Hy steel-grating

-

Upload

erin-zhao -

Category

Engineering

-

view

54 -

download

0

Transcript of Hy steel-grating

STEEL [email protected]

0086-535-6501817

www.hygrating.com

HY

Features & Benefits

Steel grating is the workhorse of theindustrial flooring market, findingapplications in conveyor systems,operating plants, highways andbridge platforms and walkways,machinery floors, refineries, tankstairways and walkways, and powerplants. The open grid construction ofsteel grating provides maximumpassage for light, air circulation anddrainage, while offering lowinstallation and maintenance costs.

In addition to fabricating standardelectro forge welded steel grating,Gratings manufactures andfabricates Dove Tail pressure lockedgrating, Riveted Steel grating, andSwaged Carbon and Stainless Steel

grating. Dove Tail pressure locked,Riveted and Swaged grating offersmoother lines and a more pleasingappearance than the typical weldedgrating. While still industrial in nature,these grating types may be moreappropriate than welded grating forsome applications used in a widevariety of application:.

Our gratings are

●Walkways●Access platforms●Balcony balustrades●Stair treads●Plant enclosures●Flooring –anti-slip●Risers●Louvers●Car park screening●Car park ventilation grillage●Drainage covers●Fencing●Staircase mesh infill

STEEL [email protected]

0086-535-6501817

www.hygrating.com

HY

Type of steel grating

Type “WG”-Welded SteelElectroforming a machine processcombining hydraulic pressure and heatfusion, is the most popular and mosteconomical method for manufacturingsteel grating panels. Gratings maintains agenerous inventory of 24˝ and36˝ wide panels in standard bearingbar/cross bar spacing, and in specialspacing, available for next day shipmentor custom fabrication.

STEEL [email protected]

0086-535-6501817

www.hygrating.com

HY

Type “DTG” -Steel Dove TailTraditionally designed, Dove Tail slotpressure locked grating, offers the highstrength and stiffness of welded steelgrating, along with the smooth, cleanlines of a flush top rectangular cross bar.This grating is available in spacingwhich provide a 1/4˝ or 1/2˝ opening inconformance with provisions for thegrating products.

Type “SG” -Swaged Carbon SteelBy taking advantage of the most moderntechnology available, Gratings isable to offer Swaged Carbon Steel gratingsimilar in construction to our aluminum bargrating products. Rectangular bearingbars and tubular cross bars are joinedtogether via the swaging process. Thismanufacturing method offers smoothsurfaces and clean lines, free from thewarping and weld flash inherent in theelectroforming process.

Type “WG”-Welded SteelProduct Specification Guide

Plain surface Serrated surface

Our most economical steel grating products, type "W" Welded Steel Gratingsare manufactured by forge welding rectangular bearing bars and drawn crossbars. This welding process provides a positive fused connection providingyears of service under the most demanding conditions.

STEEL [email protected]

0086-535-6501817

www.hygrating.com

HY

When selecting a bar grating product, consider Welded Steel Grating first.Usually our most economical products, they provide a comfortable walking

surface with nearly 80 percentopen area. This, combinedwith the positive welded crossbar/bearing bar intersection,make these products our mostpopular. Manufactured fromcarbon steel, welded gratingsare recommended for nearlyall industrial flooringapplications.

Product Applications

Steel grating is the workhorse of the industrial flooring market and is used formany different types of pedestrian(walking) applications. The open gridconstruction provides maximum passage for light, air circulation and.

STEEL [email protected]

0086-535-6501817

www.hygrating.com

HY

Electro forging, a machine process combining hydraulic pressure and heatfusion, is readily available and aneconomical method for manufacturingsteel grating panels. The bearing barsurface can be ordered smooth or witha serrated surface for maximum skidresistance.

