Hot Tap/Line Intervention Fitting Products Catalog

Transcript of Hot Tap/Line Intervention Fitting Products Catalog

Hot Tap/Line Intervention Fitting Products Catalog

REVISION 1, JUNE 2020

Fitting Products

Introduction

TEAM Fitting Products are engineered to exceed standard ASME industry codes and are enhanced with supplemental testing. The testing exceeds code calculated failure limits, providing a robust and reliable product.

The forged split tee utilized for the fitting products is manufactured using the most advanced process in the market. All raw material goes thru a comprehensive third-party inspection and testing prior to the forging process to ensure compliance with code-driven standards. TEAM takes the standards further by validating the material post process.

The patent-pending automated manufacturing process ensures repeatability, reliability, velocity, precision, quality and comprehensive material traceability. The state-of-the-art material traceability process differentiates TEAM’s Fitting Products. Visibility of material life is seamless as related data is captured and recorded at all stages of the manufacturing process.

TEAM Fitting Product Benefits

Safety & Quality – Reduced Operator Exposure

Engineering – Exceeds Code and Industry Standard

Reliability – Testing Results Exceed Code Calculation

Repeatability – Scalable Standard Product

Process – Patent Pending

Pipeline Series FittingsDesign

TEAM’s Pipeline Series Fittings are offered with full-size branch outlets in sizes 4” through 36”. They are designed to exceed ASME B31.4 and B31.8 criteria and meet ASME Class rating of 300 and 600 flanges (150 optional). The full-size branch offering range is 4” thru 36”. Fabricated tee options are available upon request. Through meticulous design and application validation, the Pipeline Series Fittings are universal for use with all industry standard hot tap and line stop equipment resulting in vast and extensive serviceability.

Material

Pipeline Series Fittings exceed ASME B31.4 and B31.8 material requirements. The extruded tee material meets low temperature Charpy requirements at -50°F, with flange material that complies with the tee material requirement.

Standard Option

The line stop fitting option incorporates proprietary TEAM Pipeline Completion Flange Technology. The completion flange design is proven compatible with industry standard equipment for continued serviceability. The completion plug utilizes a standard Buna O-ring, with other options available. The hot tap fitting utilizes standard ASME raised face weld neck flanges.

Design Code Design Factor NDE

B31.4 0.72 API 1104

B31.8 0.72 API 1104

Tee Material CE Value

0.43 Maximum

Class Parameters

150# 285 psi @ 100°F (-20°F MDMT)

300# 740 psi @ 100°F (-20°F MDMT)

600# 1480 psi @ 100°F (-20°F MDMT)

