Hybrid Time-Cost Optimization of Nonserial Repetitive

description

Transcript of Hybrid Time-Cost Optimization of Nonserial Repetitive

Dow

nloa

ded

from

asc

elib

rary

.org

by

Coi

mba

tore

Ins

titut

e of

Tec

hnol

ogy

on 1

2/10

/14.

Cop

yrig

ht A

SCE

. For

per

sona

l use

onl

y; a

ll ri

ghts

res

erve

d.

Hybrid Time-Cost Optimization of Nonserial RepetitiveConstruction Projects

A. Samer Ezeldin1 and Ahmed Soliman2

Abstract: Time-cost trade-off analysis represents a challenging task because the activity duration and cost have uncertainty associatedwith them, which should be considered when performing schedule optimization. This study proposes a hybrid technique that combinesgenetic algorithms �GAs� with dynamic programming to solve construction projects time-cost trade-off problems under uncertainty. Thetechnique is formulated to apply to project schedules with repetitive nonserial subprojects that are common in the construction industrysuch as multiunit housing projects and retail network development projects. A generalized mathematical model is derived to account forfactors affecting cost and duration relationships at both the activity and project levels. First, a genetic algorithm is utilized to find optimumand near optimum solutions from the complicated hyperplane formed by the coding system. Then, a dynamic programming procedure isutilized to search the vicinity of each of the near optima found by the GA, and converges on the global optima. The entire optimizationprocess is conducted using a custom developed computer code. The validation and implementation of the proposed techniques is doneover three axes. Mathematical correctness is validated through function optimization of test functions with known optima. Applicabilityto scheduling problems is validated through optimization of a 14 activity miniproject found in the literature for results comparison. Finallyimplementation to a case study is done over a gas station development program to produce optimum schedules and correspondingtrade-off curves. Results show that genetic algorithms can be integrated with dynamic programming techniques to provide an effectivemeans of solving for optimal project schedules in an enhanced realistic approach.

DOI: 10.1061/�ASCE�0733-9364�2009�135:1�42�

CE Database subject headings: Hybrid methods; Optimization; Construction management; Uncertainty principles.

Introduction

The time-cost trade-off optimization of construction projects is acornerstone in construction scheduling and planning efforts be-cause it aims at finding the minimum cost to finish the project ontime. Time-cost trade-off problems attempt to strike a balancebetween resource allocation costs and project schedule duration.

There is a need to construct models and algorithms for generalconstruction project scheduling optimization. These modelsshould be able to account for real-world uncertainties, as well ascorrelation between cost and duration of numerous schedulingoptions available. In general, the required models should accountfor the stochastic nature of the scheduling problem, and be appli-cable to actual size problems.

Construction schedule trade-off problems have been tackledrepeatedly in the literature using different methods. Heuristicmethods, although widely used for their simplicity and generalability to produce good results, are problem dependent with vary-ing effectiveness on different cases. In addition, despite the good

1Professor, Dept. of Construction Engineering, American Univ. inCairo, 113 Kasr El Aini St., P.O. Box 2511, Cairo 11511, Egypt �corre-sponding author�. E-mail: [email protected]

2Graduate Student, Dept. of Construction Engineering, AmericanUniv. in Cairo, 113 Kasr El Aini St., P.O. Box 2511, Cairo 11511, Egypt.

Note. Discussion open until June 1, 2009. Separate discussions mustbe submitted for individual papers. The manuscript for this paper wassubmitted for review and possible publication on February 16, 2006;approved on July 29, 2008. This paper is part of the Journal of Con-struction Engineering and Management, Vol. 135, No. 1, January 1,

2009. ©ASCE, ISSN 0733-9364/2009/1-42–55/$25.00.42 / JOURNAL OF CONSTRUCTION ENGINEERING AND MANAGEMENT ©

J. Constr. Eng. Manage.

solutions they provide, they do not guarantee optimality. Analyti-cal techniques utilize mathematical models such as linear or dy-namic programming to solve for optimum project schedules.These techniques, although guaranteed to find local optima, aredifficult to generalize, and when used alone require great compu-tational effort. Additionally, their computational difficulty ex-plodes as the problem complexity grows, making them onlysuitable for small projects. As such, there is a need to constructmodels and algorithms for general construction project schedulingoptimization.

This study is concerned with the development of a mathemati-cal model and a solution procedure to perform time-cost trade-offoptimization on nonserial repetitive projects. Nonserial repetitiveprojects are those that consist of several subprojects of similarcomponents and activities, but whose starting and finishing datesare largely independent of each other. The model proposes a hy-brid technique that combines genetic algorithms �GAs� with dy-namic programming �DP� to solve construction project time-costtrade-off problems under uncertainty. A generalized mathematicalmodel is derived to account for factors affecting cost and durationrelationships at both the activity and the project levels. First, aGA is utilized to find optimum and near optimum solutions fromthe complicated hyperplane formed by the coding system. Then, aDP procedure is utilized to search the vicinity of each of the nearoptima found by the GA, and converges on the global optima.The entire optimization process is conducted using a custom de-veloped computer code that extracts project data from MSProject. The study also provides the validation and implementa-tion of the proposed mathematical model. The followed method-

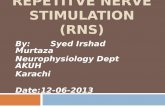

ology in this study is summarized in Fig. 1.ASCE / JANUARY 2009

2009.135:42-55.

Dow

nloa

ded

from

asc

elib

rary

.org

by

Coi

mba

tore

Ins

titut

e of

Tec

hnol

ogy

on 1

2/10

/14.

Cop

yrig

ht A

SCE

. For

per

sona

l use

onl

y; a

ll ri

ghts

res

erve

d.

Literature Review

Uncertainties should be considered when minimizing project costand duration, which leads to the so-called stochastic time-costtrade-off problem �Feng and Liu 2000�. One way to optimizetime-cost trade-off combinations for all activities is to use linearprogramming �LP�. The basic assumption of linear cost-durationrelationships, based on the normal and crashed points only, ren-ders the obtained solutions only usable as approximate startingpoints rather than actual optima �Callahan et al. 1992�.

Dynamic programming is the process of making a sequence ofinterrelated decisions. The procedure starts with a small portion ofthe original problem and finds the optimal solution for thissmaller problem. It then enlarges the problem finding the currentoptimal solution from the preceding one until the original prob-lem is solved entirely. Dynamic programming problems are eitherdeterministic or probabilistic �Betrsekas 1987; Senouci 1996; ElRayes and Moselhi 2001; Adeli and Karim 1999, Karim andAdeli 1999�.

There are a number of characteristics to dynamic program-ming that limit its applicability to complicated multivariableproblems. Among the most hindering factors is the number of

ReviewCurrent

Techniques

Develop GAFormulation

Develop DPformulation

Processhistorical data Derive resource

capacity factors

Derive financingfactor

Derive revenuefactor

Derive certaintyfactor

Derive localityfactor

Factorsarecasestudyspecific

Develop dataflow diagrams

Develop codein VB.Net

Validation &Implementation

MathematicalSoundness

SchedulingApplicability

Establish Casestudy controls

Three case studyruns &

evaluation

Fig. 1. Methodology diagram

functional constraints. Current dynamic programming techniques

JOURNAL OF CONSTRUCTION

J. Constr. Eng. Manage.

work with problems with one or two functional constraints. Thisvery feature, however, is what makes dynamic programming agood candidate for coupling with solution procedures that addressa problem globally, and generally reach near optimum solutions,especially in multimodal problems. In this coupling, dynamic pro-gramming is employed to search the vicinity of near optimumsolutions reached by other procedures, such as GAs, and convergeon the global optimum solution �Goldberg 1989; Lieberman andHillier 1992�.

