Hydro Cracking Tech for Middle Dist

-

Upload

api-3709413 -

Category

Documents

-

view

781 -

download

2

description

Transcript of Hydro Cracking Tech for Middle Dist

1

PEP REVIEW 98-7

PEP Review 98-7HYDROCRACKING TECHNOLOGY FOR MIDDLE DISTILLATE

ByDavid Netzer

(OCTOBER 2001)

ABSTRACT

The objective of this review is the production of middle distillate, 300-650°F cut point, whilemaximizing diesel (550-650°F) yield. The new UOP’s new HyCycle (TM) Unicracking hydrocrackingtechnology is the basis of the evaluation. US Patents 5,980,729, 5,885,440 and a 2001 NPRApublication [R98-07-001] have been served as a basis for evaluating the technology. The keyattributes to this technology are:

• Reverse arrangement of reactors system. The hydrocracking, with low conversion perpass, about 33%, comes first followed by hydrotreating. The preheated feed enters thehydrotreating reactor along with hydrocracker outlet product, for very deep sulfur andnitrogen removal.

• The cracked products are separated from the reactor loop at about 1,800 psig inhydrogen rich vapor phase. Product is condensed outside reactor loop prior toconventional products recovery. An overall conversion of above 98% and below 650°Fcut point is achieved.

• Reactor loop nominal pressure of about 1,800 psig as opposed to 2,400 psig in moreconventional double reactor system.

• For 21.5 API, 2.5 wt% sulfur, 980°F TBP cut POINT VGO, the yield is 38 vol% diesel, 42vol% kerosene and 29 vol% naphtha. The equivalent yield in conventional doublereactor system with 97% conversion to 650°F cut point is 19 vol% diesel, 54 vol%kerosene and 36 vol% naphtha.

• The system comprises a finishing reactor, and naphtha product, meeting the 1 ppmsulfur specification for typical downstream processing such as catalytic reforming.

• The hydrogen consumption for the above yield basis is reduced from 1,950 Scf/bbl inconventional double reactor to 1,700 Scf/bbl in HyCycle.

• It is thought that the capital cost investment will be reduced by about 10-14% subject tomore detailed cost comparison.

2

PEP REVIEW 98-7

INTRODUCTION

Middle distillates, diesel and kerosene are the more important refinery products for Asiancountries like China and India, and other countries with emerging economy and infrastructure.Even in Western European countries, the ratio of demand of middle distillate to gasoline productsis considerably higher compared to the ratio in North America. The newly emerging HyCycle(TM)

hydrocracking technology as developed by UOP is geared toward maximizing diesel yield, andthis is the focus of this report.

The hydrocracking process and chemistry are discussed along with the economics ofhydrocracking VGO to middle distillates in PEP Report 211, Hydrocracking (1994).Hydrocracking of residual oils is discussed in PEP Report 228, Refinery Residue Upgrading(2000).

The model used for this evaluation is a feed rate of 35,000 BPSD of (5,160 TPD, 5665M3/day) of combined AGO and VGO (Atmospheric gas oil and 980°F TBP cut point vacuum gasoil). These originate from atmospheric and vacuum fractionation of Arabian Light, crude oil, 34.5API (SG=0.852). This capacity is based on an assumed 168,000 BPSD (350 days per year, 8.0MMTPY) grass roots refinery, which is judged to represent an average future size refinery to bebuilt in emerging markets. The Arabian Light represents a common world benchmark of crudeoil. The results of this evaluation can be adjusted to many other potential hydrocracking feedsand capacities while maintaining a reasonable accuracy. The size range of future hydrocrackingunits is expected to be in the range of 20,000-50,000 BPSD per single train of production.

Diesel Specifications

Diesel fuel regulations over the next decade are reducing the sulfur content in all the majormarkets to approach “sulfur free” fuel in order to reduce vehicle NOx and particulate emissions.Parts of Europe have led the sulfur reduction. For instance, since 1991 Swedish Class 1 dieselfuel has had <10 ppm sulfur, typically 1-3 ppm with cetane rating >51 [R98-07-005]. Diesel sulfurcontent in Europe will be reduced to 50 ppm in 2005 (European Union, Stage 4 regulation). TheEuropean commission’s (EC) latest Auto-Oil II discussion paper proposes a 10 ppm sulfur UltraLow Sulfur Diesel fuel be phased in starting on January 1, 2007 with a 10% supply requirement[R98-07-004].

In the U.S., the Environmental Protection Agency has set a specification of 15 ppm sulfur forJune 1, 2006 [R98-07-006]. This regulation, concurrent with implementation of new gasolineregulations, is being challenged in federal court by the National Petrochemical and RefinersAssociation [R98-07-007; R98-07-008; R98-07-009]. The U.S. specification is currently 500 ppmsulfur with aromatics <35 wt% (10 wt% in California with polyaromatics 1.4 wt%) and cetaneindex >40 (>48 in California) [R98-07-002]. In order to provide 15 ppm sulfur fuel at the pump,U.S. refiners may have to produce 1- ppm sulfur fuel at the refinery due to contamination in thetransportation system.

Japan is fine-tuning its program similar to the European and U.S. programs and tighteningNOx and particulates standards for diesel powered cars and small trucks [R98-07-003]. SouthKorea is making major cuts in diesel sulfur levels later in the decade.

The Association for Latin American Refiners has proposed diesel sulfur and cetanespecifications of 2000 ppm sulfur and 47 respectively for 2005 [R98-07-003].

So far, the EC proposal and U.S. regulations have only defined the sulfur concentration;other properties such as cetane number and aromatics content, have not yet been proposed.However, the Category 3 diesel fuel specifications proposed under the automaker’s “World Wide

3

PEP REVIEW 98-7

Fuel Charter” suggest sulfur <30 ppm with cetane number >55 (or Cetane Index >52), totalaromatics <15 vol% with polyaromatics <2 vol%, and a density of 820-840 kg/m3 [R98-07-005].

HyCycle Unicracking-Key Process Features

The HyCycle Unicracking process is considered by many as a step change in technology formaximum diesel yield in hydrocracking. The concepts of this process are described in threepatents [US 5,885,440; US 5,980,729; WO 97/38066]. This is a flow scheme for maximizing theyield of high-quality diesel fuel. The quality of the diesel fuel is measured in terms of Cetane(1)

Index, aromatic content, sulfur content and nitrogen content.

HyCycle cracking process equipment features include [R98-07-001]:

• Separator/finisher

• Back-staged series flow reactors

• Novel fractionator design

Process and catalytic features include:

1. Low per pass conversion of 20-40% with high overall conversion of over 98%

2. Hydrogen consumption is reduced up to 20% compared to conventional technology

3. Selectivity to higher boiling products is high. Up to 5 vol% more yield of middle distillatewith a 15% shift towards diesel compared to other full conversion maximum dieselprocesses

4. Operating pressure is 25% lower than conventional gas oil hydrocracking

5. Hydrogen partial pressure is lower

6. Space velocity is higher than conventional reactors but catalysts life and product qualityare unchanged.

The HyCycle process operates at low per pass conversion(2) in the reactor loop, whichminimizes the undesired cracking reactions, particularly of the diesel range molecules, and alsominimizes coke formation reactions, which reduce catalyst activity. Selective ring opening inHyCycle shifts the equilibrium toward a more favorable regime for producing high-quality dieselfuels.

The first key feature of the HyCycle Unicracking is the higher selectivity toward dieselproduct. This shift in selectivity avoids cracking of diesel product while at the same timeincreases saturation of aromatics. This is estimated to result in a net reduction of about 15% inhydrogen consumption, in this particular application, compared with the present state of the art ofhydrocracking technology.

A second key feature of the HyCyle process is the 25% reduced operating pressure and thehigher space velocities obtained when compared with the present state of the art inhydrocracking technology. This step change technology improvement can be accomplishedwithout compromising on catalyst life or diesel product quality.

A third key feature of the HyCycle Unicracking, and assuming a FCC unit in parallel tohydrocracking, is the potential synergism in hydrotreating and aromatic saturation of light cycle oil(LCO) produced at the FCC unit. The LCO is high in aromatic low valued diesel range productthat would be upgraded to high-quality diesel fuel.

4

PEP REVIEW 98-7

The design of the HyCycle combined with HPNA, heavy polynuclear aromatic, managementconcept. The HPNA is known to be one of the undesirable hydrocracking products. The HPNAseparates from the cracked liquid at lower temperature and creates severe maintenance in thecolder sections, resulting in excessive down time of the hydrocracking unit. Using of hotenhanced oil separation, at near reactor exit conditions, combined with downstream purge ofHPNA results in increasing catalyst cycle time and overall profitability. The enhanced separatoris using internal high pressure stripping with hydrogen, of diesel from liquid unconverted oil(UCO) product. The enhanced separator /stripper recovers the distillate products as vapor atreactor loop pressure. Liquid, consisting of unconverted oil from the separator, depleted ofdistillate, recycles to the hydrocracker reactor within the hot high pressure loop. A small portion ofthe unconverted oil in the “hot loop” high pressure cycle is let down from reactor loop pressure toproduct fractionation, operating at close to atmospheric pressure this let down avoids build up ofHPNA in the reactor loop. The enhanced separator is combined with a finishing reactor. Tracesof olefins that exist in hydrocracking products could recombine with H2S and form mercaptans.The finishing bed hydrotreats these mercaptans and bring down the sulfur content of the naphtharange material, to under 1 ppm.

A range of catalysts are available from UOP for the HyCycle process [R98-07-001]. Theseare zeolite based catalysts impregnated with metals on a proprietary support material. Theoptimum balance between cracking and hydrogenation is judged on a case by case basis. TheDHC-32 LT catalyst can be operated for maximum diesel and no jet fuel or in a flexible modewhere naphtha and jet fuel are both produced along with increased diesel. The DHC-43 LTcatalyst is offered for maximizing the yield of jet fuel. Maximum naphtha yield is produced withthe HC-170 LT catalyst.

The reactor yields of the HyCycle process, when using a flexible, mixed mode catalystassumed in this Review, are compared with a conventional process in the table below. Theconventional hydrocracker is the unit described in PEP Report 211 for middle distillates. Thesame Arabian Light VGO is processed in both cases. The single pass conversion of theconventional process of Report 211 is 66%. The single pass conversion of the HyCycle processin 30%. This comparison shows the yield for identical boiling range of diesel fuel is over 17%points higher for the HyCycle process than for the conventional process. Incremental diesel isproduced at the expense of lighter products and fuel oil.

