Hydraulic Bolt Tensioning - hctools.com.t 1500bar bolt... · BOLTIGHT is the UK Registered Trade...

Transcript of Hydraulic Bolt Tensioning - hctools.com.t 1500bar bolt... · BOLTIGHT is the UK Registered Trade...

BOLTIGHT is theUK RegisteredTrade Mark of

Boltight Limited

BOLTIGHT LIMITED, Unit 2 Junction 10 Business Park, Bentley Mill Way, Walsall,West Midlands, WS2 OLE, UK Tel: +44 (0) 870 77 44 66 1 Fax: +44 (0) 870 77 44 66 2Email: [email protected] Web: www.boltight.com

DATASHEETDS 11

Copyright Boltight Ltd October 2005

Hydraulic Bolt Tensioning

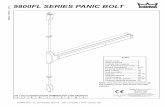

The tensioning force is transferredto the BOLT by the PULLER

PULLER

Tommy barholes

Piston

Bolt one diameterextra long

Body

HYDRAULIC CYLINDERannular hydraulic jack

The hydraulic forceis transferred to thePULLER

OIL INLET

Window for turning theSOCKET with a tommy bar.

The nut can be turnedwith zero torque as theoil pressure is increased

BRIDGE

SOCKET

Seal

A hydraulic bolt tensioning tool provides a quick and easy method for tightening large diameter bolts to high and accurate pre-loads. Unlike conventional methods it does not use torque and does not require any forceful turning of the nut or bolt, like impact wrenches, flogging spanners or hydraulic torque wrenches. All of these methods have one common enemy, FRICTION. Overcoming thread friction and friction between the nut and the washer uses up over 80% of the torque energy applied to the nut or bolt, leaving less than 20% of the energy to produce useful tension in the shank of the bolt. Variations in this friction loss, from bolt to bolt causes non uniform tension in bolts that have been tightened to the same torque or impact wrench setting.

A hydraulic bolt tensioner is an annular jack which fits over the bolt and nut to be tightened. The jack pushes against the bolted joint and pulls on the end of the bolt, which needs to be at least one diameter longer to accommodate the bolt tensioning tool. Because the force produced, by the jack, is applied directly to the end of the bolt, a tension equal to the load generated by the jack is developed in the shank of the bolt. With the jack applying the tension, it is possible to turn the nut with zero torque until it is tight. The load applied by the jack is then relaxed and a high percentage, depending on the length of the bolt and its diameter, is retained in the shank of the bolt.

Bolt tensioning tools can be ganged together to enable multiple bolts to be tightened simultaneously, to the same high and accurate pre-load. This is particularly useful when compressing gaskets in pipeline or pressure vessel flanged connections. The high load developed by the multiple bolt tensioning tools, is evenly distributed around the joint causing the gasket to flow into the surface irregularities of the flange giving a much better seal.

Flexible hoses with self sealing quick connect couplings are used to gang the bolt tensioning tools together to form a hydraulic ring main. The ring main and tensioning tools are normally pressurised using an air driven pump working from a compressed air supply.

HYDRAULICCYLINDER

BOLTIGHT is theUK RegisteredTrade Mark of

Boltight Limited

BOLTIGHT LIMITED, Unit 2, Junction 10 Business Park, Bentley Mill Way, Walsall,West Midlands, WS2 OLE, UK Tel: +44 870 77 44 66 1 Fax: +44 870 77 44 66 2Email: [email protected] Web: www.boltight.com

DATASHEETDS 15

Copyright Boltight Ltd Mar 2006

NOTES1 - Maximum load is generated at the maximum operating pressure of 1500 bar.2 - For hoses fittings and pumps see Data Sheets DS 601, DS 602, and DS 6033 - Unless specified inch size tooling will be threaded UNC up to 1 inch and UN8 for 1-1/8 inch upwards.4 - Equivalent metric sizes are also available. Specify diameter and thread pitch when ordering.5 - This range of tooling has been designed to suit most standard flanges used in the oil and gas industry6 - Each tool comprises one Hydraulic Cylinder, Bridge, Puller and Socket.7 - Extra Bridges Pullers and Sockets can be purchased to adapt the Hydraulic Cylinder to fit other bolt sizes.8 - All tools are assembled, filled with oil, pressure tested and a test certificate issued prior to despatch.9 - Each tool is marked with the maximum operating pressure, load and stroke. All tools are CE marked.10 - Any number of tools can be connected together for simultaneous operation.11 - Pullers can be machined with other thread forms - specify when ordering.12 - Larger bolt sizes are available. Send application details to Boltight Limited.13 - Tools are fitted with self sealing quick connectors.14 - Due to continuous product development dimensions may change without notice.

