IF 1659 Revision 1:- - Cooper Industries · 2020-01-21 · Cable Entries Acc. to customer’s...

Transcript of IF 1659 Revision 1:- - Cooper Industries · 2020-01-21 · Cable Entries Acc. to customer’s...

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

IF 1659

SynergEX PanelboardsPanelboards for Hazardous LocationsInstallation & Maintenance Information

IF 1659 • 04/13 Copyright© 2013, Cooper Industries, Inc. Page 1

TABLE OF CONTENTS

WARNING

Do not alter this product in any way. Doing so may lead to serious injury or death.

To avoid dangerous overheating, do not use aluminum wiring. Use copper wire only.

To avoid electrical shock, electrical power must be “OFF” before and during installation, inspection,and maintenance.

Observe the national safety rules and regulations.

CAUTION

Read these operating instructions and all other information sheets before wiring and use.

Dimensional Drawings:SynergEX Panelboards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1. Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21.1 Complete Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21.2 Technical Data Busbar System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.1 Busbar System Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21.2.2 Rated Current of Connectors/Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31.2.3 Clearance and Creepage Dimensions of Busbar System . . . . . . . . . . . . . . . . . . . . 31.2.4 Connection Busbar System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Hazardous Location Technical Data for Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41.3.1 Mechanical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41.3.2 277/480V Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41.3.3 120/240V Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41.3.4 Aux./Signal Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53. Conformity with Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54. Field of Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55. Application/Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

6.1 Transport/Storage Before Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56.1.1 Transport. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

6.2 Mounting/Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56.3 Opening SynergEX Panelboards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66.4 Electrical Connection General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66.5 Busbar System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6.5.1 Electrical Connection Busbar System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66.5.2 Busbar Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6.6 Cable Entries, Blanking Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76.6.1 Drilling for Additional Cable Entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6.7 Flanges, Metal Plates, and External Earth Connection . . . . . . . . . . . . . . . . . . . . . . . . . 76.8 Closing Apparatus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76.9 Putting Into Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7. Maintenance/Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88. Repairs/Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89. Disposal/Recycling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 810. Dimensional Drawings, Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

10.1 Tripping Characteristic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1010.2 Derating Table for Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Certificate of Conformity enclosed separately.

30.51

”(77

5mm)

37.40”(950mm)

11.81

”(30

0mm)

43.31

”(11

00mm)

37.40”(950mm)

11.81

”(30

0mm)

62.99

”(16

00mm)

37.40”(950mm)

11.81

”(30

0mm)

74.80”(1900mm)

50.39

”(12

80mm)

11.81

”(30

0mm)

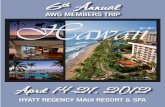

12 Circuit

24 Circuit

42 Circuit

60 Circuit

Figure 1. Dimension Drawings

IF 1659 • 04/13 Copyright© 2013, Cooper Industries, Inc. Page 2

1. TECHNICAL DATA1.1 Complete Distribution

Master Contract 240 700Explosion Category: -20°C or -20°C to -40°C with heater

For USL AEx de IIC T4For CNL Ex de IIC T4; Ex tb IIIC T100°C Db

Certifications and Compliances:

For USLClass I, Zones 1 & 2Class I, Division 2, Groups A, B, C, D; Class II, Division 1, Groups E, F, G

For CNLZone 1 & 2Class I, Division 2, Groups A, B, C, D; Class II, Division 1, Groups E, F, G, Extb IIIC T100°C Db

Rated Voltage to 600VAC / 60 HzRated Current Max. 225A

Up to 40°CSize A (12 cct) up to 100ASize B (24 cct) up to 150ASize C (42 cct) up to 225ASize D (60 cct) up to 225A

Ambient Temperature -40°C to +55°C (varies with configuration)Perm. Storage Temperature in Original Packing -40°C to +55°CDegree of Protection to EN/IEC 60529 IP66 (standard version); Type 4XInsulation Class to EN/IEC 61140 IMaximum Number of Breakers (Single Pole)

