

difficult to anticipate freight rates in a

very specific element of commercial

framework.

— It’s a very difficult issue as to who should absorb this additional cost. So, this is challenging in any sector such as ship owner, as well as shipyard, machinery side. Do you think that there might be some kind of answer for this issue?

Mr. Stephen GORDON: Historically,

things are changing all the time. Currency

price, market cycle, supply demand, steel

prices, interest rates, all of the factors for

price are changing all the time. I think

that the price will recuperate accordingly

over time in relation to those factors and

it is difficult to predict the price by those

specific issues.

— I would like to change the topic. Iranian sanctions will be released. What could you imagine as the impact on new shipbuilding orders from this?

Mr. Stephen GORDON: There are

ranges of forecast regarding the Iranian

oil production, from additional output in

the short medium terms 2-300,000

barrel/day up to close to a million/barrel.

Also, there are a number of large shipping

companies in Iran which will require new

building. Although it is still relatively early

to quantify the potential of the Iranian

impact, generally speaking, there are

clearly opportunities for marine and oil

& gas business internationally.

— Could we expect some more orders in tankers sector?

Mr. Stephen GORDON: Certainly the

fleet strategy of large shipping companies

in Iran will go forward and we would

expect that there will be some new

building activities.

— If we include Iranian crude oil, the quantity will be increased. Considering current low price of oil and new Tier III regulations, what do you imagine for the scenario of fuel oil for the large vessels?

Mr. Stephen GORDON: The low oil

price makes LNG as fuel less persuasive.

However, in a long term view such as the

next 10 years, or in the case of ships,

over 20 to 25 years, oil and gas price may

settle down. LNG as a fuel has a number

of advantages and also has a number of

disadvantages. Firstly I think it is

important to take a long term view when

we talk about fuel prices.

Secondly, I think regulation regarding

emissions globally is something that will

be on the political agenda over the next

10 to 20 years, and we feel that regulations

inc luding emiss ions wi l l increase

significantly in the long term.

— You mentioned that steel production in China is very low. The recession in China including steel production is having a large impact on this market. Could you tell me some key factors or key words to recover the market from this situation?

Mr. Stephen GORDON: I think China is

moving to a more mature phase of its

economy. Rather than talking about the

recession, we should be thinking that

China is moving into a more mature

economy, having gone through its

developing phase.

In a more mature economy, new

commodities and cargos will be needed,

for example, the cruise sector in China is

doing very well at the moment.

So, I think as China matures into a

different type of economy, then that will

create new opportunities for shipping

although it might not be such aggressive

growth for cargo.

I think there is still potential for growth

in the market in the long term view,

considering that 85% of all international

trade is carried by ships and that there is

totaled 10.8 billion tonnage which is

equivalent to 1.5 tonnes of trade per

single person on the planet. The world

trade has grown quite consistently and

steadily for nearly 50 years, experiencing

only one or two interruptions, such as the

financial crisis.

However, of course in the short term,

we have a business cycle to deal with,

some surplus capacity and the Chinese

economy maturing. These are causing a

decl ine in growth rates in certain

economies or certain trades and making

the markets challenging.

I think that shipbuilding surplus

capacity is a problem both in China,

Korea and Japan and I think that is

something challenging for the marine

industry for this next couple of years.

— From a broking or funding point of view, can you find some good signs for the future?

Mr. Stephen GORDON: I think that

there are a lot of challenges across the

markets.

However, we are seeing a lot of buying

interests in capesize at the moment, a lot

of well established and successful ship

owners are investigating capesizes today.

We have seen 15 to 20 more capesize sold

in last 4 or 5 weeks.

This is because those owners believe

that this is an attractive point in the cycle

to acquire ships and they feel the market

will recover in the long term, and I think

that is a good signal.

Also, the financial landscape in the

shipping world is very different today

from pre-financial crisis. It is very

different in terms of the number and

types of banks involved, and terms and

nature of lending are different from pre-

financial crisis.

— What is the biggest difference between today and pre-financial crisis?

Mr. Stephen GORDON: I think we have

s m a l l e r n u m b e r o f b a n k s , m o r e

conservative terms, more regulations,

more focus on certain top tier owners,

more export credits, and less private

equity which was very active in 2013 and

2014.

— My last question is about the current over-capacity situation. Do you think this can be regulated in 2 or 3 years?

Mr. Stephen GORDON: Clearly the

market i s very chal lenging today,

however, marine industry plays an

incredibly important role in the world

economy. If you believe in long term

development of world economy and

globalization, then the marine industry

will continue to have an important role

to play. However, the cycle of timing is

very difficult.

Apart from that, I think there are a lot

of exciting opportunities in the marine

industry, particularly from technology, IT,

au tomat ion , and the innova t ion

perspective, such as the advancement

seen in IT and satellite connections. We

feel that there are a lot of exciting

opportunities for innovation that can be

driven by the marine equipment sector as

well as other parts of the shipping

industry. Those are exciting opportunities

in the short term when the fleet market is

challenging.

MHI-MME has a great potential as one

of the worldwide technology provider,

and we believe that you have a great

opportunity in this field, too.