Type “DTG” -Steel Dove TailProduct Specification Guide

STEEL [email protected]

0086-535-6501817

www.hygrating.com

HY

Type "DT" steel gratings have deep rectangular cross bars and aremanufactured by inserting pre-punched bearing bars and cross bars into an“egg-crate” configuration and deforming the cross bars under intense hydraulicpressure. The deep cross bars on type "DT" gratings make them popular forarchitectural applications such as sun shades and infill panels with the deepercross bar serving as a distinct architectural accent.

Pressure Locked Gratings manufactured with deep rectangular cross bars areidentified as dovetail pressure. These products are assembled bypre-punching both thebearing bars and crossbars, aligning the bars inan egg-crate manner, anddeforming the cross barinto the dovetail slot in thebearing bar under intensehydraulic pressure.

Product Applications

STEEL [email protected]

0086-535-6501817

www.hygrating.com

HY

Traditionally designed, Dove Tail slotpressure locked grating offers the highstrength and stiffness of welded grating,along with the smooth, clean lines of aflush top rectangular cross bar. Bearingbars and cross bars are precision slotted,assembled in egg-crate fashion andhydraulically pressed together to form atightly locked, rigidly stable panel grid.

This grating is available in awide variety of spacingincluding a 1/4" or 1/2" openingproduct. These products arepart of our Grater Access lineand are available with crossbars on 2" or 4" centers.

This is also a popular style inthe architectural communitybecause of the aesthetic eyeappeal of the product and theability to maintain tightertolerances. This style is alsoavailable in stainless steel. Slip resistant surfaces are available upon request.

STEEL [email protected]

0086-535-6501817

www.hygrating.com

HY

Type "SG" Swage Locked Steel GratingType "SG" steel gratings are manufactured by inserting hollow tube cross barsinto pre-punched holes in the bearing bars and swaging the cross bars forminga positive mechanical connection. The cross bars are recessed below the topsurface of the bearing bars providing a uniform and attractive architecturalappearance. Swage locking is a particularly efficient process for the productionof close mesh gratings. Type SG 7-4 with 3/16" thick bearing bars provides anet 1/4" clear opening between the bearing bars. This narrow opening is oftenpreferred in public areas where concerns of drainage and the presence of highheeled shoes converge.

Pressure Locked Gratings manufactured by swaging are designated by theprofile "PS." These productsare assembled by insertinghollow tube cross bars intopre-punched holes in thebearing bars and thenswaging the cross bars(similar to the aluminumgratings). This permanentlylocks the entire crossbar/bearing barintersection withinthe interior of thebearing bar.

STEEL [email protected]

0086-535-6501817

www.hygrating.com

HY

Product Applications

The swaging process allows theassembly of bar grating panels bymechanically locking the cross barsat right angles to the bearing bars.It provides the clean crisp line of arecessed cross bar and eliminatesthe jagged weld flash inherent withwelded bar grating.Additionally, the heat generated aspart of the electro-forging process,limits how close together the bars may be placed.By using the most modern technology available, swaged bar grating isavailable in a wide variety of spacing including a 1/4" or 1/2" opening product.Because of its aesthetic appeal and the ability to meet tight tolerances, this

product is often used forarchitectural applications.Slip resistance surfaces areavailable upon request.

STEEL [email protected]

0086-535-6501817

www.hygrating.com

HY

Use this table when evaluating spans and loads for the following types ofsteel grating: WG 19-4, WG 19-2, DTG 19-4, DTG 19-2, SG 19-4, SG 19-2

*Weight per square foot based upon WG 19-4 grating, Add, 60 psf for 2” on center crossbars.**Maximum pedestrian load is defined as a 100# Uniform Load with deflection 1/4 inch.The 1/4” maximum deflection criteria is considered consistent with pedestrian comfort.But may be exceeded for other loading conditions at the discretion of the specifyingauthority.Note: When gratings with serrated surface are specified, the depth of the gratingrequired for a specific load will be 1/4” greater than that shown in these tables

STAINLESS STEEL GRATING

www.hygrating.com

HY

Stainless steel grating is the best option for severely corrosiveenvironments such as chemical, food and hydro processing areas. It isavailable in welded, press-locked and swaged constructions and inseveral bearing bar sizes. The most common material is Type 304Stainless Steel; however Type 316 is also available by request.