Size A 12Size B 24Size C 42Size D 60

Connectors Quantity - acc. to number of breakers (poles)Cable Entries Acc. to customer’s specification and as certifiedTerminal Cross-section Max. AWG 4/0 / 120mm2

Incoming Wires 75°COutgoing Wires 75°CEnclosure Material Stainless steel

1.2 Technical Data Busbar System

Busbar Rail System 1 x 12mm x 5mm

Rated Voltage 600V / 60 Hz

Rated Current 225A (40°C)

Rated Short Time Current 4kA

Rated Short Circuit Current 10kA

Support Spacing for Is to 10kA 300mm

Test Torques:

Fixing Screws Busbar System 2.5 N-m

Figure 2. Connectors

1.2.1 Busbar System Connectors (phase X/Y/Z, neutral N, ground )

Cross Section/AWG

Connectors

Solid Stranded Number ofConnectors

d/mm / inch

a/mm / inch

b/mm / inch

c/mm / inch

Test Torque/N-mMin. Max. Min. Max.

grck 16 14 4 4 6 1 5.0 / 0.2 25.5 / 1.0 26.5 / 0.5 12.0 / 0.5 3

grck 35 10 4 4 2 1 5.0 / 0.2 26.5 / 1.0 31.5 / 1.2 16.0 / 0.6 10

grck 50 6 4 4 0 1 5.0 / 0.2 26.5 / 1.0 35.0 / 1.4 16.0 / 0.6 20

grck 70 4 - 4 2/0 1 5.0 / 0.2 28.0 / 1.1 39.0 / 1.5 20.0 / 0.7 20

grck 120 4 - 4 4/0 1 5.0 / 0.2 29.0 / 1.2 46.0 / 1.8 23.0 / 0.8 33

40°C to 55°Cup to 85Aup to 125Aup to 190Aup to 190A

-20°C to -40°C without heaterAEx de IIB T4Ex de IIB T4; Ex tb IIIC T100°C Db

IF 1659 • 04/13 Copyright© 2013, Cooper Industries, Inc. Page 3

1.2.2 Rated Current of Connectors/Wires

AmbientTemperature

Range

Rated Currentof Busbar

40°C 225A14 12 10 8 6 4 0 2/0 4/0

15A 20A 30A 40A 50A 60A 100A 150A 225A

Cross-section of Cables

Max. Rated Current of Connecting Cables

1.2.3 Clearance and Creepage Dimensions of Busbar System

120V/240V 277V/480V

Minimum Spacing Through Air “A” between phases >= 19.0mm >= 25.0mm

Minimum Spacing Through Air “B” between phases and ground >= 12.5mm >= 12.5mm

Minimum Spacing Over Surface “C” between opposition phases >= 31.0mm >= 50.0mm

Minimum Spacing Over Surface “D” between phases and ground >= 31.0mm >= 50.0mm

Figure 3. Stripping Length

1.2.4 Connection Busbar System

Cross Section / AWG

StrippingLengthConnectors

StrandedMin. Max.

grck 16 14 6 16

grck 35 10 2 18

grck 50 6 0 22

grck 70 4 2/0 22

grck 120 4 4/0 25

1 Phase120/240V

3 Phase277/480V

IF 1659 • 04/13 Copyright© 2013, Cooper Industries, Inc. Page 4

Figure 4. Contact Arrangement/Circuit Breaker

Figure 5. Contact Arrangement/Additional Devices

1.3 Hazardous Location Technical Data for BreakersMaster Contract 240 700Explosion Category:

For USL AEx de IIB/IICFor CNL Ex de IIB/IIC

Certifications and Compliances:

For USLClass I, Zone 1Class I, Division 2, Groups A, B, C, D

For CNLZone 1Class I, Division 2, Groups A, B, C, D

Ambient Temperature Range:IIC: -20°C to +55°C (GHG62-1/2/3/4...R...)IIB: -45°C to +55°C (GHG62-1/2...R...)

Permissible Service Temperature Range:IIC: -20°C to +110°C (GHG62-1/2/3/4...R...)IIB: -45°C to +110°C (GHG62-1/2...R...)

