Id_mangga2square Energy Management Updated 22 Mei 091

Transcript of Id_mangga2square Energy Management Updated 22 Mei 091

APPLICATION FORM

The Third ASEAN Best Practice Competition for Energy Management in Buildings and Industries

ASEAN Energy Awards 2009

p a g e 1

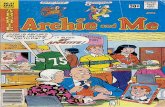

Category: □ Buildings * □ Industries Title of Activity / Project / Theme:

1. Application General Information Name of Company : PT. MANDIRI DIPTA CIPTA Business Address : Jl. Gunung Sahari Raya No. 1 Jakarta – Utara 14420 Number of Employees : 218 Type of Building/Industry : Property Management Age of Building/Industry : 5 years Nature of Business : Multi Shopping Center area, Entertainment, Hotel, Exhibition, Parking, Home office ( Rukan ) and others Contact Person Name : Didik Kurniadi Position : Facilities Management Manager Telephone : (021) 6231 – 3000, Ext.1060 Fax : (021) 6231 – 2939 E-mail : [email protected] Project Abstract: Mangga Dua Square ( M2S ) is a Multi Shopping Complex / one stop Shopping Complex, where in Mangga Dua Square area placed : Novotel Mangga Dua Square Hotel, JITEC ( Jakarta International & Exhibition Centre ), Carrefour Hypermarket, Sands Entertainment Centre , Trade Centre, Offices, Banks, etc. The Company from Top Management, Employee, Customer, Tenants are supporting to utilize energy consumption (Gas, Water, Electricity) etc in order to make more efficient to use and to keep our environment clean. Managing the operation of utilities such as : Chiller Aircondition Unit, AHU/FCU/Split unit, Escalator, Travelator with installing energy saver device and rescheduling operation time. Our Committee of Energy Conservation which was established last year, from several activity has achieved some data base on internal audit. A) Loses base on solar gain thru roof, window glass RTTV = 29 W/M2 (Standard maximum 45 Watt/M2 = 1743 KW, or equal to : 495,21 TR ( 1 KW – 0,284 TR) B) loses due to infiltration = Rp 107.860.000,-/month C) Losses from exhaust kitchen = 13,82 TR = Rp 7.114.476/month this activity inviting all Employees, Tenant of Mangga Dua Square.

ENERGY SAVING/CONSERVATION MANAGEMENT FOR BUILDING

APPLICATION FORM

The Third ASEAN Best Practice Competition for Energy Management in Buildings and Industries

ASEAN Energy Awards 2009

p a g e 2

2. CERTIFICATION AND ENDORSEMENT The Mangga Dua Square hereby agreed to allow the ASEAN Board of Judges and other experts that may be designated by ACE to visit the building/factory and verify the authenticity of the data. However, two weeks advance notice is required to allow for necessary arrangements. We also hereby agreed that ACE can publish the whole submission in ACE publications and website, without any prior consent of the owner of the buildings and industries (factories). If the submission will be published in other publications, the consent of the concerned building and industry (factory) would be required. We, the undersigned certified that the information given is true and accurate and prepared with the consent of the party/ies involved. _____________________ Eva Lioe General Manager Mangga Dua Square Telephone : (021) 6231 – 3000, Ext. 1111 Fax : (021) 6231 – 3338 E-mail : [email protected] ____________________ Didik Kurniadi Facilities Management Manager Mangga Dua Square Telephone : (021) 6231 – 3000, Ext. 1060 Fax : (021) 6231 – 2939 E-mail : [email protected] ____________________ Ibu Indarti Head of Energy Conservation Division Jl. HR. Rasuna Said Blok X-2, Kav. 7-8 Kuningan, Jakarta 12950 Telephone : (021) 522 – 4483 Fax : (021) 522 – 4483 Email : [email protected]

For further inquiries, please contact :

Mr. Christopher G. Zamora ASEAN Centre for Energy 6th Floor, Jl. HR Rasuna Said, Blok X-2 Kav. 07-08 Kuningan, Jakarta 12950, Indonesia Tel.: (6221 – 527-9332) Fax: (6221 – 527-9350), E-mail: [email protected]

APPLICATION FORM

The Third ASEAN Best Practice Competition for Energy Management in Buildings and Industries

ASEAN Energy Awards 2009

p a g e 3

PROJECT PREVIEW

COMPANY BACK GROUND Agung Sedayu Group is a well known Profesional Property Developer in Indonesia with retail, commercial building, housing and apartment development, where Mangga Dua Square ( MDS ) is the one that built in 2004. With experience more than 30 years in the business, Agung Sedayu Group is the best location choice and the valuable investment. Holding Certificate SGS No. ID 04 / 0416.

