HIGH-TECH FOLDINGmagazine.fsmdirect.com/2016/may/d/pdf/download.php?f=FSM...• 30 day money-back...

Transcript of HIGH-TECH FOLDINGmagazine.fsmdirect.com/2016/may/d/pdf/download.php?f=FSM...• 30 day money-back...

M A Y

2016

GIANT PRESS BRAKES | MATERIALS | WELDING DATA

HIGH-TECH FOLDING

800-553-2112 bull infooeocom

BEFORE W METAL HALIDE

AFTER W THE OEO EZ LED

X

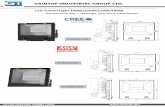

OEO EZ LED LED Metal Halide Direct Replacement

bull Simply screw it inItrsquos EZbull Saves up to 68 in energy costs = $364 per light per yearbull No fixture change or rewiringbull Long LED life technologybull Payback less than one year (before rebates)bull Equals or exceeds brand new metal halide light outputbull No mercury No radiation No UV RoHS compliantbull Rebate eligiblebull 5 year warrantybull 55000+ hour lifebull Free shipping this monthbull 30 day money-back guarantee

145W ldquoBRIGHTrdquo Saves 68 = up to $364 per light per year

180W ldquoBRIGHTERrdquo Saves 62 = up to $324 per light per year

230W ldquoBRIGHTESTrdquo Saves 50+ = up to $267 per light per year

Operating 247 national kWh average of 136 cents per US Dept of Labor Statistics 2015

ldquoPLUG rsquon PLAYrdquo LE D fo r Metal Hal ideSaves $1000s in Monthly Energy Costs

LED METAL HALIDE DIRECT REPLACEMENT

SAVES 68 SIMPLY BY CHANGING ldquoBULBSrdquo

| EDITORrsquoS LETTER

THE EVOLVING lsquoCELLrsquo

If yoursquove been involved in metalworking long enough you get to see Darwinian Evolution occur before your eyes Itrsquos like watching pterodactyls evolve into prairie chickens

This recognition struck us hard when we began doing research for an upcoming article on fabricating ldquocellsrdquo We were there when the concept of machining cells was created ndash early lsquo70s ndash and it had a clear meaning It was an arrangement of machines usually three or four more or less in a circle with one operator in the middle First he would drill then move the part to a lathe then to a mill etc The benefit was twofold eliminate wasted steps and waiting time by the operator and eliminate in-process inventory (work-in-process or WIP) The cost was in some cases a high level of idle time on individual machines Benefits usually won the cost competition Call it the nascent step in the development of lean manufacturing Or donrsquot if yoursquod rather stick with cells because they get interesting in and of themselves

Along came CNC and rather than being driven by the movements of an operator the cell was paced by the controller All machines could be working at once The operator was there to do setups to load

and unload and possibly to do in-process inspection (sort of ) The operator became something like a one-armed paper hanger or the Charlie Chaplin character in ldquoModern Timesrdquo

Now the paper hanger in a growing number of cases really is one-armed itrsquos a robot The ldquocellrdquo term has been adopted by fabricating But our machines can be big and the robot usually is planted in one place like a tree In-process parts often have to be shuttled from one machine to another The circle-of-machines concept has largely disappeared The cell has become a special case of ldquoleanrdquo which itself is a topic for another day

Thus our jargon terms can get a little fuzzy around the edges One of our jobs at Fab Shop is to de-fuzz fuzziness so we will explore the remnants of the original cell concept in its current implementations Are the central goals still central We think so although it forces us to make some distinctions Wersquoll continue to explore it and to see what we can winnow from the chaff looking for some gems of wisdom to guide us in evaluating alternative operating ideas

Grant us some of that wisdom stuff and stay tuned to Fab Shop as always

Ed Huntress

Editor ehuntresstechgenmediacom

Amada America Inc180 Amada Court

Schaumburg IL 60173

wwwamadacomamerica877-262-3287

The LC 2515 C1 AJ combines the force of a 22-ton turret punch presswith the flexibility of a 2kW fiber laser A 49-station MPT (Multi-PurposeTurret) provides for unique forming and tapping features mdash furtherenhancing productivity and reducing secondary operations

Benefits of Amadarsquos Lean and Extremely FlexibleManufacturing Solution

bull Unmatched Efficiency (The LC 2515 C1 AJ enables LampT to punch cutform and tap on a single machine Combined processing in addition to the abilityto nest punch and laser parts has reduced setup and processing times by 85)

bull Cost-Effective Production Regardless of Lot Size(Many of LampTrsquos bending lot sizes consist of 20 parts or less Previously opera-tors were spending up to 90 of their time on setup Today manual setup and test pieces have been eliminated as the HG 1003 ATC provides automatic and precise tool changes)

bull Reduced Lead Times and Increased Productivity (Seamless process integration of the C1 AJ combined with the automated fea-tures of the HG ATC have significantly reduced LampTrsquos lead times Additional benefits include maximizing both productivity and flexibility while reducing secondary operations and costs)

Amadarsquos ATC (Automatic ToolChanger) is equipped with 18magazines for dies and 15 for

punches mdash providing theflexibility to accommodate rush

jobs seamlessly and triple orquadruple the number ofbending setups per day

Founded in 1984 LampT PrecisionCorporation began doing business ina 1500 sq ft shop with 4 employees Today staffed with over 100 employeesLampT operates from a 48687 sq ft facility in Poway California serving awide range of industries including aerospace defense medical communi-cation and commercial An ongoing commitment to exceed customersrsquoexpectations is key to LampTrsquos growth mdash itrsquos also the reason for partneringwith Amada LampT was searching for an innovative and integrated punch-ing laser cutting and bending solution mdash and thatrsquos precisely whatAmada provided Included in Amadarsquos innovative solution is an LC 2515C1 A J punchfiber laser combination machine and an HG 1003 ATC hybrid-drive press brake thatrsquos equipped with an Automatic Tool Changer

Russell Nguyen LampTrsquos President CEO reflects on the purchaseldquoAmadarsquos punchfiber laser technology and Automatic Tool Changer allow us to cost-effectively produce what our customers need when they need it The C1 AJ maintainsconsistent accuracy through multiple processes while eliminating secondary operations Its unique processing features reduced our tapping times by 95 and reduced the timerequired for countersink operations by 90 In addition the HG ATC allows us to achieveunprecedented productivity What used to require 2 operators and 3 press brakes isnow produced quicker and with greater accuracy by one operator and the HG ATCrdquo

Russell L Nguyen PresidentCEO of LampT Precision Corporation

ldquoAmadarsquos C1 AJ and HGATC allow us to seamlesslyaccommodate any job anytimerdquo

mdash Russell L Nguyen PresidentCEO LampT Precision Corporation

UltimateFlexibility

C1 AJ Video

HG ATC Video

EDITOREd Huntressehuntresstechgenmediacomp 732-239-8499

MANAGING EDITORSusan Woodsswoodstechgenmediacomp 847-973-2271

SENIOR EDITORLarry Adamsladamstechgenmediacomp 773-392-1096

DIRECTOR OF E-MEDIAJustin Stiversjstiverstechgenmediacom

FAB Shop Magazine Direct is a registered trademark of Techgen Media Group We publish monthly All rights reserved under the US International and Pan-American Copywrite Conventions No part of this publication may be reproduced stored in a retrieval system or transmitted in any form or by any means such as mechanical photocopying electronic recording or otherwise without the prior written permission of Techgen Media Group Contact us at 732-239-8499 for permission Produced in the US

VP SALESAlan Bergp 732-438-5801 c 732-995-6072abergtechgenmediacom

ADVERTISING SALES DIRECTORNeil Kellyp 610-584-5560nkellytechgenmediacom

OFFICE MANAGERACCOUNTINGKyle Grossikgrossitechgenmediacom

THE INFORMATION CONDUIT FOR FABRICATINGAND STAMPING PROFESSIONALS

SUBSCRIBE FORWARD

C

M

Y

CM

MY

CY

CMY

K

YLS Next Generation Laser Ad REV 4Aai 1 412015 115708 AM

They look like giant versions of standard press brakes but theyrsquore a world apart in terms of capacity and workhandling challenges