Other temperatures possible with special versions.

Perm. Ambient Temperature in Original Packing -45°C to 60°C

1.3.1 Mechanical Data

Terminal Cross Section: Stripping LengthMain Terminal Module Size 1-3

Current 15A or less AWG 14 11mm / 0.4”20A AWG 12 11mm / 0.4”25A AWG 10 11mm / 0.4”30A AWG 10 11mm / 0.4”40A AWG 8 11mm / 0.4”

Aux. Terminals AWG 14 11mm / 0.4”Quantity Terminals for the Module Size: 1 2 3

Main Terminals 1 2 3Aux. Terminals 2 3 4

Test Torques:

Main Contacts 3.5 N-mAux. Contacts 1.0 N-mMounting Screws 2.5 N-m

Enclosure Material Polyamide

1.3.2 277/480V Circuit Breakers

Rated Voltage Main contact to 277/480VAC; 60 Hz

Rated Current Main contact 10A-40A

Types 1-pole GHG 623 1101 R...

2-pole GHG 623 2101 R...

3-pole GHG 623 3101 R...

Rated Switching Capacity 10kA

Non-ambient Compensated Temperature 25°C

Component Size 1 2 3

Weight ca. 0.60 kg 0.90 kg 1.20 kg

1-pole* 2-pole* 3-pole*Tripping characteristic of circuit breaker, see last page.*Circuit breakers with additional devices are built into larger component enclosures.

1.3.3 120/240V Circuit Breakers

Rated Voltage Main contact to 120/240VAC; 60 HzRated Current Main contact 10A to 40ATypes 1-pole GHG 623 1001 R...

2-pole GHG 623 2001 R...Rated Switching Capacity 10kANon-ambient Compensated Temperature 40°CComponent Size 1 2Weight ca. 0.90 kg 1.20 kg

1-pole* 2-pole*Tripping characteristic of circuit breaker, see last page.*Circuit breakers with additional devices are built into larger component enclosures in bigger size.

1.3.4 Aux./Signal Contact

Rated Voltage to 230VAC 277VAC 480VACRated Current 2A 2A 1AMinimum Switching Capacity 5 mA at 24V

The technical data relates to standard built-in apparatus. Ifother built-in apparatus is used, the technical data sheetsor the data on the type label shall be observed.

IF 1659 • 04/13 Copyright© 2013, Cooper Industries, Inc. Page 5

WARNING

For installation only by a qualified electrician in accordance with the National Electric Code®, theCanadian Electric Code, applicable local codes, and these instructions.

SynergEX Panelboards are not suitable for Zone 0 or Zone 20 hazardous areas.

The temperature class and explosion group marked on the distributions shall be observed.

The permissible ambient temperature, the terminal cross-section, and the self-heating of the appa-ratus, which is mainly caused by the power dissipation, are to be observed to ensure that the tem-perature class stated on the type label of the apparatus is maintained. (Test criterion for the self-heating is an overload of 10%).

The apparatus shall be used for the intended purpose and shall be in a perfect and clean state.

Check to see that the rating label on the device is correct for the installation.

Only original parts from the manufacturer may be used as replacements and for repairs.

Repairs that affect the explosion protection may only be carried out by Cooper Crouse-Hinds / CEAGor by a qualified electrician in compliance with the respective national regulations.

Modifications to the distributions or design changes are not permitted.

Prior to being put into operation, the distributions shall be checked in accordance with the instruc-tions given in Section 6.

Before initial operation, any foreign matter shall be removed from the distribution enclosures.

Before opening the enclosure dead front, it is necessary to ensure that the distributions are isolatedfrom the voltage supply or take the appropriate protective measures.

The minimum terminal cross-sections of the flameproof components shall be observed during con-nection in accordance with CSA C22.2 No. 29 / UL67.

Maximum continuous load on all circuit breakers (including main and subfeeder breakers) not toexceed 80% of rating.

The national safety rules and regulations for the prevention of accidents, as well as the safetyinstructions included in these operating instructions, shall be observed.

