I N S T A MCH418/MCH618 L 24V DC Powered TMCH18).pdf · Recommended Battery Specifications: 12V DC...

Transcript of I N S T A MCH418/MCH618 L 24V DC Powered TMCH18).pdf · Recommended Battery Specifications: 12V DC...

INSTALLATION-SAFETY-OPERATION-

MAINTENANCE

INSTALLATION-SAFETY-OPERATION-

MAINTENANCE

MCH418/MCH618Four Post/Six Post Mobile Column Lift

24V DC Powered

© June 2015 by Vehicle Service Group. All rights reserved. CO9304.4 IN20540 Rev. G 6/12/2015

MCH418 Capacity 72,000 lbs.MCH618 Capacity 108,000 lbs.

18,000 lbs. per column

IMPORTANT Reference ANSI/ALI ALIS, Safety Requirements for

Installation and Service of Automotive Lifts before installing lift.

2

IndexSet-Up Instructions .................................................. 2Safety Instructions ................................................... 4Owner/Employer Responsibilities .......................... 4Quick Start Operating Instructions ........................ 5Emergency Lowering ................................................ 7Detailed Operating Instructions .............................. 8

Battery Charging ........................................................ 9Maintenance Instructions ..................................... 10Trouble Shooting ...................................................... 11Lift Lockout/Tagout Procedure .............................. 12Wiring Diagram ........................................................ 13

Set-Up InstructionsFollow these instructions to ensure a satisfactory set-up and operation of the lift.

• After set-up and inspection of the lift, please return this booklet to the literature package and give to lift owner/operator. Literature package should be kept attached to controls for easy access.

1. Unloading: Rotary’s Mobile Lift System units are shipped in the vertical position.

2. After unloading, remove and discard protective wrapping.

NOTE: Unit is shipped without batteries and without power unit fluid. Installation of both batteries and fluid MUST be completed prior to lift operation. Failure to do so will result in air entering the system. The unit will then have to be bled.

3. To move the column, remove protective banding and wheel clamps from wheel jack. The forklift brackets can be removed from the side of the column if desired.

4. Open power unit cover by removing the 3 M8 BHCS (Button Head Cap Screw). Fill power unit tank with ISOVG32 hydraulic oil. Tank capacity is approximately 11-1/2 quarts (11 liters). Fill until fluid is just barely visible on dipstick.

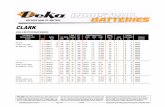

5. Install two batteries in location shown, Fig. 1. Through our research Rotary recommends Exide® brand battery part number NG-27 or DEKA® brand battery part number DC31DT. Different batteries meeting the below specifications may be used but performance can vary. Recommended Battery Specifications:12V DC Sealed Deep Cycle BatterySize 31 Frame Group105 AH Capacity (At 20 AH Rate)Stud Terminals with Stainless Steel Wing nuts

Battery wires are clearly marked/labeled inside the unit itself.

Install tie-down straps on batteries as shown.

Close lift and re-install M8 BHCS removed earlier.

After the batteries and fluid have been added, screw M20 bolt and M10 socket head bolts clockwise on wheel jack and front of superstructure to adjust unloaded column ground clearance, Fig. 1. Ground clearance is determined by how far the bolts are turned. When the column is loaded, it will automatically lower to the floor.

WARNING Permit only trained personnel to operate lift. After reviewing these instructions, become familiar with the lift controls by running the lift through a few cycles before loading a vehicle on lift. Observe and heed SAFETY and WARNING labels on the lift.

WARNING This motor has internal arcing or sparking parts. To minimize the Risk of Explosion, DO NOT expose to flammable vapors.

OPERATING CONDITIONS: Lift is not intended for outdoor use or storage and has an operating ambient temperature range of 41º-104ºF (5º-40ºC).

DO NOT use lift in a manner other than intended. Included (but not limited to) examples of unapproved uses of the lift are: lifting vehicle by only one side, lifting different axles with a column pair (lifting on the diagonal), and lifting non-approved items.

6. Bleed mobile columns:a.) Raise forks 150-200mm do not lift forks high enough to engage locks.b.) Loosen bleed screw to release air from system.c.) Close screw and repeat steps a and b until there is no air in the system and fluid runs clear.