FEATURES

18

24

30

Automation and accuracy add versatility and productivity to folding machines

High-Tech Folding8

In a globalized economy materials costs are driven by forces we may not see But theyrsquore affecting your margins

Material Prices ndash Going Up Down or Sideways

Collecting welding data is easy Making good use of it can boost productivity and quality in a big way

Keeping a Sharp Eye on Your Welding

NEXT MONTHrsquoS ISSUE

Press brakes

Resistance welding

Plasma

Roll forming

Really Big Press Brakes

3

35

Editorrsquos letter

DEPARTMENTS

Industry News

8

24

We can set up and run parts inones and twos

expect to see prices rise over the next couple years

Cover photo credit

Photo courtesy of RAS Systems

Whats the point in purchasing expensivelaser cutting machinery if maintenance menhave to free up slag binding dischargechains and replace bearings

When discharge systems becomewelded shut as hot slag binds and jamsordinary chain conveyors these arereasons why laser cutters sit idle mdashand competitive fabrication cost-marginsgrow wider

Thats why owners of laser cuttersare replacing their steel discharge chainsystems with Vibro Transporters and astainless steel tray for hot slag andscrap removal

The Vibro 100 air-operatedTransporter Conveying System eliminatesthe downtime associated with conventionalchain conveyors Its low profile allows theTransporter to fit in the tightest most hard-to-reach places beneath machine tools

Other benefits include 100 Air-Operated

- No MechanicalSprings

Low AirConsumption

Variable SpeedOperation

Two-Year Warranty 100 American

Made Available from Stock

Register online or call us today toreceive your product line kit applicationvideo engineering support or to locate thesales representative nearest you

Low profile air-operatedTransporter ConveyingSystem eliminates lasercutting part and scrapremoval downtime

Global DistributionFOSMO MASKIN AS Norway UPTON amp SULLIVAN CO LTD Canada MTI Monterrey Mexico

7175272094wwwvibroindustriescom

Engineered First to Last

MADE IN

USA

Is hot slag impeding your lasercutting operations

VB_6615ADBQXD_Layout 1 71614 925 AM Page 1

Another Exciting Addition to the Techgen Media FamilyThe premier edition of Tube and Pipe Magazine will appear in the October pre-Fabtech show issue of all three magazines in the Techgen family ndash Welding Productivity Fab Shop Magazine Direct and Shop Floor Lasers ndash which will reach an aggregate audience of 280000 opt-in readers

Because many of our readers self-selected an interest in tube and pipe fabricating TPM puts specific editorial emphasis on this key area of metalworking highlighting critical developments and strategies for those who fabricate tube and pipe products It supplements our range of manufacturing editorial enhancing our readership and giving your ad

a better chance of being seen and acted upon

As is true with all of our magazines TPM will provide you the chance to embed a video or a direct link to your website in the ad multiplying your impact

TPM is your opportunity to reach out and impress prospects in your market The inaugural issue will close Sept1 Contact our sales group to reserve your space

For advertising information contact

Alan Berg Advertising Salesphone 7329956072email abergtechgenmediacom

Neil Kelly Advertising Salesphone 6105845560 email nkellytechgenmediacom

Announcing Tube and Pipe Magazine

TPMCOMING

IN OCTOBER

|| by ED HUNTRESS Editor ||

HIG

H-T

ECH

FO

LDIN

GFolding machines are evolving by adding degrees of automation one feature at a time But there is a lot more to it than just replacing manual handling From CAD drawing to finished parts the most advanced folders can run lights-out producing top-level accuracy on some very difficult jobs

FOLDING

| High-Tech Folding 8

With press brakes itrsquos easy to see whatrsquos happening With folding machines

itrsquos not always so easy Laying the workpiece on a flat table clamping it and wiping or rocking a tool against it to form a bend is easy enough to follow Where it gets interesting is in manipulating the work and producing certain features on parts Add automation and it requires a close look and some background about how the machines have developed to judge where theyrsquore best employed

Fab Shop asked Bill Kennedy VP of RAS Systems USA to walk us through their evolution and to clarify how and where the latest high-tech folders compare with press brakes RAS builds folders ranging from models that are largely operator-involved to the most highly automated types and Kennedy spent 40 years selling press brakes so hersquos a go-to authority for comparing different approaches to bending

ldquoIf we were in Europe and visited a sheet-metal fabricating shop you

would likely see a couple of press brakes and a couple of folders You wouldnrsquot see a bunch of press brakes alone Wersquore a little bit behind the curve in the US and one of the main reasons that wersquove been a little slow is that if you go back ten years or more the people bending metal with a press brake were actually coining it Punches were being bottomed in the dies and displacing some metal Sharp bend radii were a lot more common and folders donrsquot bottom like that

RADII EVOLVING BY DESIGN

ldquoSince the evolution in air bending driven by engineering and product design minimum inside radii of 150 times material thickness are more common with press brake bending now Thatrsquos really quite large compared to how things were being done years ago And thatrsquos where folders come in

ldquoYou can still get tighter radii air forming with a brake because you have more tonnage and tooling geometry changes Again thatrsquos less of an issue now The tradeoff is the gains made with the folder the part handling the accuracies the quick setup They are extremely quick to set up Typically you buy one set of tools and the geometry of those tools will allow them to do a lot of partsrdquo

Among the work-handling and ndashloading options is this suction-cup table powered by a vacuum source that incrementally feeds the work into the machine

| High-Tech Folding 9

FOLDING

RAS Systems LLC 1135 DIVIDEND COURT

PEACHTREE CITY GA 30269

PH 770-415-8130 FX770-487-1007

RAS Systems has raised the bar again for maximum accuracy and repeatability Our fast forming sequences short cycle times and greatly reduced set-up times has made the MiniBendCenter and UpDownCenter the state-of-the-art in metal forming technology When combined with our ldquoBendex 3D One-Click Programmingrdquo the integration of idea and final product becomes seamless

Automated Solutions forDifficult MetalProducts

We make age old metal forming problems a thing of the past

UpDownCenterSemi-Automated Production Of Larger Complex Parts

MiniBendCenterFully Automated Small Metal Parts Manufacturing

Multibend CenterVersatile And Upgradable Modules For Folding Automation

Semi-Automated XLTbendFor Complex Precision Sheet Metal Parts

NEWWWWRAS-SYSTEMSCOM

FabShop Ad (17x11)-layout4indd 1 51316 213 PM

Kennedy points to RASrsquos FLEXIbend as an example ldquoLook at the tooling They are hardened and ground segmented tools that can be slid left or right taken off or put on in any combination you want We donrsquot sell a lot of tooling Folders donrsquot have the appetite for tools that press brakes dordquo

A few more distinguishing points On one or the other side of the folder is the table which supports the full weight and size of the workpiece material Folders make handling large blanks easier because they lay flat on

the table and donrsquot have to be held while theyrsquore bent Thus operating can require less labor Press brakes tend to be better for small parts although folders are intruding in that area as well Folders are limited to sheet metal you donrsquot have the tonnage to handle thick workpiece stock Press brakes can handle thicker material Folders can more easily make long tightly-spaced flanges even internal flanges near an edge as on door jambs computer racks and similar parts ldquoThe more complex the part the better the folding machine

lsquoOur popularityrsquos growing in precision fabricating and itrsquos coming from the push

for lean manufacturing We can truly set up and run parts in ones and twos Press

brakes start catching us at 150 partsrsquo

Bill Kennedy

Clamp the work and then apply folding tools Thatrsquos the distinguishing characteristic of a folder On this XXL-Center the manipulation needed to make closely-spaced up-and-down bends while the work is clamped firmly is all in the tooling

QUIP-MISTWELD NOZZLE CONDITIONER AND ANTI-SPATTER LIQUID

HELPING TO IMPROVE YOUR WELDING PRODUCTIVITY

Providing Welding ProfessionalsSERVICE QUALITY SOLUTIONS Since 1987

For more Information or to obtain a FREE evaluation sample contact your local American Weldquipdistributor email us at salesweldquipcom call 330-239-0317

or visit our website - wwwweldquipcom

Helps Extend Consumable Life Green and Environmentally Freindly No Harmful Odors or Fumes Non-Flammable Non- Hazardous Non-Toxic

