I~limits as prescribed by DGMS (Tech.) Circular NO.7 dated 29 September 1997). LUMPL also use blast...

Transcript of I~limits as prescribed by DGMS (Tech.) Circular NO.7 dated 29 September 1997). LUMPL also use blast...

Laforge Umiam Mining Pvt. Ltd.

A companYOflLAFARGE and OM CEMENTOS~MOLINS

NLMlMSPCB/67/2014

September 08, 2014

The Member SecretaryMeghalaya Pollution Control BoardArden LumpyngngadShillong

Subject: Environment Statement for the year 2013-2014 as per Form V ofEnvironment Protection Rules, 1986 and amendments.

We are hereby submitting an environmental statement for the financial year ending 31st

March 2014 in Form-V for our Nongtrai Limestone Mine ofM/s Lafarge Umiam MiningPvt. Ltd. as required under the condition laid in renewal of the Consent to Operate videletter NO.MPCB/TB-227/2006-2007/81 dated June 26, 2006.

Please acknowledge receipt of the above.

Thanking You,

Yours faithfully,For Lafarge Umiam Mining Pvt. Ltd.

Pramod Kumar SinghMines Manager

Enclosure: Form V

Cc: The Joint Director (S)Ministry of Environment and Forests,Near MTC Central Workshop, Law-U-Sib LumbatngenShillong-21Meghalaya.

CIN No. U14107ML 1999PTC005707 : Regd. Office: Hotel Polo Tower, Oakland, Shillong - 793001, Meghalaya,India Tel (+91 364) 2501115, Fax Tel (+91 364) 2501116

Mines Office: Nongtrai - Sheila, PO: Sheila Bazar - 793112, East Khasi Hills, Meghalaya, India: Tel (+91 3637) 261347 - 50

I~

FORM-"V"

(See Rule 14)

Environmental Statement for the financial year ending on 31st March 2014

PART - A

(i) Name&Addressofthe Mr. Ashim Kumar ChattopadhyayOwner / Occupier

ofthe Owner and Director,Industry,

OperationorLafargeUmiamMiningPrivateProcess

Limited,

Registered

, Office: Hotel Polo Towers, OaklandRoad, Shillong, Meghalaya,Pin 793001.

Mine

office:Nongtrai-Sheila,POSheila

Bazar,EastKhasiHills,

MeghalayaPin-793112.(ii)

Industry CategoryPrimary (STC Code)

Limestone MineSecondary (STC Code) (iii)

Production Capacity 2.0 million tonnes per annum.

(iv)

Year of Establishment 2006

(iii)

Dateof last environmental.26.08.2013statement submitted

\

PART- B

Water and Raw Material Consumption

(i) Water consumption in m3/day

Process 30.0 m3 per day (average) for sprinkling on haul road and foruse inHEMMworkshop [Considering 291 days of crushing and dispatch operationsfrom April 2013 to

March 2014 in the current year for water use in the process]

Cooling Not applicable

LAFARGE UMlAMM\NING P\UV ATE LIMITED, N

Total Water consumption:

Name of

Process water consumption per unit of product

outputProducts

. During the current

D~ring~he-::aerVI~~s financial year (2)fmanclal Y ( 4 5 liters per tonne1

Limestone 6.028 liters per tonne .

ONGTRAl, EAST KJ{ASI HILLS, MEGHALAYA:

ENVIRONMENTAL STATEMENT FOR THE YEAR

(ii) Raw Material Consumption

Name ofConsumption of raw materials per

* Name of Raw MaterialsProduct

unit of output

2012-20132013-2014

Explosives (i.e.Limestone0.335kg per tonne of0.317kg per tonne of

ammonium nitrate, toe-mininglimestonelimestone

blast, aqua-dyne, ener- gel, emul-boost andsuper-dyne)Explosives (Le. Detonating

Limestone0.055m per tonne of0.052m per tonne offuse and S. fuse)

mininglimestonelimestone·

Explosives

Limestone0.022nos. per tonne0.019nos. per tonne(cord relay, HTD, DTH, OD

miningof limestoneof limestone

and E/D) DieselCaptive1.730 liters per tonne1.734 liters per tonne

power

of limestoneof limestone

generation for lightingand use inHEMM&vehicles

Note: For the total limestone production of 19563SO tonnes per annum

PART - C

Pollution discharge to environment/units of output(Parameter as specified in the consent issued)