Options available :-1 - Twin Hydraulic Connections 2 - Other thread forms 3 - Special Designs.

Inch Sizes (metric sizes also available)Tool Bolt Min Bolt Hydraulic Max Tool NearestNo Dia Pitch Area Load Outside Dia Obstruction

inch mm mm sq mm kN mm mm3/4 537/8 531 62

1-1/8 621-1/4 73 C1-3/8 811-1/2 831-5/8 931-3/4 961-7/8 101

2 1042-1/4 1232-1/2 1292-3/4 150

3 1543-1/4 1763-1/2 1853-3/4 191

4 1972,629 245 32027 J 15 17,530

1,830 200 255

26 I 15 16,682 2,502 235 288

25 H 15 12,197

8,445

F

24 G 15

23E

15 5,271 791 136 200

22 15 2,884

1,555

D

Stroke

21A

12B

Bridge

145

230

233

433

1,267

73

172

108 175

Page 1 of 3

1500 Bar System Hydraulic Bolt Tensioning Tools

BOLTIGHT is theUK RegisteredTrade Mark of

Boltight Limited

BOLTIGHT LIMITED, Unit 2, Junction 10 Business Park, Bentley Mill Way, Walsall,West Midlands, WS2 OLE, UK Tel: +44 870 77 44 66 1 Fax: +44 870 77 44 66 2Email: [email protected] Web: www.boltight.com

DATASHEETDS 15

1500 Bar System Hydraulic Bolt Tensioning Tools

NOTES1 - Maximum load is generated at the maximum operating pressure of 1500 bar.2 - For hoses fittings and pumps see Data Sheets DS 601, DS 602, and DS 6033 - Metric thread pitch must be specified when ordering.4 - This range of tooling has been designed to suit most standard flanges used in the oil and gas industry5 - Each tool comprises one Hydraulic Cylinder, Bridge, Puller and Socket.6 - Extra Bridges, Pullers and Sockets can be purchased to adapt the Hydraulic Cylinder to fit other bolt sizes.7 - All tools are assembled, filled with oil, pressure tested and a test certificate issued prior to despatch.8 - Each tool is marked with the maximum operating pressure, load and stroke. All tools are CE marked.9 - Any number of tools can be connected together for simultaneous operation.10 - Pullers can be machined with other thread forms - specify when ordering.11 - Sizes above M100 are available. Send details of your application to BOLTIGHT.12 - Tools are fitted with self sealing quick connectors.13 - Due to continuous product development dimensions may change without notice.

Options available :-1 - Twin Hydraulic Connections 2 - Other thread forms 3 - Special Designs.

Metric Sizes (inch sizes also available)Tool Bolt Min Bolt Hydraulic Max Tool NearestNo Dia Pitch Area Load Outside Dia Obstruction

inch mm mm sq mm kN mm mmM20 53M22 53M24 62M27 62M33 73 CM36 81M39 83M42 93M45 96M48 101M52 104M56 123M64 129M72 150M76 154M80 176M90 185M95 191M100 197

2,629 245 32027 J 15 17,530

1,830 200 255

26 I 15 16,682 2,502 235 288

25 H 15 12,197

8,445

F

24 G 15

23E

15 5,271 791 136 200

22 15 2,884

1,555

D

Stroke

21A

12B

Bridge

145

230

233

433

1,267

73

172

108 175

Copyright Boltight Ltd Mar 2006

Page 2 of 3

BOLTIGHT is theUK RegisteredTrade Mark of

Boltight Limited

BOLTIGHT LIMITED, Unit 2, Junction 10 Business Park, Bentley Mill Way, Walsall,West Midlands, WS2 OLE, UK Tel: +44 870 77 44 66 1 Fax: +44 870 77 44 66 2Email: [email protected] Web: www.boltight.com