2. SAFETY INSTRUCTIONS

3. CONFORMITY WITH STANDARDS

SynergEX Panelboards have been designed, man-ufactured, and tested according to the followingstandards:

CSA C22.2 0-10CSA C22.2 0.5-1982 (R2003)CSA C22.2 94.1-07CSA C22.2 94.2-07CSA C22.2 No. 0.12-M85CSA C22.2 No. 29-11CSA C22.2 No. 213-M1987

CAN/CSA C22.2 No. 60079-0:11CAN/CSA C22.2 No. 60079-1: 11CAN/CSA C22.2 No. 60079-7:12CAN/CSA C22.2 No. 60079-31:12

ANSI/ISA 60079-0 (12.00.01): 2009ANSI/ISA 60079-1 (12.00.01): 2009ANSI/ISA 60079-7 (12.16.01): 2008ANSI/ISA 60079-31 (12.10.03): 2009UL67, 12th Ed., 2009UL50, 12th Ed., 2007UL50E, 1st Ed., 2007

4. FIELD OF APPLICATION

The distributions are suitable for use in hazardous areas in Class I, Division 2; Class II, Division 1; Zone1; Zone 2; Zone 21; or Zone 22 in accordance with IEC60079-10, CAN/CSA 60079-10.

The materials used for the enclosures, including the exterior metal parts, are high quality materials thatensure an appropriate corrosion protection and resistance to chemical substances according to therequirements for use in a “normal industrial atmosphere”:

- Stainless steel AISI 316L- Stainless steel AISI 304- Safety glass

In case of use in an extremely aggressive atmosphere, please refer to manufacturer.

5. APPLICATION/PROPERTIES

SynergEX Panelboards are used for distributing electric power (e.g. main, lighting, heating, control andintrinsically safe circuits, etc.). (See Technical Data for temperature classes, explosion groups, and per-missible ambient temperatures).

The function of MCB circuit breakers and ELCBs (RCDs) with circuit breakers shall be checked after sev-eral short circuits.

An ELCB (RCD) does not prevent the sensation caused by an electric shock, but it limits the duration ofthe current flow through the human body to such a short time that the probability of a fatal effect isreduced to a negligible amount.

Once the cause for the tripping of the ELCB (RCD) has been eliminated, it is reset by switching the tog-gle to the “ON” position.

Details of the electric contacts are given on the base of the component or in these operating instruc-tions.

WARNING

If not specified in these operating instructions, information on the safe use of third-party productsshall be requested from the respective manufacturer of the equipment.

6. INSTALLATION

The relevant national regulations and the generally recognized rules of engineering apply for the installa-tion and operation.

6.1 Transport/Storage Before Installation

SynergEX Panelboards shall be inspected on receipt to verify that they are complete and undamaged. Ifthe delivery is not complete, an inventory shall be drawn up immediately together with the transportcompany. Any damages shall be documented accordingly. To store, SynergEX Panelboards shall beplaced on a clean, dry, and flat surface, whereby the position shall be maintained. SynergEXPanelboards shall be protected against adverse weather conditions.

6.1.1 Transport

To transport SynergEX Panelboards, use the suitable transport aids that are put at your disposal.Depending on the size of the SynergEX Panelboards, a transport beam might have to be used.

6.2 Mounting/Installation

The mounting and installation of SynergEX Panelboards must only be carried out by skilled electricians.

SynergEX Panelboards can be mounted without opening the cover.

When SynergEX Panelboards are mounted directly onto the wall, they shall rest evenly only on the fas-tening points provided for this purpose, and they shall be fixed in such a way that they cannot twist orturn.

The screws used shall match the fixing holes (see dimension drawings) and must not damage the open-ings (e.g. use of washers).

All fixing points shall be used when screwing SynergEX Panelboards to the wall or floor.

WARNING

Excessive tightening can result in damage to SynergEX Panelboards.

WARNING

The data according to Sections 3 and 4 shall be taken into account during use.

WARNING

Applications other than those described are not permissible without a written declaration of consentfrom the manufacturer.