Quality ofConcentrations ofPercentage ofpollutants

pollutants invariation fromPollutants

dischargeddischargedprescribedmass/day

(mass/ volume)standards (withreason)(a) Water

Average discharge from Within the General•

Waste- washing of HEMM Standard of Discharge

water fromRow: 2.3 m3 per dayworkshop·pH: 7.4; ·pH average =7.3;

range 7.1 to 8.0· TSS:0.052 kg/day·TSS average 22.07mg/lit; range 5.0-· TDS:0.54 kg/day 45.0 mg/lit· TDS average 231.49· O&G:0.014 mg/lit; range 100-

kg/day320 mg/lit

•Oil & grease average

6.09 mg/I; range1.2-8. 5mo/lit(b) Air

Particulate matter:ParticulateMatter:Within the General•

Crusher 3.14 kg/dayaverageparticulateStandard of Discharge

stack

emissionof40.98mg/Nm3 and average flowof 76839.43 Nm3/day)

LAY ARGE UMIAM MiNING PRIVATE LIMITED, NONGTRAl, EAST KHAsI HILLS, MEGHALAYA:"""1""_1~

ENVIRONMENTAL STATEMENT FOR THE YEAR

PART - 0

Hazardous Waste(As specified under Hazardous Wastes (Management and Handling) Rules)

Total Quantity (KI)Hazardous Waste

During PreviousDuring currentfinancial year

financial year 2013-2012-2013

2014From Process •

Waste oil from HEMM and 4.04.9

Diesel generator FromPollutionControl.# #

Facility

# Included in the above mentioned quantity.

PART - E

Solid Waste

Waste Total Quantity (tonnes)During the previous

During the currentfinancial year 2012-

financial year 2013-2013

2014(a)

From Process

•

Soil NilNil•

Rejected grade Limestone NilNil•

Overburden NilNil

(b)FromPollutionControl N!I Nil

Facility (1)QuantityrecycledorNil Nilre-utilized within the unit

{2} SoldNilNil

(3)Disposed NilNil

PART - F

Please specify characterization (in terms of concentration and quantum) ofHazardous as well as solid wastes and indicate disposal practice adopted forboth these categories of wastes:

(1) Nature of Hazardous Waste: Category No. 5.1: Waste Oil Emulsion from Heavy EarthMoving Equipment and Diesel generator storage in 200Liters barrels on impermeable surface provided withbund and spill collection pit.

Disposal System

(2) Other Solid Waste

: The wastes oil is sold to authorized vendor.

: The mine site is devoid of soil and rejected gradelimestone any soil if recovered will be used for plantationpurpose.

The quantity of domestic food waste generated fromLUMPL Transit House, Security Barrack and MiningColony during the year April 2013 to March 2014 was1174.5 Kg. The generated food waste was disposed-offfor using in piggery through local vendors.

LAF ARGE UMiAM MiNING PRrv ATE LIMITED, NONGTRAI, EAST KHASI Hn.LS, MEGHALAYA""V'-l~

ENVIRONMENTAL STATEMENT FOR THE YEAR

PART - G

Impact of the pollution abatement measures taken on conservation ofnatural resources and on the cost of production

Following abatement measures have been adopted at the Nongtrai Limestone Mine:The mining at Nongtrai limestone Mine of Lafarge Umian Mining Private Limited(LUMPL) is carried out by using advance drilling and blasting techniques. Drillingprogram in mine is fully related to the production requirement by conventionalmethod.

