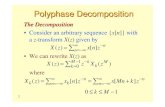

I sulting from decomposition of the material are …infohouse.p2ric.org/ref/30/29354.pdf · sulting...

Transcript of I sulting from decomposition of the material are …infohouse.p2ric.org/ref/30/29354.pdf · sulting...

n addition to the sheer volume of the construction-and-demoli- tion (C&D) debris stream that drywall represents, bad odors re- sulting from decomposition of the material are causing opera- I tors to look at ways to remove the material from the wastestream

and turn it into a marketable product.

Fishing From the Wastestream Drywall can be removed at one of two locations: the job site or a sol- id waste management facility. Both have pros and cons-with job-site removal being the option with the most pros.

Job-site removal requires that a separate pile, containment area, or rolloff box be placed on the job site for drywall only. This might re- quire a change in the way the contractor or subcontractor manages waste. Separation at the job site does mean, however, that there will be little contamination in the drywall material and less labor will be re- quired to remove drywall from the debris stream.

Disposal-site removal means that drywall is removed from loads of C&D debris after they are delivered to the solid waste management fa- cility, whether it is a landfill, a recycling center, or some other waste management facility. Because drywall waste is generated in only one phase of construction, loads generally either are at least 50% drywall or contain little or no drywall. Loads that are 50% drywall or more can be sent to a staging area where contamination can be extracted from the loads by hand or by a skid-steer (see photo 1). In addition, drywall can be manually or mechanically extracted from the face of the landfill. Although this method requires less change in the current waste management system, drywall recovery rates are less and conta- mination can be greater.

Know Your Market The most important aspect of investigating the recycling potential of a commodity is market availability. Once the end markets have been determined, it is important to know end-market specifications so that processing can be assessed.

Recycled drywall can be used as an alternative to mined or syn- thetic gypsum in a number of applications, which makes it more mar-

any size DLt tnJst not

ketable. End markets explored in Florida included agriculture, ce- ment, and new drywall. These are not the only possible end markets for recycled drywall, but they also represent some of the largest. The table above summarizes the specifications and contamination toler- ance of typical end markets.

Making a Product There are a number of technologies that have been utilized through- out the nation to process drywall into a saleable feedstock. These tech- nologies include trommel screens, tub grinders, horizontal end grinders, portable grinders, and various other types of equipment. Trommel Screens For most of the pilot drywall recycling projects in Florida, the project teams elected to use a trommel screen because the facilities already owned trommel screens (primarily for use in woodwaste and/or yard- waste processing operations) that were not fully utilized and trommel screens had proven to be an effective processing technology. Trommel screens are effective because they reduce the size of the material and remove almost all of the paper.

The drywall should be preprocessed prior to being loaded into the trommel screen. Preprocessing allows for a more effective separation and a greater recovery of gypsum in the trommel screen (see photo 2). It involves simply running over and tossing the drywall pile with a front-end loader in order to break the larger sheets into smaller pieces. Doing so allows for better separation of the paper backing from the

50 MSW Management NOVEMBER/DECEMBER 2003

Recycling Separation Technologies Los Angeles tested single-bin curbside collec- tion of all recyclables in 1996 with a resulting 148% increase in residential recycled amounts. Trucks ran with fuller loads. Auto- mated, driver-only sideloaders were used, re- ducing labor costs. But higher processing costs reduced the city’s net revenue increase to just 12%.

Over the last seven years, technology has been developed to bring down the processing costs and make recycling in general and sin- gle-stream recycling in particular more cost- effective and more efficient.

Weyerhaeuser’s system is PaperSort, a high-speed optical sorting system specifically designed to handle, identify, and separate pa- per grades for recycling. Weyerhaeuser devel- oped it with MSS Inc. of Nashville, TN. It sorts mixed loads of recovered paper into dis- tinct product streams using MultiGrade Sen- sor technology and a proprietary mechanical system design. The first site for the system was Baltimore in 1999; the second was Den- ver in 2001. Grogan says he was in Gothen- burg, Sweden, early in the year to see the technology being used at the IL Recycling fa-

!

cility there. “The system is fully automated,” he states. “Not a single employee touched the paper.”

CP Manufacturing in National City, CA, has developed a single-stream separation sys- tem for commingled, curbside-collected fiber materials and containers.

BHS has designed a newsprint sorting sys- tem that mechanically separates the news- print from mixed containers. Called the New- Sorter, it bulk-sorts the mixed material into smaller, more manageable recovery streams containing similar materials. BHS designed the system for Waste Management Inc. in Ohio in 1996.

National Recovery Technologies Inc. in Nashville, TN, and MSS Inc. have developed automated separation systems for plastic bottles and containers. In January 2003, RRT Design and Construction in Melville, NY, completed the installation of an elec- tronic plastics recycling system for Concur- rent Technologies Corporation’s DEER2 project in Largo, FL. DEER2 is a US Depart- ment of Defense project created to illustrate the best solutions for an environmentally friendly and economically sound recovery of resources from electronic equipment. The

system is designed to accept postindustrial and commercial plastics, principally elec- tronic-equipment casings for automated resin separation.

1 Beginning an article with the lyrics from “Eve of Destruction” is an ominous beginning- appropriate given the destruction of 9/11, but ominous just the same. It might be helpful to remember that we weren’t on the “eve of de- struction” in 1965 when that song was writ- ten and that three years later in 1968 people were singing of the “dawning of the age of Aquarius.”