WARNING

During operation, the instructions stated in Section 7 of the operating instructions shall be observed.

WARNING

These operating instructions also apply as instructions for the replacement or addition to individualflameproof components.

WARNING

The sole responsibility with respect to the suitable and proper use of these panels lies with the oper-ator.

IF 1659 • 04/13 Copyright© 2013, Cooper Industries, Inc. Page 6

SynergEX Panelboards must not be left near heat sources.

The correct position of the openings for power supply access must be checked before installation.

WARNING

The connections for the incoming and outgoing leads of the busbar systems shall be fitted in such away that the current load of the copper rails is distributed evenly.

6.3 Opening SynergEX Panelboards

Use the relevant key for the locking device (see Figure 6).

Figure 6. Locking Devices

Figure 7. Protective Cover, Open

After opening the lid of the SynergEX Panelboard, you can open the protective covers by unscrewing thescrews (see Figure 7).

Figure 8. Stripping Length

6.4 Electrical Connection General

The properly bared conductors of cables shall be connected with due regard to the respective regula-tions.

WARNING

Before opening the dead front in the SynergEX Panelboard, it is necessary to ensure that theSynergEX Panelboard is isolated from the voltage supply or to take suitable protective measures.

WARNING

The electrical connection of the apparatus may only be carried out by trained staff.

WARNING

The incoming and outgoing wires shall be identified as sized for 75C.

To maintain the explosion protection, conductors shall be connected with special care.

WARNING

The insulation shall reach to the terminal (see Figure 8). The conductor itself must not be damaged.

The minimum and maximum connectable conductor cross-sections are to be observed.

All screws and/or nuts of the connection terminals, including those not in use, shall be tightened downsecurely.

The circuit diagram for the built-in components is either shown on the components, or in the operatinginstructions. In the case of wired SynergEX Panelboards, the connection diagram included with theapparatus is to be observed.

If a flameproof component is disassembled before it is connected to the electric power supply, it is nec-essary to ensure that the components are put back into the distribution enclosure correctly.

WARNING

Overtightening can damage the enclosure or impair the sealing effect.

6.5 Busbar System

The maximum rated current of the busbar system, specified in the Technical Data, have to be observed.

6.5.1 Electrical Connection Busbar System

The electrical connection of the apparatus may only be carried out by skilled staff. In order to maintainthe mode of protection, special care shall be taken when connecting the conductors.

The minimum and maximum connectable conductor cross-sections are to be observed (see Table 1.2.1).

Cross Section / AWG

StrippingLengthConnectors

StrandedMin. Max.

grck 16 14 6 16

grck 35 10 2 18

grck 50 6 0 22

grck 70 4 2/0 22

grck 120 4 4/0 25

IF 1659 • 04/13 Copyright© 2013, Cooper Industries, Inc. Page 7

6.5.2 Busbar Connectors

When positioning the connectors, the required clearances “D” in Figure 1.2.4 (“Connection BusbarSystem”) shall be observed.

The possible combinations of connectors and terminal cross-sections can be seen in Table 1.2.1.

Place the connectors and wiring as shown in Figures 8 and 1.2.4 (“Connection Busbar System”).

The stripping of the cable depends on the used busbar terminal. The stripped wire should not protrudeabove the busbar terminal. The insulation must reach up to the terminal (see Figure 8).

The busbar terminal attract at least with the test torque specified in Table 1.2.1. Excessive tighteningwill damage the threads.

Before putting the apparatus into operation, the tests specified in the individual national regulationsshall be performed.

Improper validation and operation can lead to loss of warranty.

6.6 Cable Entries (KLE); Blanking Plugs

WARNING

Generally only certified cable entries and blanking plugs may be used.

WARNING

The relevant mounting directives for the built-in cable entries shall be observed.

When using cable entries for the connection to or into the apparatus, where applicable, the relevantspecial conditions for safe use given in the individual certificates shall be considered.

In order to ensure the minimum degree of protection, any unused entry holes shall be sealed with certi-fied blanking plugs.