GA has shown repeated success in attacking large size prob-lems with great complexity �Holland 2000�. They are used inconstruction scheduling optimization because they do not experi-ence combinatorial explosion and they do not rely on heuristicrules, which renders them robust in tackling such problems �Que2002�. Hegazy �2001� presented a model for scheduling and costoptimization of repetitive projects with the objective to minimizetotal construction cost comprised of direct, indirect, interruptions,incentives, and liquidated damages cost. Lue and Hwang �2001�presented a genetic algorithm based searching technique to estab-lish an optimal resource-constrained repetitive precast units’ pro-duction scheduling system with resource sharing. Weng-Tat andChua �1996� presented a GA based approach for construction re-source scheduling using genetic algorithms that do not depend onany set of heuristic rules, but rather on the selection and recom-bination operators of evolutionary algorithms to learn the domainof the specific project network.

Que �2002� introduced a hybrid approach to make GAs basedon time-cost optimization tractable for real world problems viaintegrating a GA code with Primavera. The approach utilizes ac-tivity duration-cost utility curves, and only those activities thatcan be crashed as defined by their utility data take part in theoptimization process.

Model Development and Formulation

Data Collection

Project Construction DataThe origins of data used in the problem formulation are the actualproject schedules of a retail development program undertaken byan international oil company in Egypt over the period from De-cember 2000 to June 2002. The program consists of developingnine retail outlets constituting gas stations with a chain of modernconvenience stores. At each of the nine sites, a subproject is con-structed as part of the overall development program. Each sub-project consists of the store construction and furnishing as well asfueling and services area construction and equipment installa-tions. Activities pertaining to each of the nine subprojects arealmost identical in description, as the components of all projectsare the same, thus constituting repetitive nonserial projects. Thescope and difficulty of each activity, however, is governed by thelocation of the site. Scope and difficulty are also functions ofbuilding construction type. The actual subproject schedule con-tains 100 activities covering all the different detailed steps of eachof the subprojects, rendering the collective program consisting ofclose to 900 activities. In subsequent treatments of the projectschedules, the 100 activities of a subproject’s are reduced to thosemajor activity groups that constitute the backbone of the sub-project schedule. Backbone activities are found to be 20 activities

constituting those activities under which all other detailed activi-ENGINEERING AND MANAGEMENT © ASCE / JANUARY 2009 / 43

2009.135:42-55.

Dow

nloa

ded

from

asc

elib

rary

.org

by

Coi

mba

tore

Ins

titut

e of

Tec

hnol

ogy

on 1

2/10

/14.

Cop

yrig

ht A

SCE

. For

per

sona

l use

onl

y; a

ll ri

ghts

res

erve

d.

ties can be categorized. Table 1 is a list of the 20 activity groupswith the actual duration of each activity for each of the sub-projects.

Three groups of constraints were enforced. Temporal con-straints are those related to the starting date and finishing date ofthe entire nine sites development program. The project is set tostart on December 3, 2000, and be completed with all nine sitesstreamed and operational on June 30, 2002, constituting18 months project duration. Resource constraints stem from bothcontractual terms and resource scarcity. Project resources cameunder three categories: project engineers, general contractors, andspecialty subcontractors. Table 2 includes a list of the resourcesavailable to the developer and the associated capacity of eachresource. Logical constraints are derived from the nature and typeof activities comprising each of the subprojects. Since subprojectsare identical in their activity groups, logical constraints are thesame for all nine subprojects. Table 3 illustrates the logical con-straints imposed on the precedence relationship between each ofthe subprojects activity groups. Of the three types of constraintsimposed on the program, the first two are categorized as softconstraints. Those constraints can be violated but with a conse-quential penalty function. The form and value of the penalty func-tion is also derived from the historical project resource data.Logical constraints are hard constraints that cannot be violatedwithout rendering the resulting schedule undoable and practicallyimpossible.

Project Cost DataCost data are segregated and subcategorized under each activitygroup undertaken by each contractor. By taking the cost of eachactivity incurred over the nine subprojects, the activity cost-duration curves are plotted against the time. The detailed cost-duration data and the resulting correlation curves derived for eachactivity are included in Soliman �2003�. These equations are thenused in the final formulation of the fitness �objective� function forthe program optimization model.

Project Resource DataProject resource data are obtained from the contractor assessmentforms made available by the developer. The data obtained fromthese assessments detail relevant resource attributes such as howmany sites the contractor can be engaged in simultaneously, costcorrection factors for the contractor rates when undertaking jobsinside city skirts, and a quality rating for the contractor. Fromthese usage data, the following information is calculated for eachcontractor over each activity in each of the nine subprojects:1. Percent utilization of contractor daily capacity over the ac-

tivity duration �X1�;2. Average contractor daily man-hour output over the activity

duration �X2�;3. Average activity daily man-hour demand by the contractor

�X3�;4. Activity daily man-hour demand as percent of contractor’s

daily man-hour output over the activity duration �X4�; and

44 / JOURNAL OF CONSTRUCTION ENGINEERING AND MANAGEMENT ©

J. Constr. Eng. Manage.

5. Activity daily man-hour demand as percent of the contrac-tor’s daily man-hour capacity �X5�.

From the above information, multiple linear regressions are usedto correlate the activity duration �Y� to the contractor utilizationfactors �X1–X5�. The correlation formula sought is to take thefollowing form:

Y = m1X1 + m2X2 + m3X3 + m4X4 + m5X5 + b �1�

where m1–m5=slope of the linear relation between each of theindividual capacity utilization factors with the overall activitycompletion duration.

Project CalendarTo accurately reflect actual contractual terms used by the devel-oper, project calendars are constructed using the weekly workingdays with daily working hours.

General Problem Formulation

Objective FunctionThe objective is to minimize the overall project cost versus thescheduled duration and logical relationships. There are nine costfactors to be considered as follows:1. Activity duration for each project summed up over the whole

nine subprojects. Cost is calculated from the cost-durationcurves;

2. General contractor capacity factor used as a multiplier of thecost values of activities undertaken by general contractors;

3. Electrical contractor capacity factor used as a multiplierof the cost values of activities undertaken by electricalcontractors;

4. Mechanical contractor capacity factor used as a multiplierof the cost values of activities undertaken by mechanicalcontractors;

5. Operation-transportation �OTR� equipment installation con-tractor capacity factor used as a multiplier of the cost valuesof activities undertaken by OTR installation contractors;

6. Image equipment installation contractor capacity factor usedas a multiplier of the cost values of activities undertaken byimage installation contractors;

7. Project scope certainty factor, derived from the ratio betweensubproject additional works to original contract value. Moreadditional works are an indication to a less certain workscope. This reflects on the overall subproject cost as addi-tional works are not well negotiated as the original contractprices, and hence the effects of this cost factor;

8. Lost revenues cost due to delays, calculated as the product ofdays delayed beyond planned �original� project end date andits estimated daily revenues; and