For information, we have equipments : Engine Gas ( Natural Gas ) : 2,000 kW × 12 units Chiller ( Centrifugal Type ) : 1400 TR × 5 units, supporting by 5 unit Primary Chilled

water pumps and 5 unit Secondary Chilled Water Pumps AHU : 186 units at Mall + Carrefour 16 units + Sands 36 units AHU ( FCU 122 units ) Lift ( Elevator ) : 16 units Escalator : 90 units Travelator : 10 units

The approach of saving exercises is by increasing the chiller water leaving temperature and giving understanding for Tenant participation on conserving energy setting up room/several area temperature at ±25ºC. This would decrease the difference of the chilled water temperature and those influence the tonnage and power usage. The optimizations operate by Building Automation System and Chiller Management. This achieve energy saving :

= 143.640 Kwh/Month x Rp. 1.100/Kwh = Rp. 158.004.000,- = USD 15.048/Month

APPLICATION FORM

The Third ASEAN Best Practice Competition for Energy Management in Buildings and Industries

ASEAN Energy Awards 2009

p a g e 4

9,1237,418 6,274

0

2,000

4,000

6,000

8,000

10,000

AVG FY'06 AVG FY'07 AVG FY'08

ELECTRICAL FY'08

4,763 4,873 4,665 4,813 4,731 4,582 4,741 4,7655,040 4,816

4,5194,860

4,110

4,733 4,788

0

1,000

2,000

3,000

4,000

5,000

6,000

AVGFY'06

Apr-07 May-07 Jun-07 Jul-07 Aug-07 Sep-07 Oct-07 Nov-07 Dec-07 Jan-08 Feb-08 Mar-08 AVGFY'07

AVGFY'08

Thou

sand

s

53,99956,839

41,88841,196

0

10,000

20,000

30,000

40,000

50,000

60,000

AVG FY'06 AVG FY'07 AVG FY'08 AVG FY'09

1. IMPACT 1.1 Energy Saving

Electrical

Average Energy Cosumption 2006 : 4.110 Kwh (thousands) Average Energy Cosumption 2007 : 4.733 Kwh (thousands) Average Energy Cosumption 2008 : 4.788 Kwh (thousands) Average Tenant Occupancy 2006 : 55.93% Average Tenant Occupancy 2007 : 60.23% Average Tenant Occupancy 2008 : 72.07% Average Tenant Occupancy 2009 : 79.35%

Water

Gas

31.22% Water Reduction = 7.605 M³/Year

Increasing of Tenants occupant, some of them are Cafetaria, Restaurant. Potential Saving = 2.840 M³/Month Compare with occupancy Year 2008 to Year 2009

Fig. 1.1.2 Decreasing of average water consumption

Fig. 1.1.3 Average Gas consumption FY’06 to FY’08

Fig. 1.1.1 Energy consumption in FY’08 ( Apr’07 to Mar’08 )

Comparison from Tenant occupancy compare with electricity consume, saving = 141.000 Kwh/Month

APPLICATION FORM

The Third ASEAN Best Practice Competition for Energy Management in Buildings and Industries

ASEAN Energy Awards 2009

p a g e 5

1.2 Environment Effect Reduce CO2 Gas Emission

Gas Quality

GAS Engine 2

GAS Engine 3

GAS Engine 4

GAS Engine 7

GAS Engine 12

O2 (%) 8.7 9.4 8.8 9.3 8.3 CO2 (%) 9.1 6.5 6.8 6.5 7.1 TA (0C) 38 44 49.5 48.5 49.5 Eff (%) 74.4 68.7 69.1 68 70.1 TS (0C) 410 388 394 397 388 EA (%) 69 73 65 71 59

Acid Sensor System for Rain Water A sustainable rain water system management system has been used in the Building, to conserve water and reducing dependency of treated water from city water and Deep Well especially during raining season. The collected water is mainly used irrigating the plants in the Building. The above system ( acid sensor ) if PH between 6 ~ 7 the valve will be open automatically for rain water flow to rain water tank at Basement 2.

