Ice Cream Manufacturing

-

Upload

mostafa-abd-el-alem -

Category

Documents

-

view

219 -

download

0

Transcript of Ice Cream Manufacturing

-

8/2/2019 Ice Cream Manufacturing

1/19

Intelligen, Inc. 1

Ice Cream Manufacturing

Production Scheduling Analysis

Using ScheduleProTM

INTELLIGEN, INC.

Simulation, Design, and Scheduling Toolsfor the Process Manufacturing Industries

www.intelligen.com

http://www.intelligen.com/http://www.intelligen.com/http://www.intelligen.com/ -

8/2/2019 Ice Cream Manufacturing

2/19

Intelligen, Inc. 2

Table of Contents

Table of Contents ........................................................................................................................ 2Introduction ................................................................................................................................. 3Process and Line Description ...................................................................................................... 3Building the Model ....................................................................................................................... 6

Facility ..................................................................................................................................... 6Recipes ................................................................................................................................... 7Addition and Initialization of Operations.................................................................................. 10

Production Schedule ................................................................................................................. 13Setting up the production schedule ........................................................................................ 13SchedulePro Outputs ............................................................................................................. 15

Base Case (Ice_Cream_Base_Case file) ............................................................................ 15Optimized Case (Ice_Cream_Optimized_Case file) ............................................................ 17

References................................................................................................................................ 19

http://www.intelligen.com/http://www.intelligen.com/http://www.intelligen.com/ -

8/2/2019 Ice Cream Manufacturing

3/19

Intelligen, Inc. 3

Introduction

The purpose of the example is to demonstrate how to schedule a multi-product ice cream factory

using SchedulePro and how to use the outputs of the program to optimize the schedule. Users in

the food and consumer product industries will find this example useful.

This example was based on data available in a paper published by scientists employed at the

Unilever Food and Health Research Institute in the Netherlands (1).

This plant manufactures eight different types of ice cream products (SKU-A, B, C, D, E, F, G, and

H). Each product was represented with a different recipe in SchedulePro. Production schedules

were generated to meet a certain weekly demand. This example includes two SchedulePro

project files:

1. Ice_Cream_Base_Case

2. Ice_Cream_Optimized_Case

The first one represents a rough-cut schedule. The second represents an optimized solution us-

ing flexible start time shifts in the recipes.

Process and Line Description

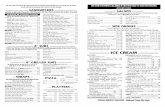

Figure 1 displays a schematic of the simplified plant analyzed in this example. The plant is

equipped with a single Process Line that mixes and pasteurizes the various ingredients. The

process line operates at a throughput of 4500 kg/h. The processed material is stored in one of the

storage tanks that feed the two Packing Lines. The two 8000 kg vessels (1 & 2) are coupled with

Packing Line 1, while the four 4000 kg tanks (3, 4, 5 & 6) are coupled with Packing Line 2.

The packing lines are cleaned and adjusted between product changes. Table 1 displays the

changeover times for the packing lines. For instance, going from SKU-C to SKU-D, a 60 minchangeover time is needed. The processing rates of the packing lines are variable and depend on

the product according to the data of (Table 2). Products A, B, C, and D are packed in Line 1.

Products E, F, G, and H are packed in Line 2.

The pasteurized material of a batch can stay in a storage tank for up to 72 h. There is also a

product-specific minimum storage time according to the data of Table 3.

-

8/2/2019 Ice Cream Manufacturing

4/19

Intelligen, Inc. 4

Table 4 displays the typical weekly demand for the various products. The objective of this project

is to find out whether this demand can be met by the production lines of this facility.

Figure 1: The simplified ice cream manufacturing plant

Note: The figure above was created in SuperPro Designer. SuperPro is a comprehensiveprocess simulator that handles modeling, evaluation, and optimization of a wide variety of

processes, including ice cream manufacturing. However, SuperPro cannot be used to model mul-

ti-product facilities, which is the case in this example. The recipes of batch processes modeled in

SuperPro can be readily exported to SchedulePro. The recipes of this example, however, were

created directly in SchedulePro.