9. Cost of imported equipment financing when stored at thedeveloper’s warehouse waiting to be installed.

To account for the above factors, a general form of the objectivefunction is proposed based on the factored cost-duration functions

used by Hegazy �1999� in the following form:Cost = �Pji=1

m=9 �Y1j+ Y2j

+ �Acti=1

n=20 � f�Cost,Duration � FProjScpCert� � FSiteLoclty � �FGenContCapac

FElecContCap1

FMechContCap1

FOTR�Cont1

FImgCont1

�i

�� �2�

ASCE / JANUARY 2009

2009.135:42-55.

n

P7Hegaz

P8Nour

P9Dokki

187 47 119

118 118 118

2 4 2

13 5 10

5 6 2

7 10 5

3 13 4

9 24 9

65 39 38

34 13 15

27 27 32

28 38 26

14 28 36

22 38 36

5 7 5

24 10 19

39 15 15

36 35 40

19 18 9

11 23 12

Mar. 2, 2002 Nov. 20, 2001 June 15, 2002

JOU

RN

AL

OF

CO

NS

TR

UC

TIO

NE

NG

INE

ER

ING

AN

DM

AN

AG

EM

EN

T©

AS

CE

/JAN

UA

RY

2009/45

Dow

nloa

ded

from

asc

elib

rary

.org

by

Coi

mba

tore

Ins

titut

e of

Tec

hnol

ogy

on 1

2/10

/14.

Cop

yrig

ht A

SCE

. For

per

sona

l use

onl

y; a

ll ri

ghts

res

erve

d.

Table 1. Listing of 20 Backbone Subproject Activities

Activitynumber

Activityname

Program subprojects and corresponding activity duratio

P1October 6

P2Fardous

P3Sphinx

P4Bakri

P5Roxi

P6New Maadi

0 Engineering & license 65 66 134 87 117 108

1 Equipment purchasing 147 147 147 147 147 147

2 Clearing old equipment 2 2 2 2 2 2

3 Clearing old building 4 4 6 10 12 5

4 Clear old tanks 3 3 3 4 3 3

5 Clear old paving 3 3 6 13 5 3

6 U/G tanks 3 3 3 8 4 3

7 UPP piping 14 14 9 16 11 14

8 Build structure 32 30 25 52 69 34

9 Canopy structure 29 23 11 10 22 17

10 Electrical network 30 32 8 18 29 34

11 Build subfinish 10 9 15 22 28 28

12 Build finish 30 31 38 42 17 46

13 Yard paving & facility 47 29 29 11 31 41

14 Network termination 9 5 40 7 5 7

15 Canopy finish 7 6 7 19 20 18

16 Signage & image 17 25 26 11 23 18

17 OTR equipm. install 36 18 32 58 36 46

18 Pumps install 6 8 15 22 22 22

19 Site streaming 6 12 17 16 8 10

Project start date Mar. 10, 2001 June 24, 2001 Mar. 18, 2001 June 6, 2001 Sept. 6, 2001 Oct. 10, 2001

J. Constr. Eng. Manage. 2009.135:42-55.

T C M M

46 / JOURNAL OF CONSTRUCTION ENGINEERING AND MANAGEMENT ©

J. Constr. Eng. Manage.

Dow

nloa

ded

from

asc

elib

rary

.org

by

Coi

mba

tore

Ins

titut

e of

Tec

hnol

ogy

on 1

2/10

/14.

Cop

yrig

ht A

SCE

. For

per

sona

l use

onl

y; a

ll ri

ghts

res

erve

d.

where Y1 and Y2 correspond to lost revenues and equipment fi-nancing factors, respectively.

Activities cost correction factors are derived as follows:1. Contractor capacity factor: The per-activity correction factor

is calculated from the ratio between optimization activity du-ration and calculated activity duration as follows:

FConCapacityi= �1 −

Ycalculated

Yoptimized + Ycalculated

i

�3�

where i=index of activities undertaken by the contractor inquestion. This derivation is used for all involved contractors;

2. Lost revenues cost factor: This cost correction factor is asso-ciated with the difference between the planned subprojectcompletion duration and actual subproject completion dura-tion for site �i�: Djo=original planned completion date ofsubproject �j�; and Dja=actual completion date of subproject�j� obtained from the optimized scheduling option.

Then we have

FLost Re venues = �j=1

n=9

DailyIncome � �Djo− Dja

� �4�

where the daily income per site is obtained from originalbusiness plan forecasts;

3. Equipment financing factor: To calculate cost of capital forequipment over its idle duration, let rf be the daily rate ofcapital cost at which the equipment purchasing is being fi-nanced, then

FEqupCost = �Pj=1

m=9

rf j� �StrtDateAct � 17 − EndDateAct � 1�

� Forexj � EqupCost �5�

where Forexj =foreign exchange rate at the time the equip-ment is being purchased;

4. Site locality factor: Site locality factor accounts for the effectof the locality of the project site on the total project cost andduration. Available data indicate that site sensitive activitiestake 70% longer to complete inside city skirts than outsidecity skirts; and

5. Project scope certainty factor: This factor relates to the de-gree of accuracy with which project quantities and tasks aredetermined, and it relates to the learning curve of the projectteam.

From the available data, and using multiple linear regression itis derived that

Y = �379.74 − 86.93 C�/10 �6�

where Y =total cost correction factor and the project certaintyfactor is

Fcertainty = �100 + Y�/100 �7�

where C=ranges from 1 to 5, with 1=low certainty and 5=highcertainty.

Formulation of Objective FunctionThe objective function is formulated along two lines: a dynamicprogramming form, and a genetic algorithm fitness function form.these two forms will be combined in a geno-dynamic hybrid�GDH� formulation to reap the power of the two approaches

able2.

Ava

ilabl

eR

esou

rces

and

Ass

ocia

ted

Cap

acity

apac

ityty

pe

Ava

ilabl

ere

sour

ces

Gen

eral

cont

ract

or1

Gen

eral

cont

ract

or2

Gen

eral

cont

ract

or3

Mec

hani

cal

cont

ract

or1

Mec

hani

cal

cont

ract

or2

Mec

hani

cal

cont

ract

or3

Mec

hani

cal

cont

ract

or4

Ele

ctri

cal

cont

ract

or1

Ele

ctri

cal

cont

ract

or2

Imag

eco

ntra

ctor

1

Imag

eco

ntra

ctor

2

OT

Rcr

ew 1

Proj

ect

engi

neer

1

Proj

ect

engi

neer

2

ax.

site

s3

21

11

11

11

11

14

4

ax.

man

-hou

r/da

y33

211

1111

1111

1111

1111

1118

18

combined.

ASCE / JANUARY 2009

2009.135:42-55.

caltor

Imagecrew

1

Imagecrew

2

OTRcrew

1

Projectengineer

1�%�

Projectengineer

2�%�

— — — 30 30

— — — 20 20

— — — — —

— — — — —

— — — — —

— — — — —

X X X 20 20

— — — 10 10

— — — 20 20

— — — 10 10

— — — — —

— — — 20 20

— — — 40 40

— — — 50 50

— — — — —

— — — 10 10

X X — 10 10

— — X 40 40

— — — 20 20

— — — 30 30

JOU

RN

AL

OF

CO

NS

TR

UC

TIO

NE

NG

INE

ER

ING

AN

DM

AN

AG

EM

EN

T©

AS

CE

/JAN

UA

RY

2009/47

Dow

nloa

ded

from

asc

elib

rary

.org

by

Coi

mba

tore

Ins

titut

e of

Tec

hnol

ogy

on 1

2/10

/14.

Cop

yrig

ht A

SCE

. For

per

sona

l use

onl

y; a

ll ri

ghts

res

erve

d.