Overtightening can impair the degree of protection.

6.6.1 Drilling for Additional Cable Entries

Additional holes for cable entries can be drilled into the metal flange.

Observe the dimensions of drilling surface, shown in Figure 11.

6.7 Flanges, Metal Plates, and External Earth Connection

If flange plates have to be removed, in order to maintain the minimum protection category, attentionshall be paid to the proper fit of the flange plates when remounting them (see Figure 9).

Figure 9. Cable Entries/Flanges

To fix the flange plates, use the high torque screws (ø 6mm, length 6mm) (see Figure 10). Pleaseobserve the respective torques given in Figure 10.

Figure 10. High Torque Screw ø 6mmTest Torque 2.8 N-m

Figure 11. Drilling Surface of Metal Flanges

Flange plates for SynergEX Panelboards shall be fitted in such a way that the IP protection is main-tained. Pay attention to the proper fit of the sealing.

WARNING

Ground conductors fed from outside are to be connected to the ground terminal provided on theSynergEX Panelboard enclosure. The maximum cross-section is 50mm2.

WARNING

Metal flanges, metal plates, and metal cable entries shall be included in the equipotential earth con-nection.

6.8 Closing Apparatus

WARNING

Any foreign matter shall be removed from the SynergEX Panelboard.

To ensure the minimum protection category, the lids of SynergEX Panelboards shall be closed correctly.

6.9 Putting Into Operation

Before putting SynergEX Panelboards into operation, the tests specified in the individual national regula-tions shall be performed.

In addition to this, before being put into operation, the correct functioning of the SynergEX Panelboardsand of the built-in components shall be checked in accordance with these operating instructions andother applicable regulations.

WARNING

The incorrect installation and operation of SynergEX Panelboards can result in the invalidation of theguarantee.

7. MAINTENANCE/SERVICING

IF 1659 • 04/13 Copyright© 2013, Cooper Industries, Inc. Page 8

WARNING

The valid regulations IEC 60079-17 for the servicing/maintenance of electrical apparatus for use inpotentially explosive atmospheres shall be observed.

WARNING

Prior to opening SynergEX dead front, it is necessary to ensure that the voltage supply has been iso-lated or to take suitable protective measures.

WARNING

The user is responsible for stipulating the necessary maintenance intervals specific to the applica-tion depending on the conditions of use, national directives, and standards.

WARNING

Should the maintenance interval for the function test of an RCD (ELCB) not be defined, the manufac-turer of the RCD (ELCB) recommends testing the function by actuating the test button twice yearly.

The RCD (ELCB) shall release when the test button is actuated. If this is not the case, the protectivefunction is no longer guaranteed and the RCD (ELCB) shall be replaced.

During servicing, above all, the correct working order of parts on which the explosion protectiondepends (e.g. intactness and efficiency of the flameproof components, the enclosure, the seals, andcable entries shall be checked).

If, in the course of servicing, it is ascertained that repairs are necessary, Section 8 of these operatinginstructions shall be observed.

8. REPAIRS/MODIFICATIONS

WARNING

Only original Cooper Crouse-Hinds / CEAG parts shall be used for carrying out repairs.

WARNING

In the event of damage to the flameproof encapsulation, replacement of the respective componentsis mandatory. In case of doubt, the respective apparatus shall be sent back to the manufacturer forrepair.

WARNING

Repairs that affect the explosion protection may only be carried out by Cooper Crouse-Hinds / CEAGor by a qualified electrician in compliance with the respective national regulations (IEC 60079-19).

Ex-d components in SynergEX Panelboards may only be replaced by components of the same type(electrical ratings and mechanical size).

When replacing these individual built-in components, Section 6.2 (“Opening Apparatus / ElectricalConnection”) shall be observed.

Apparatus modifications or design changes are not permitted; excluded from this are the fitting of addi-tional cable entries, additional RCD (ELCB), and the installation of connection terminals within the scopeof the approvals for the respective apparatus, or according to details laid down by the manufacturer.

