Hydraulic cylinder piston

-

Upload

rumeel-ahmad -

Category

Automotive

-

view

452 -

download

5

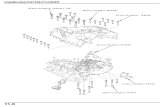

description

Transcript of Hydraulic cylinder piston

- 1.Casting of

2. Introduction Hydraulic cylinder piston is used in mechanism.hydraulicIt is used to separate the pressure zones inside the barrel. Piston is machined with grooves to fit elastomeric or metal seals and bearing elements. Difference in pressure between the two sides of the piston causes the cylinder to extend and retract piston. It is attached with the piston rod by means of threads, bolts, or nuts to transfer the linear motion.Hydraulic cylinder piston 3. Processes on Piston 4. Casting On large Scale The majority of original equipment and aftermarket pistons are manufactured through casting. The technical description is 'gravity die casting'. However for the sake of simplicity, a cast piston is manufactured by pouring molten metal into a mold to make the rough layout of piston. There are traces of many other metals in cast pistons, including copper, nickel, manganese and magnesium, all of these adding somewhat to the overall behavior and strength of the piston. Piston made by casting has some allowance to perform further processes on it.Small Industries On small scale where production is low sand casting is used as it is the cheap. Other benefit of it is that the pattern is reused that reduces the marked cost of the part. 5. Foundry A foundry is a small factory that produces metal castings.Metals are cast into shapes by melting them into a liquid, pouring the metal in a mold, and removing the mold material or casting after the metal has solidified as it cools. 6. Sand Casting Place a pattern in sand to create a mold. Break away the sand mold and remove the casting.Incorporate the pattern and sand in a gating system.Allow the metal to cool.Remove the pattern.Fill the mold cavity with molten metal. 7. Pattern Before casting mold is prepared by using the pattern, pattern may be permanent or temporary i.e. made of plastic or rubber In our case its permanent.PatternBonding agent A suitable bonding agent (usually clay) is mixed or occurs with the sand. The mixture is moistened, typically with water, but sometimes with other substances, to develop strength and plasticity of the clay and to make the aggregate suitable for moldingBonding agent 8. Mold As the part is simple in shape, sand mold is used as it is cheap. Different molds are used time to time.mold 9. Electric furnaceManual furnace (coal is used ) 10. The Process The process starts by heating the material to 1200 degrees Celsius. This is well above the melting point of the metal, but below its boiling point. The material is then scooped up with a ladle from the crucible (the pot that holds the molten material). This is then poured into the mold through the spruce. The material is then allowed to cool before it is removed from the mold and placed into a bin of hot water. This water is used to facilitate a more even settling of the hot metal. After the castings have had time to cool. This process tempers the casting and ensures the piston will have improved qualities.Molten metal 11. Lathe Process The casted piston is taken to the lathe machine for further processes. The following processes are done on piston on lathe;Turning The piston is set in the jaws of lathe and set to rotation. The turning is the process in which the diameter of the piston is reduced. The required diameter of piston is determine in this process. This process is also used for the polishing of the piston. Facing The piston is set in the jaws of lathe and set to rotation. In facing the length of the piston is reduced. The require length of piston is set in this process. Other operation The additional lines for the Rings of piston which are shown on the figure which are seen on the piston are also done on lathe machine. 12. Turning , facing on the lathe 13. Milling operation The other shape which needed on the piston which cant be made on the lathe machine is made with the help of milling machine. Like the hole for the connecting pin which connects the piston with piston rod is made by the Milling machine.Polishing The sides of the piston are highly polished to reduce the friction. This process can be done by rubbing sand papers on the piston. For high polished surface piston are placed on the lathe machine and then the sand paper are used as the tool to polish the surface of piston as shown in the figure. 14. Uses Pistons are widely used in the engines of automobiles, Ships, etc. It is used with hydraulics for the lifting purpose. The main function of the piston is to separate the pressure zones inside the barrel.