— Thank you, Steve san.

Shipbuilding surplus capacity is a problem both in China, Korea and Japan.Believing in long term development of world economy and globalization,

there will be much opportunities for innovation and growththat can be driven by the marine equipment sector.

TOPI

CS | 1

0T O P I C S

TOPI

CS | 1

1

HYBRID TURBOCHARGER AWARDED

Remote Monitoring of the Condition ofEngines by LC-AMHI-MME proactively supports customers’ operation control through land-based remote monitoring of the condition of engines at sea.For example, as the remote monitoring system for our UE engines, we have a partnership with Diesel United, Ltd. using the LC-A (LifeCycle Administrator) service developed by the company. It has already been adopted for use by 15 vessels.In addition to engine operational data, such as temperature and pressure levels, the system also routinely acquires and analyzes data on piston underside drain oil, etc. Functions include predic-tive diagnosis of problems and troubleshooting, and enable timely evaluations to be made onboard. It also allows the land-based remote monitoring of the condition of engines at sea by way of a data server.MHI-MME is leveraging the knowledge and technical expertise

it has cultivated over the years to routinely analyze data accumulated from engines to provide various advice related to main engine performance. Concrete measures are proposed when signs of problems are detected. Furthermore, when mechanical problems arise, causes are swiftly investigated and reported, suppressing the lifecycle costs of ships. The support of ship operation is carried out to ensure that our customers can feel at ease in using our UE engines for many years.The land-to-sea network environment has been rapidly improv-ing over recent years. MHI-MME will proactively incorporate environmental protection regulations-related technology and other new solutions for further enrichment of the remote monitoring system. We will continue to be committed to the provision of quality services to our customers.

REMOTE MONITORING BY LC-A

ELECTRIC ASSIST TURBOCHARGER COMPLETED

MET37SRC Electro-Assist Turbocharger CompletedIn the October 2014 6th Issue of Project MEET News, we reported that in an operational test carried out with the cooperation of Akasaka Diesels Limited, verification was made that an electro-assist turbocharger mounted on a 4-stroke engine was effective in reducing smoke during engine start-up and lowering fuel consumption during low-load operation. In this test, a high-speed motor was connected to the rotor of a MET22SRC turbocharger.With the aim of commercializing this function, we recently developed an electro-assist turbocharger, with a high-speed motor coupled to a MET37SRC turbocharger.The newly designed high-speed permanent magnet motor requires the use of neither lubricant nor cooling water. It can easily be retrofitted on a standard turbocharger.Stand-alone operational testing of this turbocharger was completed in February this year, and onboard testing began in March with the electro-assist turbocharger mounted on a marine diesel engine.

Hybrid Turbocharger Receives External Award“JMF President’s Award” of the Energy-Efficient Machinery AwardsHosted by the Japan Machinery Federation

MHI-MME’s hybrid turbocharger for large ships received the JMF President’s Award in the 2015 Energy-Efficient Machinery Awards hosted by the Japan Machinery Federation. In the 36th hosting of this authoritative award, our hybrid turbocharger was selected after rigorous examination of 28 machines that were entered for award consideration. The hybrid turbocharger developed by MHI-MME was recognized for its superior energy-efficiency, operational track record and progressiveness, all proven through actual installation and use on ships.The hybrid turbocharger couples MHI-MME’s large-size MET series turbocharger with a high-speed generator-motor. It utilizes engine exhaust gas from a marine propulsion diesel engine for efficient power generation. During low-load operation of the engine, the hybrid turbocharger can be used as an electric motor, doing away with the need of conventional auxiliary blowers. It can improve engine performance at the same time.Development of the MET83MAG, the world’s first and unrivalled practical hybrid turbocharger, was achieved with the generous support of ClassNK, Nippon Yusen Kabushiki Kaisha (NYK Line), Japan Marine United Corporation and Hitachi Zosen Corporation. The hybrid turbocharger has been installed on seven large bulk carriers built by Japan Marine United Corporation.Meanwhile, MET66MAG-VTI, the latest hybrid turbocharger with electro-assist function and variable turbine inlet, was developed with the generous cooperation of Mitsui Engineering & Shipbuilding Co., Ltd. and Kobe Diesel Co., Ltd. This hybrid VTI turbocharger has been installed on six large, state-of-the-art car carriers built by Shin Kurushima Dockyard Co., Ltd. and Imabari Shipbuilding Co., Ltd., and operated by NYK Line.This was the second time that MHI-MME won this award, following the Waste Heat Recovery Systems in FY2010. MHI-MME will continue to contribute to increasing the efficiency of ship operation and protection of the global environment through the provision of energy-efficient equipment solutions.