Net Power Net Heat Rate Thermal Eff Technology

(MW) (BTU/kWh) (kCal/kWh) (%)

Combine Cycle Unit 1.85 7.587 1.911 50

Table. 1.2.1 Table Data Exhaust Gas from Gas Engine

Table. 1.2.2 data table exhaust gas from Gas Engine

Fig. 1.2.2 Acid Sensor Fig. 1.2.1 Control Valve Acid Sensor

Total Co2 from Gas Engine Exhaust = 7, 5% x 5.225.092 kCal/hours = 391.882 Kcal/hours potential reduce emission.

APPLICATION FORM

The Third ASEAN Best Practice Competition for Energy Management in Buildings and Industries

ASEAN Energy Awards 2009

p a g e 6

1.3 Economic Effect

1.3.1 Investment

- Average working hours escalator/days = 13 Hours

1.3.2 Payback Period

Co-Gen ( Co – Generation ) Investment Scheme : a. Investment Scheme with loan system Bank interest 18% (assumption flat) Loan Period for 3 years Cash Outflow 3 years period

Investment Item

Without Inverter After Inverter Savings Potential Savings

5.409 Kwh/Years 3.036 Kwh/Years 2.373 Kwh/Years = 2.737 x Rp. 1.100

Escalator = Rp. 2.610.300/Years = USD 248/Years

Electrical

Investment

Co-Gen Absorption Chiller

Rp 11,612,702,650 Rp 12,779,843,300 = USD 1.217.128/Years

Fig. 1.3.1.1 Auto sensor escalator

This equipment conserves water average 80 M³/Day during raining season. = Rp. 12.550 x 80 M³/Day = Rp. 1.004.000 = USD 96/Day

Fig. 1.3.2.1 Co-Gen Power Plant

APPLICATION FORM

The Third ASEAN Best Practice Competition for Energy Management in Buildings and Industries

ASEAN Energy Awards 2009

p a g e 7

ELECTRICAL

4,110

4,733 4,788

3,500

3,800

4,100

4,400

4,700

5,000

AVG FY'06 AVG FY'07 AVG FY'08

Thou

sand

s

Co-Generation Value : - NPV > 0 or NPV = Rp 53.511.361.489,- - Bank Interest = 18 % - P I > 1

Inspection Result Item

Without Inverter After Inverter Savings Pay back

Period

Escalator 5.409 Kwh/Years 3.036 Kwh/Years 2.373 Kwh/Years 4 Years

Electrical

Investment

Co-Gen Absorption Chiller

Rp 11,612,702,650 Rp 12,779,843,300 12 Months

1.4 Energy Efficiency Index

As we inform previously that our just Mall established on year 2004, the electrical

Consumption increase due to increasing Occupancy from 60.23 % to 72.07 %, and year 2008 average 4.788.000 Kwh/Month Energy consumption Index : year 2008

184 Kwh/sqm/year

1.16% Increase

15.16% Increase

Fig. 1.4.1 Increasing of average energy consumption due to occupancy increase for 16 %

Fig. 1.3.2.2 Flue Gas Quality

APPLICATION FORM

The Third ASEAN Best Practice Competition for Energy Management in Buildings and Industries

ASEAN Energy Awards 2009

p a g e 8

2. SUSTAINABILITY 2.1 Level of Participation and Involvement 1. Conservation of energy thru operational discipline and procedure 2. Conservation of energy thru retrofitting activity - Water conservation makes use Air Handling Unit condensate water for Cooling Tower Chiller.

- Recycle waste water thru Sewage Treatment Plant use for Cooling Tower Chiller, and flushing Toilet

3. Tenants participation on conserving energy Attached picture was install in every Toilet Inform Tenant to participate utilized water Consume. 2.2 Top Level Management Commitment

The top management acknowledges the importance of energy as a necessary resource for successfully managing the operations of Mangga Dua Square Building Management. The resource must be used responsibility in a manner that is sustainable and complementary to the energy management policy. In addressing this statement, the management will : Incorporate energy efficiency measures including alternative and emerging technologies,

into all and new facilities through best practice in energy efficient. Maintain all equipment and control and manage systems and energy infrastructure in such

a way to reduce energy wastage. Promote awareness of the responsibility for energy conservation to all employees, tenant

by using energy in efficient manner, including the operation of personal equipment and environment.

Strive to procure, distribute and maintain energy resources at the adequate cost.