NEW Formulation Provides a Major Breakthrough in Welding Spatter Control

Made in the USA - Engineered and Manufactured in Sharon Center Ohio

Biodegradable Water Based Will Not Plug or Clog Feed Lines and Sprayers 32 oz Spray 1 Gallon 5 Gallons and 55 Gallons

QuipMist Ad March 2016 WProdMagpdf 1 1282016 85408 AM

| High-Tech Folding 11

FOLDING

isrdquo says Kennedy ldquoMultiple angles within a part and many bends are handled better on a folder just simply from a manipulation standpointrdquo Brakes can cycle faster although that doesnrsquot necessarily mean greater productivity Applying a broad generalization folders can produce greater accuracy and less scrap

So itrsquos a tit-for-tat with each machine type having advantages in one application versus another Kennedy says he really enjoys analyzing

customersrsquo applications because he often can see where folders will do a job better which the customer hadnrsquot thought of Imagining what folding machines can do is not easy unless yoursquove looked at a lot of applications and solutions

But back to new developments and the evolution ldquoOur popularityrsquos growing in precision fabricatingrdquo says Kennedy ldquoAnd itrsquos coming from the push for lean manufacturing We can truly set up and run parts in

The trend toward larger-radius bends works in favor of folders They

canrsquot coin like a press brake thatrsquos set to bottom the punch in the die

producing a very sharp bend but contemporary product design has

reduced the need for it

Tooling with programmable adjustable height provides access to internal bends such as tabs that are otherwise difficult to access

ones and twos Press brakes start catching us at 150 parts When we go to the more advanced folders to automation therersquos no catching us And when you start getting into the part-size range of four or five feet and complex parts you should be at least entertaining the idea of using a folding machinerdquo

EVOLUTION STEP ONE

But there are markets and machines for all levels of automation Starting simple Kennedy points to the

companyrsquos FLEXIbend It has CNC features but the operation is still operator-dependentldquoHerersquos a machine with which the operator is totally involved and it only bends uprdquo he says ldquoThis is where the evolution started

ldquoThe FLEXIbend though also has lsquointelligent crowningrsquo which was introduced around ten years ago When you change material thickness and tell the controller the machine makes adjustments for that material

| High-Tech Folding 12

FOLDING

thickness When you then bend that new part for the first time the folding beam will come out 10 degrees and then a computer-controlled motorized adjustment is made in the crowning It does that individually for every bend length because every bend length is going to have a different deflection The program also compensates for the part configuration and it knows the material thickness Once itrsquos gone through the adjustment which really is pretty quick itrsquoll do it for every partrdquo

Even at this ldquostep onerdquo level of complexity the functions and features of the machine are more involved than these few highlights and a video is a far better way to appreciate them than to try to explain it in words You can see them in this video

STEP TWO

RAS Systemrsquos XLTbend is a machine that bends up and down There is no need to flip the work for making reverse bends It also incorporates a

ldquobeam-in-beamrdquo folding-beam design that eliminates the need for crowning adjustments while producing much greater straightness in bends

It also incorporates several more automation features It has a series of suction cups that takes the part from the operator (they can be seen best in this video of the RAS UpDownCenter) The only operator involvement occurs if the part needs to be rotated

The XLTbend was introduced just last November and its mechanical features are numerous This is where folding machines become more difficult to follow than press brakes To appreciate the features you have to start with the geometry challenges involved in making boxes panels and cassettes

For example when bending up and down without flipping the part the tooling and folding beam have to be able to clear a pre-bent flange when theyrsquore folding a flange in the opposite direction Bending internal features such as welding tabs ndash one of the strengths of folders ndash is made

Industrial Magnetics IncCall 8885820823 bull Surf wwwmagneticscomScan QR code with your smart device

We help you makethings faster safer better

Industrial Magnetics Inc fabricates innovative and unique magnetic solutions for industrial lifting holding fixturing and moving applications as well as wide variety of conveying products for ferrous metal parts lids containers and more

Made to Handle MetalPlates Pipes Parts

No Problems

| High-Tech Folding 13

We donrsquot sella lot of tooling Folders donrsquot have the

appetite for tools that press brakes do

FOLDING

Bill Kennedy

The ProfileCenter is tailored to make long closely-spaced bends up and down for such applications as making door frames and computer-rack frames

Closely-spaced bends are a danger to an operatorrsquos fingers

With automated work-feeding the operator is

kept in the clear

possible by a tooling innovation that allows some tools to move up and down during the cycle under CNC control to get inside of other elements of the workpiece

These complexities are necessary to achieve application flexibility in the machine Traditionally folding machine features have been tailored to specific narrow ranges of applications This narrowness is being overcome by innovations in the mechanical and tooling features and extensively by advanced CNC They are still designed around classes of

work however As Kennedy says ldquoAll these features have been designed with products in mind Instead of us making the machine and telling people lsquoThis is what we have see what you can do with itrsquo we go to them and say lsquoWe know these are your problems This is how we can solve themrsquordquo

| High-Tech Folding 14

Traditionally foldingmachine features have beentailored to specific narrowranges of applications Thisnarrowness is being overcome by innovations in the mechanical and toolingfeatures and extensivelyby advanced CNC

Itrsquos these combinations of bends exampled here with

some closely-spaced and tedious folds many involving a reversal in direction that is

the forte of folders

The XLTbend includes RASrsquos all-out CNC-program-streamlining Bendex3D software which they call ldquoOne-click programmingrdquo Intelligence is built into in the machine software so either the operator or an off-line programmer just imports STEP DXF or GEO files (which were previously checked for potential collisions) and the machine-programming is done Thatrsquos all it takes to program the complete setup and bend sequence automatically

When alternate strategies are available to form the imported part the CNC shows alternative sequences and ranks each on a 5-step rating scale to help judge the best strategy for production The operator has the option to simulate each strategy in 3D from any perspective and to zoom on the simulation Once the operator evaluates and selects a strategy all that remains is to press the ldquoStartrdquo button to begin forming

Whether it was the proliferation of mechanical features that drove the need for this intelligent programming or whether it was

the other way around we didnrsquot ask Regardless this is what makes it possible to combine one-part programming automated back-gauge setting work-feeding automated tool movement workpiece versatility and high productivity The concept reminds us of the stealth fighter planes that are impossible for a human to fly without their computers In the case of the folder itrsquos almost like autopilot

STEP THREE THEN QUICK-STEP TO STEP FOUR

We can keep step three short itrsquos the UpDownCenter which conceptually is similar to the XLTbend plus an automatic toolchanger Now wersquore getting close to hands-off automation the operator just has to rotate the part if needed Wersquoll take a quick step to four RASrsquos ProfileCenter

ldquoAgain wersquore trying to find solutions for difficult products and the ProfileCenter was originally designed for door jamb manufacturesrdquo says Kennedy ldquoThese are very tedious

| High-Tech Folding 15

FOLDING

and dangerous parts to make on a press brake It really requires flexible and automatic profile bending and itrsquos hard to automate -- or it has been really hard to automate in the past Very large manufactures are still using press brakes and they have operators involved These tight profiles cause the operators fingers to be in some very dangerous places and the same applies to similar tight profiles For example big computer racks

ldquoThe parts have a lot of positivenegative bends so the bending is going up and down The ProfileCenter takes the part and handles it any way you want to do it If you want to feed it with robots you can There are so many different ways of feeding parts and typically the automation is very customized You really have to watch this one in a videordquo

There is more to the companyrsquos machine lineup including large and small fully automated machine models We watched a lot of videos to prepare for this article Advanced folders can be intimidating to write

about because there are so many things that are hard to explain in words This editor is a former job shop owner who recognized right away that they are not machines you can dope out on your own with articles brochures and videos It requires real application experience ndash in other words a good sales engineer ndash to see the possibilities for any given application This reflects what Bill Kennedy told us too and he has 40 years of background in bending and folding

But the videos wersquove embedded in this article should give you an idea of how many possibilities there are to take a job yoursquore doing on a press brake and convert to a folder The accuracy repeatability automation and safety potentials have to be appealing