3

Power Unit Tank

Battery Locations

M20 BoltAdjust For GroundClearance M10

Socket HeadAdjust ForGround Clearance

IMPORTANT! NegativePost Must Be LocatedOn This Side

Bleed Screw

Do Not Exceed Torque Values On Bleeder Screw

Torque Values: 177-230 In/Lbs (20Nm-26Nm)

IMPORTANT

Fig. 1

DO NOT use on asphalt. Lift must be on concrete with a minimum strength of 3000PSI and a minimum thickness of 4.5”. Maximum allowed floor slope is 1/8” per foot side to side of vehicle and 1/4" per foot front to rear of vehicle. DO NOT use on a suspended floor structure without specific approval from structural engineer.

Upon completion of the assembly of the lift, the lift is to be operated to assure proper function. Observe for locks operating in all locking positions, each side lifts equally, hydraulics do not leak, all electrical controls function as labeled, all pneumatics are functional and leak free, ramps rotate freely (if applicable), and proper clearances with all items in bay have been maintained.

Operate the lift with a typical vehicle and observe to assure the same items for proper functioning.

Ensure tires are properly inflated before lifting. DO NOT exceed tire load rating when raising vehicle.

DO NOT raise/lower only one side of a vehicle.

Lift only on same axle. DO NOT stagger between axles.

DO NOT drive over or pinch electrical cables.

4

SAFETY INSTRUCTIONS• Inspect your lift daily. Never operate if it

malfunctions or if it has broken or damaged parts. Use only qualified lift service personnel and genuine Rotary parts to make repairs.

• Thoroughly train all employees in use and care of lift, using manufacturer’s instructions and “Lifting It Right” and “Safety Instructions” supplied with the lift.

• Never allow unauthorized or untrained persons to position vehicle/lift or operate lift.

• Prohibit unauthorized persons from being in shop area while lift is in use.

• Do Not permit anyone on lift or inside vehicle when it is either being raised or lowered.

• Do Not operate lift while batteries are charging.• Always keep area around lift free of tools, debris,

grease and oil.• Never Overload lift. Capacity of lift is shown on

nameplate affixed to the lift.• Do Not hit or run over lift forks or base. This could

damage lift or vehicle. Before driving vehicle into

area, position lift units to provide unobstructed entrance onto lift area.

• Load vehicle on lift carefully. Position lift forks to fully contact the vehicle tires. Release parking break on vehicle. Raise lift until tires clear the floor. Check lift forks for secure contact with vehicle tires. Raise lift to desired working height.

• Do Not block open or override self-closing lift controls, they are designed to return to the Off or Neutral position when released.

• Remain clear of lift and vehicle when lowering.• Avoid excessive rocking of vehicle while on lift.• Clear area if vehicle is in danger of falling.• Remove tool trays, stands, etc. before lowering lift.• Position lift units to provide an unobstructed exit

before removing vehicle from lift area.• Do Not perform any maintenance on the control

panels until the power has been shut off to the lift.• Do Not operate equipment with a damaged cord or

if the equipment has been dropped or damaged.

The Owner/Employer:

• Shall ensure that lift operators are qualified and that they are trained in the safe use and operation of the lift using the manufacturer’s operating instructions; ALI/SM 93-1, ALI Lifting it Right safety manual; ALI/ST-90 ALI Safety Tips card; ANSI/ALI ALOIM-2000, American National Standard for Automotive Lifts-Safety Requirements for Operation, Inspection and Maintenance; ALI/WL Series, ALI Uniform Warning Label Decals/Placards; and in the case of frame engaging lifts, ALI/LP-GUIDE, Vehicle Lifting Points/Quick Reference Guide for Frame Engaging Lifts.

• Shall establish procedures to periodically inspect the lift in accordance with the lift manufacturer’s instructions or ANSI/ALI ALOIM-2000, American National Standard for Automotive Lifts-Safety Requirements for Operation, Inspection and Maintenance; and The Employer Shall ensure that lift inspectors are qualified and that they are adequately trained in the inspection of the lift.