Table 3. Precedence Relationships and Resource Assignments of 20 Subproject Backbone Activities

ActivityPrecedencerelationship

Resources assignments and precedence

Generalcontractor

1

Generalcontractor

2

Generalcontractor

3

Mechanicalcontractor

1

Mechanicalcontractor

2

Mechanicalcontractor

3

Mechanicalcontractor

4

Electricalcontractor

1

Electricontrac

2

0 Start — — — — — — — — —

1 0-SS — — — — — — — — —

2 0-FS — — — X X X X — —

3 2-FS X X X — — — — — —

4 3-FS X X X X X X X — —

5 4-SS X X X — — — — — —

6 4,2-FS — — — — — — — — X

7 6-FS — — — X X X X — —

8 5-FS X X X — — — — — —

9 6-SS X X X — — — — — —

10 7-SS — — — — — — — X X

11 8-FS X X X X X X X X X

12 11-FS X X X — — — — X X

13 7-FS,10SS X X X — — — — — —

14 10,11,13-FS — — — — — — — X X

15 9,13-FS X X X — — — — — —

16 12,13-FSX — — — — — — — — —

17 12,13-FS — — — — — — — — —

18 13-FS — — — X X X X — —

19 15,16,17,18-FS — — — — — — — — —

J. Constr. Eng. Manage. 2009.135:42-55.

Dow

nloa

ded

from

asc

elib

rary

.org

by

Coi

mba

tore

Ins

titut

e of

Tec

hnol

ogy

on 1

2/10

/14.

Cop

yrig

ht A

SCE

. For

per

sona

l use

onl

y; a

ll ri

ghts

res

erve

d.

GA Fitness Function. GA fitness function formulation is doneby expanding on the formulation logic employed by Que �2002�,by mapping the objective function into a non-negative fitnessform. Mapping is done to render the following fitness formfeatures:1. Fitness form must always yield a positive value of the fitness

parameters;2. Cost to fitness transformation is done as follows:

f�x� = Cmax − g�x� when g�x� � Cmax

f�x� = 0 otherwise �8�

negative values;

48 / JOURNAL OF CONSTRUCTION ENGINEERING AND MANAGEMENT ©

J. Constr. Eng. Manage.

The coefficient Cmax can be: �1� the largest g value observedso far; �2� the largest g value in the current population; �3�the largest of the k generations; or �4� Cmax may vary accord-ing to the population variance; and

3. The fitness form used must exhibit fitness scaling to regulatethe level of competition between population members, allow-ing interim algorithm performance.

To meet the above-mentioned criteria, fitness function formula-tion will follow the following steps:1. Segment the objective function into a form that can be en-

coded in gene form. Starting from the basic form of the prob-lem:

Max fitness = MinFitness − �j=1

9 �Y1j+ Y2j

+ �i=1

20 � f�cos t,durationcorrectedfor certa int y

�i � �F1

F2

F3

F4

F5

��� �9�

which after segregation becomes

�j=1

9

Y1j+ �

j=1

9

Y2j+ �

i=1

20

f�C,D� � F1 + �i=1

20

f�C,D� � F2

+ �i=1

20

f�C,D� � F3 + �i=1

20

f�C,D� � F4 + �i=1

20

f�C,D� � F5

+ �i=1

20

f�C,D� � F6 + �i=1

20

f�C,D� � F7 �10�

with each segment mapping only the portion of the solution spaceyielding positive values of the fitness function. Hence the genecoding will bear the allele value of

gene value = f�C,D� � Fr; f�C,D� � 0

0; f�C,D� � 0� �11�

where the summation is removed since each cost-duration func-tion should be evaluated separately, and set to zero if yielding

2. Nitching will be used to allow diversity in the populationthrough preserving other individual groups �species� that areuseful in probing probable useful realms of the solutionspace. Hence when a fitness parameter is sighted to weighheavily on the dominant fitness value, it will be forced toshare its fitness value with other parameters proportionally toits weight in the fitness value evaluation versus the collectiveshare of all other parameters. The nitching ratio used will bein the form

fs�C,D� =f�C,D� � Fr

�r=17 f�C,D� � Fr

�12�

where fs=derated fitness of the individual parameter and�r�=index identifying the eight cost factors of the objectivefunction developed earlier; and

3. The final form of the GA fitness function will be

fitness Value = ��j=1

9

Daily Revenues � �Dpj − �

i=1

20

Dikj ; Dp

j � �i=1

20

Dikj

0; Dpj � �

i=1

20

Dikj � + �

j=1

9

rf j� �T17k

j − T1kj + D1k

j � � �j=1

9

FX�D17kj − T1k

j + D1kj

31

+ T17kj � +

�i=120 f�C,D� � F1

�r=17 �i=1

20 f�C,D� � Fr

+�i=1

20 f�C,D� � F2

�r=17 �i=1

20 f�C,D� � Fr

+�i=1

20 f�C,D� � F3

�r=17 �i=1

20 f�C,D� � Fr

+�i=1

20 f�C,D� � F4

�r=17 �i=1

20 f�C,D� � Fr

+�i=1

20 f�C,D� � F5

�r=17 �i=1

20 f�C,D� � Fr

+�i=1

20 f�C,D� � F6

�r=17 �i=1

20 f�C,D� � Fr

+�i=1

20 f�C,D� � F7

�r=17 �i=1

20 f�C,D� � Fr

�13�

ASCE / JANUARY 2009

2009.135:42-55.

Dow

nloa

ded

from

asc

elib

rary

.org

by

Coi

mba

tore

Ins

titut

e of

Tec

hnol

ogy

on 1

2/10

/14.

Cop

yrig

ht A

SCE

. For

per

sona

l use

onl

y; a

ll ri

ghts

res

erve

d.

This form is mapped on the chromosomes, with each param-eter separately.

Dynamic Programming Objective Function. Formulation ofthe objective function for dynamic programming optimization isdone following Adeli and Karim �1997�, over the following threesteps:1. Breaking the project into subprojects, resources, and

activities;2. Representing internal precedence relationships. This is done

using the AON notation following El Maghraby’s �1977�which allows for the representation of all four-precedencerelationships available for the project schedule. The repre-sentation of the four precedence relationships is done asfollows:

a. Start-to-Start �SS� lags

Tukj = min�Duk

j ,LSS ;LSS � �SSlag�

Fukj = Duk

j − Tukj

Tvkj = max�LSS − Duk

j ,Dvkj − Fvk

j

b. Finish-to-finish �FF�

Fvkj = max�0,min�Dvk

j ,LSS + Dvkj − Duk

j �

lags

Tukj = min�0,LFF − Dvk

j + Dukj ;LFF � �FFlag�

Fvkj = Duk

j − Tukj ;Tvk

j = Dvkj − Fvk

j

Fvkj = min�LFF − max�0,LFF − Dvk

j �

c. Start-to-finish lags

Tukj = min�Duk

j ,LSF − Dvkj ;LSF � �SFlag�

Fukj = Duk

j − Tukj

Fvkj = min�Dvk

j ,max�0,LSF − Dukj

Tvkj = max�Dvk

j − Fvkj ,LSF − Fvk

j − Dukj

d. Finish-to-start lags

Tvkj = max�Duk

j − Fvkj ,LSF − Fvk

j − Dukj

Dukj = Duk

j ;Tvkj = Dvk

j

Dv�kj = LSF;LFS � �FSlag�

3. Starting from the general problem formulation presentedabove, the following dynamic programming problem specificformulation is formulated:

minimize Costj = �Pj=1

m=9 �j=1

m=9

Daily Project Revenue

� �Dpj − �

i=1

20

Dikj + �

j=1

m=9

rf j

� �Tj − Tj + D1kj�

17k 1kJOURNAL OF CONSTRUCTION

J. Constr. Eng. Manage.

� �j=1

9

FX�D17kj − T1k

j + D1kj

31 + T17k

j �+ �

Ni=1j

20

f�Tikj + Dik

j �

� �n=1

k=18 1 −Dik�calculated

j

Dik�optimizedj �� �14�

subject to the following set of constraints:

1. Total project duration constraints where the summation ofthe duration of the critical path for all subprojects i shouldnot exceed the maximum duration of the planned develop-ment program set by the business plan at the outset of theprogram. This constraint is formulated as follows

�j=1

9 �Tikj + �

i

20

Dikj � Dmax �15�

2. The activity duration should fall between the minimum andmaximum duration permissible by the business plan. Thisconstraint is formulated as follows:

�Dij�min � Di

j � �Dij�max �16�

Resource capacity constraints associated with situationswhere the resource capacity is exceeded by the utilizationnecessary to undertake tasks assigned to it by any of theoptimization scheduling options. This constraint is formu-lated as follows:

�j=1

9

�i=1

20

�Dikj � contractor Daily Output�

� Contractor Daily Capacity � �i=1

20

Dikj �17�

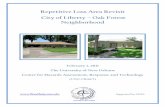

Scheduling Data StructuresCoding of schedules on strings is done using a two-dimensional�2D� array with each column in the array containing the attributesof each activity. Array width is that of the maximum number ofactivities, which are 180 activities in the case study program. Fig.2 illustrates the general chromosome representation followed inschedules data coding. For the coding process to start, the userenters the number of subprojects and the number of tasks persubproject, into the interface form in Fig. 3. The computer pro-gram then reads activity data from the interface output file ex-tracted from MS Project, and fills in data fields of activitynumber, and activity logical relationships.

To ensure that all activity durations over the entire optimiza-tion process fall into the data range over which cost-durationcurves are applicable, a random number generation routine gen-erates activity durations randomly for each activity. Random ac-tivity durations are generated from the range of minimum andmaximum durations found for each activity over all nine sub-projects of the program.

Solution Algorithms

GA Optimization Algorithm. The genetic algorithm proceeds

as follows:ENGINEERING AND MANAGEMENT © ASCE / JANUARY 2009 / 49

2009.135:42-55.

Dow

nloa

ded

from

asc

elib

rary

.org

by

Coi

mba

tore

Ins

titut

e of

Tec

hnol

ogy

on 1

2/10

/14.

Cop

yrig

ht A

SCE

. For

per

sona

l use

onl

y; a

ll ri

ghts

res

erve

d.

1. GA operating parameters are selected and fixed. Those pa-rameters are population size, crossover probability �rate�,mutation probability, maximum number of generations, andminimum fitness function enhancement gradient. The lasttwo parameters are the stopping criteria of the procedure;

2. Using the schedule chromosome-coding array, an initial ran-dom population of solutions is generated. This initial popu-lation has a number of chromosomes equal to the populationsize entered by the user in the interface form. Each chromo-some in the population represents a scheduling option for theentire program over all nine subprojects, generated by ran-domly filling activity durations and subproject starting dates.The scheduling routine then calculates early and late dates,and fills in the remaining scheduling information for eachchromosome. Fig. 4 illustrates an example of two chromo-somes in the initial population, highlighting the randomlygenerated components. It should be noted that randomly gen-erated components are only generated when constructing theinitial population;

3. Based on initial population scheduling data, cost and dura-tion correction factors are evaluated and initial populationfitness values is calculated for each of the separate compo-nents of the GA fitness function formulated earlier. Fitnessstatistics including maximum fitness, average, and minimumfitness, along with operators transition and convergenceprobabilities are reported. No optimization is started up untilthis stage, since it is intended only for setting up and initial-izing a solution space. Optimization starts when the userclicks on the “Start GA” button, present on the interface formof Fig. 3;

4. When optimization starts the only parameters that undergomanipulation and reshuffling using evolutionary operatorsare activity durations previously generated;

5. Based on calculated initial population fitness, the first gen-eration starts with the biased roulette wheel selection opera-tor to generate a mating pool for crossover and mutation;

Sub-Project - 1

Activity # P11 P21 Pm1

ActivityDuration

D11 D21 Dm1

Predecessor

Logic

Lag

ES P1 start date

EF

LS

LF

Slack 0

Fig. 2. General form of sch

6. Crossover applies to the population followed by mutation

50 / JOURNAL OF CONSTRUCTION ENGINEERING AND MANAGEMENT ©

J. Constr. Eng. Manage.

prior to any cancellation of any of the parents from the mat-ing pool;

7. New individuals resulting from crossover and mutation havenew subproject activity durations and starting dates. There-fore, the scheduling routine is applied to calculate new activ-ity dates and resulting subprojects and hence entire programduration. Fitness values are reevaluated for the members ofthe mating pool �new schedules on chromosomes� and high-

Fig. 3. User interface form for GDH algorithm

Sub-Project – 2 … n

-n P22-n Pm2-n

2-n D22-n Dm2-n

-n start date

Programfinish dates

0

g data chromosome coding

P12

D1

P2

edulin

ASCE / JANUARY 2009

2009.135:42-55.

Dow

nloa

ded

from

asc

elib

rary

.org

by

Coi

mba

tore

Ins

titut

e of

Tec

hnol

ogy

on 1

2/10

/14.

Cop

yrig

ht A

SCE

. For

per

sona

l use

onl

y; a

ll ri

ghts

res

erve

d.

est fitness children forming a new generation of populationwill replace lowest fitness parents. New population fitnessstatistics are calculated and reported and a new generationwill proceed; and

8. This is repeated until one of the stopping criteria is met.Either generation number equals maximum generation set atthe outset of the algorithm parameter setting, or the percent-age change in new generation average fitness from old gen-eration average fitness is within the minimum change offitness value. A convergence curve is plotted live as thepopulation converges to monitor its GA behavior. In addi-tion, a timer clock is running over the entire optimization runto calculate the amount of time that it takes the GDH toconverge on the optimum or near optimum solution.