What management activities have been implemented ? Energy Efficiency Measures :

- Air conditioning control ( Chiller, AHU, FCU ) Etc. - Reducing night base loads. - Purchase of energy efficient equipment bulb.

Fig. 2.1.1 Tenants Participation on conserving energy

This Conserves water usage of 900 M³/Month = Rp. 11.295.000 = USD 1.076/Month

This activity conserve of 6.000 M³/Month = Rp. 75.300.000 = USD 7.171/Month

APPLICATION FORM

The Third ASEAN Best Practice Competition for Energy Management in Buildings and Industries

ASEAN Energy Awards 2009

p a g e 9

Keeping almost the same lumen : - HQITS 70 W = 230 Lux - PLC 2 x 18 W = 235 Lux Total replacement within 15 month = 3.843 Ea HQITS 70 W Type

Identification, development and implementation of awareness programmed among Employees :

- Trainings - Ad hoc programs - Continuous energy campaign 2.3 Short and Long Term Plan

Down light efficiency replacing bulb for Public lighting.

Arrange Gathering Meeting among Top and Middle Management for Energy

Conservation, and come up for the idea and activity as below. - Poster and slogan contest for reduce, reuse, recycle contest - Energy efficient contest among Department and Outsourcing - Submit and idea that will be impact to energy usage in Our Building

Campaign for this strategy : Reduce : Reduce exceed quantity, pressure, temperature, speed, light, etc Re use : Reuse waste energy Recycle : Recycle the waste energy Repair : Improve predictive maintenance to reduce equipment break down Off : Turn of un necessary light, equipment, etc

Fig. 2.3.1 Campaign of energy saving program

Existing Upgrade

Bulb HQITS 70W Bulb PLC 2 x 18W

Potential Saving = 52.580/Kwh/Month

APPLICATION FORM

The Third ASEAN Best Practice Competition for Energy Management in Buildings and Industries

ASEAN Energy Awards 2009

p a g e 1

Facilities Mgt, Environment & Energy Manager

Safety, Environment & Energy Coordinator

Safety, Environment & Energy Supervisor

Safety, Environment & Energy Staff

Quality Assurance Manager

Quality Assurance Supervisor

2.4 Organization The committee members of the Energy Team are :

a) Facilities, Environment & Energy Manager b) Safety, Environment & Energy Coordinator c) Safety, Environment & Energy Supervisor d) Safety, Environment & Energy Staff e) Quality Assurance Manager f) Quality Assurance Supervisor

The Committee’s responsibilities are :

1. Conduct energy conservation committee meeting weekly, and brains storming. 2. Report progressive and succeeds of each projects to management M2S. 3. Assignment target and plan for energy conservation of company. 4. Introduction to technical energy analysis and invite consultant professional to

consultant and propose for energy audit. 5. Gather all meter utility consumption data from the past. 6. Follow up result and continuous improvement.

2.5 Capacity Building 2.5.1 Management Energy Saving Program

As we realized the necessity & limitation of energy resources and in 2008 Mangga Dua Square announces for Maximizing Energy Utilization policy, tight controlling energy consumption between supply and tenant occupancy also our visitor to our Mall, some strategy has been informed to employee regarding energy conservation activities. (Targeted reduce energy consumption 3% below on 2009 compare to year 2008) stated in Balance Score Card. Activity dash board.

2.5.2 Educational Training

Fig. 2.5.1.1 Educational Training

Fig. 2.4.2 M2S Energy conservation committee organization

Fig. 2.4.1 Weekly meeting. Employees participation in executing program of saving energy by discussion.

APPLICATION FORM

The Third ASEAN Best Practice Competition for Energy Management in Buildings and Industries

ASEAN Energy Awards 2009

p a g e 2

3. REPLICABILITY 3.1 Management Practices and Measures Preventive & Energy Management

Chiller characteristic : If chilled water temperature high, chiller operate high efficiency

Example Energy Management : 1. Elevator

Fig. 3.1.1 Cooling Tower

Fig. 3.1.2 Chiller temperatures

Table 3.1.1 Elevator (lift) operation schedule

APPLICATION FORM

The Third ASEAN Best Practice Competition for Energy Management in Buildings and Industries

ASEAN Energy Awards 2009

p a g e 3

7:00 9:00 10:00 11:00 12:00 13:00 14:00 15:00 16:00 17:00 18:00 19:00 20:00 21:00 h