ProductYield, wt% FFConventional HyCycle Difference, %

Fuel Gas 0.84 0.75 -0.09

LPG 4.64 3.2 -1.44

Light Naphtha 8.22 5.70 -2.52

Heavy Naphtha 20.14 16.60 -3.54

Kerosene (Jet Fuel) 46.90 37.78 -9.12

Diesel 16.72 34.60 +17.88

Fuel Oil 2.69 2.67 -0.02

The HyCycle Unicracking process offers flexibility in staging the capital investment. As aninitial operation, the HyCycle can operate in a once through, partial conversion mode, avoiding

5

PEP REVIEW 98-7

the enhanced oil separation and post reactor. This mode of operation produces unconverted lowsulfur heavy fuel oil as a co-product in addition to diesel and lighter products and requires a lowercapital investment. As relative demand for diesel increases with time at the expense of demandfor low sulfur heavy fuel oil, the system can be modified to maximize diesel product as describedabove.

Design Basis

The HyCycle process currently produces 10 ppm sulfur, diesel product from Arabian gasoils. The diesel fuel also has a high cetane rating, low aromatics content and a density within theCategory 3 range of the automaker’s “World Wide Fuel Charter” [R97-07-005].

Design assumptions

• Make up hydrogen at 99.9 vol% is available at 340 psig from battery limits.

• Hydrocracking conversion per pass 33% and 650°F TBP cut point

• Nominal hydrocracking and hydrotreating: temperatures 700°F pressure 1,850 psig.

• Hydrogen at recycle compressor outlet: 90 mol%, for establishing purge rate.

• Operating temperature of finishing reactor 625°F.

• Sulfur content of naphtha material 1 ppm.

• Heat of reaction 45-50 Btu/Scf of hydrogen as consumed.

• Yield structure as shown

• Let down of to recycle of UCO (unconverted oil) from high pressure loop to low pressureis 0.1.

The HyCycle hydrocracking plant comprises two (2) sections: Section 100, hydrogen makeup compression system reaction loop, and Section 200, product recovery. Other associatedprocess areas such as light end processing, naphtha splitter, sour water stripping, rich amineregeneration, sulfur recovery, tail gas unit and waste water treating are considered outside thebattery limits (OBL) of the hydrocracking. The rationale is that light gases, naphtha, sour water,H2S, ammonia, and waste water are generated in other areas of the refinery such as crude unitand distillate hydrotreating. Therefore, all these streams are combined into a single centraloperation of naphtha splitting, purge hydrogen recovery, sulfur recovery and waste water treating.

Make up hydrogen compression, and reactor loop, Section 100

Hydrogen, 99.9 mol% is produced from steam reforming of light naphtha (C5/C6), LPG, ornatural gas from OBL. The assumed delivery pressure is 340 psig (25.0 kg/cm2-a) andcontaining less than 100 vol ppm of CO. This hydrogen is dedicated to the HyCyclehydrocracking. Any impure hydrogen from other sources, such as catalytic reforming will bepurified prior to entering the hydrocracking reactor loop.

The hydrogen is compressed in 3 stage reciprocating compressor to 2,050 psig (145.2kg/cm2-a), with interstage air coolers to 150°F (65°C) and trim water coolers to 100°F (38°C) instages one and two. Only partial hydrogen cooling is incorporated in to the exit of 3rd stage.Three 50% motor driven compressors are assumed, two operating and one stand by.

The reactor loop encompass the key design features of the HyCycle. The ultimateconversion(3) is 98.5% and conversion per pass(2) , at 650°F (343°C) cut point, is designed for

6

PEP REVIEW 98-7

33% conversion per pass in high pressure loop. The ultimate one pass conversion of 83% in thelong loop is achieved after accounting for low pressure product fractionation producing andrecycling of unconverted oil. Average hydrocracking pressure, at middle of the reactors cycle, ismaintained at 1,875 psig (133.0 kg/cm2-a).

H2S and ammonia are removed inside the high pressure loop by a water wash of ammoniafollowed by the use of a lean amine, about 50 wt% MDEA solution for H2S. Loaded (rich) aminesolution is routed to OBL for regeneration where it is combined with other amine streams.

The catalytic portion of the reaction loop is based on information published by UOP at NPRAconferences, which was not intended for process analysis or design. The Hydrocracking (HC)reactor vessel has an assumed inlet temperature of about 700°F (371°C) which slightlyincreasing with time. Hydrotreating (HT) reactor vessel has an assumed inlet temperature ofabout 690°F (365°C) which also slightly increasing with time. In addition, there is a FinishingReactor, which enhances the separation of distillate product vapor via hot stripping withhydrogen. It is assumed that trace sulfur removal, down to below 1 ppm for the naphtha material.The naphtha material resulted from the Finishing Reactor needs no further hydrotreating, ifintended for downstream catalytic reforming of naphtha (CCR). This Finishing Reactor iscombined with UOP proprietary enhanced hot separator, which operates close to pseudo criticalconditions and uses hydrogen stripping of residual diesel material. The assumed separation andfinishing reactor temperature is 625°F (330°C). The actual separation temperature would vary,depending on VLE (vapor liquid equilibrium) and overall heat balance. The hydrotreating andhydrocracking reactors have a design margin to work as a once through mode with 83%conversion. Under this scenario reactors will operate in a temperature range of 725-800°F and atpressure close to the design pressure. The assumed space velocities, based on coldhydrocarbon liquids is 1.15/hr in hydrocracking section and 2.3/hr at hydrotreating section. Thedesign pressure of the reactors is set at 10% above normal operating pressure of thehydrocracking reactor.

The recycle gas compressor, is a centrifugal compressor, driven by a multi-stagecondensing steam turbine using steam at 600 psig/750°F, condensing to 3.5” Hg vacuum, 120°F.The turbine is equipped with an uncontrolled extraction port at 150 psig. The extraction steamoption increases overall operating flexibility. Recycle gas cooling is provided by air coolers whichcool the gas down to 140°F (60°C) assuming an ambient air at 100°F (38°C).

A fired heater is used to provide the heat deficiency to the reactor loop. In mosthydrocracking cases firing duty is provided to a mixture of hydrogen, preheated feed andunconverted oil. In this particular design situation, using hot UCO (unconverted oil) recycle andreversed reactors arrangement, only recycle hydrogen will be heated. The heater is equippedwith low NOx burners and has no air preheaters. Therefore a de-NOx system is not needed tomeet environmental regulations. Since the recycle heater is much smaller than the fractionationheater, excess heat in flue gas is recovered to preheat boiler feed water to be delivered for steamgeneration at 600 psig (42 kg/cm2-g) and 150 psig steam (10.5 kg/cm2-g) in the fractionationheater. The flue gas is released to a common stack at OBL at about 350- 400°F (176- 205°C).The firing duty will be provided by low sulfur refinery gas, which is expected to be rich inhydrogen, (probably over 50 vol%) and available at 80 psig (5.6 kg/cm2-g).

Gas Oil, (AGO and VGO) feeds are assumed available at 420°F (215°C) from vacuum andcrude units and after heat recovery. For base case design assume that 50% of VGO is comingfrom storage at 180°F and 50% from the vacuum and crude units, thus the combinedtemperature is about 300°F. The system, is designed for gas oil feed temperature ranging from180°F to 420°F.

7

PEP REVIEW 98-7

Power recovery turbine, by reversed pumps, will be used only on one pump of the service.No power recovery is applied for spare pump and normal let down valve is used when sparepump is in service. About 300 kwh of power recovery is the assumed minimum size toeconomically justify power recovery reversed pump system.

In general, hydrocrackers are designed for high level of heat integration in order to reduceenergy cost and steam generation in hydrocracking reactor loops is un-common. In thisparticular case the level of heat integration is reduced while introducing steam generation tomove heat load from one section of the plant to the other. This is thought to result in higheroperating flexibility, at a slightly reduced thermal efficiency and probably reduced capital cost. Allsteam generated in the high pressure loop, will go through analytical hydrocarbons detection,through a “suspect” condensate system. Depending on specific application the “suspectcondensate” can be used for water wash service for ammonium sulfide in the cold section of thehydrogen recycle. Low pressure “suspect” steam can be used for stripping services in thefractionation, and ultimately will end in waste water. Therefore this practice of steam generationavoids any potential contamination of the boiler feed water system.

Product Recovery Section 200

The vapor recovery consists of mid pressure 320 psig (23.5 kg/cm2-a) V-107 and V-201drums where hydrogen rich flash gas is recovered, and usually, depending on refineryconfiguration, could proceed to hydrogen recovery by PSA along with other hydrogen purgestreams. The LPG stripper operates at 120 psig (9.5 kg/cm2-a) recovers C3/C4 as liquid productand releases light gas (methane and ethane) with residual propane to refinery fuel gas. Livesteam at 150 psig is used for the stripping.

The liquid recovery uses steam stripped fractionation, in an atmospheric column, with anominal overhead pressure of 10 psig (1.7 kg/cm 2-a) and bottom pressure of 30 psig (3.1kg/cm2-a). The fractionator is equipped with two pump-around loops for diesel and kerosene with150 psig and 50 psig steam generation respectively. As an alternate, the heat released in thepump-around loops, particularly the kerosene pump-around could be used for downstreamnaphtha fractionation which is out of the scope of this evaluation. The diesel and keroseneproducts are drawn through side strippers using 50 psig steam. A HPNA purge, at a rate ofabout 500 BPSD, 1.5% of feed rate, is drawn from the UCO produced in the productsfractionator, prior to recycling to high pressure loop. The thermal duty to the fractionation isprovided by a fired heater with dual firing capability, using refinery hydrogen rich fuel gas or lowsulfur fuel oil such as UCO. No air preheater is applied, nor de-NOx system. Steam at 600 psig(42 kg/cm2-g) and 150 psig (10.5 kg/cm2-g) will be generated for enhanced heat recovery, whileflue gas is exhausted at 400°F (205°C).

The utilities to be provided or exported to/from OBL are:

• Electric power 6,000 volt, over 200 KW service

• Electric power 380 volt 5-200 kw service.

• Electric power 220 volt 0-5 kw service.

• Steam 600 psig 750°F

• Steam 600 psig saturated, 488°F.

• Steam 150 psig 0-100°F superheat

• Steam 50 psig 0-100°F superheat

• Boiler feed water, deaerated at 250°F and 750 psig

8

PEP REVIEW 98-7

• Cooling water at 90°F and 50 psig and maximum allowed return of 115°F and minimumreturn pressure of 30 psig.