Energy-Efficient Machinery Awards JMF President’s Award

Japan Machinery Federation, FY2015

Cutaway view of the MET83MAG hybrid turbocharger Lower-half shell housingThe generator installed in the lower-half shell housing

TOPI

CS | 1

3

USER CONFFERENCE HELD IN IMABARI

EXHIBITIONS PLANNED

User Conference held in Imabari

With Rafina in the Aegean Sea as its home port, the FAST FERRIES company uses its three ferries to operate regular services to outlying islands including Andros, Tinos, and Mykonos. Of its three ferries, two are fitted with MHI-MME’s fin stabilizers. Those two ferries are both second-hand vessels made in Japan and one of them, the FAST FERRIES Andros was retrofitted with the stabilizers last year. Visitors can choose from other companies with jetfoil boats operating on the same routes as FAST FERRIES, or the option of taking a plane, so during the tourist season in summer there is always a battle amongst these companies to win customers. We spoke with Mr. Panagiotakis, who is in charge of the technical division of the FAST FERRIES company. (Interviewer: Mr. Suzuki from the Marine Machinery Equipment Section)

On Thursday, March 10, the third User Conference was held in Imabari, and we gave the attendees information about products that would be helpful in operating ship services as well as our after-service lineup. A pre-conference survey was conducted to find out what clients were most interested in. On the conference agenda were items such as the UE engine, maintenance and checkup techniques for the MET Turbocharger, leading to a lively exchange in the Q&A. The User Conference gives us the unique opportunity to hear directly from our clients. The opinions and requests we receive are shared in the company and are essential for us to develop and expand on our products and services to answer our clients’ expectations. The second Tokyo User Conference is scheduled to be held in May, and we are hoping for a large attendance.

TOPI

CS | 1

2

“Passengers’ reactions have definitely changed”Shipowner Interview, Vessel Retrofitted with a Retractable Fin Stabilizer

With Rafina in the Aegean Sea as its home port, the FAST FERRIES company uses its three ferries to operate regular services to outlying islands including Andros, Tinos, and Mykonos. Of its three ferries, two are fitted with MHI-MME’s fin stabilizers. Those two ferries are both second-hand vessels made in Japan and one of them, the FAST FERRIES Andros was retrofitted with the stabilizers last year. Visitors can choose from other companies with jetfoil boats operating on the same routes as FAST FERRIES, or the option of taking a plane, so during the tourist season in summer there is always a battle amongst these companies to win customers. We spoke with Mr. Panagiotakis, who is in charge of the technical division of the FAST FERRIES company. (Interviewer: Mr. Suzuki from the Marine Machinery Equipment Section)

“Passengers’ reactions have definitely changed”Shipowner Interview, Vessel Retrofitted with a Retractable Fin Stabilizer

Mr. Panagiotakis, Owner, Theologos P,FAST FERRIES, (Greece)

Thank you for your time today. I’d like to ask you some questions about the project carried out last year to retrofit fin stabilizers.

Q1. What was the reason that made you decide to retrofit fin stabiliz-ers on the FAST FERRIES Andros?

FAST FERRIES owns one boat (Theologos P) fitted with MHI-MME’s fin stabilizers so the deciding reason was that I already knew about their powerful ability to control the roll of a ship. I think that fin stabilizers are one marine product that is a necessity for passenger ships.

Q2. Have you asked passengers and staff working on the FAST FERRIES Andros for their response or opinions comparing the Andros with vessels not fitted with fin stabilizers?

The response from passengers is clearly different. Vessels without fin stabilizers are also in service on the same routes as the Andros. Passengers who have ever been on the Andros, or those who have heard about it, realize about our vessels either having the fin stabiliz-ers or not. So, of course, they purchase tickets for ferries with fin stabilizers so that they can enjoy a pleasant and relaxing voyage.

I’d like to share with you a certain anecdote. One day on our normal service in the Andros when the seas were a bit rough, we decided experimentally to stop using the fin stabilizers. As the effect of stopping the roll of the ship dropped off, as was to be expected, the ship started to take on a sideways roll. Because of this, the passen-gers began to wonder what had happened and everyone immedi-ately started looking outside at the ocean. In other words, the effect of the fin stabilizers was so good that even the passengers noticed it immediately. Another time, we wanted to compare what it was like using the fin stabilizers and not using them. When we stopped using them, the roll was about ± 10 degrees but when we were using the fin stabilizers this was reduced to about ± 1 degree. At the time of the fin stabilizer project, we were told that the roll would be reduced by 90% but I could feel for myself that it was higher than that. So I am extremely satisfied with how wonderful the effect is for counter-acting the roll of a ship.

Q3. Since the retrofitted Andros has been back in service, has there been any malfunctioning of the fin stabilizers?

We are using the fin stabilizers every day but we have not had any trouble at all. If anything had occurred, I would have already contact-ed your company.

Q4. How does the FAST FERRIES company evaluate the retrofitting of the fin stabilizers this time?

Overall, we are of the opinion that it was a very efficient project that didn’t require too much effort. I mean, in the initial stages of the project we just provided the essential information and data about the hull of the ship and then left everything up to your company, so from the survey of the ship to the sea trial, all the work was completed. Things such as the positioning of the fins and the reinforcement surrounding the fin stabilizers are the kind of knowhow that usually a ship owner does not have, but your company’s support was such a help to us. I am extremely satisfied with the way the entire project went.

Q5.How many points would you award out of 100?