DATASHEETDS 15

Copyright Boltight Ltd Jan 2006

New Tool No 29 now available

Page 3 of 3

Tool Bolt Min Bolt Hydraulic Max Tool NearestNo Dia Pitch Area Load Outside Dia Obstruction

mm mm mm sq mm kN mm mm1-7/8 112

2 115

2-1/4 120

M48 111

M52 114

M56 117156 230

M56

Bridge Stroke

29

2000

15

2250

6,983 1,047 156 230

29

M52

15 6,983 1,047

BOLTIGHT has noted a market need for an M56 or 2-1/4 inch tool with anoutside diameter less than 160 mm diameter and a load capacity of at least 1000 kN.

We have responded to this market need by adding a new Tool No 29 to our 1500 bar range. Details of the tool are given above.

1500 Bar System New addition to the tool range

BOLTIGHT is theUK RegisteredTrade Mark of

Boltight Limited

BOLTIGHT LIMITED, Unit 2 Junction 10 Business Park, Bentley Mill Way, Walsall,West Midlands, WS2 0LE, UK Tel: +44 (0) 870 77 44 661 Fax: +44 (0) 870 77 44 662Email: [email protected] Web: www.boltight.com

DATASHEETDS 16

Copyright Boltight Ltd July 2005

1500 Bar System Hydraulic Bolt Tensioning Tools

Twin Hydraulic Connections

This picture shows the twin hydraulic connection version of the 1500 bar tool.The tool has one quick connect nipple to feed oil in, and one quick connect coupling to feed oil out to the next tool. The quick connectors are self sealing when disconnected.

Twin connections can simplify the ring main arrangement for simultaneous bolt tensioning operations.

The tool has colour coded labels and dust caps to match the pump and hoses. (see DS3 for the BOLTIGHT colour code system).Twin Hydraulic Connection Option

Adaptor Sets

Each tensioning tool can be adapted to suit more than one bolt diameter. Small changes in diameter only require a Puller and a Socket in the adaptor set. The Bridge can suit more than one nut size.

PullerSocket

Adaptor Sets

Where larger variations in bolt diameter are encountered the adaptor set may also include a Bridge.

For example Tool No 23 has two imperial Bridges. One for 1-5/8” and 1-3/4 inch bolts and another for 1-7/8 inch and 2 inch bolts.

Tools may also have different Bridges for metric and imperial sizes.

Bridge

Puller

Socket

Coupling

Nipple

SocketBridge

HydraulicCylinder

Puller

BOLTIGHT is theUK RegisteredTrade Mark of

Boltight Limited

BOLTIGHT LIMITED, Unit 2 Junction 10 Business Park, Bentley Mill Way, Walsall,West Midlands, WS2 OLE, UK Tel: (+44) 0870 77 44 66 1 Fax: (+44) 0870 77 44 66 2Email: [email protected] Web: www.boltight.com

DATASHEETDS 17

Copyright Boltight Ltd July 2005

1500

bar

Air

Driv

en P

ower

Pac

kPa

rt N

o B

T-15

06

Bla

nk N

ippl

ePa

rt N

o B

T-15

53

Typi

cal B

olt T

ensi

onin

g To

ol(tw

in h

ydra

ulic

con

nect

ions

)

Hos

e Pa

rt N

o B

T-15

40-N

( N =

Hos

e le

ngth

in m

etre

s )

Hos

e Pa

rt N

o B

T-15

40-N

( N =

Hos

e le

ngth

in m

etre

s )

Exa

mpl

e w

ith o

nly

4 to

ols.

It is

pos

sibl

e to

sim

ulta

neou

sly

tens

ion

50%

of t

he b

olts

and

in m

any

case

s 10

0%.

1500 bar Tool, Pump and Hose arrangement.The diagram on this page shows a typical arrangement when simultaneously operating four 1500 bar tools with twin hydraulic connections.

