Ic engines

-

Upload

prabu-k -

Category

Automotive

-

view

315 -

download

2

Transcript of Ic engines

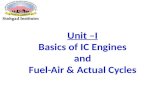

UNIT- I

INTRODUCTION TO

IC ENGINES

HEAT

HEAT AND WORK

CONVERTIONS

• WORK can be completely converted into HEAT but HEAT cannot be completely converted into WORK .

• THE DEVICE WHICH CONVERTS HEAT INTO WORK IS ENGINE

Classifications:

Internal Combustion Engines (IC Engines) External Combustion Engines (EC Engines)

Internal Combustion Engines (IC Engines): IC Engines are those in which combustion of

fuels take places inside engine cylinder (Example: Petrol, Diesel,GAS)

External Combustion Engines (EC Engines): EC Engines are those in which combustion of

fuels take places outside engine cylinder (Example: Steam Engine, Steam turbine)

Classification of IC Engines: a. According to the cycle of operation Spark ignition engines(Petrol or Constant volume

or Otto cycle) Compression ignition engines(Diesel or Constant

Pressure)b. According to the type of fuel used Petrol, Diesel, Gas Engine.c. According to the method of fuel SI & CId. According to the Process of combustion Otto cycle, Diesel cycle, Dual combustion cycle

Basic Parts of IC Engines:

cylinder,

cylinder head,

piston,

connecting rod,

crankshaft,

flywheel

Camshaft,

crankcase,

piston pin,

crankpin,

piston rings &oil ring

About Petrol Engine: A petrol engine (also known as a gasoline engine in North America) is an

internal combustion engine with spark-ignition, designed to run on petrol (gasoline).

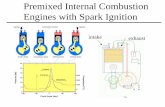

Working Cycles Four Stroke Petrol Engine: It is also known as Otto cycle or constant volume cycle. Cycle of operation is completed in 4-strokes of the piston or 2 revolutions of the

crankshaft. Each stroke consists of 180°, of crankshaft rotation and hence a cycle consists of 720°of

crankshaft rotation. 2-stroke: 1 power stroke per 1 crankshaft rev4-stroke: 1 power stroke per 2 crankshaft rev

Principle of Operation:

The series of operations of an ideal four-stroke SI engine are as follows

Suction Stroke or charging stroke

Compression Stroke

Expansion or Power Stroke or working stroke

Exhaust Stroke

Principle of Operation

Principle of Operation:

Stroke Valve Position

Suction StrokeSuction Valve openExhaust Valve closed

Compression Stroke Both Valves closedExpansion or Power Stroke Both Valves closed

Exhaust StrokeExhaust Valve openSuction Valve closed

Suction Compression Ign.-Combn. Expansion Exhaust

FOUR STROKE SI ENGINE

FOUR STROKE ENGINE

Working Principles of Four Stroke Diesel Engine:

Increased pressure of combustion gases acts on piston -> converted to rotary motion

Can be 2 or 4 stroke engines2-stroke: 1 power stroke per 1 crankshaft rev4-stroke: 1 power stroke per 2 crankshaft rev

Engine stroke:A stroke is a single traverse of the cylinder by the piston (from TDC to BDC)1 revolution of crankshaft = 2 strokes of piston

Working Principles of Four-Stroke Diesel Engine

StrokesIntakeCompression

PowerExhaust

Working Principles Of Four Stroke Diesel Engine: Intake stroke

Intake valve open, exhaust valve shutPiston travels from TDC to BDCAir drawn in

Compression strokeIntake and exhaust valves shutPiston travels from BDC to TDCTemperature and pressure of air increase

Working Principles Of Four Stroke Diesel Engine:Power stroke

Intake and exhaust valves shutFuel injected into cylinder and ignitesPiston forced from TDC to BDC

Exhaust strokeIntake valve shut, exhaust valve openPiston moves from BDC to TDCCombustion gases expelled

FOUR STROKE CI ENGINE

Working Principles Of Two Stroke Petrol Engine

Working Principles Of Two Stroke Petrol Engine

Ignition types Petrol Engine Diesel Engine Spark Ignition Compression Ignition

23

Two Stroke Cycle Petrol Engine - Construction

Construction :•A piston reciprocates inside the cylinder•It is connected to the crankshaft by means of connecting rod and crank•There are no valves in two stroke engines, instead of valves ports are cut on the cylinder walls.•There are three ports, namely inlet, exhaust and transfer ports.•The closing and opening of the ports are obtained by the movement of piston. The crown of piston is made in to a shape to perform this.•A spark plug is also provided.

24

Two stroke cycle Petrol Engines - Working

First Stroke : (Compression, ignition and inductance) (Upward stroke of piston)

(a) compression: • The piston moves up from Bottom Dead Centre (BDC)

to Top Dead Centre (TDC)• Both transfer and exhaust ports are covered by the

piston.• Air fuel mixture which is transferred already into the

engine cylinder is compressed by moving piston.• The pressure and temperature increases • at the end of compression.

25

Two stroke cycle Petrol Engines - Working

First Stroke : (Compression, ignition and inductance) (Upward stroke of piston)

(b) Ignition and Inductance:• Piston almost reaches the top dead centre•The air fuel mixture inside the cylinder is ignited by means of an electric spark produced by a spark plug•At the same time, the inlet port is uncovered by the plane.•Fresh air fuel mixture enters the crankcase through the inlet port

26

Two stroke cycle Petrol Engines - Working

Second Stroke: (Downward Stroke of the engine) :

(c)Expansion and Crankcase compression•The burning gases expand in the cylinder•The burning gases force the piston to move down. Thus useful work is obtained.•When the piston moves down, the air fuel mixture in the crankcase is partially compressed. This compression is known as Crank case compression.