• Blasting is carried out with proper planning and utmost safety aspects under the strictsupervision of blasting expert holding first/second class Manager's certificate.Blasting is performed only during the day time as per norms and conditions. It lastsfor a few milliseconds to less than 2 seconds.The non electric (NONEL) shock tube initiating system and noiseless trunk line delay(NOT) are used on the top for hole to'hole delay. In addition, pre-splitting techniqueis used before the main blast. This helps in creating a barrier thus reducingtransmittance of ground vibration waves.

• A continuous wind monitoring system has been installed to know hourly winddirections. Based on prevailing wind directions at the time of blasting, the direction ofdetonation is adjusted. This results in maintaining lower transmittance of any noiseand dust levels.In order to ensure that the ground vibrations remaining within low levels, LUMPLmonitors ground vibrations with every blast using seismographs imported fromCanada. Based on the results further modification in blasting is done from time totime. As per the monitoring results, the peak particle velocity of 0.23-3.78 mm/sec isobserved at distance of 200 to 300 m, which is much lower than the Indian Standardlimits as prescribed by DGMS(Tech.) Circular NO.7dated 29 September 1997).LUMPLalso use blast muffing mat as and when required to arrest any fly-rock. Blastmats reduces noise, shock and eliminate escape of any flying debris.

• No secondary blasting is done this is eliminated altogether with the use of hydraulicrock breakers.Provision of bag filters on crusher to minimize air emissions from the crusher.To control fugitive dust emissions during transportation of mined limestone throughdumpers, an Automatic sprinkling system installed along the haul road, water foggerin dump hopper and LBCwhich operates successfully.A greenbelt is maintained all around the mine site and plantation is done in thesurrounding area, which cools the area and acts as a barrier for maintaining low dustand noise in the surroundings. LUMPLhas planted a total of 27518 local plant saplings(with 70% survival rate from 2004 to March 2014).A continuous wind monitoring system has been installed to know hourly winddirections, rainfall, temperature and humidity.5 nos. of Sewage Treatment Plant (STP) and 1 no. of Effluent Treatment Plant (ETP)are operational.Rain water harvesting system constructed at two locations Le. the roof top of thetransit camp area and roof top of the office area. Water being discharge and stored ina separate tank for reuse.Study of ground water management carried out by the installation of vibration wirepiezometer' in three locations .Ground water being monitored on monthly basis withthe help of this equipment.

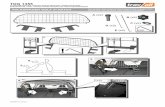

Figure 1 Automatic sprinklingSystem on haul road

LAFARGE UWAM MINING PRIvA TE LlMlTED, NONGTRAI, EAST KHAsl HILLS, MliGHALA YA.")()'''_11

Figure 2 GroundWater LevelMonitorina in action

ENVIRONMENTAL STATEMENT FOR THE YEAR

Figure 3 A views on greenbelt and plantations done at and surrounding the mining site.

PART - H

Additional measures investment proposal for environmentalprotection including abatement of pollution, prevention ofpollution.

Separate account for environmental expenses is operational and the environmentalexpenses are incurred from this account as per the procedure. The expenditure onenvironmental monitoring and studies for the period 01 April 2013 to 31 March 2014 isINR 8797322.

PART - IAny other particulars for improving the quality of the environment

Besides maintaining greenbelt around the limestone mine, LUMPL constructed aborder fencing all around the sinkhole to conserve, preserve and improve ecology ofthe area.

• To create environmental awareness and natural resource conservation LUMPLcelebrates World Environment Day every year.

Fiqure 4 World Environment Day observed at LUMPL.

LAF ARGE UMIAM MINING PRIvATE LIMITED, NONGTRAJ, EAST KHAS! HILlS, MEGHALA YA:"')()l')_' ~

ENVIRONMENTAL Sf ATEMENT FOR THE YEAR