As I am extremely satisfied, I would like to say 100 but actually it is 98. The remaining two points are for further development and expectations, so I shall take off two points for that.

Q6. I see. So what do you seek from MHI-MME in the future?

I expect your company to continue to make high quality products as you have thus far, and also I expect the development of new ideas. And I also want you to continue to make us happy.

FY2016 Planned Exhibition ListMHI-MME intends to participate in the following shows this year.

The biggest maritime show in JapanHost city: TokyoVenue: Tokyo Big SightDuration: April 13 (Wed) – 15 (Fri)Booth position: JPN-150 (In the Japan Pavilion)

SEA JAPAN 2016

Engineers will present their papersHost city: HelsinkiVenue: The Finlandia HallDuration: June 6 (Mon) – 10 (Fri)Booth position: TBC

CIMAC

International maritime exhibition held in Greece,home to many ship ownersHost city: AthensVenue: Metropolitan ExpoDuration: June 6 (Mon) – 10 (Fri)Booth position: On the right side just after the main entrance (In the Japan Pavilion)

Posidonia

The leading international maritime trade fairHost city: HamburgVenue: Hamburg MesseDuration: September 6 (Tue) – 9 (Fri)Booth position: TBC

SMM Hamburg

KOREA (KITA GYEONGNAM)

KOREA (KITA BUSAN)