If you are interested in learning how to export SuperPro recipes to SchedulePro, please study the

Pharma_Tablet_Manufacturingexample of SchedulePro as well as the manual of SchedulePro

which can be downloaded from the SchedulePro page of our website (www.intelligen.com). For

more information on the scope and capabilities of SuperPro Designer, please download the func-

tional Evaluation version of SuperPro from our website and pertinent product literature and publi-

cations from the literature page of our website (www.intelligen.com/literature ).

Process Line

4500 kg/h

Transfer Panel

Vessel 1

8000 kg

Vessel 2

8000 kg

Vessel 3

4000 kg

Vessel 4

4000 kg

Vessel 5

4000 kg

Vessel 6

4000 kg

Packing Line 1

Packing Line 2

Ingredients Line1 Products

Line2 Products

Ice Cream Plant

http://www.intelligen.com/http://www.intelligen.com/http://www.intelligen.com/http://www.intelligen.com/literaturehttp://www.intelligen.com/literaturehttp://www.intelligen.com/literaturehttp://www.intelligen.com/literaturehttp://www.intelligen.com/literaturehttp://www.intelligen.com/ -

8/2/2019 Ice Cream Manufacturing

5/19

Intelligen, Inc. 5

Table 1: The changeover times for the two packing lines.

From\To idle SKU A SKU B SKU C SKU D SKU E SKU F SKU G SKU H

idle 0 120 120 120 120 120 120 120 120

SKU A 120 0 60 60 60 0 0 0 0

SKU B 120 30 0 60 60 0 0 0 0

SKU C 120 30 30 0 60 0 0 0 0

SKU D 120 30 30 30 0 0 0 0 0

SKU E 120 0 0 0 0 0 60 60 60

SKU F 120 0 0 0 0 30 0 60 60

SKU G 120 0 0 0 0 30 30 0 60

SKU H 120 0 0 0 0 30 30 30 0

Table 2: Packing line product-dependent processing rates

Product Composition Packing Rate[kg/hr] Packing Line

SKU A mix 1750 1

SKU B mix 1500 1

SKU C mix 1000 1SKU D mix 1500 1

SKU E mix 1750 2

SKU F mix 2000 2

SKU G mix 2000 2

SKU H mix 2000 2

Table 3: The minimum and maximum storage times

Product Minimum time [h] Maximum [h]

mix A 1 72

mix B 3 72

mix C 3 72

mix D 0 72mix E 2 72

mix F 2 72

mix G 2 72

mix H 2 72

Table 4: Weekly product demand

Product Quantity [kg] # of batches

SKU A 80000 8

SKU B 48000 6

SKU C 32000 4

SKU D 80001

SKU E 112000 28

SKU F 12000 3

SKU G 48000 12

SKU H 24000 6

-

8/2/2019 Ice Cream Manufacturing

6/19

Intelligen, Inc. 6

Building the Model

In SchedulePro, each product corresponds to a recipe, while each processing step corresponds

to a procedure. Activities within a procedure are called operations. Procedures require the use of

a main piece of equipment.

Facility

The resources required for the execution of a recipe are organized under facilities. Since multiple

recipes can utilize the same equipment items of a facility, the specification of the facility along

with its assets should precede the creation of recipes. This is done by selecting the Facilities

node in the tree-control of the interface (on the LHS) and pressing the Add New Facility button

on the RHS. The user can then specify the name of the facility, Ice Cream Plant (Figure 2).

Figure 2: Specifying a new facility in SchedulePro

Next, the user has to specify the nine equipment items (one Process Line, two Packing Lines,

and six Storage Vessels). To create a new piece of equipment, the user should select the

Equipment node in the tree-control and then press the Add New Equipment button (Figure

3). To edit the properties of an equipment item, select it, and press the Edit Equipment button

(Figure 3). That brings up the Equipment Properties dialog; in the Size tab of this dialog the

user may specify batch size limits for storage-type of equipment and processing rate for through-

put-type of equipment. A processing rate of 4500 kg/h should be specified for the Process Line.

Add New Facility

button

Add Facility Outages

button

-

8/2/2019 Ice Cream Manufacturing

7/19

Intelligen, Inc. 7

Figure 3: Specifying equipment in SchedulePro

The facility of this example operates 5 days a week; it closes down for weekends. Closures (out-

ages) can be specified using the facility outages button (Figure 2). Pressing the outages button

brings up a calendar window. Right-click on the box of an appropriate starting date and select

Add new entry Then, in the dialog that pops up, specify the duration (48hrs) of the weekend

downtime and Weekly as its repeat pattern.