Itrsquos worth a call and a visit It could be good for your bottom line

RAS SYSTEMS WEBSITE

Techgen Medialsquos Turnkey Email Campaigns

Email rates

Select by Technical Interest

Base price

BendingFolding 45234

Stamping 20185

Punching 23865

Sawing 31727

Shearing 19396

Plasma Cutting 26603

Waterjet 4241

Laser Cutting 14461

Laser Welding

Welding

4612

109773

$100M

Minimum Order Quantity 5000

Techgen Media Group Email Campaigns offer a cost-effective way to expand your message reach and engage with qualified buyers By having access to our more than 195000 opted-in subscribers you can deliver professionally designed content to decision makers in targeted industry segments

Leverage Email Campaigns to

bull Keep readers up to date on your products processes and services

bull Increase foot traffic at your industry trade show booth Be it Fabtech Canada Fabtech Las Vegas Fabtech Mexico Mfg 4 IMTS or Westec reach a broad audience of readers within a 500-mile range of the trade show where yoursquoll be exhibiting

How it works

bull Provide us with your targeted content including text images and video

bull Choose the industry segments that best fit your products and services

bull Let us do the rest mdash from designing your Email Campaign to implementing best practices for delivery

How it works

bull We provide you with open and click-through rates

bull Recipients have already opted into our mailing program and consider us as a trusted source for manufacturing information

bull An education-first approach enhances the authoritative voice of your message and establishes your company as a highly valued and trusted resource

For counts and selection options

Alan Berge abergtechgenmediacomp7329956072

CUSTOMIZE based on your selection criteria

DELIVER your message to future customers

TRACK open and click-through rates

FOLDING

|| by ED HUNTRESS Editor ||

Theyrsquore the monsters of the press brake world But they operate like their smaller cousins

with a little help to handle the big work

PRESS BRAKES FOR GIANTS

| GIANT PRESS BRAKES

Zipping out small parts looking like a demo version of a ldquorealrdquo press brake LVD Strippitrsquos

Dyna-Press electric press brake was a highlight of the Fabtech show a few years ago Itrsquos small and light enough to move around the shop with a forklift and within its size range it

was demonstrating the many virtues of electric drive It looked like fun We wanted to load one in the back of a truck and take it home

Then they showed us some photos of what they build at the other end of the size scale There was a machine

| Press Brakes for Giants 18

Ursviken

Built in the Middle East desert this giant

is planted 18 feet underground and had

to have the building built around it after it

was assembled

Two or even three machines are synchronized to produce the really long lengths They operate as a single machine

being assembled with cranes out of doors in the Middle East desert The base of the machine was secured to its foundation 18 feet below the ground Parts of the brake were swinging from steel cables like pre-cast parts of a skyscraper while workers guided the crane operator to place them in position The machine was too big to assemble inside of a building So they assembled the press brake first and then built a building around it

What struck us besides the staggering scale of the giant press brakes was how much alike they were to the small ones If you took a close-up photo of each with nothing in the photo to indicate scale like a human or a capscrew yoursquod have to look at them for a moment before you could figure out their size Press brakes are press brakes even if theyrsquore so big that you have to build the machine first and then erect the building that surrounds it Itrsquos an uncommonly scalable technology

You may find it interesting that even in lengths measured in dozens of

feet with machines that often are assembled in pieces with two or even three self-contained machines lined up to make one big one and with forces measured in thousands of tons they operate in fundamentally the same way The biggest questions then become how they handle those enormous workpieces and who uses them

ldquoMost of them are bought by truck-chassis builders light-pole and power-pole manufacturers crane builders and shipyardsrdquo says Lieven Vanhoenacker LVD sales manager ldquoWe build roughly 20 of them each year year after year and every one is customized to specific requirementsrdquo

They are in other words much more tailored to particular and limited classes of work than are ordinary mid-size press brakes ldquoA lot of the material being bent is pretty exotic high-strength alloys For example the Weldox and Hardox alloys from Swedenrsquos SSRBrdquo These alloys range from just under 100 kpsi to over 190 kpsi yield strength and the

GIANT PRESS BRAKES

| Press Brakes for Giants 19

LVD Strippit

LVD Strippit

springback can be 30 Theyrsquore several times stronger than mild steel and are being used in vehicle lightweighting applications and in building crane booms among others ldquoInstead of making a truck chassis frame from 10 or 12mm material they might use four-to-six millimeter stock in the strong alloysrdquo says Vanhoenacker

As an extreme a manufacturer of power-transmission poles wanted to make them of 30mm (12 in) steel ldquoWith material that thick you need 250 tons per meter of length It required 3000 tons of force to make the 30-meter-long poles in sectionsrdquo

This is a global business with a concentration in areas that are expanding their infrastructure and building ldquoOur biggest market concentration at the moment is the Middle Eastrdquo says Vanhoenacker An example is Galva Coat based in Abu Dabi Theyrsquove grown rapidly with some big investments and now have they say 65 of the regional market for these really big pieces

And they can handle the biggest A 3000 ton LVD PPEB press brake complements a 1400-ton 14m-long tandem brake The heavy one is used to form posts and pipelines up to 15m long in thicknesses to 25mm Servo controlled with state-of-the-art hydraulics and electronics the PPEB press brake is the largest machine of its kind in the Middle East says LVD and it is a turnkey system that includes press brake automation part evacuation and bending tools

For 90 of the day the custom press brake is forming light poles It incorporates a programmable V-axis crowning system integrated and synchronized with the machinersquos control system to keep the ram and the table parallel during bending for high accuracy Rework is kept to a minimum ldquoWe make about 50000 to 60000 light poles a year with only 05 rework which shows just how consistent the technology isrdquo said Mohammed Botma factory manager at Galva Coat

The enormous tonnage needed to make long

lengths can also be applied to shorter

sections of thick plate Some of the applications

involve 50mm (roughly 2-in-thick) plate

Crane booms are made to high

accuracy because sections telescope

inside of each other while maintaining a

close fit

Another continent another application this time for making crane booms Vlassenroot is one of the worldrsquos major manufacturers of critical components for mobile cranes and operates across four sites in Belgium Germany and Poland The company expanded its capacity with the installation of a 2000-ton 14m LVD PPEB-H 2000T press brake for producing mobile crane booms Vlassenroot has all of its production processes in-house so they can offer crane manufacturers a complete fully welded boom and chassis from one supplier

Ludwig Deckers plant manager at the Schwerte plant says that in recent years the strongest part of the market has been in cranes for the wind-power sector Its big LVD press brakes give it the large-scale

| Press Brakes for Giants 20

Ursviken

Ursviken

GIANT PRESS BRAKES

lsquoIt was a hell of a job for the operators to push these long and heavy

components up against the back gaugeshelliprsquo

Ludwig Deckers

Long narrow workpieces are especially difficult to

align Automatic work handling is the answer

Power-transmission poles often are multi-

faceted and with a taper Sections

typically are joined in 12-14 meter sections

production capability for this market The largest crane for which they build parts has a 500-ton capacity and the longest section they produce at Schwerte is over 14m long They supply all leading crane companies throughout the world

The new machines LVD built for Vlassenroot were designed specifically to be the optimum configuration for crane-boom forming in high strength steels The latest machine includes a couple of further refinements The first is a series of CNC pushers at the front of the machine that ensure the plate is firmly located on the back gauges

ldquoIt was a hell of a job for the operators to push these long and heavy

components up against the back gauges so we asked LVD to come up with an automatic system rather than using manpower It has worked very wellrdquo says Deckers

The second special feature is a bottom die that can be adjusted in 10mm increments from 110mm up to 320mm This allows the company to cope with some of the very large bend radii required on the higher strength steels

ldquoIn normal steel to bend an angle of 90 degrees you may have to bend to 89 or 88 degrees to allow

| Press Brakes for Giants 21

GIANT PRESS BRAKES

Ursviken Ursviken

for springback With the 1100 Mpa (160 kpsi) tensile strength material we commonly bend you may have a springback of 30 degrees ndash so you have to bend to 60 degrees You need a lot of forcerdquo

ldquoThe bend accuracy is crucially important to us because of the requirements of the end product Although we are making very large components ndash up to more than 14m long ndash the tolerances the customers are asking for are very tight On a boom section 16m in diameter the height and the width have to be within plus or minus 2mm on the welded fabrication Otherwise the telescopic boom sections wonrsquot slide in and out properlyrdquo says Deckers