KOREA (KOMEA) CHINA

HOLLAND

TAIWAN

ジャパンパビリオン / Japan Pavillion

Event Stageイベントステージ

SeminarRoom

セミナー会場A

Organisers

主催者事務局

SeminarRoom

セミナー会場B

SeminarRoom

セミナー会場D

SeminarRoom

セミナー会場C

UK

UK

DENMARK GERMANY GERMANY

Theme Zoneテーマゾーン

東5ホール / EAST HALL 5 東6ホール / EAST HALL 6

ササクラ

TERASAKI ELECTRIC /寺崎電気産業

MITSUBISHI KAKOKI KAISHA /三菱化工機

HISAKA WORKS /日阪製作所

NK

E-CHART /イーチャート

FILTREX

JSAT MOBILE Communications

Panasonic EnviromentalSystems & Engineering /

パナソニック環境エンジニアリング

YSK Systems /ワイ・エス・ケイ・システムズ

NISHIYAMA /ニシヤマ

Furukawa Electric Industrial Cable /古河電工産業電線

OptimarineJapan

Dupont-Asahi FlashSpun Products /

旭・デュポンフラッシュパンププロダクツ

STARLITE /スターライト

工業

ELEPHANTCHAIN BLOCK /

象印チェンブロック

Sanko /サンコー

RIX /リックス

COAST

NANIWA IRON WORKS /浪速鉄工

ADY /エーディーワイ

RMS MARINESERVICE COMPANY

SAWAMURAVALVE /沢村バルブ

UBE SHIPPING& LOGISTICS /宇部興産海運

Jeppesen a Boeing

RIKEN KEIKI /理研計器

YASUKAWAELECTRIC

CORPORATION /安川電機

LUKOIL MARINELUBRICANTS

KOREANREGISTER

SHINYO KINZOKUINDUSTRY /

神陽金属工業

WÄRTSILÄバルチラ

Maritime Imabari /海事都市今治

TrelleborgMarine Systems

Japan /トレルボルグ・

マリンシステムズジャパン・

Sunflame /サンフレム

NIIKURAKOGYO /新倉工業

DAIWA /ダイワ販売

HOT START /ホットスタート

NAR /日本アイ・アール TAIYO NIPPON

SANSO /太陽日酸

MARIX /マリックス SHOYO

ENGINEERING /湘洋エンジニアリング

NakanishiShoji /中西商事

SANWA

Ecochlor

HARADA /原田産業

Turbo SystemsUnited /

ターボシステムズユナイテッド

CORNES /コーンズ

KVHIndustries

SKY Perfect JSAT / スカパーJSAT

Alfa Laval /アルファ・ラバル

FURUNOELECTRIC /古野電気 KDDI

NAKAKITASEISAKUSHO中北製作所

ABB

TOMINAGA /富永物産DNV GL

UZUSHIOELECTRIC /渦潮電機

HITACHIZOSEN /日立造船

TECHCROSS

TRATEC /トラテック Qingdao

HeadwayTechnology

Nippon MaritimeDisplay /

日本船舶表示

Kashiwa /カシワテック

AquametroJapan /アクアメトロ日本

KosakaLaboratry /小坂研究所

RFD Japan /アール・エフ・ディージャパン

Miki Pulley /三木プーリ

TST /東洋信号通信社

MARLINK

Kistler Japan /日本キスラー

TOKYO KEISO /東京計装

DIESEL UNITED /ディーゼル

ユナイテッド / IHI

CBSI /シー・ビー・エス・アイ

CBSI /シー・ビー・エス・アイ

AVEVA /アヴィバBasic JapanIntergraph Japan /

日本インターグラフ

K.STERMINALS

K AND K /ケイアンドケイ

MEIYOELECTRIC /明陽電機

Panasia

TOKYO NISSHIN JABARA /東京日進ジャバラ

Nippon ElectricInstrument / 日本エレクトリックインストルメント

Japan Digital Communications /日本デジコム

SunRui MarineEnviroment Engineering THE PANAMA

MARITIME AUTHORITY

MTU Japan /MTU ジャパン

ELECTORI /エレクトリ

SaeMah

GEM CORPORATION /ジェムコーポレーション

IHS Global

Woodman Club /ウッドマンクラブ

Earth Weather /アース・ウェザー

KANSAI HAKUYO /関西舶用

SE-WONINDUSTRIES

Showa Shell Sekiyu /昭和シェル石油

JAPAN MAGNETS /ジャパンマグネット

ONOMICHIMARITIMECITY /海事都市尾道

HANEDA PIPE WORKS /羽田パイプ製造所

GASTEC /ガステック

BC TAECHANG

Marine ServicesKojima /マリンサービス児嶋

MISEC /マイセック

YAMAZAKI /山崎産業

MITSUBISHIELECTRIC /三菱電機

LGE Japan /エル. ジー.イー.ジャパン

ZHOUSHAN IMC-YONGYUESHIPYARD & ENGINEERING

NMK Coatings / NKMコーティングス

ONURSANSAFETY

SANYO TRADING /三洋商事

The Japan TitariumSociety /日本チタン協会

SANKO ELECTRIC /三工電機

Wuxi BrightskyElectronic

Nippon Kaiji Kentei Kyokai /日本海事検定協会

Sanko Tsusho /三興通商

Port-IT

JAPAN MORECULAR SERVICE /ジャパンモレキュラーサービス

TIS

CAD CENTER /キャド

センター

The Japan Steel Works /日本製鋼所

TSURUMIMANUFACTURING /

鶴見製作所

TrafagJapan

KEMEL COMPANYa division of EAGLEINDUSTRY /イーグル工業KEMELカンパニー

Kawase /川瀬産業

HARVEST /ハーヴェスト

Meiho Electronics /名豊電機

KITO /キトー

RUD LiftingJapan /ルッド

リフティングジャパン

Nippon Export and Investment Insurance /日本貿易保険

KranendonkJapan

NHK SPRING /日本発条

BassSoftware

De Nora Water Technologies

TÜV SÜD Japan /テュフズードジャパン

Akzo Nobel / アクゾノーベルInternational Paint / インターナショナルペイント

JIANGSU JINGCHENGMARINE GLASS

APPLIED WEATERTECHNOLOGY /AWTジャパン

NAVTOR /ナブトール Haitima

Software Cradle /ソフトウェアクレイドル

K.MECS /ケーメックス

ECON /エコン

Knipex Tools Japan /クニペックスツールズジャパン

Drydocks World

SUGINO MACHINE /スギノマシン

GE Marine

Koshin Denki Kogyo /光進電気工業

Xubi-Nenogear

DAITO ELECTRON /ダイト

エレクトロン

SSI

FORUM 8 /フォーラムエイト

IKK SHOT /IKKショット

BEN LINE AGENCIES (JAPAN) / ベン・ライン・エージェンシーズ・ ジャパン

Nippon Sogo System /日本総合システム

NEWCOURSEGROUP

SEIBU GIKEN / 西部技研

Jiangsu PengfeiHaitai Machinery

Satcom Global Limited /サットコムグローバルリミテッド

Remitite

Rustibus

New Fire

ESI Japan /日本イーエスアイ

HIEN ELECTRIC Industries / ヒエン電工

Nakanishi Shoji /中西商事

FUJITSU富士通

NESSTECH /ネステック

WINTERTHUR GAS & DIESEL JAPAN /ウィンターツールガスアンド

ディーゼルジャパン

AIR LIQUIDE Kogyo Gas /エア・リキード工業ガス

Honeywell Japan /ハネウェルジャパン

MARICHEM MARIGASESWORLD WIDE SERVICES

SangbongCorporation

Elite Marine Ballast Water Treatment System

GADELIUS INDUSTRY /ガデリウス・インダストリー

G-TOOL

CHINA INSTITUTEOF MARINE TECHNOLOGY& ECONOMY

AEPジャパン /AEPJapan

Daishin-Giken /大新技研

AIS /エイ・アイ・エス

TAMAGAWA SEIKI多摩川精機

COSCO(Wei Hai) Shipbuilding

Marine Technology

Changzhou CTC Pipelines System

JIANGSU YUAN ZHUO EQUIPMENT MANUFACTURING

DALIAN XINFEI MARINEMACHINERY

SHOUGUANG CITY JINZHENG BALLONET

SUZHOU JIUMEI FIBERGLASS

ZHEJIANG SHUANGNIAO ANCHOR CHAINFukai Shipping Service

Japan Aerospace Exploration Agency /宇宙航空研究開発機構

Toko Instruments /東光計器

MobilisMarine Electronics

LONSEAL /ロンシール

工業

YOU SHIN DAN YEOL

AES /エイ・イー・エス

OKADA CORPORATION /岡田商事

Panduit Corp. Japan Branch /パンドウイットコーポレーション日本支社

Arion Japan

3S

JIANGSU XIANGSHENG HEAVY INDUSTRIES

MFE Center Investment Management (Shanghai)