• Plant air at 90 psig

• Instrument air at 90 psig

Table 1

PRODUCTS YIELD AND QUALITY

WT%Vol% (TBPcut points)

H2S 2.44

NH3 0.10

CH4 0.35

C2 H6 0.40

C3 H8 1.30

C4 H10 1.90

C5 2.20 3.01

C6 3.50 5.01

C7 –310°F (154°C) Heavy Naphtha 16.6 20.74

310-550°F (154-288°C) Kerosene 37.78 42.47

550-650°F (288-343°C) Diesel 34.6 38.46

650°F + (343°C +) Heavy fuel oil 1.50 1.46

Total 102.67 111.15

Light Naphtha (C5/C6) properties (after downstream, OBL naphtha fractionation)

Specific gravity 0.67

API 80

RON 75

Paraffin’s 84 vol%

Naphthenes 14 vol%

Benzene 2.0 vol%

Olefins 0.0

Sulfur content 1 ppm

9

PEP REVIEW 98-7

Table 1 (Concluded)

PRODUCTS YIELD AND QUALITY

Heavy Naphtha (C7-310°F) Properties

Specific Gravity 0.75

API 57

RON 60

Paraffins 48 vol%

Naphthenes 46 vol%

Aromatics 6.0 vol%

Sulfur content 1 ppm

Kerosene 310-550°F (Jet Fuel) properties

Specific gravity 0.822

API 40.6

Sulfur content 10 wt ppm

Smoke point 24.5 mm

Aromatics 11.0 wt%

Flash point 125°F 52°C

Diesel 550-650°F properties

Specific gravity 0.835

API 38

Sulfur content 10 wt ppm

Aromatics 11.0 wt%

Polyaromatics 0.20 wt%

Cetane Index 67

Flash point 320°F 160°C

10

PEP REVIEW 98-7

PROCESS DISCUSSION AND RATIONALE

The design of the HyCycle hydrocracker, the make up hydrogen compression, reaction loop,vapor recovery and liquids recovery, depend on desired product slate. This is an attempt tooptimize the design for maximum diesel yield at the expense of kerosene and naphtha. Thefollowing issues have been considered while establishing the design basis.

Feedstock

The feedstock is a blend of atmospheric and vacuum gas oils produced from Arabian LightCrude oil, 680-980°F/BP.

The blend has the following distillation curve:

ASTM D1160 Distillation °F °C

IBP 611 322

10% 702 372

30% 763 406

50% 825 441

70% 896 480

90% 966 519

EP 1040 560

The 21.5 API gravity oil (0.9246 specific gravity) contained 21 wt% monoaromatics and 32wt% total aromatics. Sulfur, nitrogen and conardson carbon contents were:

Sulfur 2.5 wt%

Total nitrogen 0.09 wt%

Conardson carbon 0.15 wt%

Hydrocracking catalyst

In general Amorphous or zeolitic catalyst is used for middle distillate hydrocracking and bothproduce high quality product. The amorphous is somewhat more distillate selective, howeverrequires a higher reaction temperature. On the basis of UOP data specific to low-conversionHyCycle, it was decided to use zeolite based catalyst. This rational can be reviewed on a casespecific basis.

Potential heat recovery at the reactors

The estimated heat of reaction is 45-50 Btu/Scf of reacted hydrogen, which amounts toabout 105-115 MM Btu/hr heat release in the reactors and end up as low level heat. Sincereactors pressure is 1,800-1,900 psig as opposed to 2,400 psig in the more traditional design, theuse of an isothermal reactor with 2,000 psig steam generation at 635°F may be worth further

11

PEP REVIEW 98-7

consideration. The steam pressure is above reaction pressure, thus avoiding a concern ofhydrocarbon leaks into the steam system, the steam can be let down in pressure if need to, andcan be superheated at the fired heaters. About 150,000 lb/hr of steam can be recoveredassuming boiler feed water preheat to about 450°F by recycle gas cooling. After the steam issuperheated to 930°F its motive power can amount to 20,000 kW. At the same time, much of thelower level heat load on the air coolers will be eliminated. Almost needless to say that undersuch a scenario, the load on the fired heaters will increase substantially due to the assumedsuperheating.

Conversion

Data from UOP’s NPRA public release suggests 20-40% conversion per pass, US5,980,729 suggests a case with 30% conversion per pass [R98-07-001]. It is understood that theabove conversion is in the high pressure hot loop. It is further understood that this lowconversion low severity is applied to avoid cracking of diesel product that recycles in the loop. Itwas judged that 33% conversion per pass is a reasonable optimum in the high pressure loop. Itwas assumed that the combined conversion per pass including the fractionation, is 83% per longpass. The ultimate conversion(3) at 650°F TBP cut point is assumed at 98.5 wt%. In 2001 issueof NPRA publications [R98-07-001] UOP indicates an ultimate conversion of 99.5%, however thecut point is not indicated in NPRA issue. Additional information received by UOP refers 99.5%conversion at 730°F cut point and the 650°F cut point in this case is the basis of the adjustmentin the overall conversion. The conversion is at 650°F cut point, however if kerosene is blended tothe diesel pool, higher cut point, gas oil material could be blended into the diesel pool. This mayresult in higher middle distillate yield.

Hydrogen Requirement

Hydrogen is consumed by hydro-desulfurization, hydro-denitrification, aromatics saturationand hydrocracking. If VGO from delayed coking or visbreaking, is combined in the feed, anadditional amount of hydrogen would be needed for saturating olefins. About 4% of the hydrogenis dissolved in the liquid product and purged from the high pressure loop. The net hydrogenconsumption was estimated at 1,630 SCF/BBL feed, about 56% in hydrocracking reactor and42% in hydrotreating reactor where most of hydrotreating is dedicated to aromatic saturation.The consumption in finishing reactor is estimated at 2% of the hydrogen. The pressure in theflash drum, 300 psig is suitable for hydrogen recovery by PSA (pressure swing adsorption) [seePEP Report 212 “Options for Refinery Hydrogen,” (1994)]. A diesel oriented refinery wouldnormally have a relatively smaller catalytic reforming unit which co-produces hydrogen at about90% purity. Under the most reasonable scenario a dedicated hydrogen plant, in this case 60 MMScfd (67,000 M3/hr) at high purity, and less than 100 ppm CO, would be required. Steamreforming of light naphtha, about 6,000 bpsd, or LPG is thought to be worth a seriousconsideration as a hydrogen source, unless low cost natural gas is available. Under thisscenario, the light naphtha and LPG produced in the hydrocracking can satisfy about 80% of thefeed to the hydrogen plant. Other light naphtha sources such as straight run naphtha from acrude unit could be a good source for hydrogen production. Any impure hydrogen resulting fromcatalytic reforming, say about 1,500 Scf/bbl, would be used as a separate hydrogen stream forless severe hydroprocessing services such as straight run diesel hydrotreating at about 1,000psig.

3x50% make up hydrogen compressors have been assumed, however 2x100% units couldbe a reasonable selection depending on a very case specific basis. Air cooling combined withtrim water cooling was assumed for interstage cooling. However, depending on water quality, aircoolers could be avoided, thus resulting in cost reduction. The hydrogen recycle loop is cooled

12

PEP REVIEW 98-7

only by air coolers as a safety concern to avoid any of the high pressure rich gas from leaking tocooling water system. It is reasonable to assume that usage of cooling water could result inlower capital and compression cost, however, at some added cost to overcome safety concerns.All these issues could be addressed on a case specific basis.

Reactors

Based on prior art and UOP patent US 5,980,729, it was estimated a cold liquid spacevelocity of 1.4 /hr for hydrocracking and 2.8/hr for hydrotreating where catalyst amounts to 80% ofreactor T-T volume. Details of the reactor internals are discussed in [R98-07-001]. A designpressure margin of 10% was allowed. Design margins of 5% could be possible under a differentASME code and these issues could be addressed on a case specific basis. External insulation ofthe reactors will bring down the outside temperature to 140°F. The option of internal insulation, a“cold wall” design is thought to be of lower capital investment but was judged to present operatingand safety risks.

The Finishing Reactor/ Enhanced Separator uses [US 5980729] hydrogen heating as areflux duty. In this particular design, reflux duty can be provided by generating 600 psig steamand hot hydrogen for diesel stripping will come from the reheated hydrogen sources. Analternative concept for stripping could be generating 2,000 psig steam in reactor effluent coolers,or by isothermal reactor, and using the steam for stripping the diesel instead of hydrogen. In thiscase the reflux duty will be provided by generating 600 psig steam.

Acid gas removal

The ammonia and some 10% of the H2S is removed by water wash. The lean aminesolution, such as MDEA, at reactor loop pressure (1,750 psig) removes the bulk of the H2S.Higher absorption pressures above 300 psig is not advantageous from the standpoint of aminecirculation for H2S removal and result in higher capital cost associated with the higher pressureand cost of pumping. As an alternate approach, the H2S could have been purged with thehydrogen rich light gases at 300 psig and to proceed to 300 psig MDEA absorber. The downside of this low pressure approach, would be the build up of H2S in the reactor loop, reducing thepartial pressure of hydrogen and increasing hydrogen losses to purge. This issue could beaddressed on a case specific basis while examining all other issues such as cracking activity andselectivity that could be somewhat affected by the content of H2S and ammonia in the high-pressure reaction loop. Acid gas removal is discussed in Pep Report 216, “Acid Gas Treatmentand Sulfur Recovery”, (1997).

Recycle compressor

A centrifugal compressor, 3,300 kW operating was selected for the recycle loop. Although acentrifugal compressor is of lower cost and higher reliability compared with a reciprocatingcompressor, several issues need to be sorted out on a case specific basis. These issues arerelated to variance in conditions between start of run (SOR) and end of run (EOR). Variation inmolecular weight, resulted from light gas production, and pressure drop, resulted from changes incatalyst, could be key issues in actual design. A steam turbine drive, using 600 psig/750°Fsteam, condensing at vacuum, with option of steam extraction at 150 psig will provide a goodspeed control on the compressor. The steam turbine would handle variance of feed and changesfrom start of run (SOR) and end of run (EOR). A multi-stage steam turbine will provide over 70%adiabatic efficiency. An electric motor drive could also be a viable selection depending on a casespecific and overall steam balance of the refinery.

13

PEP REVIEW 98-7

Product fractionation

At this point, we assume a LPG stripper at 120 psig, followed by an atmospheric column, at10 psig at the receiver. Steam is generated in pump-around loops and kerosene-diesel productside strippers. As an alternate, a combination of atmospheric distillation along with mild vacuum,of 100-150 mm Hg, could be a viable option, depending on a case specific basis. Combined fullrange naphtha C5-310°F is sent to OBL for further product recovery and upgrading. Theassumed downstream naphtha fractionation could become heat integrated with pump-aroundloops of the main distillate fractionator.

Heaters

The more common practice for recycle heater is to use a mixed phase heater in the reactionloop for both hydrogen recycle and liquid feed recycle. The alternate common approach wouldbe to use separate heaters for the liquid feed and gas recycles. In the Hycycle case, thehydrotreating and hydrocracking reactors are in reversed arrangement and the UCO recycles hotwithin the high pressure loop. Because of this configuration, heating of hydrogen recycle as anexclusive source of thermal duty, is the chosen option. This gas recycle heating results insomewhat higher exit temperature and higher skin temperature, compared with mixed phaseheating, thus fuel gas firing will be the highly preferred mode of operation.