Now 12.5

6.5

6

6.5

6

CASE- A

CASE- B

8:00

2. Lighting

Improvement of Parking Fan Operation Schedule

B2 Floor Parking Fan: 18 Units, 646 kW,

Load factor: 0.8 (presumption)

Fig. 3.1.3 Parking Area at Basement 2

Table 3.1.2 Lighting operation schedule

Effect : Electricity Reduction = 646 x 0.8 x ( 12.56.25 ) x 35 = 1.178.950 kWh/Years

APPLICATION FORM

The Third ASEAN Best Practice Competition for Energy Management in Buildings and Industries

ASEAN Energy Awards 2009

p a g e 4

0

20000

40000

60000

80000

100000

120000

8:0 9:3 11:0 12:3 14:0 15:3 17:0 18:3 20:0 21:3Time

Watt-hours (wh)

Mode-1: Daily watt-hours (Nov 12th)

Mode-3: Daily watt-hours 55 kW (Nov 13th)

Mode-2: Daily watt hours (Nov 11th )

50% reduction of electric power

Nov11thwatt-hours Nov 12th watt-hours Nov 13th watt-hours

Parking lot ventilation fan power chart

Example :

Saving energy by changing the operating mode of parking lot ventilation fans (1)

Efficiency lighting outdoor at Pagoda Food City

Calculation of Efficiency Lighting Outdoor PAGODA FOOD CITY

Before Efficiency After Efficiency No. Description Volume Unit Volume Unit 1 Total Operational Hours 6 Hours 6 Hours 2 Total Day Operational 30 Days 30 Days 3 Total power supplied (100 A ) 65.74 kva 65.74 kva 4 Total power used 26.12 KW 7.63 KW A. Lampion lamp ( 220 pcs ) 18 Watt/ea 7 Watt/ea B. Spotlight PAR ( 277 pcs ) 80 Watt/ea 22 Watt/ea

5 Subscription fee (per KVA/month) 31,000 Rp 31,000 Rp

6 Usage charge ( per KWH ) 990 Rp 990 Rp 7 Public Lighting Tax fee ( PPJU ) 3 % 3 % 8 Cos 1 1

9 Detail :

Calculation of Electric Consumption Cost : TOTAL COST = SUBSCRIPTION FEE + USAGE CHARGE + PUBLIC LIGHTING TAX FEE

A. Subscription fee 2,037,940 Rp 2,037,940 Rp B. Usage Charge 4,654,584 Rp 1,360,379 Rp C. Subscription fee 200,776 Rp 101,950 Rp D. Total Cost 6,893,300 Rp 3,500,268 Rp

Fig. 3.1.5 Pagoda Food City Night life hawker

Fig. 3.1.4 Parking lot ventilation fan power

APPLICATION FORM

The Third ASEAN Best Practice Competition for Energy Management in Buildings and Industries

ASEAN Energy Awards 2009

p a g e 5

3.2 Technology

Building Automation System (BAS) To Monitor and Control various Mechanical and electrical device and feature program are :

- Controlling on/off Air Handling Unit. - Controlling on/off Split Unit in pre lobby area. - Parameter set points on AC system temperature. - Inform to our operator if the filter of Air Handling Unit Dirty. - Control motorize valve inlet to AHU and FCU.

Indoor air quality setting temperature : 24 – 25 Degree Celsius and average RH 57 % Computerized based system responsible for Controlling and monitoring AC-Chillers, Chilled Condenser water pumps and Cooling Towers Automatic Operations. Computer Maintenance Management System ( CMMS ) For year 2009 our Management has been decided to Implement through C’WORKS CMMS program, this system will guide us for :

- Work Order Management - Planning and scheduling in Preventive Maintenance - Asset Management and Tracking - Resource Management - Management Report

Installing Load Shedding Control Devices Installed in low voltage main distribution panel ( LVMDP ) No. 1, 9, and 10 where total electric power supplied form Gas Engine 12 X 1500 kW ( 80 % load ) = 18.000 kW

Fig. 3.2.2 CWORKS CMMS Fig. 3.2.1 Building Automation System ( BAS )

Potential Saving Electricity Consumption : = Rp. 6.893.300 – Rp. 3.500.268 = Rp. 3.393.032/Month ( 49.22% ) = USD 323/Month

Fig. 3.2.3 Arrow Load Shedding Control Devices

APPLICATION FORM

The Third ASEAN Best Practice Competition for Energy Management in Buildings and Industries