ClassNK /日本海事協会

VacDrain

JESSN MARINEEQUIPMENT

SHANGHAI BAOLUO STAINLESSSTEEL YUBE

MAHLE

J.P. SAUER

GALI

BOLL & KIRCH

SKF

VOITH

MMG

BSS

MARI

DR. E.HORN

GERMANINFORMATIONSTAND

MARK.WERK

ZOLLERNWulff Entre / Napa

L ORANGE

DW-SHIPCONSULT

NOVAWARKE

KraftPowerconSweden

TOYO-KOKA /東洋硬化

Bo Sung Silicone

PLEIGER

JIANGSU YUANYANG CABLE

ReservedAZIMUTH GO HOME SAFE

MITSUBISHI HEAVY INDUSTRIES MARINE MACHINERY & ENGINE /三菱重工舶用機械エンジン

Jiangsu yangyuan Marine Equipment Casting

TANABE PNEUMATICMACHINERY /

田邊空気機械製作所

TAMAYA TECHNICS /タマヤ計測システム

TEIKOKU MACHINERY WORKS /帝国機械製作所

TAIKO SANGYO /大晃産業

NYK TRADING /郵船商事

NIPPON HAKUYO electronics /日本舶用エレクトロニクス

TOBU JUKOGYO /東部重工業

Japan Coast Guard / 海上保安庁

KEI SYSTEM /ケーイーアイシステム

MURAYAMA DENKI /村山電機製作所

NIPPON PAINT MARINE COATINGS /日本ペイントマリン

WOODS /ウッズ

GEISLINGER /ガイスリンガー

SHONAN /湘南工作所

JFE ENGINEERING /JFEエンジニアリング

UTSUKI KEIKI /宇津木計器

Maritime Repoter and Engirneering News

SATAKE /サタケ

VOLCANO /ボルカノ

SUCTION GAS ENGINE MFG /サクション瓦斯機関製作所

DAIHATSU DIESEL MFG /ダイハツディーゼル

NAKASHIMA PROPELLER /ナカシマプロペラ

AZBIL /アズビル EIZO TOKYO KEIKI /

東京計器

SHINKO /シンコー

KURUTA WATER INDUSTRIES /栗田工業

IBUKI KOGYO /伊吹工業

Fuji Electric /富士電機

HITACHI NICO TRANSMISSION /

日立ニコトランスミッション

Musasino /ムサシノ機器

YANMAR /ヤンマー

CHUGOKUMARINE PAINTS /中国塗料

OKUMURA ENGINEERING /オーケーエム

Yokogawa Denshikiki /横河電子機器

AKASAKA DIESELS /赤阪鐵工所

NABTESCO /ナブテスコ

NISHISHIBA /ELECTRIC西芝電機

Japan Radio /日本無線

FUJI TRADING /富士貿易

MANABE ZOKI /

眞鍋造機MATSUI /マツイ

YAMATO METAL /

ヤマトメタル

SEKIGAHARA SEISAKUSHO /関ヶ原製作所

Yamashina Seiki /山科精器

Naniwa Pump Manufacturing /浪速ポンプ製作所CONHIRA /

コンヒラ

SHIMADA & CO /島田燈器工業

TAIKO KIKAI INDUSTRIES /大晃機械工業

MIURA /三浦工業

TAIYO ELECTRIC /大洋電機

WAKEFIELD /ウェイクフィールド

MIZUNO MARINE /ミズノマリン

KOKOSHA /高工社

HSN-KIKAI KOGYO /兵神機械工業

TECHNO KASHIWA /テクノカシワ

MITSUI ENGINEERING

& SHIPBUILDING /三井造船

Ace Valve

ECO MARINE POWER /エコマリンパワー

USHIOREINETSU /潮冷熱

KANAGAWAKIKI KOGYO /神奈川機器工業

JRCS MFGJRCS

MINISTRY OF DEFENSE(MARITIME STAFF OFFICE)Acquisition, Technology& Logistics Agency / 防衛省防衛装備省