The heater for the fractionation unit is operating in lower severity in both temperature andpressures, thus fuel firing or dual firing would be an acceptable approach. The UCO is purged at650°F from the recycle seems to be a good low sulfur low nitrogen fuel source.

Materials of Construction

All the issues of hydrogen graphitization and sulfur corrosion resulting from high pressure,high temperature are fully considered, using the latest version of “Nelson Curves”. For aconservative design the following is suggested. For hydrocracking reactor, we selected 2.25% Cr1.0 % Mo. For hydrotreating reactor we selected 2.25 Cr 1.0% Mo, with 347 stainless cladding.For the Finishing Reactor and enhanced separation use 1.25% Cr 0.5% Mo and SS 317cladding. Outside insulation will bring the temperature to 140°F.

For reactor loop heater, 2.25 Cr 1.0 Mo is used. For the fractionator heater and allexchangers above 450°F we used 1.25% Cr 0.5% Mo. All services below 450°F use C.S,regardless of pressure. For sulfur corrosion above 625°F use 321 SS in heat exchangers.

Equipment size limitation

A size limitation of 17' - 0” (5,185 mm) is assumed for transportation of pressure vessels.This limit along with other design considerations set the diameter of the hydrocracking andhydrotreating reactors. A key design consideration is the wall thickness of the reactors. For35,000 bpsd HyCycle this wall thickness is expected to be in the order of 12” which wouldrepresent a near maximum practical fabrication. The weight of the hydrocracking reactor isexpected to be in the order of 2,200,000 lb (1,000 ton) which could present a near limit fortransportation and erection, especially in emerging markets areas.

Products quality

The diesel product will meet the Euro IV specification and will be mixed with hydrotreatedstraight run diesel, about 35,000 BPSD as produced in the crude distillation unit. The keroseneproduct, as described, meets the specifications for jet fuel. It would be a common practice to mix

14

PEP REVIEW 98-7

this kerosene product with straight run (310-550°F) kerosene material as produced in crude unitafter a MEROX (mercaptans oxidation) unit, if needed. The heavy naphtha product is of lowoctane, thus could be very synergistic for catalytic reforming (CCR) along with straight runnaphtha. The light naphtha (C5/C6) could be a good stock for hydrogen production by steamreforming. The LPG (C3/C4) could meet typical market specifications.

Waste treatment

The hydrocracking process design feature includes water wash of tube sheets and otherelements of the cold sections of the reactor loop. This water, about 80 gpm after dissolvingammonium sulfide, is directed to waste water. For the particular case as depicted in this designbasis ammonia recovery, being only about 5.0 tpd, would not be economical. The wastewater isdirected to sour water stripper along with sour water from other units such as distillatehydrotreating and CCR. The H2S and ammonia are stripped, and routed to conventional Claustype sulfur plants and associated tail gas treating. Ultimately, 99.5% or higher sulfur recovery isachieved. All the ammonia is oxidized, in the sulfur plant, to elemental nitrogen. Additionalwastewater, about 65 gpm will result from live steam stripping in fractionation. This water will berouted to API separator with other wastewater streams.

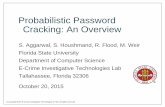

PROCESS DESCRIPTION

The conceptual design for a 35,000 B/SD gas oil HyCycle hydrocracker is shown in Figure1. The process design, yields and utility consumption rates are based upon engineeringprinciples, computations, published information and other nonconfidential information. Thedesign may or may not be similar to that licensed or otherwise used.

The product yields at the reactor discharge and product quality are listed in Table 1. Table 2provides the flows and approximate composition of the major streams. Major equipment size andmaterial of construction are listed in Table 3. Estimated utility consumption is summarized inTable 4.

The plant consists of two sections:

• Section 100—H2 Compression and Reactor Loop

• Section 200—Product Recovery

Section 100, H2 compression and reactor loop

The hydrogen is produced at 99.9 vol% purity by steam reforming of light naphtha or LPG.A partial source of hydrogen could be reformer (CCR) gas after hydrogen purification. Hydrogenat 340 psig, 100°F (25.0 kg/cm2-a, 38°C) is compressed in K-101 consisting of 3 stages.Average adiabatic efficiency of 83.0% and 97% motor efficiency was assumed. The first stagedischarge is 640 psig and achieves a discharge temperature of 225°F (61 kg/cm2-a, 107°C).Second stage discharge is 1,130 psig, 225°F (80.5 kg/cm2-a, 107°C) and 3rd stage discharge is2,050 psig, 225°F (142.7 kg/cm2-a, 107°C). Hydrogen at 150°F proceeds to mix with thedischarge of the recycle gas compressor K-102 at 2,020 psig. In the discharge of stages No-1and No-2 air cooling (E-101, E-103) is employed down to 150°F (65°C) and trim water cooling (E-102, E-104) to 100°F (38°C). Total compression power is 5,060 kw, motor power is 3x2600 Kwand are rated for 3,300 kw each. Cooling water flow rate at 90°F and assumed 20°F temperaturerise.

VGO/AGO feed from intermediate storage, and 180°F (82°C), VGO from vacuum unit andAGO from crude unit (not shown) are mixed, pumped to 2,200 psig which is the needed delivery

15

PEP REVIEW 98-7

pressure to reactor loop. The feed sent to a filter M-101 of 10 microns cut, prior to being heatedfrom 300°F to 600°F in E-107. For cold feed, exclusively from storage at 180°F, the feed isdiverted first to E-106, preheated to 300°F and then proceed to E-107 for final heating to 600°Fand prior to mixing with effluent of hydrocracking reactor R-103. In the hydrotreating reactor, allsulfur compounds are converted to H2S, nitrogen compounds are converted to ammonia almostall di and tri aromatics are saturated along with about 55% of the mono-aromatics. Traceorganomethalics are removed in the first bed. Mixed phase fluid from R-101 at 730°F is cooled to640°F in three successive heat exchanger, prior to entering R-102, enhanced separator finishingreactor: Preheating hot UCO recycle at E-108, preheating hydrogen at E-109 and generating 600psig saturated steam at E-110. The fluid enters R-102 which has three functions: vapor liquidseparation in the middle section, stripping the UCO liquid of distillate material, using preheatedhydrogen, and residual sulfur removal in the finishing catalytic section. The hydrogen preheatingis providing reflux thus minimizing UCO vapor. The finishing reactor bed removes traces ofmercaptans that could be formed by recombining of H2S with traces of olefins. Overhead of R-102 proceeds to E-107 for feed heating as discussed above. Liquid separated from the bottom ofR-102 is reheated in E-108 and recycles to cracking in R-103. In R-103 recycle UCO fromproduct fractionation (area 200) heated hydrogen as well as cold shot of cold hydrogen combinedin four beds reaction zone. The desulfurized feed is undergoing 33% cracking to a cut point of650°F. Hydrocracked mixture at 725°F merges with fresh feed as discussed earlier.

Two parallel services are used for hydrogen cooling from E-107. The first is hydrogenpreheat at E-112 and the second is low pressure steam generation at E-111. The combinedstream from E-113 and E-106 goes through E-114 dedicated as cold feed preheat. If feed isavailable at temperature below 300°F the flow rate to E-111 is reduced and more heat becomesavailable to preheat feed at E-106.

Portion of UCO from R-102, up to 10%, is let down from loop pressure, 1800 psig to a midpressure, 320 psig, hot flash drum V-107 this let down control the build up of HPNA and othernon-crackable material in the reactor loop. V-107 release most of dissolved hydrogen in the hotUCO this hydrogen is cooled in E-114 and merge with a purge stream drawn from recyclecompressor suction drum V-106 this purge stream is free of H2S. The hydrogen rich stream isrouted to cold separator V-201 in section 200.

Mixed phase of hydrogen and hydrocarbon from E-106 entering air cooler E-113 at about280°F. A wash water is introduced to wash any ammonium sulfide material from the tubes of E-113. Hydrocarbon liquids as well as sour water loaded with all the ammonia and some of the H2Sare separated from hydrogen, H2S and light gas in Cold Separator V-105. Overhead from V-105containing hydrogen, light hydrocarbon gas and H2S proceed to loop amine scrubber C-101 forbulk H2S removal with 50 wt% MDEA. Rich amine solution product is let down to amineregeneration at OBL. Overhead from C-101 at 1750 psig (124 kg/cm2-a) enters the Recycle GasCompressor K.O Drum V-106 and then to K-102, and is compressed to 2,050 psig. K-102 is acentrifugal compressor driven by a steam turbine. The steam turbine is powered by 600 psig and750°F (42- kg/cm2-g 400°C) steam, exhausting to 3.5” Hg. Compressor K-102 power is about3,300 kW. The steam requirement for the turbine is about 35,000 lb/hr, (16 TPH). Recycled gasat about 2,000 psig and 165°F is split about 15 % of it is mixed with compressed make-uphydrogen from K-101 and sent to “cold shot” in the hydrocracking reactor R-103 and also to reflux/stripping gas in the finishing reactor /enhanced separator section of R-102. The balance of thehydrogen is preheated to 625°F in feed effluent exchanger E-112 and E-109 prior to entering tocharge heater F-101. The outlet of the charge heater F-101, combined with recycled UCO is thefeed to Hydrocracking Reactor R-103 at a controlled temperature of 700°F or any othertemperature dictated by catalyst performance and overall heat integration.

16

PEP REVIEW 98-7

Section 200 product recovery

Liquid 1,765 psig from V-105 rich in diesel kerosene and naphtha is separated from sourwater and let down to Cold Flash Drum V-201 at 300 psig. Dissolved hydrogen containing tracesof H2S methane and ethane combines with purge hydrogen and flash hydrogen from area 100.This crude hydrogen stream about 3.0 Mmscfd at about 80 vol % is release to PSA hydrogenrecovery at OBL or fuel gas system. Liquids from V-201 depleted of most of the hydrogen andportion of CH4 and C2H6 is let down to C-201, LPG stripper operating at 120 psig (9.4 kg/cm2-a)where essentially all C4 and most C3 are recovered as mixed liquid, about 1,600 BPSD with 38liquid vol% propane. About 20% of C3 along with residual methane and ethane are released torefinery fuel gas header operating at 80 psig. The stripper feed is preheated by E-201 using 50psig steam, and reboiled by 600 psig steam at E-203 and stripping is enhanced by small injectionof 150 psig live steam.

Heavy liquid from Hot Flash Drum V-107 is let down to the coil of fired heater F-201 andpartially vaporized at end point of 700 F. Vapor /liquid mixture is introduced to the flash zone ofthe Fractionation Column C-202 with total of 50 trays. The UCO at 650°F and 30 psig, from thebottom of fractionation column C-202 enters a booster pump provides suction pressure to therecycle pump which recycles the UCO at 2200 psig to the hydrocracking reactor R-103 in area100. A HPNA purge of about 525 BPSD is drawn from the discharge of the booster pump andcould be used as a major source of fuel for F-201.