Pipeline Series Fittings, continued

Size Class “L” Length

“H” Height

“PTF” Pipe to

Flange End

“BID” Branch ID

“BWT” Branch Wall Thickness

“RID” Run ID

“RWT” Run Wall

Thickness

Weight Part Number

4” 300 10-5/8 6-25/32 4-17/32 4.026 0.237 4-9/16 1/2 54 HL-ST83-0404-PCB

6” 300 13-7/8 8-25/32 5-15/32 6.065 0.280 6-11/16 5/8 113 HL-ST83-0606-PCB

8” 300 16-3/8 10-9/32 5-31/32 7.981 0.322 8-11/16 5/8 179 HL-ST83-0808-PCB

10” 300 19-7/8 11-21/32 6-9/32 10.02 0.365 10-13/16 5/8 269 HL-ST83-1010-PCB

12” 300 21-7/8 13-5/32 6-25/32 12.00 0.375 12-13/16 5/8 372 HL-ST83-1212-PCB

14” 300 26 15 8 13.25 0.375 14-1/8 3/4 529 HL-ST83-1414-PCB

16” 300 30 16-3/8 8-3/8 15.25 0.375 16-1/8 3/4 684 HL-ST83-1616-PCB

18” 300 33 18 9 17.25 0.375 18-1/8 3/4 849 HL-ST83-1818-PCB

20” 300 36 19-5/16 9-5/16 19.25 0.375 20-1/8 3/4 1035 HL-ST83-2020-PCB

24” 300 43 21-3/4 9-3/4 23.25 0.375 24-1/8 3/4 1550 HL-ST83-2424-PCB

30” 300 53 27-11/64 12-11/64 29.25 0.625 30-1/8 1-1/2 3412 HL-ST83-3030-PCB

36” 300 60 31-55/64 13-55/64 35.25 0.75 36-1/8 2 5616 HL-ST83-3636-PCB

Size Class “L” Length

“H” Height

“PTF” Pipe to

Flange End

“BID” Branch ID

“BWT” Branch Wall Thickness

“RID” Run ID

“RWT” Run Wall

Thickness

Weight Part Number

4” 600 10-5/8 7-21/32 5-13/32 4.026 0.237 4-9/16 1/2 66 HL-ST86-0404-PCB

6” 600 13-7/8 9-25/32 6-15/32 6.065 0.280 6-11/16 5/8 144 HL-ST86-0606-PCB

8” 600 16-3/8 11-13/32 7-3/32 7.981 0.322 8-11/16 5/8 225 HL-ST86-0808-PCB

10” 600 19-7/8 13-13/32 8-1/32 10.02 0.365 10-13/16 3/4 378 HL-ST86-1010-PCB

12” 600 21-7/8 14-25/32 8-13/32 12.00 0.375 12-13/16 1 541 HL-ST86-1212-PCB

14” 600 26 16-3/8 9-3/8 13.25 0.5 14-1/8 1 681 HL-ST86-1414-PCB

16” 600 30 18-1/4 10-1/4 15.25 0.5625 16-1/8 1-1/8 973 HL-ST86-1616-PCB

18” 600 33 18-3/4 9-3/4 17.25 0.375 18-1/8 7/8 1052 HL-ST86-1818-PCB

20” 600 36 20-13/32 10-13/32 19.25 0.438 20-1/8 1 1378 HL-ST86-2020-PCB

24” 600 43 23-3/16 11-3/16 23.25 0.5 24-1/8 1-1/4 2229 HL-ST86-2424-PCB

30” 600 53 26-1/32 13-1/32 29.25 0.625 30-1/8 1-1/2 3128 HL-ST86-3030-PCB

36” 600 60 33 15 35.25 0.75 36-1/8 2 5032 HL-ST86-3636-PCB

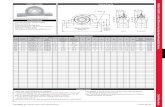

Line Stop (Available in 300# & 600#, Call for 150#)

CARRIER PIPE

L

H

PTF Ø BID X BWT

RID

RWT

Size Class “L” Length

“H” Height

“PTF” Pipe to

Flange End

“BID” Branch ID

“BWT” Branch Wall Thickness

“RID” Run ID

“RWT” Run Wall

Thickness

Weight Part Number

4” 300 10-5/8 6-25/32 4-17/32 4.026 0.237 4-9/16 1/2 47 HH-ST83-0404-R

6” 300 13-7/8 8-25/32 5-15/32 6.065 0.280 6-11/16 5/8 94 HH-ST83-0606-R

8” 300 16-3/8 10-9/32 5-31/32 7.981 0.322 8-11/16 5/8 143 HH-ST83-0808-R

10” 300 19-7/8 11-21/32 6-9/32 10.02 0.365 10-13/16 5/8 209 HH-ST83-1010-R

12” 300 21-7/8 13-5/32 6-25/32 12.00 0.375 12-13/16 5/8 285 HH-ST83-1212-R

14” 300 26 15 8 13.25 0.375 14-1/8 3/4 424 HH-ST83-1414-R

16” 300 30 16-3/8 8-3/8 15.25 0.375 16-1/8 3/4 543 HH-ST83-1616-R

18” 300 33 18 9 17.25 0.375 18-1/8 3/4 668 HH-ST83-1818-R

20” 300 36 19-5/16 9-5/16 19.25 0.375 20-1/8 3/4 806 HH-ST83-2020-R

24” 300 43 21-3/4 9-3/4 23.25 0.375 24-1/8 3/4 1156 HH-ST83-2424-R

30” 300 53 27-11/64 12-11/64 29.25 0.625 30-1/8 1-1/2 2774 HH-ST83-3030-R

36” 300 60 31-7/8 13-7/8 35.25 0.75 36-1/8 2 4554 HH-ST83-3636-R

Size Class “L” Length

“H” Height

“PTF” Pipe to

Flange End

“BID” Branch ID

“BWT” Branch Wall Thickness

“RID” Run ID

“RWT” Run Wall

Thickness

Weight Part Number

4” 600 10-5/8 7-21/32 5-13/32 4.026 0.237 4-9/16 1/2 59 HH-ST86-0404-R

6” 600 13-7/8 9-25/32 6-15/32 6.065 0.280 6-11/16 5/8 125 HH-ST86-0606-R

8” 600 16-3/8 11-13/32 7-3/32 7.981 0.322 8-11/16 5/8 190 HH-ST86-0808-R

10” 600 19-7/8 13-13/32 8-1/32 10.02 0.365 10-13/16 3/4 321 HH-ST86-1010-R

12” 600 21-7/8 14-25/32 8-13/32 12.00 0.375 12-13/16 1 456 HH-ST86-1212-R

14” 600 26 16-3/8 9-3/8 13.25 0.5 14-1/8 1 577 HH-ST86-1414-R

16” 600 30 18-1/4 10-1/4 15.25 0.5625 16-1/8 1-1/8 832 HH-ST86-1616-R

18” 600 33 18-3/4 9-49/64 17.25 0.375 18-1/8 7/8 873 HH-ST86-1818-R

20” 600 36 20-19/64 10-19/64 19.25 0.438 20-1/8 1 1148 HH-ST86-2020-R

24” 600 43 23-3/16 11-3/16 23.25 0.5 24-1/8 1-1/4 1835 HH-ST86-2424-R

30” 600 53 28-1/32 13-1/32 29.25 0.625 30-1/8 1-1/2 3128 HH-ST86-3030-R

36” 600 60 33 15 35.25 0.75 36-1/8 2 5032 HH-ST86-3636-R

Hot Tap (Available in 300# & 600#, Call for 150#)