Vik-SandvikDesign India

Aquata

Iver C. Welibach

Noverco Marine & Offshore

ROCKWOOL

DAN-FENDER

MAN Diesel &TurboHoyer

Moters

VIKING LIFE-SAVING EQUIPMENTDANISH MARINE GROUP DANISH EXPORT ASSOCIATION

APEX PRECISION

TECHNOLOGYYOKEINDUSTRIAL

Jiangsu Aohai Marine Fitting

GESCO

OSCG

HODU

Shindong Digitech

Mt.H CONTROL VALVES

ISS Machinery Services /ISS マシナリーサービス

QINGDAO WANCHENG ANCHOR

Consilium Nittan Marine /コンシリアム・

ニッタンマリーン

Dalian Yoshimoto Industries

Framoフラモ

NIPPON VULKAN /日本ブルカン

NAROC ROPE /ナロック

Sojitz Marine&Enginering /双日マリンエンジニアリング

KTMI

KSP

KOMEA

Sanil Electric

Kwang San JULI ROPE

QINGDAO SK ANCHOR CHAIN

KOMECO

DAEYANG ELECTRIC

Yangzhou Wutingqiao Cylinder Liner

Team Tec

U-03

U-04

U-06

U-08

U-14

U-26

AA-01

AA-04

AA-09 AA-10

AA-18

AA-19

AA-20

AA-26 A-33

A-27

A-25 A-26

A-17

A-13 A-18

A-14 B-11 B-12

B-16

A-09

A-12

A-07

A-02 B-02 C-01

A-32

B-24

B-26

B-30

C-25

AA-15

AA-07

AA-05

AA-03

GER-01

GER-02

GER-06 GER-07

GER-08 GER-09

GER-10

DEN-01

DEN-03

DEN-05 DEN-08

DEN-06

DEN-14

DEN-12

DEN-09

GER-11

GER-12GER-13

GER-14

GER-15GER-16

GER-17

GER-18

GER-03 GER-04

JPN-01

JPN-03

JPN-05

JPN-07

JPN-09

JPN-11 JPN-10

JPN-04

JPN-02

JPN-27

JPN-26

JPN-24

JPN-23

JPNTM-14

JPNTM-13

JPNTM-12

JPN-80

JPN-56

JPN-68

JPN-92 JPN-93

JPN-100

JPN-113

JPN-115

JPN-121 JPN-122

JPN-118

JPN-114

JPN-141 JPN-144

JPN-142

JPN-140

JPN-138

JPN-136

JPN-134

JPN-133

F-12

P-09

TW-02

L-08L-09

KOM-01 KOM-02

KOM-03 KOM-04

KOM-05 KOM-06

KOM-07 KOM-08

KOM-09 KOM-10

KOM-11 KOM-12

U-33

U-35

U-37

U-39

U-36

T-34

U-30

U-32

U-34

U-38

U-40

T-48G-45

T-41S-40

T-43 T-42S-42S-41R-44

L-50 M-50 N-53K-48

AA-27

AA-33

AA-35 B-39A-42

A-40

A-38

B-35 B-38

B-36

B-40

C-37

B-51

B-48

C-49

C-42 D-46

D-42

E-46

E-42

F-45 F-46

H-50

H-46

H-42

J-42 K-42

K-44

K-46

L-41

L-45

L-42

L-46

M-41 M-42

M-46

N-47

N-49

N-48

N-50

P-47

P-45

P-42

P-38

P-36

P-32

R-33

P-30

P-26

P-24

P-22

R-39

R-37

R-35

R-31

R-38

R-36

R-34

R-28

R-24R-25

S-31

S-37

S-35

S-33

S-36

S-34

T-33

T-39

T-37

T-35

T-40

T-38

T-36

U-21 U-22

U-19

U-23 U-24

U-25T-28

T-26

T-24

U-11

U-07

U-13

U-15T-16

T-14

T-17

T-13

T-07

T-10

CH-18

CH-16

CH-15

CH-05

CH-09

CH-08

CH-06

CH-01

N-10M-10

M-12K-12

K-16

K-08

J-14G-14E-15

E-13

E-11

F-01 J-01

K-01 M-01P-01 R-01 S-01 T-03 T-01 U-01 U-02

L-01

J-08

M-15

TW-05

TW-03

TW-01

M-16L-12

N-07

N-16 P-15

P-11

CH-14

CH-13

CH-17

T-23

T-25

T-27S-26

S-22

P-49

R-50

R-52

S-48

S-52

S-50S-49

P-48

P-50

R-49

K-50

H-45G-46

H-41G-42

G-50F-50

F-42

A-41AA-36

AA-30

R-51

JPN-13

JPN-16

JPN-17 JPN-20 JPN-32

JPN-28

JPN-38 JPN-39 JPN-44

JPN-40

JPN-48 JPN-49 JPN-54 JPN-64 JPN-65

JPN-60 JPN-61

JPN-86 JPN-87

JPN-82 JPN-103 JPN-104

JPN-107

JPN-124JPN-123

JPN-127

JPN-146

JPN-149 JPN-150

L-07

JPN-145

NIIGATA POWER SYSYTEMS /新潟原動機

SASAKURA ENGINEERING /

SHIPOWNER INTERVIEW

FIN STABILIZER / RETROFIT VESSEL

Premium AArea

Ministry of Economy,Infrastructure,Shipping and TourismM.E.I.S.T.

U.G.S. Union of Greek Shipowners

H.C.S. Hellenic Chamber of Shipping

Premium BArea

StandardArea

emergency exits

Site PlanMETROPOLITAN EXPO

6 -10 JUNE 2016

PRESSOFFICE

W.C.

W.C.

W.C.W.C.

W.C.

W.C.

W.C.

W.C.W.C.W.C.

W.C.

W.C.

W.C. W.C. W.C.

W.C.