LVDrsquos Vanhoenacker says that the work-handling issue is a very important part of designing and building these big machines ldquoHow can I push feed my material to position with front supports back supports front pushers back pushers and sheet followers All these options are functions of the length and the

weight and the product that the customer wants to make So we do the complete study of course and look at all the options Most of these machines have tight access and CNC controlled back stopsrdquo This is where much of the customization comes in he says ldquoWe have sheet followers front supports that follow and support the material during bending that can support 600 kilograms We actually can support 1200 kilograms per support so if you put in three of these you can support a lot of weight during bending So there arenrsquot many limitationsrdquo

Some shapes such as light poles frequently are air-bent incrementally

into a smooth curve to produce a cylinder Poles can be made in sections

to a height of 100 m or even more

There are some caveats The poles can be and often are conical or tapered So feeding and backstop adjustment has to be programmed for that And the tooling as noted by Ludwig Deckers may involve adjustable dies that allow for different radii In fact some poles are multi-faceted (octagonal or more) and some are cylindrical Getting the adjustments right to air-bend a series of blended radii for round poles with high levels of springback begs for adjustable dies But such dies are used in normal-sized machines as well Salvagnini makes an entire machine based on them

Custom work pushers of various types are used in most cases because the work is

either too dangerous to handle or too

heavy to push against a backgauge

| Press Brakes for Giants 22

GIANT PRESS BRAKES

Ursviken

LVD Strippit

A SERIES ON PRESSBRAKE PRODUCTIVITY

NOW CHANGE EVEN HEAVY TOOLS QUICKLY AND SAFELY

V O L U M E

04 w

ww

wila

usa

com

IMPROVE YOUR PRODUCTIVITY wwwwilausacomE2M

1-888-696-9452

mdashWILA takes no risks when it comes to creating safe and productive working environments The patented Easy to Movereg (E2M) roller bearing technology provides quick and safe loading and unloading of large heavy punches and dies The E2Mreg technology is available for all WILA punches weighing a maximum of 224 lbs (100 kg) and dies weighing a maximum of 345 lbs (155 kg)mdash

WIL151103_Ad_EM2_USA_Standardindd 1 16-11-15 1529

Back to the companyrsquos little electric Dyna-Press brake we imagined making something like say an electrical junction box on one And then within the same electrical-power industry we can use a giant press brake to make the poles that carry the electricity to the box So LVD Strippit covers both ends of the industry We may be pushing analogies and connections too far but not by much Theyrsquore all in the same family

LVD STRIPPIT WEBSITE

| Press Brakes for Giants 23

This installation in Abu Dabi

uses multi-part pushers to handle

heavy plate

LVD Strippit

|| by LARRY ADAMS Senior Editor ||

After nearly two years of depressed prices the cost of metals is expected to rise But tune in

to the variables and look ahead It could make a difference in your bottom line

MATERIAL PRICES ON THE RISE

| MATERIALS

Material Prices on the Rise 24

Fabricators who have enjoyed lower costs for their metal needs should expect to see

prices rise over the next couple years if recent prognostications come to fruition

According to analysts from IHS an industry analysis firm that considers the metals market beginning in late 2014 and early 2015 prices began to fall steadily primarily because of a glut in supply and a reduction in demand But with an improving economy a belief that production of metals will be cut especially by metal producers in China and that inventory levels will drop the analysts believe that these factors will stem this price drop off and drive prices steadily up through 2017

ldquoOver the past 2 yearsrdquo said John Mothersole director of IHS speaking at an April briefing ldquowersquove seen this very sharp and prolonged correction in commodity prices that really began back in the summer of 2014 when oil prices started to fall (see Figure 1) Prices have fallen steadily for the past year and a half now but we think a change occurred as of

mid-January and over 7 weeks prices jumped up some 20rdquo

Global steel production he said is contracting albeit slowly and not by as much as will be needed if prices are to stabilize at a more sustainable price Mothersole pointed to China as the country that still needs to take action and cut production rates ldquoBut even in Chinardquo he said ldquowersquore seeing a change in the market and that is a hopeful sign Steel as a sector remains grossly over supplied but at least conditions are moving in the right direction to begin to balance the marketrdquo

While gradual increases are expected over the next 18 months or so even with these increases ldquothe [pricing] levels are still going to be below what we were seeing in late 2014rdquo said Frank Hoffman senior economist with IHS

CHINA AND OTHER FACTORS

This upward movement is the result of several factors said Mothersole including production cuts a bloated inventory starting to slim down a

MATERIALS

copy 2016 IHS ALL RIGHTS RESERVED

Commodity prices have bottomed

7

15

20

25

30

35

40

45

50

2012 2013 2014 2015 2016 2017

IHS Materials Price Index 2002w1=10

Source IHS copy 2016 IHS

Prices have rallied 20 in the past

seven weeks

peaking of the US dollar China the worldrsquos largest steel producer and exporter accounting for about half the global production remains the X factor Its economy is stabilizing which should use some capacity but will the country reduce production

Pressure is being placed on China too and not just at the market level In April representatives from the US Canada the European Union Japan Mexico South Korea Switzerland

and Turkey issued a joint statement calling for nations to act lsquoquicklyrsquo to reduce global steel output Nations in this case being a synonym for China

In an interview with National Public Radio US Commerce Secretary Penny Pritzker said ldquoThe steel market is in a state of crisis primarily due to massive global excess capacity In this current crisis the United Statesrsquo industry has suffered price declines

Material Prices on the Rise 25

Figure 1

copy 2016 IHS ALL RIGHTS RESERVED

We are seeing production cuts

12

-8

-6

-4

-2

0

2

4

6

8

2012 2013 2014 2015 2016

Global raw steel production year over year change

Source International Iron and Steel Institute

6

7

8

9

10

2012 2013 2014 2015 2016

US Oil production millions of barrels per day

Source EIA

copy 2016 IHS ALL RIGHTS RESERVED

We are seeing production cuts

12

-8

-6

-4

-2

0

2

4

6

8

2012 2013 2014 2015 2016

Global raw steel production year over year change

Source International Iron and Steel Institute

6

7

8

9

10

2012 2013 2014 2015 2016

US Oil production millions of barrels per day

Source EIA

decreased profitability mdash and over 13000 jobs have been lost in the last year or sordquo

Whether China acts to cut production is unknown China is able to export a record amount of steel because of demand In March Chinese companies hit a record monthly high of nearly 78 million tons of steel according

MATERIALS

to data from the China Iron amp Steel Association This is at a time when less steel that is being produced is being used due to a faltering economies such as in China If US steel mills raise prices service centers and other suppliers can take advantage of lower international steel prices

MarketRealistcom also points to the falling prices of raw materials including iron ore coal and steel scrap which would make it difficult for US steel mills to justify price increases According to MarketRealist suppliers such as AK Steel Holding Corp United States Steel Corp and Steel Dynamics have already cut spot steel shipments in the last few months as spot steel prices sharply deteriorated

SELECT METALS

Hoffman the IHS economist said that prices on materials from aluminum to Zinc would be increasing throughout 2016 (as seen in Figure 3) stating that there has been a rebound in prices in base metals he said

Here is a brief rundown of individual metal predictions

--Aluminum prices he said are unsustainably low Primary capacity in the Western Hemisphere has been gutted This means elevated premiums in North America going forward But inventory remains ldquohugerdquo Hoffman expects production cuts that will start to foster price increases Where these production cuts come from will dictate partially how much prices will come up (However NPR reported that the Chinese might be flooding the US market with low-cost aluminum as well)

ldquoThey really need to [cut production] in China for some meaningful price gains as a lot of the capacity in the Western Hemispherersquos been cutrdquo he said ldquoOne big looming issue has been inventory which is currently bloated and this high level of inventory is really going to cut into the rebound in pricesrdquo

--CopperFor copper IHSrsquo forecasts a bullish market The reason behind that

Material Prices on the Rise 26

Figure 2

Service costs expected to rise

Fabricators should expect to see additional increases in costs when it comes to services such as transportation warehousing temporary staffing legal services equipment and real estate leases and engineering services