The 10,066 BPSD full range naphtha C5-310 F is recovered as overhead product of C-202and sent to OBL by the reflux pump. About 14,836 BPSD kerosene product from KeroseneStripper C-203 is cooled by E-209, generating 50 psig steam , followed by air cooler E-210. Thediesel product, about 13,461 BPSD from Diesel Stripper C-204 is cooled by generating 150 psigsteam at E-211, followed by air cooler E-212 to 160°F and sent to OBL.

17

PEP REVIEW 98-7

Table 2

Hycycle ™ Unicracking Hydrocracking for Middle Distillate STREAM FLOWS

CAPACITY: 1372 MILLION LB/YR

Mol. Wt. (1) (2) (3) (4) (5) (6) (7) (8)Water 18.0 895 895 895 160 -- --Hydrogen 2.0 13,165 -- 77,450 70,885 65,080 12,515 Trace TraceHydrogen Sulfide 34.1 -- -- 110 110 11,618 9 -- --Ammonia 14.3 -- -- -- -- 472 -- -- --Methane 16.0 -- -- 24,265 24,265 24,415 1,985 -- --Ethane 30.1 -- -- 35,950 37,645 37,385 2,265 -- --Propane 44.1 -- -- 19,450 24,980 25,580 1,600 -- --Butane ( mix) 58.1 -- -- 13,385 21,545 22,345 1,095 -- --Pentane ( mix) 72.2 -- -- 2,300 11,675 12,675 182 -- --Hexane ( mix) 86.2 -- -- 600 15,510 17,110 45 -- --C7-310 F TBP -- -- 110 73,400 78,400 10 -- --310-550 F TBP -- -- 11 168,190 178,190 1 Trace --550 F-650 F TBP -- -- 153,182 163,182 -- Trace --650 F-980 F TBP -- 471,625 955,305 999,579 964,514 -- 947,305 82,000

Total, lb/hr 13,165 471,625 1,129,831 1,601,861 1,601,861 19,867 947,305 82,000 Total, kg/hr 5,972 213,925 512,483 726,592 726,592 9,012 429,690 37,195

Mol. Wt. (9) (10) (11) (12) (13) (14) (15) (16)Water 18.0 -- -- 10 743 180 1,055 740 41,055 Hydrogen 2.0 Trace Trace 215 65,395 12,705 77,995 54,995 77,995 Hydrogen Sulfide 34.1 -- -- 1 91 10 11,630 8,176 11,630 Ammonia 14.3 -- -- 472 330 472 Methane 16.0 -- -- 79 22,080 2,185 26,735 19,820 26,735 Ethane 30.1 -- -- 106 32,558 2,940 39,650 27,755 39,650 Propane 44.1 -- -- 73 17,689 1,760 27,180 19,025 27,180 Butane ( mix) 58.1 -- -- 48 12,180 1,205 23,440 16,410 23,440 Pentane ( mix) 72.2 -- -- 5 2,099 200 12,857 9,000 12,857 Hexane ( mix) 86.2 -- -- 2 553 50 17,155 12,010 17,155 C7-310 F TBP -- -- 2 190 10 78,510 54,955 78,510 310-550 F TBP Trace Trace -- 68 1 179,250 125,475 179,250 550 F-650 F TBP Trace Trace -- 80 -- 163,285 114,282 163,260 650 F-980 F TBP 82,000 Trace -- 955,305 -- 15,209 10,500 15,000

Total, lb/hr 82,000 Trace 541 1,109,031 21,246 674,423 473,473 714,189 Total, kg/hr 37,195 Trace 245 503,048 9,637 305,913 214,764 323,951

STREAM FLOWS, LB/HR

STREAM FLOWS, LB/HR

18

PEP REVIEW 98-7

Table 2 (Continued)

Hycycle ™ Unicracking Hydrocracking for Middle Distillate STREAM FLOWS

CAPACITY: 1372 MILLION LB/YR

Mol. Wt. (17) (18) (19) (20) (21) (22) (23) (24)Water 18.0 39,900 Trace 1,155 1,065 1,055 35,000 - - Hydrogen 2.0 5 325 77,665 77,665 77,450 -- 260 65 Hydrogen Sulfide 34.1 1,890 550 9,190 110 110 -- 350 200 Ammonia 14.3 472 Trace -- -- -- -- -- --Methane 16.0 -- 1,572 24,750 26,330 26,250 -- 750 762 Ethane 30.1 -- 1,781 38,343 38,343 37,763 -- 300 1,481 Propane 44.1 -- 6,058 21,449 21,449 21,049 -- 50 6,008 Butane ( mix) 58.1 -- 8,913 14,745 14,745 14,480 -- 20 8,893 Pentane ( mix) 72.2 -- 10,371 2,511 2,511 2,481 -- -- 10,371 Hexane ( mix) 86.2 -- 16,505 658 658 648 -- -- 16,505 C7-310 F TBP 10 78,288 220 220 210 -- -- 78,288 310-550 F TBP 10 179,170 70 70 70 -- -- 179,120 550 F-650 F TBP 10 163,170 80 80 80 -- -- 163,170 650 F-980 F TBP 5 14,995 -- -- -- -- -- 14,995

Total, lb/hr 42,302 481,698 190,836 183,246 181,646 35,000 1,730 479,858 Total, kg/hr 19,188 218,495 86,562 83,119 82,393 15,876 785 217,660

Mol. Wt. (25) (26) (27) (28) (29) (30) (31) (32)Water 18.0 4,000 3,900 20 10 3,900 100 45 30 Hydrogen 2.0 -- 65 - 65 - -- --Hydrogen Sulfide 34.1 -- 190 20 160 10 10 -- --Ammonia 14.3 -- -- -- -- -- -- -- --Methane 16.0 -- 780 5 757 - - -- --Ethane 30.1 -- 1,550 50 1,431 - - -- --Propane 44.1 -- 7,900 4,785 1,203 1 20 30 20 Butane ( mix) 58.1 -- 10,300 8,640 193 1 60 90 60 Pentane ( mix) 72.2 -- 1,200 80 5 -- 10,286 15,430 10,286 Hexane ( mix) 86.2 -- 300 10 2 -- 16,493 24,740 16,493 C7-310 F TBP -- -- -- -- -- 78,288 117,432 78,288 310-550 F TBP -- -- -- -- -- 179,120 -- --550 F-650 F TBP -- -- -- -- -- 163,170 -- --650 F-980 F TBP -- -- -- -- -- 14,995 -- --

Total, lb/hr 4,000 26,185 13,610 3,826 3,911 462,542 157,767 105,177 Total, kg/hr 1,814 11,877 6,173 1,735 1,774 209,805 71,562 47,707

STREAM FLOWS, LB/HR

STREAM FLOWS, LB/HR

19

PEP REVIEW 98-7

Table 2 (concluded)

Hycycle ™ Unicracking Hydrocracking for Middle Distillate STREAM FLOWS

CAPACITY: 1372 MILLION LB/YR

Mol. Wt. (33) (34) (35) (36) (37)Water 18.0 50 50 30 28 2 Hydrogen 2.0 -- -- -- -- --Hydrogen Sulfide 34.1 -- -- -- -- --Ammonia 14.3 -- -- -- -- --Methane 16.0 -- -- -- -- --Ethane 30.1 -- -- -- -- --Propane 44.1 -- -- -- -- --Butane ( mix) 58.1 -- -- -- -- --Pentane ( mix) 72.2 -- -- -- -- --Hexane ( mix) 86.2 -- -- -- -- --C7-310 F TBP -- -- -- -- --310-550 F TBP 179,120 -- -- --550 F-650 F TBP -- 163,170 -- -- --650 F-980 F TBP -- -- 97,000 90,000 7,000

Total, lb/hr 179,170 163,220 97,030 90,028 7,002 Total, kg/hr 81,270 74,035 44,012 40,836 3,176

STREAM FLOWS, LB/HR

20

PEP REVIEW 98-7

Table 3

HYDROCRACKING TECHNOLOGY FOR MIDDLE DISTILLATE

MAJOR EQUIPMENTCAPACITY: 1,372 MILLION LB/YR (622,000 T/YR)

DIESEL FUELAT 0.96 STREAM FACTOR

EQUIPMENTNUMBER NAME SIZE MATERIAL OF CONSTRUCTION REMARKS

------------------- ---------------------------------------------- ---------------------------------------- ---------------------------------------------------------- ----------------------------------------------------------------------------------

REACTORS

R-101 HYDROTREATING REACTOR 15 FT DIA CLADDING: 347 SS 2.25 CR/1 MO50 FT T-T 3 BEDSD

R-102 FINISHING REACTOR 15 FT DIA CLADDING: 347 SS 2.25 CR, 1 MO50 FT T-T 1 BED; 8 STRIPPING TRAYS

R-103 HYDROCRACKER 15 FT DIA SHELL: 2.25%CR, 1%MO 4 BEDS80 FT T-T

COLUMNS

C-101 AMINE ABSORBER 8 FT DIA SHELL: C.S. 15 VALVE TRAYS, 24 INCH SPACING36 FT TRAYS: C.S.

C-201 LPG STRIPPER 10 FT DIA SHELL: C.S. 24 VALVE TRAYS, 24 INCH SPACING60 FT TRAYS: C.S.

C-202 PRODUCT FRACTIONATOR 16 FT DIA SHELL: C.S. 50 VALVE TRAYS, 24 INCH SPACING120 FT TRAYS: C.S.

C-203 KEROSENE STRIPPER 6 FT DIA SHELL: C.S. 8 VALVE TRAYS, 24 INCH SPACING25 FT TRAYS: C.S.

C-204 DIESEL STRIPPER 7.5 FT DIA SHELL: C.S. 10 VALVE TRAYS, 24 INCH SPACING33 FT TRAYS: C.S.

COMPRESSORS

K-101A-C H2 MAKE UP COMPRESSORS 3,500 BHP C.S. 3 STAGES EACH, RECIPROCAL; MOTOR DRIVE.2 OPERATING, 1 SPARE.

K-102 H2 RECYCLE COMPRESSOR 4,025 BHP C.S. 1 STAGE, CENTRIFUGAL; TURBINE DRIVER

HEAT EXCHANGERS

E-101A,B H2 COMPRESSOR COOLER 1 380 SQ FT SHELL: C.S. AIR COOLER1.7 MMBTU/HR TUBES: C.S. 1 SPARE

E-102A-C H2 COMPRESSOR TRIM 1 COOLER 700 SQ FT SHELL: C.S. IN PARALLEL1.2 MMBTU/HR TUBES: C.S.