BOLTIGHT is theUK RegisteredTrade Mark of

Boltight Limited

BOLTIGHT LIMITED, Unit 2 Junction 10 Business Park, Bentley Mill Way, Walsall,West Midlands, WS2 0LE, UK Tel: +44 (0) 870 77 44 661 Fax: +44 (0) 870 77 44 662Email: [email protected] Web: www.boltight.com

DATASHEETDS 21

Copyright Boltight Ltd July 2005

Tool Selection Tables ANSI B16.5 Welding Neck Flanges

Pipe Size Bolt Dia 1000 bar 1500 barinch inch Tool Nos Tool No10 12 7/8 1 2112 12 7/8 1 2114 12 1 2, 3 2116 16 1 2, 3 2118 16 1-1/8 2, 3 2120 20 1-1/8 2, 3, 4 2124 20 1-1/4 3, 4, 5 22

Class 150No of Bolts

Pipe Size Bolt Dia 1000 bar 1500 barinch inch Tool Nos Tool No

4 8 3/4 1 215 8 3/4 1 216 12 3/4 1 218 12 7/8 1, 2 21

10 16 1 2, 3 2112 16 1-1/8 2, 3, 4 2114 20 1-1/8 2, 3, 4 2116 20 1-1/4 3, 4, 5 2218 24 1-1/4 3, 4, 5 2220 24 1-1/4 3, 4, 5 2224 24 1-1/2 5, 6, 7 22

Class 300No of Bolts

Pipe Size Bolt Dia 1000 bar 1500 barinch inch Tool Nos Tool No

4 8 7/8 1 215 8 7/8 1 216 12 7/8 1, 2 218 12 1 2, 3 21

10 16 1-1/8 2, 3 2112 16 1-1/4 3, 4 2214 20 1-1/4 3, 4, 5 2216 20 1-3/8 4, 5, 6 2218 24 1-3/8 4, 5, 6 2220 24 1-1/2 5, 6, 7 2224 24 1-3/4 7, 8, 9 23

Class 400No of Bolts

Pipe Size Bolt Dia 1000 bar 1500 barinch inch Tool Nos Tool No3-1/2 8 7/8 1 21

4 8 7/8 1, 2 215 8 1 2, 3 216 12 1 2, 3 218 12 1-1/8 2, 3, 4 21

10 16 1-1/4 3, 4, 5 2212 20 1-1/4 3, 4, 5 2214 20 1-3/8 4, 5, 6 2216 20 1-1/2 5, 6, 7 2218 20 1-5/8 6, 7, 8 2320 24 1-5/8 6, 7, 8 2324 24 1-7/8 8, 9, 10 23

Class 600No of Bolts

Pipe Size Bolt Dia 1000 bar 1500 barinch inch Tool Nos Tool No

3 8 7/8 1, 2 214 8 1-1/8 2, 3, 4 215 8 1-1/4 3, 4, 5 226 12 1-1/8 2, 3, 4 218 12 1-3/8 4, 5, 6 22

10 16 1-3/8 4, 5, 6 2212 20 1-3/8 4, 5, 6 2214 20 1-1/2 5, 6, 7 2216 20 1-5/8 6, 7, 8 2318 20 1-7/8 8, 9 2320 20 2 9, 10 2324 20 2-1/2 11, 12 24

Class 900No of Bolts

Pipe Size Bolt Dia 1000 bar 1500 barinch inch Tool Nos Tool No

2 8 7/8 1 212-1/2 8 1 2, 3 21

3 8 1-1/8 2, 3 214 8 1-1/4 3, 4 225 8 1-1/2 5, 6 226 12 1-3/8 4, 5, 6 228 12 1-5/8 6, 7, 8 23

10 12 1-7/8 8, 9, 10 2312 16 2 9, 10 2314 16 2-1/4 10, 11 2416 16 2-1/2 11, 12 2418 16 2-3/4 12, 13 2520 16 3 13, 14, 15 2524 16 3-1/2 15 26

Class 1500No of Bolts

Pipe Size Bolt Dia 1000 bar 1500 barinch inch Tool Nos Tool No1-1/2 4 1-1/8 2 21

2 8 1 2, 3 212-1/2 8 1-1/8 2, 3, 4 21

3 8 1-1/4 3, 4, 5 224 8 1-1/2 5, 6, 7 225 8 1-3/4 7, 8, 9 236 8 2 9, 10 238 12 2 9, 10 23