According to Emily Crowley senior economist IHS these costs often fly under the radar but that doesnrsquot diminish their importance ldquoIndirect cost recently rarely captured headlinesrdquo said Crowley ldquoand one of the reasons that that is is because they have been quite stable unlike material prices which experienced a recent decline Services have been growing around 25 percent One of the things about services is that they really are an important contributor to operational costrdquo

In 2012 when the Bureau of Labor completed an economic census contracted services accounted for a total of 3-5 percent of total spending in manufacturing and construction industries A conservative estimate Crowley said because of the broad spectrum of services ldquoIt can be transportation if you donrsquot want to invest in a fleet of trucks and the labor required to operate those trucks on your own It can be warehousing even temporary staffing services Legal services if you donrsquot have an in house council Equipment and leasing services engineering services They really do run the gamutrdquo

She said that there is a perfect storm thatrsquos starting to coalesce that will be driving these costs higher The key driver there will really be labor market and labor market conditions and the material cost increases

| MATERIALS

copy 2016 IHS ALL RIGHTS RESERVED

Metal prices have bottomed and will increase this year

90

100

110

120

130

140

150

160

170

Aluminum Copper Nickel Zinc

Prices will continue to increase over 2016 (January 2016=100)

Source IHS copy 2016 IHS

17

Metal Change since Jan 1 2016

Overall LME Big Six +80

Tin +158

Zinc +158

Aluminum +67

Copper +62

Lead +55

Nickel +32

for copper is that IHS is seeing a fundamental deficit (supply to demand) in 2016 and thatrsquos going to push prices up higher Now wersquore seeing some production cuts and state reserve bureau purchases but we see consumption growing and part of that is because we donrsquot see manufacturing activity getting weaker Also last year we had this inventory destocking cycle so that

kind of artificially made apparent consumption a little bit lower and why therersquos a consumption decrease in 2015

--NickelNickel is one of the metals that have the potential to see the biggest price increases Hoffman said Roughly seventy percent of the market is underwater where production costs

Material Prices on the Rise 27

Figure 3

Steel as a sector remains grossly over supplied but at least conditions are

moving in the right direction to begin to balance the market

Call TODAY to set up a DEMONSTRATION at your work site

5014 ETIRONWORKER

CPO 350 LTCOLD SAW

AL100U-02TUBE amp PIPE

GRINDERNOTCHER

Best-in-the -Business WARRANTY

You can count on +- 006 per diameter inch in squareness

More options and accessories keep costs down and productivity and profits up

DEPENDABILITY DEPENDABILITY

VERSATILITY VERSATILITY

QUALITY QUALITY American manufacturer and importer of quality machinery

GUARANTEED

PRECISION PRECISION

Call Toll Free 1-800-843-8844 or Call Direct 605-859-2542 bull Fax 1-800-843-5545 or 605-859-2499 wwwscotchmancom bull infoscotchmancom bull Scotchman Industries Inc PO Box 850 Philip SD 57567

THE SOLUTION PREFERRED BY METAL FABRICATORS

LEASINGAVAILABLE

| MATERIALS

are greater than the current price Hoffman is anticipating production cuts are going to occur ldquoTheyrsquore inevitablerdquo he said ldquoso we see those happening this year and really eating into supply and creating some upward pressure on pricesrdquo

Therersquos currently a modest deficit in the nickel market but this has been just ldquoabsolutely dwarfed by inventory levels so as things stand without these production cuts there really isnrsquot much pressure to push up prices which is why these production cuts are necessary to really propel prices upwardrdquo he said

--Zinc Hoffman said that therersquos ldquoa lot of mined production coming off line due to production cuts and then also just general buying closures that have occurred last year and were exogenous to this down turn in overall commodity pricesrdquo The year 2015 ended the year in surplus but most of the surplus occurred in the first half of last year As IHS looks later in the year Hoffman says he can see

that there is an overall deficit ldquoWe can really see that reaction to low prices has caused these production cutsrdquo Now the bulk of the big production cuts occurred late last year It typically takes two or three months for these cuts to really hit the refined market after that last bit of material was mined ldquoThat really started to impact the market in mid January or sordquo he saidldquo and thatrsquos led to this upswing in prices for zinc rdquo

While Hoffman and Mothersole are predicting price increases through 2017 pretty much across the board as economies improve inventories reduce and production presumably falls they reiterated that these prices will continue to be below the market prices of 2014 Still fabricators may need to adjust their budgets with an eye to future price hikes or considering contracting for the materials at these lower prices

Material Prices on the Rise 28

John Mothersole

IHS WEBSITE

If you can measure it track it and display it you can improve the performance of your welding operations

WELDING DATA A KEY TO BETTER PRODUCTIVITY

|| by CALEB KRISHER business development manager welding information Miller Electric Mfg Co ||

WELDING DATA

Welding Data A Key to Better Productivity 30

Like nearly every other metalworking process today welding is getting a

performance boost from shop-floor data You can collect it automatically analyze it easily with charts and graphs and put that information to work to improve your quality your productivity and your training Tools are readily available now for turning raw welding data into knowledge

With greater competition and a sometimes less-experienced workforce companies may use data acquired for each operator to make decisions about a possible need for additional training as well as to seek increased productivity and lower costs Initiatives that reduce quality risks also are of key importance

A welding information management system is one way to achieve these goals for both robotic and semi-automatic welding systems The real-time productivity and quality weld data provided by basic or entry-level software systems in particular can help management implement positive changes within their welding operation

Here are some of the benefits such a system can provide

bull The ability to gather real data rather than just opinions about the welding operation

bull Real-time data collection by way of a wired or wireless Ethernet connection eliminating the need for time-consuming manual data collection

bull Easy access via Web browsers to data and online data storage

bull Measurement of productivity metrics such as arc-on time and total deposition

bull The identification of potential problems (such as out-of-threshold welds) and potential operator-training needs

bull A benchmark for measuring the impact of continuous improvement efforts

WHAT ARE THE ADVANTAGES

The ability to identify problem areas in the welding operation isnrsquot the only benefit of basic welding

WELDING DATA

Cell-by-cell or operator-by-operator productivity in welding can be compared on various reports Likewise measuring error frequency by part type and

productivity trends over time are among the many custom reports that give you insight into your welding operations

31Welding Data A Key to Better Productivity

Basic or entry-level welding information management systems gauge both productivity and quality and provide real-time weld data for management to enact positive changes within the welding operation

information management systems Companies can also gather the data necessary to establish a baseline for improvements based on productivity and quality metrics

Welding information management systems can be installed via an external module that monitors welding parameters from outside the power source (as opposed to being integrated within a new machine) allowing companies to leverage welding equipment they already have There are various methods available for connecting the modules to a welding system external sensing devices upgrade modules for specific brands of equipment and in-line devices between the power source and feeder

For companies that want to buy and install new machines welding systems are available in factory-built models All of these systems allow for data transmission via wired Ethernet connection However newer versions include built-in Wi-Fi capability providing quick easy setup and flexibility on the shop floor

Management can track and assess how individual machines are performing compared to specific departments or the company as a whole since companies can organize their welding information-capable systems in an online asset tree by weld cell department or building (this is explained in more detail in the next section) Using a secure user ID and password on any Web-enabled device companies can access weld data online for a given period of time providing an ongoing view of welding operation activities The system generates reports comparing any combination of machines and cells there is no software or applications to install or maintain The information can also be downloaded into a standard spreadsheet for analysis at a later date giving companies the ability to assess progress over a longer period of time

This automatic real-time data collection is much quicker and more accurate mdash with less opportunity for incorrect interpretation mdash than

32Welding Data A Key to Better Productivity

WELDING DATA

manual collection The faster that production problems can be fixed the better companies can prevent errors from becoming a part of ongoing production