Recipes

Eight recipes were created, one for each SKU. Each recipe consists of three unit procedures:

1. Prepare-Mix, the preparation of the mixture using the Process Line as equipment.

2. Store-Mix, the intermediate storage step that utilizes either one of the 8000 kg or one of

the 4000 kg vessels. The choice on the type of the vessel depends on the Packing line

specification (Table 2). The two 8000 kg vessels (1 & 2) are associated with packing line

1 while the four 4000 kg (3, 4, 5 & 6) are coupled with packing line 2. The available ves-

sels are specified as a pool of equipment for the corresponding storage procedures. The

batch size is also determined by the tank used and is either 8000 kg or 4000 kg and thatwill determine how many batches need to be executed per campaign to satisfy the order.

3. Pack-mix, depending on the product Packing Line 1 or 2 is selected.

Add New Equipment

button

Equipment Properties

button

-

8/2/2019 Ice Cream Manufacturing

8/19

Intelligen, Inc. 8

Figure 4: The product recipes in SchedulePro

To create a new recipe, select the Recipes node on the LHS, and press the Create New Rec-

button on the RHS

-

8/2/2019 Ice Cream Manufacturing

9/19

Intelligen, Inc. 9

(

Figure 5). To specify the batch size of a recipe, select the recipe and press the Edit Recipe but-

ton. The batch size of recipes A, B, C, and D should be 8000 kg, because they are packed in Line

1 that is equipped with the two 8000 kg storage tanks. The batch size of recipes E, F, G, and H

should be 4000 kg, because they are packed in Line 2 that is equipped with four 4000 kg storage

tanks. The batch size of a recipe is used for calculating the duration of certain operations.

Figure 5: Creating a new recipe in SchedulePro

The next step is to specify the procedures. To add a procedure to a recipe, select the appropriate

recipe in the tree-control and press the Add New Procedure button on the RHS. Next, allocate

appropriate equipment to each procedure. To do that, select the appropriate procedure and press

the Edit Procedure Data button to bring up the Procedure Details dialog and then switch to

the Main Equipment Pool tab where the appropriate equipment can be allocated. For instance

Figure 6 displays the equipment pool (Vessel 1 and Vessel 2) for the Store-Mix procedure of the

SKU-A recipe. The equipment pool is a set of equipment which may be used for the procedure.

For the case of SKU-A, a batch of SKU-A can be stored in either Vessel 1 or Vessel 2; whichever

is available during the processing of an SKU-A batch. If none of the storage tanks is available, the

entire batch should be delayed until a tank becomes available.

Add New Recipe

button

-

8/2/2019 Ice Cream Manufacturing

10/19

Intelligen, Inc. 10

Figure 6: Specifying the equipment pool for a procedure

Addition and Initialization of Operations

The next step is to add operations to procedures. A procedure in a SchedulePro recipe may in-

clude any number of operations. Operations represent the smaller activities that are carried out in

vessels in typical batch manufacturing facilities. Resources other than main equipment are as-

signed to operations. To add operations to a procedure, select the appropriate procedure on the

LHS (under its corresponding recipe) and press the Add New Operation button on the RHS.

The duration of an operation in SchedulePro is either specified directly or calculated based on

batch size and processing rates. Also, each operation is scheduled relative to other operations or

the beginning of the batch.

For SKU A: The Prepare-Mix procedure includes one operation called Mix and Pasteurize. The

duration of this operation (106.67 min) is determined by the processing rate of the Process Line

(4500 kg/h)and the size of a single batch (in this case 8000 kg). The duration of the operation is

calculated based on the batch size divided by processing rate of the equipment level. Figure 7

displays the Durationtab of an operations properties dialog.