27

Two stroke cycle Petrol Engines - Working

Second Stroke: (Downward Stroke of the engine) :(d) Exhaust and transfer:

•At the end of expansion, exhaust port is uncovered.•Burnt gases escape to the atmosphere.•Transfer port is also opened. The partially compressed air fuel mixture enters the cylinder through the transfer port.•The crown of the piston is made of a deflected shape. So the fresh charge entering the cylinder is deflected upwards in the cylinder. •Thus the escape of fresh charge along with the exhaust gases is reduced.

CompressionIntake and exhaust valves shutPiston travels from BDC to TDCTemperature and pressure of air increase

Power strokeIntake and exhaust valves shutFuel injected into cylinder and ignitesPiston forced from TDC to BDC

Working Principles Of Two Stroke Diesel Engine

Working Principles Of Two Stroke Diesel Engine

• Strokes– Compression

– Power– (Intake/Exhaust)

Working Principles Of Two Stroke Diesel Engine

Application Of Four stroke Cycle Engine

Used in heavy vehiclesBuses,Lorries, Trucks etc.,

Application Of Two stroke Cycle Engine

Used in light vehicles Bikes, Scooters, MopedsShip propulsion

Application Of Four stroke Petrol Engine

Buses ,Trucks Mobile electric generating sets.Small pumping sets with side cars

Application Of Four stroke Diesel Engine30kw-Tractors40to 100kw – jeeps, buses and trucks200 to 400kw-Earthmoving m/c100 to 35000kw-Marine application

33

I.C ENGINE TERMINOLGOGY

34

I.C ENGINE TERMINOLGOGY

The standard terms used in I.C Engines are1. Bore: Inside diameter of the cylinder is termed as Bore

and it is designated by the letter d and is usually expressed in millimeter (mm)

2. Top Dead Center (TDC): The extreme position reached by the piston at the top of the cylinder in the vertical engine is called Top Dead center. It is also called the Inner dead centre (IDC).

3. Bottom Dead Center (BDC): The extreme position reached by the piston at the Bottom of the cylinder in the vertical engine is called Bottom Dead center. It is also called the Outer dead centre (ODC).

35

I.C ENGINE TERMINOLGOGY

4. Stroke: The nominal distance travelled by the piston in the cylinder between the extreme upper and lower positions of the piston (TDC &BDC) is termed as stroke and it is designated by the letter Land is usually expressed in millimeter (mm)

5. Compression ratio (r): It is the ratio of Maximum cylinder volume to the Clearance volume.

6. Cylinder volume (v): It is the sum of swept volume and the Clearance volume.

V = Vs + Vc

36

I.C ENGINE TERMINOLGOGY

• 7. Displacement (or)Swept volume (Vs): It is the volume of space generated by the movement of piston from one dead center to another dead center. It is expressed in terms of cubic centimeter (cc) and given by

VS = A * L = * d2 * L / 4

8. Clearance Volume( Vc): It is the space in the cylinder, when the piston is at Top Dead Center It is designated as VC and expressed in cubic centimeter (cc).

Comparison of Petrol and Diesel Engines

Petrol Engines1. A petrol engine draws a mixture

of petrol and air during suction stroke.

2. The carburettor is employed to mix air and petrol in the required proportion and to supply it to the engine during suction stroke.

3. Pressure at the end of compression is about 10 bar.

4. The charge (i.e. petrol and air mixture) is ignited with the help of spark plug.

Diesel Engines A diesel engine draws only air

during suction stroke.

The injector or atomiser is employed to inject the fuel at the end of combustion stroke.

Pressure at the end of compression is about 35 bar.

The fuel is injected in the form of fine spray. The temperature of the compressed air is sufficiently high to ignite the fuel.

Comparison of Petrol and Diesel Engines (contd..)

10. The maintenance cost is less.11. The thermal efficiency is about

26%.12. Overheating trouble is more

due to low thermal efficiency.13. These are high speed engines.

14. The petrol engines are generally employed in light duty vehicle such as scooters, motorcycles and cars. These are also used in aeroplanes.

The maintenance cost is more. The thermal efficiency is about

40%. Overheating trouble is less due

to high thermal efficiency. These are relatively low speed

engines. The diesel engines are generally

employed in heavy duty vehicles like buses, trucks, and earth moving machines.

ENGINE SPECIFICATIONS

ENGINE SPECIFICATIONS

ENGINE SPECIFICATIONS

ENGINE SPECIFICATIONS

ENGINE SPECIFICATIONS

ENGINE SPECIFICATIONS

ENGINE SPECIFICATIONS

ENGINE SPECIFICATIONSEngine capacity : 177.4ccEngine type : single cylinder, air cooled 4stMax Power : 17.3bhp @ 8500rpmMax Torque : 1.58kgm @ 6500rpmGear box : 5 speed constant meshFuel system : carburetedFront brake : 270mm petal disc brakeRear brake : 200mm petal disc brakeFront suspension : Telescopic hydraulic forkRear suspension : gas shocksFront tyre: 90/90 x17Rear tyre : 110/80 x 17Height : 100mmLength : 2085mmWidth : 730mmGround clearance : 180mmKerb weight : 137kgFuel tank capacity : 16 liters