The new cost-reducing technologies that are mentioned in this article are what recy- cling has been looking for since it caught na- tional attention again in the 1980s. Perfect or not, perhaps they can make recycling more viable, steer it through budgetary crises, and indeed move it toward, if not a new age, then at least a newer age. MSW

John T. Aquino is a writer and an attorney based in Washington, DC, and is executive di- rector of TASWER (Tribal Association for Sol- id Waste and Emergency Response).

www.mswmanagement.com

Circle #47 on Reader Service Card

MSW Management 49

- r T

gypsum during processing in the trommel screen. Once the material has been preprocessed, it is loaded into a trom-

me1 screen. A trommel screen is a large cylindrical screen that rotates. As the drywall material enters the screen, the rotation of the screen causes the material to tumble, breaking it apart by sheer gravity. The small gypsum pieces fall through the screen, and the paper and other large pieces continue to tumble out the end of the screen, where they are caught on a conveyor belt. The gypsum pieces are caught on an- other conveyor belt, where they can be transported to a container. The size of the gypsum pieces is determined by the screen size. Some mar- kets prefer small sizes, while others do not care how large or small the gypsum is. It is important to know the specifications of the end mar- ket prior to processing. The effectiveness of the separation is depen- dent on the speed of the trommel and the size of the screen. The faster the trommel and the smaller the desired end product, the more gyp- sum will end up in the discard pile and will not be removed from the paper. If a smaller-size end product is desired, the speed of the trom- me1 will have to be slower. Tub and Horizontal End Grinders Tub and horizontal end grinders do not allow separation of paper or other contaminants from the gypsum material, but they do provide a fast, effective way of reducing the size of the material. No preprocess- ing is involved. Extra precaution, however, should be taken to remove contaminants, as all of the material will be ground together. This pro- cessing method is best for markets that do not require paper separa- tion, such as agriculture. Similar to trommel screens, grinders are fre- quently found at solid waste management facilities to process yard trash and wood debris. Thus, no additional equipment would have to be purchased. Portable Grinders Portable grinders are slowly becoming more popular as states are ex- ploring the idea of grinding C&D debris at the job site and applying it below the sod layer. These grinders are small enough to be towed by a truck and can be moved from job site to job site. Drywall can be eas- ily ground in these machines. Paper separation is not necessary, as the paper will biodegrade in the ground. Some states, however, do not al- low for drywall to be placed on the job site in this fashion due to the fact that gypsum alters the pH of soil, which in some cases is already particularly alkaline. Other Processing Equipment Several companies manufacture equipment geared specifically for re- cycling drywall. The equipment removes the paper from the gypsum and reduces the size of the material. In addition, many of the ma- chines have coverings that prevent dust from escaping, as processing drywall can create a great amount of dust. These are all excellent ma- chines for large drywall recycling operations or locations that plan on processing a lot of drywall. Because they cannot be used for process- ing other materials, they are not ideal for locations with smaller quan- tities of drywall.

Skid-steer pulling drywall from a waste pile

Preprocessing performed by a frontad loader

Money Talks There are a number of stakeholders and factors that affect the eco- nomics of drywall recycling. In order for drywall recycling to be sus- tainable, the long-term economics must be favorable.

While many factors impact long-term sustainability, three in par- ticular truly drive the economic viability of drywall recycling:

Tipping fees Transportation costs Cost of virgin material

www.mswmanagement.com

Loading drywall into a trommel screen for processing

MSW Management 51

Processed gypsum coming off a trommel screen conveyor Close-up of processed gypsum

For any type of wastestream (including vegetative waste), the most significant challenge to recycling is low tipping fees. With low tipping fees, the cost for disposal might be less than the cost to recycle, de- pending on location and any surcharge for contamination. This cost differential creates a significant disincentive to recycling.

Hauling costs are proportional to distance. As the distance in- creases, the cost to haul the material will also increase. Thus, if the re- cycling facility is too far away, the material will not be recycled due to cost. Similarly, if the distance to the end market is too far, recycling be- comes uneconomical.

The Whisper Series" I

The "Quiet One"! Polyethylene Containers from American Container i% Recycling

>> Quiet.. . features dramatically reduce noise >> Lightweight.. . 30% less then steel, easier to handle for crews

>> Tough.. .impact/dent-resistant UDPE Polyethylene hw '

information: 1.866.694.4773 ancontainer.org

American Container & Recycling

Future Forecast Processing drywall is an easy operation that can be performed by equipment that many solid waste managers might already own. The tougher steps in drywall recycling are removing the drywall from the wastestream and finding a market suitable for the end product. Once these steps have been overcome, a successful drywall recycling pro- gram could be viable for any area. MSW

Guest author Kim Cochran is an environmental engineer for R.W Beck's Infrastructure Services Group in Orlando, FL.

WITH MORE THAN 1.7 MILLION TONNES RECYCLED TO DATE, WE ARE

Highvolume capacity $Reliable process ) Highqualiky recycled feedstock )Wet and dry waste recycling )Portable or permanent faciliies

Years of experience recy

Recycled gyp feedstock for

5620 1 9dh Street Langley, BC Canada V3A 7C7

For more information contact us at: (604) 534-9925 or info@nwgypsum .com

Circle #43 on Reader Service Card

52 MSWNIanagement

Circle #32 on Reader Service Card

NOVEMBER/DECEMBER 2003