Hydraulic Elevators

-

Upload

hemanth-sai -

Category

Documents

-

view

212 -

download

0

Transcript of Hydraulic Elevators

HYDRAULIC ELEVATORS

Hydraulic elevators are elevators which are powered by a piston that travels inside a

cylinder.

An electric motor pumps oil into the cylinder to move the piston. The piston smoothly lifts the

elevator cab. Electrical valves control the release of the oil for a gentle descent.

Hydraulic elevators are used extensively in buildings up to five or six stories high. These

elevators, which can operate at speeds up to 61 meters (200 ft) per minute, do not use the

large overhead hoisting machinery the way geared and gearless traction systems do.

All modern hydraulic pumps are either equipped with a Solid-State Contactor or a mechanical Y-

Delta starter. Solid-State Contactor starters are better for the motor and the building's power supply,

as the windings last longer and there are no voltage drops across the line of the building's power

supply. Y-Delta starters use two contactors to start the motor on a reduced speed, then kick on full

speed. Old hydraulic elevators just started up abruptly, sending mains power at full blast right into

the motor. This puts a lot of strain on the motor which, in turn, makes it burn out faster than motors

on Y-Delta or Solid-State Contactor starters.

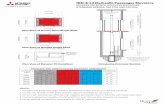

There are three types of hydraulic elevator; holed hydraulic, holeless hydraulic and roped hydraulic.