• Shall establish procedures to periodically maintain the lift in accordance with the lift manufacturer’s instructions or ANSI/ALI ALOIM-2000, American National Standard for Automotive Lifts-Safety Requirements for Operation, Inspection and Maintenance; and The Employer Shall ensure that lift maintenance personnel are qualified and that they are ad-equately trained in the maintenance of the lift.

• Shall maintain the periodic inspection and maintenance records recommended by the manufacturer or ANSI/ALI ALOIM-2000, American National Standard for Automotive Lifts-Safety Requirements for Operation, Inspection and Main-tenance.

• Shall display the lift manufacturer’s operating instructions; ALI/SM 93-1, ALI Lifting it Right safety manual; ALI/ST-90 ALI Safety Tips card; ANSI/ALI ALOIM-2000, American National Standard for Automotive Lifts-Safety Requirements for Op-eration, Inspection and Maintenance; and in the case of frame engaging lifts, ALI/LP-GUIDE, Vehicle Lifting Points/Quick Reference Guide for Frame Engaging Lifts; in a conspicuous location in the lift area convenient to the operator.

• Shall provide necessary lockout/tagout means for energy sources per ANSI Z244.1-1982 (R1993), Safety Requirements for the Lockout/Tagout of Energy Sources, before beginning any lift repairs.

• Shall not modify the lift in any manner without the prior written consent of the manufacturer.

5

Lights on/off (Optional Accessory)

Activate Column Buttons (8 Total)

Lower To Locks

Height Limit Setting Battery Charge Indicator

System Configuration Lock/Unlock

Single/Pair/All Mode

E-Stop

Raise

Lower Slow Lower

Yellow, Green, RedActivation LED’s(8 Total)

Data Information Display and Buttons

Quick Start Operating InstructionsControl Panel Diagram

1. The service area must be clear of all personnel before the vehicle is positioned.

WARNING Locate lift on level concrete surface with a minimum strength of 3000 psi.

2. Spotting: Position the vehicle in the location where it is to be lifted.

Note: See Fig. 2 for the general arrangement of each lift column.

3. Loading:Position one column at a lifting wheel location. Position so that the forks are under the tire and the unit is pushed in as far as possible, Fig. 3. Ensure fork width is adjusted to properly accommodate the tire/wheel size. Turn on the Power Up Switch, Fig. 4.

4. Using the Control Panel and the bus diagram as a reference (see graphic above), press the Activate Column Button relative to the location where the column was just placed. The column will show Green when activated.

5. Plug the fixed length communication cable from the cord reel into the bottom of the control panel.

6. Position next column at second wheel using loading instructions from step 3.

7. Run the reel-end of the communication cable from the first column and plug into the side of the control panel on the second column. Turn on second column. Again, using the Control Panel and the bus diagram as a reference, press the Activate Lift Button relative to the location of the second column. The lift will show Green when activated. The first lift you activated should now be flashing yellow on your control panel.

8. Repeat step 5 thru 7 for remaining columns. When the entire system of columns is complete, press the System Configuration Lock/Unlock button to lock the lift configuration for operation.

NOTE: The electrical communication cables do not have to make a complete loop. You do not have to plug the last lift back into the first lift.

6

Power UpSwitch

CommunicationCable Reel

ROTARY LIFT EXPRESS

DO NOT RUN CABLES IN EXIT PATH OF AUTOMOBILE

Communication Cable

DO NOT RUN CABLES IN EXIT PATH OF AUTOMOBILE

Communication Cable

Fig. 3

Fig. 4

Fig. 2

NOTE: Ensure Communication Cables are clear of forks, from under columns, and automobile when raising or lowering.

7

WARNING Before attempting to lift any vehicle, be sure that:

A. Vehicle individual axle weight does not exceed two lift columns combined capacity.

B. Lift forks are in secure contact with vehicle tires.C. Adequate overhead clearance is provided to raise

vehicle to desired height.D. Parking brake is released on vehicle.E. Adjustable forks must be equally spaced off centerline

of lift carriage, and adjusted to properly accommodate the tire/wheel size.

F. Ensure tires are properly inflated before lifting. DO NOT exceed tire load rating when raising vehicle.

9. To Raise Lift:A. Ensuring that the System Configuration Lock/Unlock

light is green, press the Raise Button. Raise the vehicle until vehicle tires clear the floor.