HOW DO THE DASHBOARDS WORK

Multiple levels of customizable dashboards are available with some of the better basic welding information management systems This feature provides an ldquoat a glancerdquo view of performance from the machines in operation including information such as amperage and volts arc-on time and arc starts and weld deposition amounts A main dashboard shows a composite overview of the welding operation with details such as an asset tree organized to the companyrsquos preference machine status indicators arc-on comparisons performance relative to goals quality limits and more A productivity dashboard is also provided with some systems This

dashboard can be customized to graphically display arc-on times and deposition for a better picture of how much welding has occurred by the hour day week or month Using this information companies can identify high and low productivity periods and what is causing them and identify the potential need for additional intervention Additionally a quality dashboard shows if welds are capable of meeting quality standards and if they are within acceptable limits for things such as voltage or amperage thresholds Companies also can use the quality dashboard to determine if quality risks (eg weld defects such as porosity or lack of fusion or the presence of out-of-spec parameters) have increased or decreased over time and be immediately alerted to potential problems The tool can even help identify welding operators who may need additional training Another dashboard option available with the most capable welding information management systems

WELDING DATA

Management or other authorized personnel can

access weld data from a basic welding information

management system via a standard Web browser

using a secure user ID and password on any

Web-enabled device including a computer

smartphone or tablet The trend is toward storing data

in the cloud

allows managers to establish goals for metrics such as arc-on time deposition and arc starts Setting these goals makes it easier to identify areas that need attention This dashboard can help identify and track production and quality goals as part of continuous improvement efforts by

bull Assessing the result of initiatives aimed at improving weld quality including the use of appropriate shielding gas flow to correct porosity tightening of weld parameters reducing over-welding or correcting travel speeds Initiatives can also include fixing problems that originate before welding such as gaps in parts

bull Monitoring the impact of changes to increase arc-on time by reducing non-value-added activities such as grinding or tacking by the welding operator (ie assign these tasks to non-production fabrication staff) and also monitoring welding deposition

bull Evaluating the effectiveness of welding operator training

The numerous dashboards help monitor progress toward specific continuous improvement goals The weld data can also help determine true welding costs provide options for reducing costs and offer ways to track the outcome of those efforts

33Welding Data A Key to Better Productivity

WHAT ARE THE REPORTING OPTIONS

The powerful reporting tools of a basic welding information management system can provide customized views of each of the dashboards These views help

management analyze a companyrsquos productivity and quality metrics in the way that makes the most sense and is most in line with its continuous improvement efforts Pre-configured reporting capabilities available in the more sophisticated

lsquoThe system generates reports comparing any

combination of machines and cells there is no

software or applications to install or maintainrsquo

| WELDING DATA

MILLER ELECTRIC

welding information management systems make it even easier to evaluate different aspects of the welding operation Management can review reports regarding

bull Arc-on time percentagebull Trends for arc-on time and

arc startsbull Comparisons of weld duration

(tack welds versus longer welds)bull Histograms for arc durationbull Current and voltagebull Comprehensive detailed

weld history

The presentation of productivity and quality data is nearly limitless The asset tree has the flexibility to show custom machine groupings and to vary the time scope of the reports The information provided by the reports can help welding engineers identify out-of-threshold welds assess and improve weld process setup and monitor machine configurations and performance The systems also can provide information to empower welding operators to take an active role in advancing their skills

IS A BASIC WELDING INFORMATION SYSTEM THE RIGHT CHOICE

Implementing such a system can help companies make improvement decisions based on facts The real-time data allows companies to make real change in a more practical and accurate manner than via manual collection and interpretation With the cooperation of management owners welding engineers and welding operators such a system can also offer a significant return on investment through quality and productivity improvements Just as any investment in the welding operation however the decision to implement such a system should be made with care and consideration Consulting a trusted power source manufacturer or welding distributor is a good first step in determining the most appropriate technology to meet specific needs

34Welding Data A Key to Better Productivity

Trumpf(860) 255-6000

wwwustrumpfcom All Metals Fabricating Inc has expanded its roster of fabricating equipment with a TruLaser 5030 fiber with an 8-kW-TruDisk laser with two TruStore 3030 storage towers The Trumpf laser system is a 2D laser-cutting machine that is available with an 8kW solid-state laser With its BrightLine fiber technology the 8-kW-TruLaser 5030 fiber can process up to 1-in-steel and 1-frac12-in-stainless and aluminum The laser source machine optics optional cutting technologies automation storage systems and software were all developed by Trumpf to work in tandem achieving maximum performance and keeping cost-per-part to a minimum the company says

All Metals Fabricating wanted to invest in the best fiber-laser-machine-technology to achieve fast ROI The job shop located in the Dallas area is a fully integrated sheet metal fabrication company offering precision fabricating and machining services for a broad base of industry clients

For more information on the laser system visit wwwustrumpfcom

For information on All Metals Fabricating visit wwwametalscom

Texas Job Shop Expands Capabilities

| INDUSTRY NEWS

35

nLIGHTwwwnlightnet

Two new fiber lasers have been added to the portfolio of lasers offered by nLIGHT

For industrial material processing the nLIGHT medium-power fiber-lasers are now available from 500 W to 1200 W

For metal cutting welding and advanced fabricating nLIGHT introduces fiber lasers from 2 kW to 4 kW with fast modulation rates and short pulse rise and fall times the company says The fiber lasers are now available at power levels from 500 W to 4kW and incorporate programmable pulse shaping and triggering that improves process optimization the company says

The lasers feature failsafe back reflection isolation technology for full power processing of highly reflective materials across all power levels

For more information visit wwwnlightnet

| INDUSTRY NEWS

nLIGHT Releases 1200 W Single-Mode Fiber Laser

36

Matersquos Press Brake Tooling Forms up to 40 Degrees

Mate wwwmatecom

Matersquos CleanBend forming technology press-brake-tooling dies can bend delicate and standard materials up to 40 degrees with minimal to no marking on the piece Utilizing rotating supports within the tooling Matersquos new CleanBend press brake tooling enables precise bending the company says

CleanBend is designed for a wide range of applications including bending short flanges bending a flange to a diagonal sharp or across existing holes and bending delicate and highly polished materials

The tooling is made from high-speed tool steel and is backed by Matersquos unconditional guarantee It is available for press brakes configured with European Precision Wila-Trumpf and American style tooling systems in a full range of sizes from 8 mm to 30 mm

Matersquos press brake tooling line also includes a full array of Bevel Tang European Precision and Wila Trumpf style punches dies standard specials specials and accessories available in segmented full-length and half-length sizes

For more information about CleanBend phone (800) 328-4492

Outside the US and Canada call (763) 421-0230

| INDUSTRY NEWS

37

Kyocerawwwkyoceracom

Kyocera recently launched new mobile devices for ATampT customers rounding out its rugged portfolio to offer a flip-feature phone a Smartphone and a ldquophabletrdquo (combination phone and tablet) with its DuraXE DuraForce and DuraForce XD devices

The military-grade DuraXE is an inexpensive option for users that need talk text and push-to-talk (PTT) capability The IP68 rated products are designed to withstand dust drop shock vibration temperature extremes blowing rain low pressurehigh altitude solar radiation salt fog humidity and immersion in up to 6 ft of water for up to 30 minutes The company says it fills the need for a standard Android-Smartphone experience A large screen display on the DuraForce XD makes it ideal for jobs with forms schematics and multimedia displays that need to be viewed in a larger format

Both the DuraForce XD and the DuraXE are certified for use in hazardous work locations where flammable gases vapors or mists are not normally present in an explosive concentration but may accidentally materialize

For more information on Kyocerarsquos DuraForce XD DuraXE and other

products visit wwwkyoceramobilecombusiness

Kyocera Launches Rugged Mobile Devices

| INDUSTRY NEWS

38

PFERD(800) 342-9015

wwwpferdusacom

PFERD Inc has introduced its latest depressed center grinding wheels featuring an advanced ceramic oxide grain that delivers excellent stock removal rates long service life and cost cutting performance Ideally suited for working with steel and stainless steel the new PFERD Inc wheels designated CO 24 Q SG have a hardness grade Q and excel at a variety of applications including weld grinding chamfering deburring and surface grinding the company says

The grinding wheels achieve optimal results on high-powered angle grinders and are available in sizes ranging from 4-frac12 -in dia by frac14-in thickness and a maximum rpm of 13300 to 9-in dia by frac14-in thickness and a maximum rpm of 6600

The ceramic oxide grinding wheel employs contamination-free abrasives without fillers and is rated for stainless steel (INOX)