E-103A,B H2 COMPRESSOR COOLER 2 406 SQ FT SHELL: C.S. AIR COOLER1.7 MMBTU/HR TUBES: C.S. 1 SPARE

E-104A-C H2 COMPRESSOR TRIM 2 COOLER 600 SQ FT SHELL: C.S. IN PARALLEL1.2 MMBTU/HR TUBES: C.S.

E-105A,B H2 COMPRESSOR COOLER 3 406 SQ FT SHELL: C.S. AIR COOLER1.7 MMBTU/HR TUBES: C.S.

E-106 H2-FRESH FEED EXCHANGER 5,000 SQ FT SHELL: C.S.31 MMBTU/HR TUBES: C.S.

E-107A,B FRESH FEED -H2 EXCHANER 7,000 SQ FT SHELL: 1.25CR, 0.5 MO45.5 MMBTU/HR TUBES: 1.25 CR, 0.5 MO

E-108 RECYCLE UCO-EFFLUENT EXCHANGER 10,000 SQ FT SHELL: 2.25CR, 1 MO50 MMBTU/HR TUBES: 321 SS

E-109 H2 FEED-EFFLUENT EXCHANGER 5,000 SQ FT SHELL: 1.25CR, 0.5 MO45 MMBTU/HR TUBES: 321 SS

E-110 R-101 EFFLUENT-STEAM EXCHANGER 2,000 SQ FT SHELL: C.S.37 MMBTU/HR TUBES: 321 SS

E-111 R-102 CONDENSER 1,500 SQ FT SHELL: C.S.21 MMBTU/HR TUBES: 321 SS

21

PEP REVIEW 98-7

Table 3 (Continued)

HYDROCRACKING TECHNOLOGY FOR MIDDLE DISTILLATE

MAJOR EQUIPMENTCAPACITY: 1,372 MILLION LB/YR (622,000 T/YR)

DIESEL FUELAT 0.96 STREAM FACTOR

EQUIPMENTNUMBER NAME SIZE MATERIAL OF CONSTRUCTION REMARKS

------------------- ---------------------------------------------- ---------------------------------------- ---------------------------------------------------------- -------------------------------------------------------------------------------

E-112 H2-STEAM BOILER 4,500 SQ FT SHELL: C.S.39 MMBTU/HR TUBES: C.S.

E-113A-D H2-H2 EXCHANGER 6,000 SQ FT SHELL: C.S.16.4 MMBTU/HR TUBES: C.S.

E-114A-C RECYCLE GAS COOLER 6,000 SQ FT SHELL: C.S. AIR COOLER33.3 MMBTU/HR TUBES: C.S.

E-115 FLASH H2 COOLER 250 SQ FT SHELL: C.S.1.5 MMBTU/HR TUBES: C.S.

E-116 TURBINE EXHAUST CONDENSER 6,500 SQ FT SHELL: C.S.35 MMBTU/HR TUBES: C.S.

E-201 COLD SEPARATOR HTR 7,000 SQ FT SHELL: C.S.30 MMBTU/HR TUBES: C.S.

E-202 STRIPPER CONDENSER 8,000 SQ FT SHELL: C.S.27 MMBTU/HR TUBES: C.S.

E-203 STRIPPER REBOILER 3,500 SQ FT SHELL: C.S.27 MMBTU/HR TUBES: C.S.

E-204 UCO PROD COOLER 1,000 SQ FT SHELL: C.S.13.7 MMBTU/HR TUBES: C.S.

E-205 KEROSENE PUMP AROUND COOLER 2,200 SQ FT SHELL: C.S.20 MMBTU/HR TUBES: C.S.

E-206 DIESEL PUMP AROUND COOLER 2,000 SQ FT SHELL: C.S.20 MMBTU/HR TUBES: C.S.

E-207A-D FRACTIONATOR CONDENSER 2,800 SQ FT SHELL: C.S. AIR COOLER15 MMBTU/HR TUBES: C.S.

E-208 NAPHTHA PROD COOLER 1,500 SQ FT SHELL: C.S.2.2 MMBTU/HR TUBES: C.S.

E-209 KEROSENE PROD COOLER 1,700 SQ FT SHELL: C.S.10.7 MMBTU/HR TUBES: C.S.

E-210A,B KEROSENE COOLER 1,200 SQ FT SHELL: C.S. AIR COOLER8 MMBTU/HR TUBES: C.S.

E-211 DIESEL PROD COOLER 2,000 SQ FT SHELL: C.S.13.7 MMBTU/HR TUBES: C.S.

E-212A,B DIESEL COOLER 2,229 SQ FT SHELL: C.S. AIR COOLER18 MMBTU/HR TUBES: C.S.

PROCESS FURNACES

F-101 FEED-RECYCLE FURNACE 33 MMBTU/HR 347 SS GAS FIREDF-201 PRODUCT FRACTIONATOR 161 MMBTU/HR CHROME-MOLY

TANKS (OFFSITE)

T-101A,B STARTUP OIL TANK 2,205,000 GAL C.S. 3 DAYS SUPPLYT-201 NAPHTHA 1,250,000 GAL C.S. 3 DAYS PRODUCTIONT-202 KEROSENE-JET FUEL 2,000,000 GAL C.S. 3 DAYS PRODUCTIONT-203 DIESEL FUEL 2,000,000 GAL C.S. 3 DAYS PRODUCTIONT-204 FUEL OIL 110,000 GAL C.S. 5 DAYS PRODUCTION

22

PEP REVIEW 98-7

Table 3 (Concluded)

HYDROCRACKING TECHNOLOGY FOR MIDDLE DISTILLATE

MAJOR EQUIPMENTCAPACITY: 1,372 MILLION LB/YR (622,000 T/YR)

DIESEL FUELAT 0.96 STREAM FACTOR

EQUIPMENTNUMBER NAME SIZE MATERIAL OF CONSTRUCTION REMARKS

------------------- ---------------------------------------------- ---------------------------------------- -------------------------------------------------------- -------------------------------------------------------------------------------

PRESSURE VESSELS

V-101 H2 COMPRESSOR K.O. DRUM 1 700 GAL C.S.V-102 H2 COMPRESSOR K.O. DRUM 2 700 GAL C.S.V-103 H2 COMPRESSOR K.O. DRUM 3 700 GAL C.S.V-104 FEED SURGE DRUM 9,000 GAL C.S.V-105 COLD SEPARATOR 32,000 GAL C.S. HORIZONTALV-106 RECYCLE COMPRESSOR KO. DRUM 3,400 GAL C.S.V-107 HOT FLASH DRUM 4,000 GAL 1.25%CR, 0.5%MO

V-201 COLD FLASH DRUM 28,500 GAL C.S.V-202 LPG REFLUX DRUM 1,000 GAL C.S.V-203 FRACTIONATOR REFLUX DRUM 5,400 GAL C.S. HORIZONTAL

MISCELLANEOUS EQUIPMENT

M-101 FRESH FEED FILTER SYSTEM CARBON STEEL 100 MESH SS SINTERED, BACKFLUSHM-201 UCO FILTER SYSTEM CARBON STEEL 100 MESH SS SINTERED, BACKFLUSH

SPECIAL EQUIPMENT

S-101 CATALYST INITIAL CHARGE

PUMPS

SECTION OPERATING SPARES OPERATING BHP--------------- ------------------- -------------- -------------------------

100 19 9 3,578200 10 8 1,010

23

PEP REVIEW 98-7

Table 4

HYDROCRACKING TECHNOLOGY FOR MIDDLE DISTILLATE

UTILITIES SUMMARYCAPACITY: 1,372 MILLION LB/YR (622,000 T/YR)

DIESEL FUELAT 0.96 STREAM FACTOR

BATTERY LIMITS SECTION SECTIONUNITS TOTAL 100 200

--------------- ---------------------- --------------- ---------------

AVERAGE CONSUMPTIONSCOOLING WATER GPM 6,660 3,740 2,920PROCESS WATER GPM 80 80 --ELECTRICITY KW 10,574 9,394 1,181NATURAL GAS MM BTU/HR 205 44 161STEAM, 50 PSIG M LB/HR 28 -- 28STEAM, 150 PSIG M LB/HR 4 -- 4STEAM, 600 PSIG M LB/HR 72 35 37STEAM, 50 PSIG M LB/HR -102 -40 -62STEAM, 150 PSIG M LB/HR -43 -- -43STEAM, 600 PSIG M LB/HR -44 -38 -6

PEAK DEMANDSCOOLING WATER GPM 7,992 4,488 3,504PROCESS WATER GPM 96 96 --STEAM, 50 PSIG M LB/HR 34 -- 34STEAM, 150 PSIG M LB/HR 5 -- 5STEAM, 600 PSIG M LB/HR 86 42 44

24

PEP REVIEW 98-7

COST ESTIMATES

The capital investment and production costs for hydrocracking as oil produced from ArabianLight crude oil for the production of jet and diesel fuels are presented. Costs are based on anU.S. Gulf Coast location for the second quarter of 2000. Overnight construction is assumed (ie,the cost of funds spent during construction are excluded).

Investment Costs

Table 5 sets forth the total fixed capital (TFC) investment for a 35,000 B/SD HyCyclehydrocracking unit. The costs are calculated at a PEP Cost Index of 624. The design has notbeen fully optimized either for equipment size or energy consumption. Owner’s costs such ascleared land are excluded. Licensing or royalty fees are regarded as proprietary and are notincluded in these costs.

The boundary limit installed costs was $151 million before contingency. This cost is 14%lower than the corresponding cost of the conventional VGO middle distillate hydrocrackerevaluated in PEP Report 211. Both units cracked Arabian Light gas oil. The conventional unitoperates at 2645 psi compared to 1910 psig in the HyCycle process. The lower pressurereduces the reactor cost and hydrogen compressor cost. UOP has estimated a 5% capitalreduction compared to “previous offerings” due to these factors [R98-007-001]. Table 6 showsthe investment costs broken down by section. The major items are the reactors and initialcatalyst charge and the hydrogen compressors. The estimated cost of catalysts, about $10 MM,is based on generic industry data from hydrocracking projects. Because of the large sizehydrocracking reactors and the subsequent portion of capital cost attributed to these reactors, itshould be noted that the process specifications of these items could be highly influenced by sitespecific factors such as transportation local construction capability. Material of constructiondesign codes, desired run length on the catalyst could be subject to operator’s preference andwould affect capital investment. Adding 15 or 25% contingency to the current estimate results ina boundary limit investment of 174 million $ or 189 million $ respectively.