Check Fork Contact: Stop and check for secure fork contact with tires, at all columns.

B. Continue to raise the vehicle to desired height.

NOTE: While cycling the lift, you may observe the individual columns slowing down and speeding up at various stages of travel. This is a normal characteristic of the lift leveling system.

Do Not go under vehicle unless all tires are in secure contact with forks. Lower lift and repeat vehicle and/or lift spotting and loading procedure if required.

C. Press the Lower To Locks Button to lower columns onto the locking latches.

10. While Using Lift: Avoid excessive rocking of vehicle while on the lift.

11. Before Lowering Lift: Remove tool trays, safety stands, etc. from area.

10.To Lower Lift:A. Ensuring that the System Configuration Lock/Unlock

light is green, press the Raise Button to raise lifts off the locks.

B. Press the Lower Button to lower lift. The Slow Lower Button (1/3 speed) can be used if desired. Observe that all columns are lowering and vehicle remains level.

C. Remain clear of forks and vehicle when lowering. Observe pinch point WARNING decals.

D. Reset the parking brake.E. Move all lift units away from the vehicle to provide an

unobstructed exit before removing the vehicle.

IMPORTANT Do Not drive vehicle over communication cables.

• During lowering of lifts, ensure that vehicle does not move into an inclined position.

• Lower columns equally.• Remove tool trays, safety stands, etc. from area.• Remain clear of forks and vehicle when lowering.

NOTE: In the event batteries become fully discharged, plug the columns into electrical outlet for approximately 15 minutes to achieve adequate charge for one operation cycle. Length may vary based on battery type, condition, etc.

A. Remove M8 BHCS and open Power Unit Cover. Pull lock open. Push the Manual Lowering Valve Button and the carriage will begin lowering.

C. If lift is on locks, slightly lift carriage until lock is free.D. Lower each carriage a small increment at a time

keeping the vehicle level.E. Release the Manual Lowering Valve Button and the

downward movement will stop. F. After lowering is finished, close and re-install M8 BHCS

in Power Unit Cover.G. If lift is not operating properly, Do Not use until

operation is corrected or repairs are made by qualified lift service personnel.

Emergency (no power) Lowering:

NOTE: Top cover not shown for clarity.

Manual LoweringValve

Pull To Release Lock

8

A. The configuration will not lock if there is not an acceptable pairing of columns. Columns must be paired left/right directly across from one another.

B. In a locked system, pressing the button next to a column on the control panel will toggle the LED between active and inactive states. Active columns are represented as solid green, and inactive columns are represented by blinking yellow. A column will not respond to motion commands when inactive.

Note: The system must be raised and lowered from an active column.

C. In a locked system, the Single/Pair/All Mode Button may also be used to quickly activate and deactivate selected combinations of columns. Pressing the Single/Pair/All Mode Button will toggle through single column mode, column pair mode, and all columns mode.

D. Column LED Indication – Summary of column LED’s:Green – indicates a column ready for motion.Yellow blink – indicates an inactive column, which does not respond to motion commands until activated. Red fast flash– indicates a column with an error.

Operating Instruction Details/Options

Changing the System Configuration

Columns may only be added to, or removed from, a system by unlocking the existing configuration and then configuring the additional columns as described above. To unlock the configuration press the System Configuration Lock/Unlock Button. Upon pressing the System Configuration Lock/Unlock Button the Green Lock/Unlock LED will go dark and the configuration will unlock. At this time, columns may be safely turned off and removed, and/or replacement or additional columns may be assigned by the same procedure for adding columns as outlined above.

Height Limit Setting

The Height Limit Setting is a user setable stop to limit height travel.A. To memorize a height stop: Raise all columns to the desired height position. Hold down the Height Limit Setting Button until it begins flashing. Flashing indicates that the height setting has been memorized.B. Once a height stop has been memorized, press the Height Limit Setting Button to turn the stop on and off. When turned on, the system will stop whenever any column reaches the memorized height stop.

*Maximum operation pressure is:2755 psi for MCH418, MCH618

9

Battery Charging1. Battery chargers can be plugged in nearly continuously or as needed. Life of the battery can be prolonged if the batteries are charged regularly (for example, after every use), and not allowed to be fully discharged.