What is Stainless Steel?

Stainless steel is essentially a low carbon

steel which contains chromium at 10% or

more by weight. It is this addition of

chromium that gives the steel its unique

stainless, corrosion resisting properties.

The chromium content of the steel allows the

formation of a rough, adherent, invisible,

corrosion-resisting chromium oxide film on

the steel surface. If damaged mechanically

or chemically, this film is self-healing,

providing that oxygen, even in very small

amounts, is present. The corrosion

resistance and other useful properties of the

steel are enhanced by increased chromium

content and the addition of other elements

such as molybdenum, nickel and nitrogen

Benefits of Stainless Steel

·Corrosion resistance

Lower alloyed grades resist corrosion in

atmospheric and pure water environments,

while high-alloyed grades can resist

corrosion in most acids, alkaline solutions,

and chlorine bearing environments,

properties which are utilized in process

plants.

·Fire and heat resistance

Special high chromium and nickel-alloyed

grades resist scaling and retain strength at

high temperatures.

·Strength-to-weight advantage

The work-hardening property of austenitic

grades, that results in a significant

strengthening of the material from

cold-working alone, and the high strength

duplex grades, allow reduced material

thickness over conventional grades,

therefore cost savings.

·Impact resistance

The austenitic microstructure of the 300

series provides high toughness, from

elevated temperatures to far below freezing,

making these steels particularly suited to

cryogenic applications.

STAINLESS STEEL GRATING

www.hygrating.com

HY

Type "WS" Welded Stainless Steel Grating

Our strongest and most economical stainless product, type"WS" gratings are manufactured by forge weldingrectangular bearing bars and drawn cross bars. Thiswelding process provides a positive fused intersectionproviding years of service under the most demandingconditions.

Type "SS" Swaged Stainless Steel Grating

Hollow tube cross bars are hydraulically swaged intopre-punched holes in the bearing bars to make type "SS"swaged stainless steel grating. Minimizes distortion fromwelding or punching top surfaces of the bearing bars.Available in any quantity.

Type "DTS" Dovetail Pressure LockedStainless Steel Grating

Manufactured with a deep rectangular cross bar, type"DTS" dovetail stainless grating is commonly preferred forarchitectural applications. Sunscreens, grilles and infillpanels are just some of the applications where this distinct“egg-crate” configuration is the ideal building accent.

STAINLESS STEEL GRATING

www.hygrating.com

HY

"WS" SERIESPRODUCT SPECIFICATION GUIDEPART 1: GENERAL

Type "WS" welded stainless steel gratingsare manufactured by forge welding

rectangular bearing bars and drawn crossbars. This welding process provides apositive fused connection providing years ofservice under the most demandingconditions.

PART 2: PRODUCT

STAINLESS STEEL GRATING

www.hygrating.com

HY

"WS" SERIESPART 3: STANDARD

Product Applications:

Stainless Steel Grating is manufacturedfrom alloy types 304, 304L, 316 and 316L.When caustic atmospheres are encountered,or when corrosion resistance and/orminimum carbide precipitation are essentialconsiderations, stainless steel grating is theanswer.

The longer lasting capabilities of stainlesssteel under these special conditions make itan economical selection over the long term.

It is ideal for use in food processing areas,breweries, bottling plants, dairies and meatpacking plants. Stainless steel can also beused in power plants, sewage treatmentplants, pumping stations and hydrocarbonprocessing facilities where various causticenvironments are normal. It also hasapplication in shipboard and buildingindustries where saline solutions oratmospheres are present.