MEETINGROOM

HOUSECONTRACTOR

FIRSTAIDBUSINESS

CENTREORGANISERSユINFO DESK

MINIMARKET

CLOAKROOM

POSIDONIACONFERENCEHALL

REGISTRATIONAREA

POSIDONIASEMINARROOM

RESTAURANTRESTAURANT

ORGANISERユSOFFICE

REGISTRATIONAREA

EXHIBITORSユPARKING AREA

EXHIBITORSユPARKING AREA

EXHIBITORSユPARKING AREA

ENTRANCE 2

ENTRANCE 1

HALL 3HALL 2HALL 1 HALL 4

CAFE

- BA

R

CAFE

- BA

R

CAFE

- BA

R

CAFE

- BA

R

CAFE

- BA

R

CAFE

- BA

R

CAFE

- BA

R

WS12-11-10CWS 1

MAIN CORRIDOR

SHUT

TLE B

US &

TAXI

STAT

ION

W.C.

W.C.

TRAV

EL A

GENT

FORWARDERS

WS9-8-7

WS6-5-4 WS3-2-1

LWS1 LWS2 LWS3 LWS4CWS 2 CWS 3 CWS 4 CWS 5 CWS 6 CWS 7

CWS 8

EVENTS AREA 1

EVENTS AREA 2

IPDC

4.134

4.1364.2324.229

4.2274.322

4.225

4.223

4.2214.318

4.311

4.317

4.215

4.109

4.212 4.107

4.210 4.105

4.101

4.202

4.2054.305

4.303

4.301

4.203

4.201

4.213

4.2114.309

4.320 4.320

4.321

3.1383.1433.2423.2413.335

3.325

3.430

3.136

3.134

3.132

3.128

3.126

3.122

3.121

3.221

3.223

3.225

3.229

3.316

3.318

3.3263.231

3.233

3.2353.330

3.334

3.332

3.239

3.123

3.131

3.2363.133

3.137

3.116

3.112

3.110

3.106

3.104

3.1023.101

3.202

3.1053.205

3.2113.307

3.309

3.414

3.3153.419

3.421

3.423

3.521

3.519

3.515

3.513

3.511

3.507

3.505

3.503

3.501

3.525

3.529

3.425

3.429

3.426

3.428

3.531

3.533

2.145

2.140

2.138

2.136

2.2462.2472.3372.4462.4492.545

2.539 2.442 2.333

3.319

3.420

3.311

3.411

3.413

3.415

3.213

3.215

3.217

3.216

3.2183.113

3.111

3.203

3.201

3.301

3.401

3.403

4.219

4.217

4.1314.230

4.228

4.226

4.129

4.127

4.125

4.117

4.115

4.128

4.126

4.124

4.120

4.118

4.116

4.114

4.110

4.108

4.106

4.104

4.101

H.C.S.U.G.S.M.E.I.S.T.

50m2

50m2

45m2

30m2

32.5m2

35m2

30m2

40m2

50m2

40m2

40m2

170m2

220m2

99m2

49.5m249.5m2

38.5m238.5m2

121m2

28m235m2

32m2

80m2

115.5m2

121m2

99m251.75m2

32m2

24m256m2

60m296.75m2

50m2

80m2

40m2

47.5m2

45m2

45m2

80m2

110m2

156.75m252.25m2

72m2

51m2130m2

85m2

60m260m2

119m242.5m2

50m2

30m2

30m2

60m2

35m2

30m2

60m2

59.5m2

56m2

66m2

42m2

42m2

42m2

12m212m2

12m212m2

66m2

12m227m2105m270m2

35m2

147m280 m2

45 m2

15m2

24m212m2

12m2

12m212m2

155m284m2

70m2

35m256m2

42m2

60m2

40m2

30m2

41.25m2

44m2

85.25m2

231m2

55m2

132m2

49.50m2 30.25m2

19.25m2

198m2

42m2

60m2290m249m2

3.40549m2

105m2

40m2

40m2

50m2

25m2

25m2

35m2

3.1443.53725m2

15m218m2

3.1453.24415m218m2

3.1473.24615m218m2

3.14615m2

15m2

18m2

3.24318m2

15m215m2

3.3373.43215m215m2

42m2

3.2473.3393.4343.539 3.43518m215m215m221m224m2

33.75m2

63m2

104m2

104m2

56m2

72m2

58.5m2

54m2

40.5m2

58.5m2

35.75m241.25m2

22m2

44m2

35.75m2

35.75m2

21m217.5m215.75m2

72.25m2

108m2

15.75m2

40.5m2

36m2

84m2

35m2

net:192m2

15m2

27.5m2

27.5m2

50m2

18m2

2.1392.24238.5m238.5m2

2.1372.24038.5m2

2.1352.238

2.228

2.226

2.119

2.123 2.126

2.122

2.120

2.121

30.25m2

30.25m2

46.75m2

46.75m235.75m2

41.25m2

132m2 70m2

2.515

2.51332.5m2

67.5m2

2.511

2.509

2.505

1.501

1.503

1.4011.305

1.505

1.507

1.511 1.409

1.411

1.415

1.317 1.314

1.213

1.212

1.210

1.211 1.113

1.115

1.119

1.112

1.116

1.118

1.120

1.1221.1231.318

1.320

1.3221.323

1.424 1.327

1.324

1.326