IMPORTANT Do Not operate lift while batteries are charging.

2. The supplied battery charger is not intended for use with a gelled-electrolyte type battery. Please see the supplied battery charger manual for further details on the use of the battery charger.3. When batteries are not being charged, the front panel indicator can be used to determine the battery charge level. On the front panel, a yellow light indicates that the battery is partly discharged and should be recharged. A red light indicates that you are near the end of the battery capacity and may not have enough energy left to complete a fully loaded lift cycle; the batteries must be recharged. When the batteries are being charged, the lights on the battery charger will indicate whether the battery is being charged (yellow light) or has reached full charge (green light).4. Charge time will vary depending on the amount of energy that was discharged. A fully discharged battery will need to be recharged overnight to be fully restored. However, if a single lift is required, a short charge time (such as 15 minutes) should restore the batteries enough for a fully loaded lift cycle.5. Battery performance will vary depending on the brand of battery selected, the battery specifications, how well the batteries are maintained, and the age of the batteries.

Safety InformationIMPORTANT SAFETY INSTRUCTIONSKEEP THESE INSTRUCTIONS!

The battery charger is a powerful electrical device. If incorrectly installed, configured or operated, the battery charger can damage batteries and/or electrical equipment. Please read thoroughly the instructions and safety information contained in the charger manual before operating the battery charger.

RISK OF EXPLOSIVE GASES

WORKING IN THE VICINITY OF A LEAD ACID BATTERY IS DANGEROUS. BATTERIES CONTAIN SULFURIC ACID AND PRODUCE EXPLOSIVE GASES. A BATTERY EXPLOSION COULD RESULT IN LOSS OF EYESIGHT OR SERIOUS BURNS. FOR THIS REASON, IT IS OF UTMOST IMPORTANCE THAT YOU FOLLOW THE INSTRUCTIONS EACH TIME YOU USE THE CHARGER.

TO REDUCE THE RISK OF BATTERY EXPLOSION, FOLLOW THESE INSTRUCTIONS AND THOSE PUBLISHED BY THE BATTERY MANUFACTURER FOR ANY EQUIPMENT YOU INTEND TO USE IN THE VICINITY OF THE BATTERY. REVIEW CAUTIONARY MARKINGS ON THESE PRODUCTS AND ON ENGINE, MOTOR OR OTHER EQUIPMENT REQUIRING BATTERY USAGE.

Refer to charger manual, it contains important safety and operating instructions applicable to the safe and efficient use of your battery charger. To reduce risk of damage to electric plug or cord, pull by the plug rather than the cord when disconnecting the battery charger.

An extension cord should not be used unless absolutely necessary. Use of improper extension cord could result in a risk of fire or electric shock. If extension cord must be used, make sure:

a) That pins of plug of the extension cord are the same number, size and shape of those of the plug on the battery charger;

b) That extension cord is properly wired and in good electrical condition;

c) That wire in extension cord is proper size as follows:

Minimum recommended AWG wire size for various length extension cords used with each battery charger:

Length of Cord in meters 7.5 15 30 AWG Size 16 14 12

Do not operate the battery charger with a damaged cord or plug.

Do not operate the battery charger if it has received a sharp blow, been dropped or otherwise damaged in any way.

Do not disassemble the charger. Incorrect reassembly may result in a risk of electric shock or fire.

To reduce the risk of electric shock, unplug the charger from outlet before attempting any maintenance or cleaning. Disconnecting the leads will not reduce this risk.

To reduce the risk of shock or spark, never touch the ring terminals together while the charger is plugged into an outlet or extension cord.

External connections to the battery charger shall comply with all local, state, and federal regulations.

WARNING

10

Maintenance Instructions

WARNING If you are not completely familiar with automotive lift maintenance procedures Stop: contact factory for instructions.

To Avoid Personal Injury: Permit only qualified personnel to perform maintenance on this equipment.

• Never overload lift. See capacity nameplate.• Never direct water stream at control box or cable

connections.• Never place sharp objects on Communication Cables or

drive over cables. • Always keep locking latch free.• Always keep all bolts tight.• Always keep lift and lift area clean.

• Monthly: Check Emergency Stop: Push the “Emergency Stop” button. Columns should be inoperative with any emergency stop button depressed.