Dynamic Programming Algorithm. A conditional dynamicprogramming network optimization procedure is employed overthe top 5% of the GA generated solution population. The proce-dure proceeds as follows:1. A review by the user is done over the results of the GA

population;2. The user elects to either run the DP while fixing the cost

variable and search for the minimum project duration, or fixthe project duration and search for the minimum cost corre-sponding to this duration. This is done through a single pointentry selection;

3. By fixing one parameter �decision variable�, optimizationover two decision variables is transformed to two searches inone dimension solution space;

Sub-Project - 1Activity # P11 P21 PmActivityDuration 120 50 …

Predecessor

Logic

Lag

1 FS 0 2 SS

ES Dec.12th2000 Mar. 14th 01 Jun. 1EF Mar. 13th 01 May. 30th 01 …LS Dec.12th2000 Mar. 17th 01 …LF Mar. 13th 01 Jun. 3rd 01 …Slack 0 3 …

Sub-Project - 1Activity # P11 P21 PmActivityDuration 119 52 …

Predecessor

Logic

Lag

1 FS 0 2

ES Jan. 5th 2001 Apr. 12th 01 Jun. 15EF Apr. 11th 01 Jun. 14th 01 …LS Jan. 5th 2001 Apr. 19th 01 …LF Apr. 11th 01 Jun. 21st 01 …Slack 0 7 …

Fig. 4. General form of sch

4. A precedence matrix is generated for each of the top tear

JOURNAL OF CONSTRUCTION

J. Constr. Eng. Manage.

solutions �El Maghraby 1977�. This matrix is used to identifythe set of activities common to all paths of the project activ-ity network;

5. Let “c” denote the fixed decision variable. “c” can either becost or duration;

6. The dynamic programming algorithm will proceed in theform

f�c� = minXc�c

�max�gi�Xi�;gi�c − Xi� � �18�

where XIc=value of the decision variable that yields the mini-

mum in the above equation; and7. Then proceeding along the path of common activity set,

starting from the last activity to the first activity, the costfunction derived earlier will be calculated for each segment,and the path satisfying the following criteria will beregistered:

min�gN�XN�;gN−1�XN−1�� �19�

Hybrid Algorithm. The GDH algorithm is a straightforwardsuperposition of both the GA algorithm followed by the DP algo-rithm. It should be noted that the user would see the results ofboth the GA and the DP procedures while working within theframework of the GA-hybrid procedure. The hybrid procedureproceeds as follows:1. GA parameters are set by the user based on the test run

results for best suitable parameter values;

Sub-Project – 2 … nP12-n P22-n Pm2-n

123 48 …

1 FS 0 2 SS 2

Mar.1st 2001 Jun. 3rd 01 Jul. 23rd 01Jun. 2nd 01 Jul. 22nd 01 ….Mar. 1st 2001 Jun. 8th 01 ….Jun. 2nd 01 Jul. 14th 01 ….

0 5 ….

CHROMOSOME1

Sub-Project – 2 … nP12-n P22-n Pm2-n

121 49 …

1 FS 0 2 SS 2

Feb. 5th 2001 Jun. 8th 01 Jul. 27th 01Jun. 7th 01 Jul. 26th 01 ….Feb. 5th 2001 Jun. 12th 01 ….Jun. 7th 01 Jul. 30th 01 ….

0 4 ….

CHROMOSOME2

g data chromosome coding

1

.

2

st 01....

1

SS 2th 01....

edulin

2. GA algorithm is run to its terminal criteria;

ENGINEERING AND MANAGEMENT © ASCE / JANUARY 2009 / 51

2009.135:42-55.

Dow

nloa

ded

from

asc

elib

rary

.org

by

Coi

mba

tore

Ins

titut

e of

Tec

hnol

ogy

on 1

2/10

/14.

Cop

yrig

ht A

SCE

. For

per

sona

l use

onl

y; a

ll ri

ghts

res

erve

d.

3. The top 5% solutions generated by the GA procedure arereviewed by the user and decision variable fixing options areselected;

4. The DP procedure is applied to the top tear solution optionsgenerated by the GA solution; and

5. The final output is a single scheduling option representingthe global optimum satisfying a limiting criterion for eithercost or duration.

The computer implementation of the GDH algorithm constructionschedule optimization algorithms is done over three modules,namely; the data interface module, the main optimization program�MOP�, and the output reporting module �ORM�, used to reporton the progress and parametric performance results of the GAhybrid. Soliman �2003� illustrates the data flow diagrams of theentire computer implementation system including all three mod-ules as well as the listing of the computer code for the GA com-puter implementation system.

Validation

Validation of the proposed techniques is done over three axes.First, the mathematical correctness is validated through functionoptimization of two test functions with known optima. The hybridtechnique is used to locate the optima of a two peak trap functionreported by Li et al. �2002�. The technique is used on the 2DShubert function as reported by Li et al. �2002�. In both cases, theGDH consistently found all global optima. More details on themathematical soundness are found in Soliman �2003�.

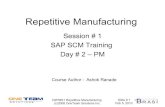

Second, a 5-km-long, two lane highway construction project is

MiniPro

80

90

100

110

120

130

140

40 50 60 70

Cos

t(10

00$)

(74, 121

Fig. 5. Miniproject

used to illustrate the capabilities of the solution procedure em-

52 / JOURNAL OF CONSTRUCTION ENGINEERING AND MANAGEMENT ©

J. Constr. Eng. Manage.

ployed by the GDH algorithm �Adeli and Karim 1997�. Thisminiproject test problem is used here to compare results obtainedfrom the GDH approach with results reported by others for thesame problem.

The final trade-off curve is illustrated in Fig. 5. The resultsindicate that a minimum total project cost of $121,975 corre-sponds to a total project duration of 74 days. These results are ingood agreement with Adeli and Karim �1997� which are $122,414project cost over a 70 day project duration.

Implementation on Case Study Project Optimization

To illustrate the applicability of the proposed algorithm to real-life projects, the implementation of the GDH algorithm is con-ducted for the gas station development program. The data used inthe case study are the actual project schedules of a retail devel-opment program undertaken by an international oil company inEgypt over the period from December 2000 to June 2002 as pre-sented earlier. The case study is mainly a development programconsisting of nine retail outlets �subprojects�. The original pro-gram duration is 24 months. The construction of the nine sub-projects consists of identical activity classes with varying site andresource conditions. Each subproject is made of 20 backboneactivities.

The case study project optimization is performed over threeruns using GDH algorithm. On all three runs, the GDH algorithmis able to converge on a number of optimum and near optimumschedules that result in overall case study project duration reduc-

deOff

80 90 100 110

n (d)

ost trade-off curve

ject Tra

Duratio

.9)

time-c

tion and associated minimum cost. On average, the GDH is able

ASCE / JANUARY 2009

2009.135:42-55.

T P P P P P P P P P P P P

Dow

nloa

ded

from

asc

elib

rary

.org

by

Coi

mba

tore

Ins

titut

e of

Tec

hnol

ogy

on 1

2/10

/14.

Cop

yrig

ht A

SCE

. For

per

sona

l use

onl

y; a

ll ri

ghts

res

erve

d.

to converge on the optima region in 20 min, with a success rate of100%.

To draw a comparison, a solution for the case study modelproblem is also obtained using MS Excel Solver. To achieve that,the problem along with its parameters and cost correction factors,are structured in tabular formats using MS Excel. Subsequently,four optimization runs are conducted on the spreadsheet modelutilizing the generalized reduced gradient nonlinear optimizationmethod built into MS Excel Solver. Comparisons are drawn be-tween the results obtained from both GDH and MS Excel Solverin the coming subsections.

Case Study Time-Cost Trade-Off Results

Table 4 illustrates the resulting improvements in total project costand duration as a result of three optimization runs. On averagetotal project cost was reduced by 14.4% and total project durationwas also reduced by 21%.