Offsite investment before contingency (Table 5) totals 21 million $. The offsite investment isrelatively small percentage of the boundary limit investment due to the high cost of the reactorsand credit for steam generation within the boundary limits. The cost of the offsite is based on anassumed generic integration with other refinery units such as crude distillation, vacuum distillationsulfur recovery, waste water treating, spent catalyst, and intermediate storage. Offsiteinvestment includes the incremental cost of utilities and storage. Gas oil feed and productstorage are based on 3 days production (except fuel oil, 5 days). The allowance for generalservice facilities includes a control room, roads, fire protection and equipment. The cost of richMDEA stripping is included in the waste treatment investment. The allocation also covers theflare and relief system and incremental additions to the water collection and treatment system.Contingencies of 15 or 25% bring the total offsite investment to 23.8 million $ or 26.5 million $respectively.

The total fixed capital cost or boundary limits investment is 198 million $ including a 15%contingency or 216 million $ when including a 25% contingency.

Production Costs

Table 7 lists the unit cost and consumption factors used in estimating the value offeedstocks, products and utilities included in the production cost. By-products are shown as acredit (negative). Feedstock and product values are mid-2000 values determined by PEP. The

25

PEP REVIEW 98-7

gas oil feed is based on 10 vol% atmospheric gas oil and 90% vacuum gas oil. The on streamfactor is 0.96.

Raw material cost of 24.51 ¢/lb of diesel fuel includes catalyst replacement every threeyears (UOP expects 4 years catalyst life with their new catalysts [R97-07-001]. By-product salesand credits of mainly jet fuel and full range naphtha offset most of the raw material cost. Utilitycosts, 0.52 ¢/lb of diesel, are relatively low due to credit for steam generation.

Plant cash costs total 4.48 ¢/lb of diesel fuel. Adding depreciation at 10%/yr of total fixedcapital of $216 million (including a 25% contingency) and an allowance for generaladministration, sales and research expenses gives a net production cost of 6.15 ¢/lb. At a 25%contingency factor, the product value is 9.51 ¢/lb of diesel fuel.

Product value of units of 0.5 and 1.5 times the base case capacity were also calculated at a0.96 on stream factor and a constant 25% ROI. With a 25% contingency, the product value fromthe half capacity plant is 11.49 ¢/lb, 14% higher than the 10.08 ¢/lb of the base case. Increasingcapacity to 150% of the base case reduces the product value 4.6% to 9.62 ¢/lb. With a 15%contingency, the respective product values at 0.5 and 1.5 times the base case capacity are 10.81and 9.07 ¢/lb of diesel fuel.

With 25% contingency, reducing the time on stream factor to 0.92 from 0.96 reduces theproduction of diesel fuel to 1315 million lb/yr (12,342 B/D) from 1,372 million lb/yr (12,878B/D).Plant cash costs increase to 4.55 ¢/lb from 4.48 ¢/lb of diesel. Net production cost becomes 6.29¢/lb, up from 6.15 ¢/lb. The total product value at 25% ROI rises to 10.39 ¢/lb from 10.08 ¢/lb.Similarly, with 15% contingency, the base unit’s total production cost decreases to 10.21 ¢/lb ofdiesel with less time on steam.

Profitability

Based upon a total fixed capital cost (included 25% contingency) of $216 million and a 0.96operating factor, the total return on investment (ROI) before income taxes, was an attractive29.3% at the mid 2000 prevailing diesel fuel market value of 10.77 ¢/lb. When the plant capacityis half the base case capacity, the ROI reduces to 21.1%. Increasing capacity to 1.5 times thebase case increases the ROI to 32.7%. Similarly, but with a 15% capital cost contingency, thebase case unit’s ROI increases to a very attractive 33.6%, the half capacity case returns 24.7%and the 1.5 times case return rises to 37.4%.

At a 0.92 operating factor instead of 0.96 and a product value of 10.77¢/lb of diesel fuel, thebase case unit’s ROI decreases 2.1 percentage points to 27.2% with a 25% contingency andrises 2.0 points to 31.4% with a 15% contingency. At 25% contingency, the 0.5 and 1.5 timescapacity plants' returns are 19.2% and 30.5% respectively. Also with a 15% contingency, the 0.5and 1.85 times plant capacity plants returns are 22.7% and 34.9% respectively, down 2.0 and 2.5percentage points when the time on stream is reduced to 0.92.

26

PEP REVIEW 98-7

Table 5

HYDROCRACKING TECHNOLOGY FOR MIDDLE DISTILLATE

TOTAL CAPITAL INVESTMENTCAPACITY: 1,372 MILLION LB/YR (622,000 T/YR)

DIESEL FUELAT 0.96 STREAM FACTOR

PEP COST INDEX: 624

CAPACITYEXPONENT

COST --------------------------($1,000) UP DOWN------------ ---------- ----------

BATTERY LIMITS EQUIPMENT, F.O.B.REACTORS 24,383 0.98 0.90COLUMNS 1,373 0.95 0.81VESSELS & TANKS 1,834 0.84 0.97HEAT EXCHANGERS 5,666 0.78 0.63FURNACES 5,897 0.82 0.82COMPRESSORS 9,921 0.76 0.76SPECIAL EQUIPMENT 10,000 1.00 1.00MISCELLANEOUS EQUIPMENT 700 1.00 1.00PUMPS 2,670 0.79 0.74

---------TOTAL 62,444 0.90 0.85

DIRECT INSTALLATION COSTS 37,163 0.86 0.73INDIRECT COSTS 37,915 0.84 0.76UNSCHEDULED EQUIPMENT, 10% 13,752 0.87 0.79

---------BATTERY LIMITS, INSTALLED 151,274 0.87 0.79

CONTINGENCY, 25% 37,819 0.87 0.79---------

BATTERY LIMITS INVESTMENT 189,093 0.87 0.79

OFF-SITES, INSTALLEDCLARIFIED WATER 578 0.74 0.64COOLING WATER 1,284 0.92 0.92PROCESS WATER 302 0.62 0.62BOILER FEED WATER 2,695 0.52 0.39STEAM 2,739 0.48 0.00TANKAGE 6,662 0.65 0.65

---------UTILITIES & STORAGE 14,261 0.62 0.47

GENERAL SERVICE FACILITIES 4,067 0.86 0.77WASTE TREATMENT 2,888 0.84 0.74

---------TOTAL 21,216 0.70 0.56

CONTINGENCY, 25% 5,304 0.70 0.56---------

OFF-SITES INVESTMENT 26,519 0.70 0.56

TOTAL FIXED CAPITAL 215,612 0.85 0.76

27

PEP REVIEW 98-7

Table 6

HYDROCRACKING TECHNOLOGY FOR MIDDLE DISTILLATE

CAPITAL INVESTMENT BY SECTIONCAPACITY: 1,372 MILLION LB/YR (622,000 T/YR)

DIESEL FUELAT 0.96 STREAM FACTOR

PEP COST INDEX: 624

REACTOR LOOP PRODUCT RECOVERY------------------------------------------------- -------------------------------------------------

CAPACITY CAPACITYEXPONENT EXPONENT

COST ------------------------- COST -------------------------($1,000) UP DOWN ($1,000) UP DOWN------------ ----------- ---------- ------------ ----------- ----------

BATTERY LIMITS EQUIPMENT, F.O.B.REACTORS 24,383 0.98 0.90 -- -- --COLUMNS 520 1.12 0.95 853 0.84 0.74VESSELS & TANKS 1,565 0.86 1.03 269 0.75 0.68HEAT EXCHANGERS 4,466 0.79 0.64 1,200 0.77 0.62FURNACES 2,813 0.82 0.82 3,085 0.82 0.82COMPRESSORS 9,921 0.76 0.76 -- -- --SPECIAL EQUIPMENT 10,000 1.00 1.00 -- -- --MISCELLANEOUS EQUIPMENT 450 1.00 1.00 250 1.00 1.00PUMPS 1,707 0.83 0.76 963 0.73 0.70

--------- ---------TOTAL 55,824 0.92 0.87 6,620 0.80 0.75

DIRECT INSTALLATION COSTS 30,654 0.87 0.77 6,509 0.77 0.56INDIRECT COSTS 32,917 0.86 0.79 4,997 0.75 0.61UNSCHEDULED EQUIPMENT, 10% 11,940 0.89 0.82 1,813 0.78 0.64

--------- ---------BATTERY LIMITS INSTALLED 131,335 0.89 0.82 19,939 0.78 0.64

CONTINGENCY, 25% 32,834 0.89 0.82 4,985 0.78 0.64--------- ---------

BATTERY LIMITS INVESTMENT 164,169 0.89 0.82 24,924 0.78 0.64

OFFSITES, INSTALLEDCLARIFIED WATER 309 0.74 0.64 269 0.74 0.64COOLING WATER 721 0.92 0.92 563 0.92 0.92PROCESS WATER 130 0.62 0.62 102 0.62 0.62BOILER FEED WATER 1,028 0.51 0.34 1,667 0.53 0.42STEAM 258 0.48 0.00 2,481 0.48 0.00TANKAGE 2,772 0.65 0.65 3,890 0.65 0.65

--------- ---------UTILITIES & STORAGE 5,219 0.66 0.58 8,972 0.60 0.41

28

PEP REVIEW 98-7

Table 7

HYDROCRACKING TECHNOLOGY FOR MIDDLE DISTILLATE

PRODUCTION COSTSPEP COST INDEX: 624

VARIABLE COSTSCONSUMPTION

UNIT COST PER LB ¢/LB------------------------- -------------------------- ----------

RAW MATERIALSFRESH FEED 10% AGO 6.442 ¢/LB 2.89017 LB 18.62HYDROGEN 99.9% 73.21 ¢/LB 0.07717 LB 5.65CATALYST & CHEMICALS 834 ¢/LB 0.000292 LB 0.24MDEA 183 ¢/LB 0.000002 LB NEGL

---------GROSS RAW MATERIALS 24.51

BY-PRODUCTSC1 FUEL GAS 7.806 ¢/LB -0.01012 LB -0.08C2 FUEL GAS 11.11 ¢/LB -0.01156 LB -0.13C3 FUEL GAS 12.05 ¢/LB -0.03757 LB -0.45C4 FUEL GAS 11.55 ¢/LB -0.05491 LB -0.63FULL NAPHTHA 13.13 ¢/LB -0.64451 LB -8.46KEROSENE(JET FUEL) 11.12 ¢/LB -1.09191 LB -12.14H. FUEL OIL 7.671 ¢/LB -0.04335 LB -0.33

---------TOTAL BY-PRODUCTS -22.22

CONSUMPTION CONSUMPTIONUNIT COST PER LB PER KG

------------------------- -------------------------- --------------------------UTILITIES

COOLING WATER 7.45 ¢/MGAL 2.45 GAL 20.4 LITERS 0.02PROCESS WATER 1.101 $/MGAL 0.0294 GAL 0.245 LITERS NEGLSTEAM, 600 PSIG 5.72 $/MLB 0.172 LB 0.172 KG 0.10STEAM, 50 PSIG 3.5 $/MLB -0.453 LB -0.453 KG -0.16STEAM, 150 PSIG 4.51 $/MLB -0.239 LB -0.239 KG -0.11ELECTRICITY 4 ¢/KWH 0.0648 KWH 0.143 KWH 0.26NATURAL GAS 3.24 $/MMBTU 1,260 BTU 698 KCAL 0.41