• Monthly Lubrication1. Lower lift, check oil level in oil tanks on each column:

Open Power Unit Cover. Remove oil cap and check oil level. It should just be touching the dipstick. If necessary, fill with ISOVG32 hydraulic oil.

2. Oil the bushings on the jack handle and brake mechanism assembly.

• Monthly: Examine Cords: Check the condition of the charging cord and the communication cords on each column. Replace worn or broken cords as required.

• Change fluid in accordance with oil manufacturer's recommendations:

1. Columns must be completely lowered.2. Remove cover panel from power unit.3. Remove oil from power unit tank.4. Refill with approximately 11-1/2 quarts (11 liters) of

hydraulic oil meeting ISOVG32 specifications, into each tank. Fill until fluid is just barely visible on dipstick.

5. Check oil level in oil tanks on each column, add if necessary.

6. Dispose of waste oil according to legal regulations.

11

TROUBLE SHOOTINGCode Description Troubleshooting stepsE0 CPU error The processor has detected an error. Press “x” to clear. If the problem

continues, call for service.E1 Improper configuration The column has not been assigned a position, and is connected to a locked

system. Press “x” to clear. To add the column to the system, first power down the column, and then unlock the system. Power up the column, assign a position, then re-lock the system.

E2 Improper column pairing Unless a column is run by itself in single mode, it must be selected and moved with it’s pairing column. Press “x” to clear.

E3 Communication Error 1) Check for a loosened or unhooked communication cable. Reattach the cable and press “x” to clear.2) Check for a powered down column. If one column has been powered down, the other columns must be powered down to re-initialize the system.

E4 Out of Level One or more columns in the system can not maintain level synchronization1) Ensure that no columns are hung up on the safety locks2) Check battery power3) Check for overloadingPress “x” to clear. Individually move each column back into a level position. Once all the jacks are level, they may be moved as a group.

E5 Emergency Stop To restore operation, clear the emergency stop button at the indicated column. E6 Potentiometer Error An error has occurred with the string potentiometer, and synchronization can

no longer be guaranteed. Follow manual lowering procedures.E7 Short circuit detected A short has been detected in the lift actuators. Press “x” to clear. To determine

the faulty component, run the faulty column by itself. Press the buttons below in exact order until the error is generated:1) While not operating (Error? Check/replace contactor)2) Up button (Error? Check/replace contactor)3) Slow lower (Error? Check/replace small lowering valve)4) Lower to locks (Error? Check/replace large lowering valve)5) Down button (Error? Check/replace lock solenoid)

E8 Software mismatch Power down and disconnect the column from the system. Load the column with the newest software code. To check the revision level of the software, insert a service card. Revision level is indicated in the service menus as “r__”.

E9 Stuck Key A stuck keypad button or motion push button has been detected on startup, or a motion push button has been held on for longer than 2-1/2 minutes.

E10 Display Communication Error Communication lost between display board and control board inside control cabinet. Check cable connections.

E11 Low Battery Error Batteries reached critical level. Check battery charge.

Display Unresponsive Turn off power and check wire connections on the display board for the keypad, the pushbuttons, and the control board. Restart power and test.

Slow To Rise Overloaded, check battery and connections, dirt, debris, in oil system.Lift Drifts Down Dirt, Debris, in oil system.

Trouble Lift will not raise off of latches.

Remedy1. Contact lift manufacturer’s Customer

Service.

Cause1. Motor, pump, or cylinder failure.

12

Purpose

This procedure establishes the minimum requirements for the lockout of energy that could cause injury to personnel by the operation of lifts in need of repair or being serviced. All employees shall comply with this procedure.

Responsibility

The responsibility for assuring that this procedure is followed is binding upon all employees and service personnel from outside service companies (i.e., Authorized Rotary Installers, contactors, etc.). All employees shall be instructed in the safety significance of the lockout procedure by the facility owner/manager. Each new or transferred employee along with visiting outside service personnel shall be instructed by the owner/manager (or assigned designee) in the purpose and use of the lockout procedure.