10 12 2-1/2 11, 12 2412 12 2-3/4 12, 13 25

Class 2500No of Bolts

Page 1 of 4

BOLTIGHT is theUK RegisteredTrade Mark of

Boltight Limited

BOLTIGHT LIMITED, Unit 2 Junction 10 Business Park, Bentley Mill Way, Walsall,West Midlands, WS2 0LE, UK Tel: +44 (0) 870 77 44 661 Fax: +44 (0) 870 77 44 662Email: [email protected] Web: www.boltight.com

DATASHEETDS 21

Tool Selection Tables MSS SP44 Welding Neck Flanges

Pipe Size Bolt Dia 1000 bar 1500 barinch inch Tool Nos Tool No12 12 7/8 1 2114 12 1 2, 3 2116 16 1 2, 3 2118 16 1-1/8 2, 3 2120 20 1-1/4 2, 3, 4 2222 20 1-1/4 3, 4, 5 2224 20 1-1/4 3, 4, 5 2226 24 1-1/4 3, 4, 5 2228 28 1-1/4 3, 4, 5 2230 28 1-1/4 3, 4, 5 2232 28 1-1/2 5, 6, 7 2234 32 1-1/2 5, 6, 7 2236 32 1-1/2 5, 6, 7 2238 32 1-1/2 5, 6 2240 36 1-1/2 5, 6, 7 2242 36 1-1/2 5, 6, 7 2244 40 1-1/2 5, 6, 7 2246 40 1-1/2 5, 6, 7 2248 44 1-1/2 5, 6, 7 2250 44 1-3/4 7, 8, 9 2352 44 1-3/4 7, 8, 9 2354 44 1-3/4 7, 8, 9 2356 48 1-3/4 7, 8, 9 2358 48 1-3/4 7, 8, 9 2360 52 1-3/4 7, 8, 9 23

Class 150No of Bolts

Pipe Size Bolt Dia 1000 bar 1500 barinch inch Tool Nos Tool No12 16 1-1/8 2, 3, 4 2114 20 1-1/8 2, 3, 4 2116 20 1-1/4 3, 4, 5 2218 24 1-1/4 3, 4, 5 2220 24 1-1/4 3, 4, 5 2222 24 1-1/2 5, 6, 7 2224 24 1-1/2 5, 6, 7 2226 28 1-5/8 6, 7, 8 2328 28 1-5/8 6, 7, 8 2330 28 1-3/4 7, 8, 9 2332 28 1-7/8 8, 9, 10 2334 28 1-7/8 8, 9, 10 2336 32 2 9, 10 2338 32 1-1/2 5, 6, 7 2240 32 1-5/8 6, 7 2342 32 1-5/8 6, 7, 8 2344 32 1-3/4 7, 8 2346 28 1-7/8 8, 9 2348 32 1-7/8 8, 9 2350 32 2 9 2352 32 2 9 2354 28 2-1/4 10 2456 28 2-1/4 10 2458 32 2-1/4 10 2460 32 2-1/4 10 24

Class 300No of Bolts

Pipe Size Bolt Dia 1000 bar 1500 barinch inch Tool Nos Tool No12 16 1-1/4 3, 4 2214 20 1-1/4 3, 4, 5 2216 20 1-3/8 4, 5, 6 2218 24 1-3/8 4, 5, 6 2220 24 1-1/2 5, 6, 7 2222 24 1-5/8 6, 7, 8 2324 24 1-3/4 7, 8, 9 2326 28 1-3/4 7, 8, 9 2328 28 1-7/8 8, 9 2330 28 2 9, 10 2332 28 2 9, 10 2334 28 2 9, 10, 11 2336 32 2 9, 10 2338 32 1-3/4 7, 8, 9 2340 32 1-7/8 8, 9 2342 32 1-7/8 8, 9 2344 32 2 9 2346 36 2 9, 10 2348 28 2-1/4 10 2450 32 2-1/4 10, 11 2452 32 2-1/4 10, 11 2454 28 2-1/2 11, 12 2456 32 2-1/2 11, 12 2458 32 2-1/2 11 2460 32 2-3/4 12, 13 25