---------TOTAL UTILITIES 0.52

29

PEP REVIEW 98-7

Table 7 (concluded)

HYDROCRACKING TECHNOLOGY FOR MIDDLE DISTILLATE

PRODUCTION COSTSPEP COST INDEX: 624

CAPACITY (MILLION LB/YR)* 686 1,372# 2,058------------ ------------ ------------

INVESTMENT ($ MILLIONS)BATTERY LIMITS (BLI) 109.0 189.1 269.6OFFSITES 18.0 26.5 35.2

--------- --------- ---------TOTAL FIXED CAPITAL (TFC) 127.0 215.6 304.8

SCALING EXPONENTS 0.76 0.85

PRODUCTION COSTS (¢/LB)RAW MATERIALS 24.51 24.51 24.51BY-PRODUCTS -22.22 -22.22 -22.22UTILITIES 0.52 0.52 0.52

--------- --------- ---------VARIABLE COSTS 2.81 2.81 2.81

OPERATING LABOR, 4/SHIFT, $33.58/HR 0.17 0.09 0.06MAINTENANCE LABOR, 3%/YR OF BLI 0.48 0.41 0.39CONTROL LAB LABOR, 20% OF OPER LABOR 0.03 0.02 0.01

--------- --------- ---------LABOR COSTS 0.68 0.52 0.46

MAINTENANCE MATERIALS, 3%/YR OF BLI 0.48 0.41 0.39OPERATING SUPPLIES, 10% OF OPER LABOR 0.02 0.01 0.01

--------- --------- ---------TOTAL DIRECT COSTS 3.99 3.75 3.67

PLANT OVERHEAD, 80% OF LABOR COSTS 0.54 0.42 0.37TAXES AND INSURANCE, 2%/YR OF TFC 0.37 0.31 0.30

--------- --------- ---------PLANT CASH COSTS 4.90 4.48 4.34

DEPRECIATION, 10%/YR OF TFC 1.85 1.57 1.48--------- --------- ---------

PLANT GATE COSTS 6.75 6.05 5.82

G&A, SALES, RESEARCH 0.12 0.11 0.10--------- --------- ---------

NET PRODUCTION COST 6.87 6.16 5.92

ROI BEFORE TAXES, 29.3%/YR OF TFC 5.42 4.60 4.34--------- --------- ---------

PRODUCT VALUE 12.29 10.76 10.26

-----------------------------------* OF DIESEL FUEL# BASE CASE

30

PEP REVIEW 98-7

CONCLUSION

If the high yield of diesel product would represent a desired product slate, the preliminaryconclusion about the HyCycle(TM) Unicracking technology is very positive. This preliminaryconclusion could be enforced by confirmation of the assumption made during the course of thisevaluation, in terms of reactor operating conditions, vapor product separation conditions, andproduct yield. It is recognized that a non-disclosure agreement with UOP would have beenrequired in order to further establish the technical integrity of the above report.

FOOTNOTES

(1) Cetane Index. A Nomograph for calculating Cetane Index is presented in StandardMethods For Analysis and Testing of Petroleum and Related Products. 1988 issue BritishInstitute of Petroleum. Vol 1 218-3. API gravity and 50% boiling point by ASTM distillation isneeded.

(2) Per pass conversion: 100- 650°F+ material in distillate product (liquid volume) 650°F+ in (fresh feed + recycle)

(3) Overall conversion : 100- 650°F+ in distillate product (liquid volume) 650°F+ material in feed

31

PEP REVIEW 98-7

CITED REFERENCES

LiteratureR98-07-001 Antos, G.J., et al., “Unicracking TM Innovations Delivery Profit,” National

Petrochemical and Refiners Association 2001 Annual Meeting, New Orleans,LA, (March 18-20, 2001), Paper AM-01-30

R98-07-002 Lamourelle, A.P., et al., “Clean Fuels: Route to Low Sulfur Low Aromatic Diesel,”National Petrochemical and Refiners Association 2001 Annual Meeting, NewOrleans, LA, (March 18-20, 2001), Paper AM-01-28

R98-07-003 Adler, K., “2001 In Review: Europe, Asia See Trends of Fuels Regulations,”World Refining, 11,1 (January/February 2001), 36, 38-40

R98-07-004 Peckham, J., “Euro Commission Proposes 10 ppm ULSD Phase-in from 2007,”Diesel Fuel News, 5, 5 (March 5, 2001), 11\

R98-07-005 Roj, A., “Fuel Quality for the Future—an Automotive Industry View,” CleanerFuels for Europe workshop, Helsinki, Finland, (Nov. 23-23, 2000)

R98-07-006 U.S. Environmental Protection Agency, “EPA Gives the Green Light on Diesel-Sulfur Rule,” News Release (R-30), (February 28, 2001)

R98-07-007 National Petrochemical and Refiners Association, “NPRA to Challenge DieselSulfur Rule in Court: Decision Motivated by Supply Concerns,” News Release(January 23, 2001)

R98-07-008 National Petrochemical and Refiners Association, “NPRA Files Petition forReview of EPA’s Diesel Sulfur Rule,” News Release (February 2, 2001)

R98-07-009 National Petrochemical and Refiners Association, “NPRA Reaction to Reports ofAdministration Decision on Diesel Rule,” News Release (February 28, 2001)

PatentsUS 5885440 Hoehn, R.K., et al., (to UOP LLC), “Hydrocracking process with integrated

effluent hydrotreating zone,” U.S. 5,885,440 (March 23, 1999)

US 5980729 Kalnes, T.N., (to UOP LLC),”Hydrocracking Process,” U.S. 5,980,729 (Nov. 9,1999)

WO 97/38066 Cash, I. R., (to Chevron U.S.A.), “Process for Reverse Staging inHydroprocessing Reactor Systems,” WO 97/38066 (application) (Oct. 16, 1997)

Reports211 Chang, E.J., “Hydrocracking,” PEP Report 211, SRI Consulting, Menlo Park, CA

(April 1994)

212 Leiby, S.M., “Options for Refinery Hydrogen,” PEP Report 212, SRI Consulting,Menlo Park, CA (February 1994)

216 Ma, J.J. “Acid Gas Treatment and Sulfur Recovery,” PEP Report 216, SRIConsulting, Menlo Park, CA (November 1997)

32

PEP REVIEW 98-7

228 Nielsen, R. H., “Refinery Residue Upgrading,” PEP Report 228, SRI Consulting,Menlo Park, CA (May 2000)

1

2

15

13

6

14

5

7

8

12

3

9

10

19

21

22

16

20

11

4

17

18

UnconvertedOil from

Section 200

BFWO250 F

F-101Feed-Recycle

Furnace

Atmospheric Gas Oil

Vacuum Gas Oil

From Storage

Vent

V-104

Make-up H2

V-101

K-101A

E-102E-101

O225 F1130 psig

O225 F

640 psig

K-101B

E-103E-104

O150 F O100 F

V-103

O225 F2050 psig

E-105

O150 F

V-105

WasteWater

E-114

WashWater

V-106

C-101

2020 psigO165 F

K-102

CW

E-116

To V-201

Rich MDEA

Lean MDEA

To V-201

UnconvertedOil to E-204

E-115

V-107

R-103Hydrocracker

E-113

V-102

O100 F

K-101A,B,CH Make up2

E-111

E-106

E-108

E-112

BFW

M-101

E-110

E-109BFW

600 psig Steam

E-107

R-101Hydrotreating

Reactor

V-104Feed Surge

R-103

V-105Cold

Separator

V-107Hot Flash

Drum

V-106Recycle

CompressorK.O.

C-101Amine

Absorber

O150 F

Vac.

36

F-101

K-102H2 Recycle

V-103H Co mpressor2

K.O.3

O300 F

O330 F

O690 F

O490 F

O630 F

O600 F

O625 F

O695 F

O400 F

O715 F1950 psig

O730 F1820 psig

O320 F

O700 F1910 psig

O725 F

1860 psig

O320 F1860 psig

O150 F

O140 F

O130 F

O130 F1750 psig

K-101C

1800 psig

O500 FO640 F

V-101H Co mpressor2

K.O.1

M-101 A,BFresh Feed

Filter System

R-102FinishingReactor

V-102H Co mpressor2

K.O.2

2001

(TM)HYCYCLE UNICRACKING HYDROCRACKINGFOR MIDDLE DISTILLATE

Figure 1 (Sheet 1 of 2)

33

H COMPRESSION AND REACTOR LOOP2

PEP Review 98-7

O625 F

R-101R-102

23

11

18

24

25

26

9

30

28

29

27

36

35

37

34

33

32

H2

V-201O140 F

300 psig

From V-105

E-201

From V-106 & V-107

Steam 50 psig32,000 lb/hr

Steam 150 psig

120 psig

O280 F

O180 F O100 F

O360 F

From V-107

O625 F

O650 F 2200 psig

To R-103

C-201

E-202

FuelGas

V-202

CW

120 psig

LPG

E-203

37,000 lb/hr600 psig Steam

F-201

Steam 10 psig20,000 lb/hr

C-202

BFW

E-205

O375 F

Steam 150 psig20,000 lb/hr

FuelOil

E-206

Steam 150 psig6000 lb/hr

Steam O600 psig /750 F

9000 lb/hr

O650 F, 30 psigO700 F

E-204

M-201

BFW

E-208O450 F

O475 FO550 F

O450 F

O550 FC-204

E-211

C-203

Steam 50 psig10,000 lb/hr

Steam 50 psig14,000 lb/hr

E-210

E-212

Kerosene

Steam 50 psig28,000 lb/hr

UCO to Fuel Oil

Fuel Gas

28,000 lb/hrWaste Water

Naphtha

E-207

V-203

O265 F

Water

18,000 lb/hr

10 psigO

140 F

E-209

BFW

O400 F BFW from F-101 Diesel

V-201Cold Flash

Drum

C-201LPG Stripper

V-202LPG

Reflux Drum

F-201FractionatorFeed Heater

M-201UCO Filter

System

C-202Product

Fractionator

V-203Fractionator

Reflux

C-203KeroseneStripper

C-204Diesel

Stripper

BFW

O140 F

O160 F

CW

200134

(TM)HYCYCLE UNICRACKING HYDROCRACKINGFOR MIDDLE DISTILLATE

Figure 1 (Sheet 2 of 2)

PRODUCT RECOVERY

PEP Review 98-7