-

8/2/2019 Ice Cream Manufacturing

11/19

Intelligen, Inc. 11

Figure 7: The Operation Details dialog where the user can specify duration of an operation

The Store-Mix unit procedure includes 3 operations:

1. Receive Mix, this operation is executed in parallel to the Mix and Pasteurize operation.

Select the Duration Equal to Another Operation or Sequence of Operations option

(Figure 7), and specify Prepare-Mix and Mix and Pasteurize as the master procedure

and operation, respectively. This sets the duration of this operation equal to the duration

of specified master operation. Use the Scheduling tab to specify that the operation starts

when the Mix and Pasteurize operation starts.

2. Hold, the hold operation starts when the previous operation (Receive Mix) finishes and

has a set duration of 60 min, equal to the minimum storage time required for this product.

Constant durationset by the user

Duration calculated

based on processing

rate and batch size

Duration calculated

based on other

operation

-

8/2/2019 Ice Cream Manufacturing

12/19

Intelligen, Inc. 12

3. Feed Packing Line, this operation has duration equal to the duration of the Pack opera-

tion. It starts when the previous operation (Hold) finishes. In the case that a packing line

is not available, however, a Flexible Shift has been specified. This allows the material to

wait in storage until a line is available up to a maximum of 71 h (maximum storage al-

lowed for this product). The flexible start time shift is specified through the scheduling tab

in the operation dialog (Figure 8). In the results section, a scenario with and without the

flexible shifts times will be demonstrated.

Figure 8: The scheduling tab of the Operation Details dialog

Scheduling

Options

Flexible

Shift

-

8/2/2019 Ice Cream Manufacturing

13/19

Intelligen, Inc. 13

The Pack-Mix unit procedure consists of one operation, which starts when the Feed Packing Line

operation starts, and the duration (274.26 min) is determined from the batch size (in this case

8000 kg). The processing rate depends on the type of product (in this case 1750 kg/h) (Table 2).

All the other product recipes are created in the same way as the one for SKU-A. A recipe can be

visualized using the recipe Gantt chart (Figure ). This chart is brought up by selecting a recipe

and pressing the ViewRecipe Gantt Chart button ( ) on the right hand side.

Figure 9: The recipe Gantt chart for SKU-A

Production Schedule

Setting up the production schedule

A production plan was generated to satisfy the demands according to Table 4. The plan consists

of several campaigns. A campaign is defined as a set of batches of a certain recipe. In this case,

8 different campaigns were scheduled (one for each product):

10 batches (of 8000 kg) of SKU-A

6 batches (of 8000 kg) of SKU-B

4 batches (of 8000 kg) of SKU-C

1 batch (of 8000 kg) of SKU-D

28 batches (of 4000 kg) of SKU-E

3 batches (of 4000 kg) of SKU-F

12 batches (of 4000 kg) of SKU-G

6 batches (of 4000 kg) of SKU-H

Hold/Standing time

(min 1hr, max 72hr)

-

8/2/2019 Ice Cream Manufacturing

14/19

Intelligen, Inc. 14

Campaign scheduling in SchedulePro follows the order in which these campaigns. It is therefore

important to set the priorities correctly (usually based on the desired due date) when declaring

campaigns. In this example, all orders have to be completed within a week but at no specific or-

der. Nevertheless, the campaign order can de defined based on the changeover requirements.

As seen in Table 1, the changeover time is less if switching between products in the reverse or-

der of their definition (from D to A and also from H to E). With some simple process time calcula-

tions, it also becomes obvious that Packing Line 1 is the time bottleneck and, therefore, product

campaigns assigned to this line should be given priority. With these considerations, it makes

sense, at least at the onset, to declare the campaigns in the following order: D,C, B, A, H, G, F, E.

If needed, that order can be changed later on to optimize the schedule.

To introduce a campaign, select the Production Schedule node in the tree-control on the LHS,

and press the Add NewCampaign button on the RHS.

Figure 10: Adding a campaign in SchedulePro

The Campaign Setup dialogthat pops upallows the user to specify the associated recipe and

number of batches (in the ID/Amount tab) and the campaign start mode (in the Time

/Sequencing tab). For each campaign, specify the number of batches shown in Table 4 and set

the Start Mode to On or after Release Date with the release date set at the schedule start. With

this Start Mode selection, SchedulePro will try to find the earliest possible time to start each cam-

paign within the production week.