9. DISPOSAL/RECYCLINGThe respective valid national regulations for waste disposal shall be observed when disposing of appa-ratus.

To facilitate recycling of individual parts, parts made of molded plastic shall bear the marking for thetype of plastic used.

The product range is subject to changes and additions.

IF 1659 • 04/13 Copyright© 2013, Cooper Industries, Inc. Page 9

10. DIMENSIONAL DRAWINGS, BREAKERS

6.97

” (1

77m

m)

X 6.

54”

(166

mm

)

X 0.98” (25mm)

1.42” (36mm)

0.22

” (ø

5.5m

m)

5.20” (132mm)4.49” (114mm)

4.02” (102mm)

6.97

” (1

77m

m)

X 6.

54”

(166

mm

)

0.22

” (ø

5.5m

m)

X 1.69” (43mm)

4.02” (102mm)

4.49” (114mm)5.20” (132mm)

5.20” (132mm)4.49” (114mm)

4.02” (102mm)

0.22

” (5

.5m

m)

X 6.

54”

(166

mm

)6.

97”

(177

mm

)

X 2.40” (61mm)

2.83” (72mm)

6.97

” (1

77m

m)

X 6.

54”

(166

mm

)

0.22

” (5

.5m

m)

X 1.69” (43mm)

5.20” (132mm)4.49” (114mm)

4.02” (102mm)

6.97

” (1

77m

m)

X 6.

54”

(166

mm

)

0.22

” (5

.5m

m)

2.83” (72mm)2.13” (54mm)

X 2.40” (61mm)

5.20” (132mm)4.49” (114mm)

4.02” (102mm)

0.22

” (5

.5m

m)

6.97

” (1

77m

m)

X 6.

54”

(166

mm

)

X 3.82” (97mm)

4.25” (108mm)

5.20” (132mm)4.49” (114mm)

4.02” (102mm)

2.13” (54mm)

10.1 Tripping Characteristic of Breakers

K - Characteristic

10.2 Derating Table for Breakers

Cooper Industries Inc. IF 1659Crouse-Hinds Division Revision 1PO Box 4999, Syracuse, New York 13221 • U.S.A. New 04/13Copyright© 2013, Cooper Industries, Inc.

All statements, technical information and recommendations contained herein are based on information and tests we believe to be reliable. The accuracy or completeness thereof are not guaranteed. Inaccordance with Crouse-Hinds "Terms and Conditions of Sale," and since conditions of use are outside our control, the purchaser should determine the suitability of the product for his intended use andassumes all risk and liability whatsoever in connection therewith.

GHG 680 7001 P0001 (-)

277/480V 10-25A 120/240V 10-40A277/480V 30-40A

In (A)Ambient Temperature T (°C)

0 10 20 30 40 5010 13.0 12.6 11.8 11.0 10.0 9.0

15 19.5 18.9 17.7 16.5 15.0 13.5

20 26.0 25.2 23.6 22.0 20.0 18.0

25 30.0 29.3 28.0 27.0 25.0 24.3

30 36.0 35.1 33.6 32.4 30.0 29.1

35 42.0 41.0 39.2 37.8 35.0 34.0

40 48.0 46.8 44.8 43.2 40.0 38.8

277/480VAC

120/240VAC

In (A)Ambient Temperature T (°C)

-40 -30 -20 -10 0 10 20 30 40 5010 13.2 12.7 12.2 11.7 11.2 10.6 10.0 9.4 8.7 7.9

15 21.2 20.4 19.6 18.8 17.9 17.0 16.0 15.0 13.9 12.6

20 26.5 25.5 24.5 23.5 22.4 21.2 20.0 18.7 17.3 15.8

25 33.1 31.9 30.6 29.3 28.0 26.5 25.0 23.4 21.7 19.8

30 - - 36.9 36.0 35.0 33.9 32.7 31.4 30.0 28.5

35 - - 44.0 42.6 41.2 39.7 38.2 36.6 35.0 33.3

40 - - 49.4 48.4 46.9 45.3 43.6 41.9 40.0 38.0