Class 400No of Bolts

Pipe Size Bolt Dia 1000 bar 1500 barinch inch Tool Nos Tool No12 20 1-1/4 3, 4, 5 2214 20 1-3/8 4, 5, 6 2216 20 1-1/2 5, 6, 7 2218 20 1-5/8 6, 7, 8 2320 24 1-5/8 6, 7, 8 2322 24 1-3/4 7, 8, 9 2324 24 1-7/8 8, 9, 10 2326 28 1-7/8 8, 9 2328 28 2 9 2330 28 2 9, 10 2332 28 2-1/4 10 2434 28 2-1/4 10, 11 2436 28 2-1/2 11, 12 2438 28 2-1/4 10, 11 2440 32 2-1/4 10 2442 28 2-1/2 11, 12 2444 32 2-1/2 11 2446 32 2-1/2 11, 12 2448 32 2-3/4 12 2550 28 3 13, 14 2552 32 3 13 2554 32 3 13, 14 2556 32 3-1/4 14, 15 2658 32 3-1/4 14, 15 2660 28 3-1/2 15 26

Class 600No of Bolts

Page 2 of 4

Copyright Boltight Ltd July 2005

BOLTIGHT is theUK RegisteredTrade Mark of

Boltight Limited

BOLTIGHT LIMITED, Unit 2 Junction 10 Business Park, Bentley Mill Way, Walsall,West Midlands, WS2 0LE, UK Tel: +44 (0) 870 77 44 661 Fax: +44 (0) 870 77 44 662Email: [email protected] Web: www.boltight.com

DATASHEETDS 21

Tool Selection Tables MSS SP44 Welding Neck Flanges

Pipe Size Bolt Dia 1000 bar 1500 barinch inch Tool Nos Tool No12 20 1-3/8 4, 5, 6 2214 20 1-1/2 5, 6, 7 2216 20 1-5/8 6, 7, 8 2318 20 1-7/8 8, 9 2320 20 2 9, 10 2324 20 2-1/2 11, 12 2426 20 2-3/4 12, 13 2528 20 3 13, 14 2530 20 3 13, 14, 15 2532 20 3-1/4 14, 15 2634 20 3-1/2 15 2636 20 3-1/2 15 2638 20 3-1/2 15 2640 24 3-1/2 15 2642 24 3-1/2 15 26

Class 900No of Bolts

Page 3 of 4

Copyright Boltight Ltd July 2005

BOLTIGHT is theUK RegisteredTrade Mark of

Boltight Limited

BOLTIGHT LIMITED, Unit 2 Junction 10 Business Park, Bentley Mill Way, Walsall,West Midlands, WS2 0LE, UK Tel: +44 (0) 870 77 44 661 Fax: +44 (0) 870 77 44 662Email: [email protected] Web: www.boltight.com

DATASHEETDS 21

Tool Selection Tables

API 605 Welding Neck Flanges

Pipe Size Bolt Dia 1000 bar 1500 barinch inch Tool Nos Tool No36 40 3/4 1 2142 48 3/4 1 2148 44 7/8 1 2154 48 7/8 1 2160 44 1 use 1500 bar 21

Class 75No of Bolts

Pipe Size Bolt Dia 1000 bar 1500 barinch inch Tool Nos Tool No26 36 3/4 1 2128 40 3/4 1 2130 44 3/4 1 2132 48 3/4 1 2134 40 7/8 1, 2 2136 44 7/8 1, 2 2142 48 1 2 2154 56 1-1/8 2, 3, 4 2160 52 1-1/4 3, 4, 5 22

Class 150No of Bolts

Pipe Size Bolt Dia 1000 bar 1500 barinch inch Tool Nos Tool No26 32 1-1/4 3, 4, 5 2228 36 1-1/4 3, 4 2230 36 1-3/8 4, 5, 6 2232 32 1-1/2 5, 6, 7 2234 36 1-1/2 5, 6, 7 2236 32 1-5/8 6, 7, 8 2342 36 1-3/4 7, 8, 9 2348 40 1-7/8 8, 9, 10 2354 48 1-7/8 8, 9 2360 40 2-1/4 10, 11, 12 24

Class 300No of Bolts

Page 4 of 4

Copyright Boltight Ltd July 2005