"SS" SERIES

STAINLESS STEEL GRATING

www.hygrating.com

HYPRODUCT SPECIFICATION GUIDE

PART 1: GENERAL

The swaging process allows the assemblyof bar grating panels by mechanicallylocking the cross bars at right angles tothe bearing bars at a maximum of 4” oncenter. This process provides the cleancrisp lines of a recessed cross bar andeliminates the discoloration inherent with

welded bar grating. As with swagedcarbon, this product is manufactured freeof the warping, twisting and burn marks,which are characteristic of electro forgewelded stainless steel grating. Additionally,the heat generated as part of that process,limits how close together the bars may beplaced.

PART 2: PRODUCT

"SS" SERIES

STAINLESS STEEL GRATING

www.hygrating.com

HYPART 3: STANDARD

Product Applications:

Stainless steel grating has been thestandard industrial footwalk product forsevere corrosive environments and hasbeen a popular grating choice for manyyears.

HY manufactures stainless swaged bargrating from type 304 stainless steel bar.Type 316 is also available (limited stock)along with other special alloys by specialorder.

Special finishes are available dependingon the requirements set forth by thearchitect. Stainless steel grating is used atchemical plants, food processing facilities,oil and gas producers, metal and miningfacilities, pulp and paper plants and is alsoused in many other commercial andarchitectural applications.

"DTS" SERIES

STAINLESS STEEL GRATING

www.hygrating.com

HYPRODUCT SPECIFICATION GUIDEPART 1: GENERAL

Assembled by inserting pre-punchedbearing and cross bars into an "egg-crate"configuration and deforming the cross

bars under intense hydraulic pressure.Allows for the manufacture of gratings withcustom spacing.

PART 2: PRODUCT

STAINLESS STEEL GRATING

www.hygrating.com

"DTS" SERIESPART 3: STANDARD

Product Applications:

Manufactured with a deep rectangular cross bar, type "DTS" dovetail stainless grating iscommonly preferred for architectural applications. Sunscreens, grilles and infill panels arejust some of the applications where this distinct “egg-crate” configuration is the idealbuilding accent.

STAINLESS STEEL GRATING

www.hygrating.com

Load Table19 Space Load Table

Use this table when evaluating spans and loads for the following types ofstainless steel grating: WS 19-4, WS 19-2, SS 19-4, SS 19-2, DTS 19-4 andDTS 19-2

*Weight per square foot based upon ws 19-4 grating, Add, 60 psf for 2” on center cross bars.**Maximum pedestrian load is defined as a 100# Uniform Load with deflection ≤1/4 inch.

The 1/4” maximum deflection criteria is considered consistent with pedestrian comfort. Butmay be exceeded for other loading conditions at the discretion of the specifying authority.Note: When gratings with serrated surface are specified, the depth of the gratingrequired for a specific load will be 1/4” greater than that shown in these tables

RAILING & STANCHION

www.hygrating.com

[日期]

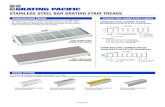

Stair Tread

Fabricated Aluminum stair treadsare available in Aluminum FlushTop, Aluminum Rectangular Bar,Aluminum I-Bar, Aluminum DoveTail, Aluminum Riveted andAluminum Plank. Treads can beordered with a plain or serratedsurface.

Carbon and stainless steel gratingstair tread is available in threedifferent profiles including our lightduty welded steel, carbon steel dovetail and swaged carbon or stainless.Treads can be ordered with a plain(smooth) or serrated surface.

RAILING & STANCHION

www.hygrating.com

[选取日期]

Railing & stanchionAluminum Railings adopt ball joint design,steel grade Q235,hot dip galvanizedfinish. Featuring robustness, convenientinstallation, elegant appearance, andgood anti-corrosive property benefitingfrom hot dip galvanizing. It is widely usedin shipyard, bridgework, power plant,petrochemicals, iron & steel works, sewage treatment plant, waterworks,gardens, municipal roads, air ports, etc.