For more information visit wwwpferdusacom or phone toll free in the

US at (800) 342-9015 or in Canada at (866) 245-1555

PFERDrsquos New Grinding Wheels Feature Advanced Ceramics

| INDUSTRY NEWS

39

Fabricators have a triple-barreled resource they can reach through FAB Shop Direct or through our sister publications Shop Floor Lasers and Welding Productivity Together we cover fabricating topics from different angles each with a different focus linked to give you more depth or a different take on the topics you see in one of the three

Follow the links below to see the latest coverage from our magazine group More information is just a click away no matter where you start

Techgen Mediarsquos Information forFabricators is Bigger than Fabshop

ROBOTIC WELDING ADVANCESInnovations abound for robot supplier

BETTER BEVELINGPrep pipe and plate more productively

UPSWINGS FOR DOWNSTREAMSTesting to see what works

THE ART OF MANUFACTURINGA refresher on where fiber is better

More Information is Just a Click Away

800-553-2112 bull infooeocom

BEFORE W METAL HALIDE

AFTER W THE OEO EZ LED

X

OEO EZ LED LED Metal Halide Direct Replacement

bull Simply screw it inItrsquos EZbull Saves up to 68 in energy costs = $364 per light per yearbull No fixture change or rewiringbull Long LED life technologybull Payback less than one year (before rebates)bull Equals or exceeds brand new metal halide light outputbull No mercury No radiation No UV RoHS compliantbull Rebate eligiblebull 5 year warrantybull 55000+ hour lifebull Free shipping this monthbull 30 day money-back guarantee

145W ldquoBRIGHTrdquo Saves 68 = up to $364 per light per year

180W ldquoBRIGHTERrdquo Saves 62 = up to $324 per light per year

230W ldquoBRIGHTESTrdquo Saves 50+ = up to $267 per light per year

Operating 247 national kWh average of 136 cents per US Dept of Labor Statistics 2015

ldquoPLUG rsquon PLAYrdquo LE D fo r Metal Hal ideSaves $1000s in Monthly Energy Costs

LED METAL HALIDE DIRECT REPLACEMENT

SAVES 68 SIMPLY BY CHANGING ldquoBULBSrdquo

| EDITORrsquoS LETTER

THE EVOLVING lsquoCELLrsquo

If yoursquove been involved in metalworking long enough you get to see Darwinian Evolution occur before your eyes Itrsquos like watching pterodactyls evolve into prairie chickens

This recognition struck us hard when we began doing research for an upcoming article on fabricating ldquocellsrdquo We were there when the concept of machining cells was created ndash early lsquo70s ndash and it had a clear meaning It was an arrangement of machines usually three or four more or less in a circle with one operator in the middle First he would drill then move the part to a lathe then to a mill etc The benefit was twofold eliminate wasted steps and waiting time by the operator and eliminate in-process inventory (work-in-process or WIP) The cost was in some cases a high level of idle time on individual machines Benefits usually won the cost competition Call it the nascent step in the development of lean manufacturing Or donrsquot if yoursquod rather stick with cells because they get interesting in and of themselves

Along came CNC and rather than being driven by the movements of an operator the cell was paced by the controller All machines could be working at once The operator was there to do setups to load

and unload and possibly to do in-process inspection (sort of ) The operator became something like a one-armed paper hanger or the Charlie Chaplin character in ldquoModern Timesrdquo

Now the paper hanger in a growing number of cases really is one-armed itrsquos a robot The ldquocellrdquo term has been adopted by fabricating But our machines can be big and the robot usually is planted in one place like a tree In-process parts often have to be shuttled from one machine to another The circle-of-machines concept has largely disappeared The cell has become a special case of ldquoleanrdquo which itself is a topic for another day

Thus our jargon terms can get a little fuzzy around the edges One of our jobs at Fab Shop is to de-fuzz fuzziness so we will explore the remnants of the original cell concept in its current implementations Are the central goals still central We think so although it forces us to make some distinctions Wersquoll continue to explore it and to see what we can winnow from the chaff looking for some gems of wisdom to guide us in evaluating alternative operating ideas

Grant us some of that wisdom stuff and stay tuned to Fab Shop as always

Ed Huntress

Editor ehuntresstechgenmediacom

Amada America Inc180 Amada Court

Schaumburg IL 60173

wwwamadacomamerica877-262-3287

The LC 2515 C1 AJ combines the force of a 22-ton turret punch presswith the flexibility of a 2kW fiber laser A 49-station MPT (Multi-PurposeTurret) provides for unique forming and tapping features mdash furtherenhancing productivity and reducing secondary operations

Benefits of Amadarsquos Lean and Extremely FlexibleManufacturing Solution

bull Unmatched Efficiency (The LC 2515 C1 AJ enables LampT to punch cutform and tap on a single machine Combined processing in addition to the abilityto nest punch and laser parts has reduced setup and processing times by 85)

bull Cost-Effective Production Regardless of Lot Size(Many of LampTrsquos bending lot sizes consist of 20 parts or less Previously opera-tors were spending up to 90 of their time on setup Today manual setup and test pieces have been eliminated as the HG 1003 ATC provides automatic and precise tool changes)

bull Reduced Lead Times and Increased Productivity (Seamless process integration of the C1 AJ combined with the automated fea-tures of the HG ATC have significantly reduced LampTrsquos lead times Additional benefits include maximizing both productivity and flexibility while reducing secondary operations and costs)

Amadarsquos ATC (Automatic ToolChanger) is equipped with 18magazines for dies and 15 for

punches mdash providing theflexibility to accommodate rush

jobs seamlessly and triple orquadruple the number ofbending setups per day

Founded in 1984 LampT PrecisionCorporation began doing business ina 1500 sq ft shop with 4 employees Today staffed with over 100 employeesLampT operates from a 48687 sq ft facility in Poway California serving awide range of industries including aerospace defense medical communi-cation and commercial An ongoing commitment to exceed customersrsquoexpectations is key to LampTrsquos growth mdash itrsquos also the reason for partneringwith Amada LampT was searching for an innovative and integrated punch-ing laser cutting and bending solution mdash and thatrsquos precisely whatAmada provided Included in Amadarsquos innovative solution is an LC 2515C1 A J punchfiber laser combination machine and an HG 1003 ATC hybrid-drive press brake thatrsquos equipped with an Automatic Tool Changer

Russell Nguyen LampTrsquos President CEO reflects on the purchaseldquoAmadarsquos punchfiber laser technology and Automatic Tool Changer allow us to cost-effectively produce what our customers need when they need it The C1 AJ maintainsconsistent accuracy through multiple processes while eliminating secondary operations Its unique processing features reduced our tapping times by 95 and reduced the timerequired for countersink operations by 90 In addition the HG ATC allows us to achieveunprecedented productivity What used to require 2 operators and 3 press brakes isnow produced quicker and with greater accuracy by one operator and the HG ATCrdquo

Russell L Nguyen PresidentCEO of LampT Precision Corporation

ldquoAmadarsquos C1 AJ and HGATC allow us to seamlesslyaccommodate any job anytimerdquo

mdash Russell L Nguyen PresidentCEO LampT Precision Corporation

UltimateFlexibility

C1 AJ Video

HG ATC Video

EDITOREd Huntressehuntresstechgenmediacomp 732-239-8499

MANAGING EDITORSusan Woodsswoodstechgenmediacomp 847-973-2271

SENIOR EDITORLarry Adamsladamstechgenmediacomp 773-392-1096

DIRECTOR OF E-MEDIAJustin Stiversjstiverstechgenmediacom

FAB Shop Magazine Direct is a registered trademark of Techgen Media Group We publish monthly All rights reserved under the US International and Pan-American Copywrite Conventions No part of this publication may be reproduced stored in a retrieval system or transmitted in any form or by any means such as mechanical photocopying electronic recording or otherwise without the prior written permission of Techgen Media Group Contact us at 732-239-8499 for permission Produced in the US

VP SALESAlan Bergp 732-438-5801 c 732-995-6072abergtechgenmediacom

ADVERTISING SALES DIRECTORNeil Kellyp 610-584-5560nkellytechgenmediacom

OFFICE MANAGERACCOUNTINGKyle Grossikgrossitechgenmediacom