In the Advanced tab of the same dialog any in-between-campaigns cleaning or changeover can

be specified. As shown in Figure , a changeover time of 0.5hrs (30 min) is specified (according to

Table 1) for the SKU-D campaign because it is followed by the SKU-C campaign.

Add New Campaign

button

-

8/2/2019 Ice Cream Manufacturing

15/19

Intelligen, Inc. 15

Figure 11: The Campaign setup dialog

No changeover time is specified for campaigns SKU-A-1 and SKU-E-1 which are the last to be

executed in the respective packing lines 1 and 2 (alternatively, a changeover time of 2hrs can be

specified to indicate the transition to Idle for both lines).

Once all eight campaigns have been specified the user can proceed with the scheduling of the

campaigns by pressing the Schedule All Campaigns button on the main toolbar.

SchedulePro Outputs

Base Case (Ice_Cream_Base_Case file)

Production schedules in SchedulePro may be visualized through the Operations Gantt chart, the

Equipment Occupancy chart, and the reports that the application generates. The Operations

-

8/2/2019 Ice Cream Manufacturing

16/19

Intelligen, Inc. 16

Gantt chart (Figure ) can be visualized at various levels of detail. The green bars in Figure

represent campaigns and the yellow bars represent batches of a campaign. A batch can be ex-

panded down to its procedures (by clicking on the [+] box in the cells of the Task column of the

grid on the LHS), and a procedure can be expanded down to its operations.

Figure 12: The Operations Gantt chart for the schedule

The Equipment Occupancy chart is shown in Figure 13. This chart is displayed by pressing the

Show Occupancy Chart button ( ) on the main toolbar. The total duration (make span) of the

entire production schedule is approximately 7 days, excluding the weekend break (shaded area).

Different colors represent the various product campaigns. The grey shaded area corresponds to

the facility shutdown for the weekend. The base case solution cannot meet the weekly demand.

Figure 13: The equipment occupancy profile of the production schedule

Changeover

time

-

8/2/2019 Ice Cream Manufacturing

17/19

Intelligen, Inc. 17

Packing Line 1 is the piece of equipment with the highest time utilization followed by Packing Line

2 (Figure 14). The Equipment Time Utilization chart of Figure 14 is generated by selecting View

\ Equipment Time Utilization from the main menu of the application.

It can be noted from the equipment occupancy chart (Figure 14) that the two packing lines are not

utilized to their fullest extent. More specifically, Line 1 is underutilized towards the end of the

week and Line 2 is underutilized during the first three days of the week.

Can we improve the solution and generate a schedule that meets the weekly demand?

Figure 14: Equipment time utilization

Optimized Case (Ice_Cream_Optimized_Case file)

By zooming in the Equipment Occupancy chart (Figure 15) we can see that the Process Line

(top equipment) has enough capacity to satisfy both Packing Lines if it can use the idle gaps.

Those gaps are the result of the inflexible way the recipe was set up: a new batch in the ProcessLine cannot start unless both a storage vessel and the corresponding packing line are available.

Since all products can be stored in the vessels for up to 72 hrs, we can use this flexibility to re-

lieve the Process Line from the above constraint. This is done by specifying appropriate Flexible

Start Time Shift values for the Feed Packing Line operation in the Store-Mix procedure (Figure

8) for all recipes. The improved solution (after rescheduling) is shown in Figure 16. It can be

noted that the make span of the entire production plan has been reduced to 5 days and the utili-

-

8/2/2019 Ice Cream Manufacturing

18/19

Intelligen, Inc. 18

zation of both packing lines is now quite high. The utilization of all the equipment has been in-

creased considerably with the packing lines exceeding 90% (Figure 7).

Figure 15: Zooming in the equipment occupancy chart

Figure 16: The optimized schedule

Space for a Process

Line 2 SKU

If Process Line 2 is not

available, product can be

stored for up to 72hrs

Extended

Storage

-

8/2/2019 Ice Cream Manufacturing

19/19

Intelligen, Inc. 19

Figure 17: Equipment time utilization for the optimized schedule

References

(1) Peter M.M. Bongers, B.H. Bakker (2006), Application of multi-stage scheduling, 16th

European

Symposium on Computer Aided Process Engineering and 9

th

International Symposium onProcess Systems Engineering, Elsevier