CARRIER PIPE

L

H

PTF Ø BID X BWT

RID

RWT

Plant Series FittingsDesign

TEAM Plant Series Fittings are designed to exceed ASME B31.3 criteria and meet ASME Class rating of 150 and 600 flanges (300 optional) for line stop option and 150, 300 and 600 for hot tap option. The full size branch offering range is 4” thru 16”. Fabricated tee options are available upon request. Through meticulous design and application validation, the Plant Series Fittings are universal to all industry standard hot tap and line stop equipment lending to vast and extensive serviceability.

Material

Plant Series Fittings exceed ASME B31.3 material requirements. The extruded tee material meets low temperature Charpy require- ments at -50°F, with flange material that complies with the tee material requirement.

Standard Option

The line stop fitting option incorporates proprietary TEAM Plant Completion Flange Technology with benefit of high-temperature applications. The completion flange design is proven compatible with industry standard equipment for continued serviceability. Completion plugs utilizes a standard Buna O-ring, with other options available. The hot tap fittings utilize a standard ASME raised face weld neck flange.

Class Parameters

150# 285 psi @ 100°F (-20°F MDMT)

300# 740 psi @ 100°F (-20°F MDMT)

600# 1480 psi @ 100°F (-20°F MDMT)

Design Code NDE

B31.3 B31.3 NFS (Current Edition)

Tee Material CE Value

0.43

Plant Series Fittings, continued

Size Class “L” Length

“H” Height

“PTF” Pipe to

Flange End

“BID” Branch ID

“BWT” Branch Wall Thickness

“RID” Run ID

“RWT” Run Wall

Thickness

Weight Part Number

3” 150 7 5-25/32 4-1/32 3.068 0.216 3-9/16 1/2 24 HL-ST31-0303-FSB

4” 150 10-3/4 6-13/32 4-5/32 4.026 0.237 4-9/16 1/2 41 HL-ST31-0404-FSB

6” 150 14 8-13/32 5-3/32 6.065 0.280 6-11/16 5/8 86 HL-ST31-0606-FSB

8” 150 16-1/2 9-29/32 5-19/32 7.981 0.322 8-11/16 5/8 134 HL-ST31-0808-FSB

10” 150 20 11-1/32 5-21/32 10.020 0.365 10-13/16 5/8 198 HL-ST31-1010-FSB

12” 150 22 12-17/32 6-5/32 12.000 0.375 12-13/16 5/8 274 HL-ST31-1212-FSB

14” 150 26 14-3/8 7-3/8 13.250 0.375 14-1/8 3/4 394 HL-ST31-1414-FSB

16” 150 30 15-5/8 7-5/8 15.250 0.375 16-1/8 3/4 513 HL-ST31-1616-FSB

Size Class “L” Length

“H” Height

“PTF” Pipe to

Flange End

“BID” Branch ID

“BWT” Branch Wall Thickness

“RID” Run ID

“RWT” Run Wall

Thickness

Weight Part Number

3” 600 7 6-17/32 4-25/32 3.068 0.216 3-9/16 1/2 33 HL-ST36-0303-FSB

4” 600 10-3/4 7-21/32 5-13/32 4.026 0.237 4-9/16 1/2 65 HL-ST36-0404-FSB

6” 600 14 9-25/32 6-15/32 6.065 0.280 6-11/16 5/8 140 HL-ST36-0606-FSB

8” 600 16-1/2 11-13/32 7-3/32 7.981 0.322 8-11/16 5/8 215 HL-ST36-0808-FSB

10” 600 20 13-13/32 8-1/32 10.020 0.365 10-13/16 3/4 356 HL-ST36-1010-FSB

12” 600 22 13-29/32 7-17/32 12.000 0.500 12-13/16 1 528 HL-ST36-1212-FSB

14” 600 26 15-7/16 8-7/16 13.250 0.500 14-1/8 1 660 HL-ST36-1414-FSB

16” 600 30 17-3/8 9-3/8 15.250 0.625 16-1/8 1-1/8 946 HL-ST36-1616-FSB

Line Stop (available 150#, 600# and 300# upon request)