ASEAN Energy Awards 2009

p a g e 6

When the load comparison between PLN and gas engine generator is assumed = 5000 kVA to 8000 kVA with 20 KV automatic synchronize system. The load shedding control device will control the frequency so that stabilizing above 48,5 Hz and can be setted according to requirement ( pictures with red arrow ). Currently has been installed 3 units of load shadding control device for 3 of our LVMDP where those panels supplying electricity for chilled water pumps condenser water pumps and for the chillers themselves. In case of the electric supply by PLN/Grid trip and the electric frequency is decreasing then the load shading control device will automaticaly shut down the electric supply for each particular LVMDP at the same time.

We always monitor of daily consumption load if there is losses of energy, or if there is any sudden load can be monitored immediately.

0:00 1:00 2:00 3:00 4:00 5:00 6:00 7:00 8:00 9:00 10:00 11:00

Eng. Load [MW] 3561.100 3482.633 3363.567 3142.633 2991.033 2417.900 1566.533 1551.367 1832.600 3285.467 4739.567 5158.633

PLN Load [MW] 816.233 780.000 704.233 500.267 445.233 377.400 854.267 1037.567 1955.233 3280.167 3289.567 3671.333

Total [MW] 4377.333 4262.633 4067.800 3642.900 3436.267 2795.300 2420.800 2588.933 3787.833 6565.633 8029.133 8829.967

12:00 13:00 14:00 15:00 16:00 17:00 18:00 19:00 20:00 21:00 22:00 23:00

Eng. Load [MW] 5250.400 5520.367 5563.300 7075.733 8804.367 9365.967 10195.000 10251.667 9750.500 9077.433 6908.733 3910.167

PLN Load [MW] 4000.033 3933.700 3853.400 2738.900 1160.433 750.833 317.733 177.800 113.467 91.800 108.933 859.767

Total [MW] 9250.433 9454.067 9416.700 9814.633 9964.800 10116.800 10512.733 10429.467 9863.967 9169.233 7017.667 4769.933

AVERAGE DAILY LOAD CHARACTERISTIC

0.000

2000.000

4000.000

6000.000

8000.000

10000.000

12000.000

0:00 1:00 2:00 3:00 4:00 5:00 6:00 7:00 8:00 9:00 10:00 11:0012:0013:00 14:00 15:0016:00 17:0018:00 19:0020:0021:00 22:00 23:00

TIME

LOAD (kWh) Eng. Load [MW] PLN Load [MW] Total [MW]

Fig. 3.2.4 Daily Load Characteristic

Potential Saving due to installing Load Shedding Devices = Rp. 279.159.051/Month = USD 26.587/Month

APPLICATION FORM

The Third ASEAN Best Practice Competition for Energy Management in Buildings and Industries

ASEAN Energy Awards 2009

p a g e 7

9.2%

54.7%5.5%

4.8%

25.8% MallOutdoorAir-ConPumpESC.&LiftTenant

0

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

00:00 - 10:00 10:00 - 18:00 18:00 - 22:00 22:00 - 24:00 Total

Gas Engine [KWH]PLN [KWH]

0

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

00:00 - 10:00 10:00 - 18:00 18:00 - 22:00 22:00 - 24:00 Total

Gas Engine [KWH]PLN [KWH]

Energy Consumption & Energy Source parallel between electrical supply from Grid and Gas Engine

4. FUTURE ENERGY CONSERVATION/IMPROVEMENT ACTIVITIES

Future main improvement activities - Additional Double Door at Main Entrance Door to reduce losses because of air

infiltration. Potential Saving = 209.52 TR x 1.1 kw/TR x 12 hr/day x 30 day/month x 1100 rph/wh = Rp. 91.266.912/Month = USD 8.693/Month Pay back period = 11 Months Total = 16 access doors

Fig. 3.2.5 Electrical load percentage

Fig. 3.2.6 Energy consumption PLN and Gas Engines

![基図7000-1 [cs2] - MLIT › kanazawa › river › census › h25 › img › ...堰 0.0km 0.0km 2.0km 2.0km 1.0km 1.0km 27 27 27 091 091 091 091 091 091 091 091 091 091 101 101](https://static.fdocuments.in/doc/165x107/5ed6eb3eff4a11075f770b64/7000-1-cs2-a-kanazawa-a-river-a-census-a-h25-a-img-a-.jpg)