Preparation

Employees authorized to perform lockout shall ensure that the appropriate energy isolating device (i.e., circuit breaker, fuse, disconnect, etc.) is identified for the lift being locked out. Other such devices for other equipment may be located in close proximity of the appropriate energy isolating device. If the identity of the device is in question, see the shop supervisor for resolution. Assure that proper authorization is received prior to performing the lockout procedure.

Sequence of Lockout Procedure

1) Notify all affected employees that a lockout is being performed and the reason for it.2) Unload the subject lift. Shut it down and assure the disconnect switch is “OFF” if one is provided on the lift.3) The authorized lockout person operates the main energy isolation device removing power to the subject lift.

• If this is a lockable device, the authorized lockout person places the assigned padlock on the device to prevent its unintentional reactivation. An appropriate tag is applied stating the person’s name, at least 3” x 6” in size, an easily noticeably color, and states not to operate device or remove tag.

• If this device is a non-lockable circuit breaker or fuse, replace with a “dummy” device and tag it appropriately as mentioned above.

4) Attempt to operate lift to assure the lockout is working. Be sure to return any switches to the “OFF” position.5) The equipment is now locked out and ready for the required maintenance or service.

Restoring Equipment to Service

1) Assure the work on the lift is complete and the area is clear of tools, vehicles, and personnel.2) At this point, the authorized person can remove the lock (or dummy circuit breaker or fuse) & tag and activate

the energy isolating device so that the lift may again be placed into operation.

Rules for Using Lockout Procedure

Use the Lockout Procedure whenever the lift is being repaired or serviced, waiting for repair when current operation could cause possible injury to personnel, or for any other situation when unintentional operation could injure personnel. No attempt shall be made to operate the lift when the energy isolating device is locked out.

LIFT LOCKOUT/TAGOUT PROCEDURE

Lift is not intended for outdoor use and has an operating ambient temperature range of 41º-104ºF (5º-40ºC).

OPERATING CONDITIONS

13

COLUMN WIRING DIAGRAM

Oper

ated

Solen

oid

Oper

ated

Solen

oid

S S

12v B

atter

y

12v B

atter

y

200A

Motor

K1K2

S

K1K2

Fast

Valve

Slow

Valv

e

Lock

Sole

noid

FA79

89-5

24VD

C3.0

KW

8A

8A

24v D

C

Bat. V

oltag

e Mon

itor

Disc

onne

ct

Up

Down

Slow

Lock

s

Emer

Stop

Keyp

ad

Beep

er

RS48

5 Co

mm

WEM

U W

ire D

iagra

m

24v B

atte

ry S

yste

m

K3Lig

hts re

lay -O

ption

alSe

e Sup

pleme

ntal

Diag

ram

Strin

g

+ -

NP93

2 Rev

. A

AC in

230 V 2.2

A1Ø

50Hz

Batte

ryCh

arge

r

RS48

5 Co

mm

Pot

Conta

ctors

Red

Blac

k

Black

Red W

hite

Blue

Blac

k 1

Whit

e Bl

ack 2

Red

Red

Blac

k

Red

Blac

k

Blac

k

Red

Blac

k

Red

Blac

k

Red

Blac

k

Red

Blac

k

Red

Blac

k

Red

Blac

k

30A

30A

30A

30A

+1

-1

Whit

e

Whit

e

Blue

+1

1 2 3

1 TB2

8 7 8 7 P6

P7

2 1 P8

3

31 J3

1 1 2 2

21

TB5

TB8

TB6

TB3

1 DIN 2 1 2 1 2 DIN

6 2 7

Contr

ol PC

B

4 9 5 10

2 3 4 TB1

-1

OFF

1 JJ1

6 2 7 3 8 4 9 5 10

JJ2

P2

P1

Fron

t Pa

nel

PCB

Pend

ant -

Optio

nal

See S

upple

menta

lW

iring D

iagra

m

14

THIS PAGE INTENTIONALLY LEFT BLANK

15

THIS PAGE INTENTIONALLY LEFT BLANK

Installer: Please return this booklet to literature package, and give to lift owner/operator.

Thank You

Trained Operators and Regular Maintenance Ensures Satisfactory Performance of Your Rotary Lift.

Contact Your Nearest Authorized Rotary Parts Distributor for Genuine Rotary Replacement Parts. See Literature Package for Parts Breakdown.