CARRIER PIPE

L

H

PTF Ø BID X BWT

RID

RWT

Size Class “L” Length

“H” Height

“PTF” Pipe to

Flange End

“BID” Branch ID

“BWT” Branch Wall Thickness

“RID” Run ID

“RWT” Run Wall

Thickness

Weight Part Number

3” 150 7 5-25/32 4-1/32 3.068 0.216 3-9/16 1/2 23 HH-ST31-0303-R

4” 150 10-3/4 6-13/32 4-5/32 4.026 0.237 4-9/16 1/2 38 HH-ST31-0404-R

6” 150 14 8-13/32 5-3/32 6.065 0.280 6-11/16 5/8 76 HH-ST31-0606-R

8” 150 16-1/2 9-29/32 5-19/32 7.981 0.322 8-11/16 5/8 117 HH-ST31-0808-R

10” 150 20 11-1/32 5-21/32 10.020 0.365 10-13/16 5/8 169 HH-ST31-1010-R

12” 150 22 12-17/32 6-5/32 12.000 0.375 12-13/16 5/8 230 HH-ST31-1212-R

14” 150 26 14-3/8 7-3/8 13.250 0.375 14-1/8 3/4 341 HH-ST31-1414-R

16” 150 30 15-5/8 7-5/8 15.250 0.375 16-1/8 3/4 440 HH-ST31-1616-R

Size Class “L” Length

“H” Height

“PTF” Pipe to

Flange End

“BID” Branch ID

“BWT” Branch Wall Thickness

“RID” Run ID

“RWT” Run Wall

Thickness

Weight Part Number

3” 300 7 6-5/32 4-7/16 3.068 0.216 3-9/16 1/2 27 HH-ST33-0303-R

4” 300 10-3/4 6-25/32 4-17/32 4.026 0.237 4-9/16 1/2 47 HH-ST33-0404-R

6” 300 14 8-25/32 5-15/32 6.065 0.280 6-11/16 5/8 95 HH-ST33-0606-R

8” 300 16-1/2 10-9/32 5-31/32 7.981 0.322 8-11/16 5/8 144 HH-ST33-0808-R

10” 300 20 11-21/32 6-9/32 10.020 0.365 10-13/16 5/8 211 HH-ST33-1010-R

12” 300 22 13-5/32 6-25/32 12.000 0.375 12-13/16 5/8 286 HH-ST33-1212-R

14” 300 26 15 8 13.250 0.375 14-1/8 3/4 424 HH-ST33-1414-R

16” 300 30 16-3/8 8-3/8 15.250 0.375 16-1/8 3/4 543 HH-ST33-1616-R

Size Class “L” Length

“H” Height

“PTF” Pipe to

Flange End

“BID” Branch ID

“BWT” Branch Wall Thickness

“RID” Run ID

“RWT” Run Wall

Thickness

Weight Part Number

3” 600 7 6-17/32 4-25/32 3.068 0.216 3-9/16 1/2 30 HH-ST36-0303-R

4” 600 10-3/4 7-21/32 5-13/32 4.026 0.237 4-9/16 1/2 60 HH-ST36-0404-R

6” 600 14 9-25/32 6-15/32 6.065 0.280 6-11/16 5/8 126 HH-ST36-0606-R

8” 600 16-1/2 11-13/32 7-3/32 7.981 0.322 8-11/16 5/8 191 HH-ST36-0808-R

10” 600 20 13-13/32 8-1/32 10.020 0.365 10-13/16 3/4 324 HH-ST36-1010-R

12” 600 22 14-25/32 8-13/32 12.000 0.500 12-13/16 1 460 HH-ST36-1212-R

14” 600 26 16-3/8 9-3/8 13.250 0.500 14-1/8 1 578 HH-ST36-1414-R

16” 600 30 18-1/4 10-1/4 15.250 0.625 16-1/8 1-1/8 832 HH-ST36-1616-R

Hot Tap (Available in 150#, 300# and 600#)

CARRIER PIPE

L

H

PTF Ø BID X BWT

RID

RWT

Performance Assurance Solutions for Total Integrity ManagementPerformance assurance is a key component for a successful asset management program to ensure that equipment and infrastructure perform safely. When integrity services are critical to the successful completion of a project, subcontracting vital parts of a project to multiple sources can lead to longer turnaround times, lessened quality and increased costs

TEAM responds to clients’ needs for increased asset management efficiency and reliability with a holistic, digitally-enabled approach. Focus is placed on providing higher-value solutions with integrated services, covering projects from inception to completion. This allows for time and cost saving opportunities to be identified from reduced man hours and increased time on tools throughout the project.

From planning and scheduling to cost tracking and complete staff execution, TEAM unites the delivery of conventional to highly-specialized inspection, condition assessment, maintenance and repair services that result in greater safety, reliability, and operational and economic efficiency for a client’s most critical assets.

TeamInc.com