Results obtained from running MS Excel Solver are not aseffective. To begin with, due to the complexity and the number offactors used to direct the solution trajectory, it is not possible toapply the Solver on the problem as a whole because the numberof variable parameters is too large for Solver to operate on. Henceto obtain solutions, each run is conducted under the added as-sumption of fixing the parameters of three projects as they arecalculated from the original schedule and optimizing by changingthose of the remaining six. Only then is the problem size tractableby Solver. This serious limitation reflects that results obtainedfrom all four Solver runs are not consistent and do not constitutea clear trade-off result. It is observed that Solver does not changemost of the activity durations and only concentrates on changinga limited number of them. In addition, many other significantfactors remain the same, which suggests that Solver is not able tosearch for an optimum through all possible solution combinationseven after limiting the search to six out of the nine subprojects.Over the four runs conducted using Solver, one run results in a50% decrease in project duration with a corresponding 17% in-crease in cost. Two runs result in 16% reduction in duration with2% reduction in cost and only one run results in a 21% reductionin project duration and 11% reduction in project cost. The lastresult is the only one that is comparable with those obtained fromapplying the GDH, even though GDH results are quite better.

Consistency of Finding Optimum Solutions

Considering over three optimization runs on the case study sched-ule, the GDH is able to find equally good solutions with similarfitness values. Variation of the top five solution fitness values overthe three runs is always within 5% of the average fitness of thetop five solutions of each run and within 8% of the average of alltop five solutions over the three runs. Fig. 6 is a plot of theaverage fitness of the top five solutions in each run over the threeruns. This result shows that GDH is able to zoom in on the sameoptimum, or near optimum solution region of the solution spaceunder the same application parameters.

Case Study Optimization Convergence Rate

Figs. 7�a–c� illustrate the convergence curve of GDH for all threeoptimization runs conducted on the case study problem. From thefigures, it is evident that the convergence rate is determined pri-marily by the schema length, crossover rate, and mutation rate. In

Fig. 7�a�, for the first run, a mutation rate of 0.0 is used to limitJOURNAL OF CONSTRUCTION

J. Constr. Eng. Manage.

able

4.Su

mm

ary

ofC

ase

Stud

yO

ptim

izat

ion

Run

s

Ori

gina

lsc

hedu

les

Opt

imiz

atio

nR

un�1

Opt

imiz

atio

nR

un�2

Opt

imiz

atio

nR

un�3

roje

ctSt

art

date

Fini

shda

teD

urat

ion

Con

st.

St.d

ate

Con

st.

Fn.d

ate

Con

st.

dura

tion

Cos

tSt

art

date

Fini

shda

teD

urat

ion

Cos

tFi

tnes

sva

lue

Star

tda

teFi

nish

date

Dur

atio

nC

ost

Fitn

ess

valu

eSt

art

date

Fini

shda

teD

urat

ion

Cos

tFi

tnes

sva

lue

1D

ec.

3,20

00Ju

ly7,

2001

244

Mar

.19

,20

01Ju

ly5,

2001

123

2,40

5,14

6D

ec.

15,

2000

Aug

.15

,20

0130

02,

0630

0019

.31

Dec

.17

,20

00Ju

ly27

,20

0127

02,

1000

0017

.62

Dec

.16

,20

00A

ug.

12,

2001

290

2,08

1000

31.3

7

2D

ec.

3,20

00O

ct.

4,20

0134

5Ju

ne24

,20

01O

ct.

4,20

0111

62,

517,

508

Dec

.17

,20

00N

ov.

25,

2001

400

2,07

0000

114.

84D

ec.

19,

2000

Oct

.15

,20

0129

02,

1470

0010

4.83

Dec

.19

,20

00Se

pt.

26,

2001

380

2,17

0000

186.

57

3D

ec.

3,20

00Ju

ly22

,20

0126

1M

ar.

19,

2001

July

22,

2001

141

2,25

3,79

0D

ec.

21,

2000

July

28,

2001

280

2,06

0000

99.5

6D

ec.

22,

2000

July

3,20

0122

01,

7990

0090

.88

Dec

.21

,20

00A

ug.

21,

2001

260

2,02

5000

161.

75

4D

ec.

3,20

00N

ov.

20,

2001

397

June

2,20

01N

ov.

20,

2001

193

2,04

0,41

7D

ec.

16,

2000

Dec

.3,

2001

250

2,08

8000

6.11

Dec

.16

,20

00O

ct.

22,

2001

351

1,96

3000

5.58

Dec

.17

,20

00Ja

n.17

,20

0131

02,

0770

009.

93

5D

ec.

3,20

00Fe

b.11

,20

0249

1Se

pt.

6,20

01Fe

b.10

,20

0217

72,

126,

031

Dec

.20

,20

00M

ar.

8,20

0229

02,

0500

003.

23D

ec.

22,

2001

Dec

.17

,20

0128

01,

7210

002.

95D

ec.

22,

2000

Feb.

6,20

0230

01,

9800

005.

25

6D

ec.

3,20

00M

ar.

13,

2002

525

June

10,

2001

Mar

.13

,20

0217

42,

164,

231

Dec

.19

,20

00Fe

b.16

,20

0227

02,

0400

0086

.29

Dec

.20

,20

01Fe

b.4,

2002

280

2,04

9000

78.7

7D

ec.

21,

2000

Mar

.14

,20

0228

02,

0650

0014

0.19

7D

ec.

3,20

00Ju

ly14

,20

0266

3M

ar.

2,20

02Ju

ly14

,20

0215

22,

343,

909

July

5,20

01Se

pt.

29,

2002

270

2,07

0000

2.67

July

6,20

01Ju

ly1,

2002

320

2,02

5000

2.44

July

5,20

01A

ug.

17,

2002

300

2,08

0000

4.34

8D

ec.

3,20

00A

pr.

30,

2002

579

Nov

.20

,20

01A

pr.

30,

2002

182

2,94

6,83

2Ju

ly10

,20

01M

ay31

,20

0229

02,

0670

007.

08Ju

ly11

,20

01A

pr.

14,

2002

290

2,06

7000

6.46

July

11,

2001

May

28,

2002

290

2,07

7000

11.5

0

9M

ar.

2,20

02N

ov.

13,

2002

289

June

16,

2002

Nov

.13

,20

0216

92,

662,

566

July

8,20

01M

ay8,

2002

290

2,06

5000

7.79

July

9,20

01A

pr.

13,

2002

270

2,07

0000

7.11

July

8,20

01M

ay24

,20

0229

02,

0800

0012

.65

rogr

amdu

ratio

n71

055

954

658

3

rogr

amco

st21

,460

,430

18,5

73,0

0017

,941

,000

18,6

35,0

00

ENGINEERING AND MANAGEMENT © ASCE / JANUARY 2009 / 53

2009.135:42-55.

Dow

nloa

ded

from

asc

elib

rary

.org

by

Coi

mba

tore

Ins

titut

e of

Tec

hnol

ogy

on 1

2/10

/14.

Cop

yrig

ht A

SCE

. For

per

sona

l use

onl

y; a

ll ri

ghts

res

erve

d.

disruptions, a crossover rate of 0.6 and a population size of 200are used. The cardinality of the alphabet used to represent thepopulation strings is ten, which is constant over all runs. Theseparameters correspond to 257 possible transition states and a state

0

100

200

300

400

500

600

0 1 2 3 4

Opt imizat ion Run

0

100

200

300

400

500

600

Solut ion 1Solut ion 2Solut ion 3Solut ion 5Solut ion 4

Fig. 6. Average fitness of top five solutions in case studyoptimization

Fig. 7. �a� Convergence of three optimization runs; �b� convergence

54 / JOURNAL OF CONSTRUCTION ENGINEERING AND MANAGEMENT ©

J. Constr. Eng. Manage.

transition probability of 0.37. This probability to shift the popu-lation from on state to the next out of the 257 possible statesresults in a Robbin’s equilibrium rate of 0.178. This rate is inunits of population that transcend to Robbin’s equilibrium pergeneration. Hence the convergence curve for Fig. 7�a� is flatterthan the others succeeding, indicating a slower rate of conver-gence. This is also translated into a longer time of convergenceabove the average as indicated by the convergence time watch ofthe figure for this run.

