Hydraulic hammers (S-90 and S-150) - c-i-services.com · –20 to 50°C, which enables them to be...

Transcript of Hydraulic hammers (S-90 and S-150) - c-i-services.com · –20 to 50°C, which enables them to be...

Extremely high structural integrity and high levels of control can be achieved when conductors are driven into place with a hydraulic hammer.

Selecting the right hammer for the application, however, is crucial. Not only do you need to choose a model that is powerful enough to drive the conductor to the desired penetration, but its weight must also be within the rig’s crane limits. Selecting an inadequate hammer can cause extremely expensive project delays. There are other key considerations too, such as reliability and environmental performance.

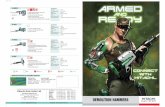

CIS, as one of the world’s leading installers of oilfield conductors, has a fleet of S-90 and S-150 hydraulic hammers located strategically around the world. Most of these are S-90 hammers – the oil and gas industry’s conductor driving tool of choice. We also have several S-150 hydraulic hammers for projects that require more driving energy owing to the size of the pile being driven or to the formation resistance encountered.

The S-90 and S-150 hammers are ideal for sinking steel piles, H-beams and offshore piles as well as for conductor driving.

Hydraulic hammers (S-90 and S-150)

High-performance hammers backed by industry experience

About the technology

The S-90 and S-150 hammers combine a solid one-piece ram with a fully enclosed hammer housing. The modular structure protects the working parts from the elements and reduces the risk of breakdowns.

In addition, the hammers have an extremely wide operating window, from –20 to 50°C, which enables them to be used in most climates. They are also environmentally friendly: there are no waste gases or oil splashes, and the oil-lubricated bearings have a long service life.

The hammers are serviced by qualified mechanics either at our base in Great Yarmouth, UK or at any of our other bases worldwide. Field servicing can also be undertaken because over 50% of CIS’s offshore supervisors and technicians are fully qualified mechanics. Operating data are shown overleaf.

Adding value

Operators place a premium on the ability of their service providers to adapt to oilfield situations as they emerge; experience is paramount in conductor installation projects.

CIS has a highly skilled and experienced onshore team that can provide further support and guidance if project plans need to be adjusted before or during the execution phase.

Moreover, where appropriate, we can also take full project management responsibility for the process of installing conductors. This can include performing engineering studies; recommending and then manufacturing the drive shoes; supervising the shoe welding; and supplying all the conductor handling equipment along with the hammer equipment. Once the driving is finished, we can also complete the project by cutting and bevelling the conductor ready for the wellhead to be fitted.

Operating data

S-90 S-150

Energy

Maximum net energy/blow (kN.m) 90 150

Minimum net energy/blow (kN.m) 2 6

Blow rate (maximum energy) (blows/min) 50 45

Weights

Ram (t) 4.5 7.5

Hammer (including ram in air plus 36-in. sleeve) (t) 13.2* 19.6*

Hydraulic data

Operating pressure (bar) 230 260

Maximum pressure (bar) 350 350

* Shipping weights will depend on the specific hammer configuration and type of transportation

cradle supplied. Please contact CIS for further information.

Project profile

A project offshore Trinidad required four 26-in. diameter, 1-in. wall thickness conductors to be batch driven to a prescribed penetration below the seabed. Using an S-150 hammer, CIS completed the operation in textbook fashion with lower than normal levels of vibration, a feature that the client particularly valued.

The S-90 hydraulic hammer is the most widely accepted conductor-driving tool in the oil and gas industry. Most operating companies in the international arena select it for their conductor driving projects.

Hydraulic hammers (S-90 and S-150)

Please contact CIS for further information.

Conductor Installation Services LtdCIS HouseEurocentreNorth River RoadGreat YarmouthNorfolk NR30 1TEUnited Kingdom

Tel: +44 (0)1493 849680 Fax: +44 (0)1493 849681Email: [email protected]

www.c-i-services.com

OHSAS 18001