Figs. 7�b and c� exhibit steeper convergence curves corre-sponding to higher convergence rates stimulated with increasingmutation rates. This result confirms that as the mutation rate isincreased, the dynamic behavior of the population shifts fromRobbin’s equilibrium to an accelerated steady state correspondingto increased mutation rates. This increased convergence rate is notwithout cost, since an increase in mutation rate for long schemata,as in this case, also corresponds to an increase in disruption rate.This is illustrated in the increase of calculated expected disruptionrates presented in the interface window for those used prior toeach run, as illustrated in Figs. 7�a–c�. A higher disruption prob-

e optimization runs; and �c� convergence of three optimization runs

of threASCE / JANUARY 2009

2009.135:42-55.

Dow

nloa

ded

from

asc

elib

rary

.org

by

Coi

mba

tore

Ins

titut

e of

Tec

hnol

ogy

on 1

2/10

/14.

Cop

yrig

ht A

SCE

. For

per

sona

l use

onl

y; a

ll ri

ghts

res

erve

d.

ability may result in no convergence at all; even after all, possiblestates have been probed at a high rate. This perplexing case isclear in Fig. 7�c�, which shows convergence to lower quality fit-ness even though the time taken for this convergence is shorterthan the average time over all three runs.

The above discussion clearly signifies the importance of testruns to determine most favorable parameters setting to achieveconvergence to high quality fitness at a reasonable time. The in-terface window with precalculated probabilities presents a goodtool for conducting the test runs and it presents the user with allparameters involved in determining the quality of the solutionconvergence, both beforehand and live as the run is conducted.

Conclusions

This study is concerned with applying a hybrid genetic algorithmwith dynamic programming techniques for nonserial repetitiveconstruction project schedule time-cost optimization. The pro-posed technique is aimed at circumventing combinatorial explo-sion and NP-hard characteristics of the stochastic constructionschedules optimization problem. In addition to test problems andminiprojects found in the literature, the merits of the new tech-nique are demonstrated on a real-world case study.

The formulation is based on the sum of the cost-duration rela-tionship for each activity in the nonserial repetitive subproject,which is modified with multiplier factors. Activity cost-durationrelationships are derived from historical project data, and multi-plier factors are relational equations which yield collectivelymodifying fractions to each activity duration-cost value to correctit for construction conditions prevailing at the time of its execu-tion along the entire schedule make span. The resulting general-ized formulation is applicable to all nonserial repetitive projectsfor which cost-duration and correction factors can be derived.

The outcomes of the extensive validation and evaluationscheme undertaken to establish the mathematical soundness of thetechnique and the applicability of the formulation to generalprojects indicate the following:1. The proposed hybrid technique is mathematically sound hav-

ing the necessary robustness to optimize test functions andnonserial repetitive project schedules. This is not attainablehowever until suitable operating parameters are establishedafter conducting several test runs. It can also be concludedthat the geno-dynamic hybrid solution procedure is able tooptimize multimodal problems as it is designed to do whilebeing extremely sensitive to its operating parameters, requir-ing several test runs to come up with those suitable toachieve optimization;

2. The hybrid approach is applied to a small test schedule andto a full scale case study project schedule. On both accountsthe approach performed advantageously. When applied onthe 14 activity miniprojects, the geno-dynamic hybrid is ableto find several scheduling options yielding the same optimumsolution. In addition, the optimum solution obtained iscomparable to that obtained in the literature by a differentprocedure;

3. When applied to the case study project, the optimization re-

JOURNAL OF CONSTRUCTION

J. Constr. Eng. Manage.

sults obtained over three runs were within 5% of each otherat the total project level. The resulting optimum schedules inall three runs reduced overall project cost by and average of14.4% and overall project duration by an average of 21%;and

4. In addition, results are compared to those obtained using MSExcel Solver, which is applied under relaxed special cases ofthe case study problem to render it tractable. The resultsobtained using the GDH outperform those obtained usingSolver in both the value of the optimum and the consistencyof finding it.

References

Adeli, H., and Karim, A. �1997�. “Scheduling/cost optimization and neu-ral dynamics model for construction.” J. Constr. Eng. Manage.,123�4�, 450–458.

Adeli, H., and Karim, A. �1999�. “CONSCOM: An OO constructionscheduling and change management system.” J. Constr. Eng. Man-age., 125�5�, 368–376.

Betrsekas, D. P. �1987�. Dynamic programming: Deterministic & sto-chastic models, Prentice-Hall, Englewood Cliffs, N.J.

Callahan, M. T., Quackenbush, D. G., and Rowing, J. �1992�. Construc-tion projects scheduling, McGraw-Hill, New York.

El Maghraby, S. E. �1977�. Activity networks: Project planning and con-trol by network models, Wiley-Interscience, New York.

El Rayes, K., and Moselhi, O. �2001�. “Optimizing resource utilizationfor repetitive construction project.” J. Constr. Eng. Manage., 127�1�,18–27.

Feng, C.-W., and Liu, L. �2000�. “Stochastic construction time-cost trade-off analysis.” J. Comput. Civ. Eng., 14�2�, 117–126.

Goldberg, D. E. �1989�. Genetic algorithms: In search, optimization, andmachine learning, Addison-Wesley, Reading, Mass.

Hegazy, T. �1999�. “Optimization of resources allocation and levelingusing genetic algorithms.” J. Constr. Eng. Manage., 125�3�, 167–175.

Hegazy, T. �2001�. “Cost optimization in projects with repetitive non-serial activities.” J. Constr. Eng. Manage., 127�3�, 183–191.

Holland, J. H. �2000�. “Building blocks, cohort genetic algorithms, andhyperplane-defined functions.” Evol. Comput., 8�4�, 373–391.

Karim, A., and Adeli, H. �1999�. “OO information model for constructionproject management.” J. Constr. Eng. Manage., 125�5�, 361–367.

Li, J. P., Balazs, M. E., and Paeks, G. T. �2002�. “A species conservinggenetic algorithm for multimodal function optimization.” Evol. Com-put., 10�3�, 207–237.

Lieberman, G., and Hillier, F. �1992�. Introduction to operations re-search, McGraw-Hill, New York.

Lue, S.-S., and Hwang, S.-T. �2001�. “Optimal repetitive model withsharable resource constraint.” J. Constr. Eng. Manage., 127�4�, 270–280.

Que, B. C. �2002�. “Incorporating practicability into genetic algorithms-based time-cost optimization.” J. Constr. Eng. Manage., 128�2�, 139–143.

Senouci, A. B. �1996�. “Dynamic programming approach to schedulingof non-serial linear project.” J. Comput. Civ. Eng., 10�2�, 106–114.

Soliman, A. �2003�. “A geno-dynamic hybrid approach for time cost op-timization of non-serial repetitive construction project.” MS thesisAmerican Univ. in Cairo, Cairo, Egypt.

Weng-Tat, C., and Chua, D. K. �1996�. “Construction resource schedulingwith genetic algorithms.” J. Constr. Eng. Manage., 122�2�, 125–132.

ENGINEERING AND MANAGEMENT © ASCE / JANUARY 2009 / 55

2009.135:42-55.