High Speed Catamaran Design

Transcript of High Speed Catamaran Design

ARTICLE IN PRESS

0029-8018/$ - se

doi:10.1016/j.oc

�CorrespondiE-mail addre

Ocean Engineering ] (]]]]) ]]]–]]]

www.elsevier.com/locate/oceaneng

Multiple criteria optimization applied to high speed catamaranpreliminary design

H.B. Moraesa, J.M. Vasconcellosb,�, P.M. Almeidac

aFederal University of Para, Belem/Para, BrazilbCOPPE, Federal University of Rio de Janeiro, Brazil

cCOPPE, Rio de Janeiro, Brazil

Received 6 June 2005; accepted 1 December 2005

Abstract

The demand for high-speed craft (mainly catamarans) used as passenger vessel has increased significantly in the recent years. Looking

towards the future and trying to respond to the increasing requirement, high-speed crafts international market is passing through deep

changes. Different types of high-speed crafts are being used for passenger transport. However, catamarans and monohulls have been the

main choice not only for passenger vessel but also as ferryboat.

Generally speaking, the efficient hydrodynamic hull shapes, engine improvements, and lighter hull structures using aluminum and

composite materials make possible the increase in cruising speed.

The high demand for catamarans are due to its proven performance in calm waters, large deck area compared to monohull crafts and

higher speed efficiency using less power. Although the advantages aforementioned, the performance of catamaran vessels in wave

conditions still needs to be improved.

The high-speed crafts (HSC) market is demanding different HSC designs and a wide range of dimensions focusing on lower resistance

and power for higher speed. Therefore, the hull resistance optimization is a key element for a high-speed hull success.

In addition to that, trade-off high-speed catamaran (HSCat) design has been improved to achieve main characteristics and hull

geometry. This paper presents a contribution to HSCat preliminary design phase. The HSCat preliminary design problem is raised and

one solution is attained by multiple criteria optimization technique.

The mathematical model was developed considering: hull arrangement (area and volume), lightweight material application (aluminum

hull), hull resistance evaluation (using a slender body theory), as well as wave interference effect between hulls, calculated with 3D theory

application. Goal programming optimization system was applied to solve the HSCat preliminary design.

Finally this paper includes an illustrative example showing the mathematical model and the optimization solution. An HSCat

passenger inland transport in Amazon area preliminary design was used as case study. The problem is presented, the main constrains

analyzed and the optimum solution shown. Trade off graphs was also included to highlight the mathematical model convergence process.

r 2006 Elsevier Ltd. All rights reserved.

Keywords: High speed craft; Ship design; Multiple criteria optimization

1. Introduction

The Amazon region is one of the poorest areas in Brazil,with a low population density. Few railroads, roadprecariousness and airplane ticket high cost impose theriver as an available alternative to transport cargo andpassenger. The majority of the eight million habitants of

e front matter r 2006 Elsevier Ltd. All rights reserved.

eaneng.2005.12.009

ng author. Tel.: +5521 25628742; fax: +55 21 25628715.

ss: [email protected] (J.M. Vasconcellos).

the states in the Brazilian Amazon region need a low-pricedand reliable means of transport. The rivers in this area are,therefore, an attractive way to develop cargo and passengertransport.Despite this undesirable transport situation in the

Amazon area, some development can be seen. In Belem-Macapa river line, there is one SES (surface effect ships)and some moderate speed monohulls sailing and changingthe old scenario of low speed wood or steel vessels. Newtechnology is also changing the way people at Amazon

ARTICLE IN PRESS

Nomenclature

L total length (m)B catamaran beam (m)b twin hull beam (m)T draught (m)D vessel height (including superstructure) (m)S space between hulls (m)N rpmNtrip crew numberNpass passenger numberPtp average passenger weight (135 kg for long trips

and 80 kg for short trips)Pot cruising power (HP)SPF specific fuel consumption (0.19 kg/HPh ) at

1900 rpm in averageDist distance (km)V cruising speed (knots)Cad consumption—water (l/passenger x day)Pest structure weight (ton)M material cost/ton (aluminum ¼ US$ 5250)LWork hours/ton (600 for simple structures and 900 for

complex structures)

H man–hour cost (US$ 30)Pequi equipment weight (ton)Cest structure cost (US$)Cequi equipment cost (US$)Cma engine cost (US$)Nva number of trip/yearTn sailing time (h)Tp stop time at schedule (h)CTA building cost (US$)sm crew average salary (US$ 710,00)enc social taxes ( 0.87)Alim crew average expenses (food)—US$ 4.00Prcomb oil cost (US$/t)Prlub lub cost (US$/t)Ts cruising time (s)Cf frictional resistance coefficientRn Reynolds numberV speed (m/s)L length (m)Am wetted area (m2)P density (kg/m3)m viscosity (m2/s)

H.B. Moraes et al. / Ocean Engineering ] (]]]]) ]]]–]]]2

travel by boat. Comfortable armchairs are replacing thehammocks (very common in Amazon area) providing moresafety to passengers. Air conditioning, audio and videoservices are also bringing leisure to passengers.

Major changes are necessary to transform the existingboat transport in a reasonable and reliable way totransport people in Amazon area. The creation of privatepassenger ports is urgent in almost all the Amazon area. Itis unbelievable, but many times passengers can spend up tothree days for boat departure. In these cases manypassengers end up using the boat as temporary hostels.

Currently, investments in updating equipments andtechnologies have been the main concern for ship ownersin Amazon region. Competition in Amazon passengertransport market is remarkable. Traditional companies aretrying to improve their management procedures andrelationship with their clients. Nevertheless, technologicaladvancements in Amazon region are insignificant ifcompared to the real needs (see Figs. 1 and 2), somechanges can be noticed. Comfort, safety and speed are themain challenges to achieve.

Fig. 3 presents the increasing in speed considering boatsused in Amazon region since 1950. The graph shows anaverage speed of 13 knots. In 1998 the Arapari III craftstarted to operate in Belem-Macapa line with cruisingspeed of 28 knots. In 2000 the craft named Atlantico Iserving the same line started to sail at cruising speed of 30knots. These new aluminum vessels reduced the trip Belem-Macapa from 24 to 11 h in average.

This paper focuses the HSCat preliminary design withthe objective of helping designers, ship owners and

government investment analysts to assess the potential ofpassenger transport in many Amazon routes. Although thefocus is the Amazon area, the mathematical model has abroad-spectrum and can be applied in many places.The mathematical model presented herein is for cata-

maran craft. Monohull vessel mathematical model shouldalso be assessed and compared to determine the bestchoice.

2. Design methodology

The mathematical model developed herein for HSCatriver transport preliminary design was organized as per theflowchart presented in Fig. 4.This paper includes module II (HSCat Preliminary

Design) and IV (HSCat Cost Analysis) for HSCatpreliminary design.

3. HSCat preliminary design

3.1. Power evaluation

Hull hydrodynamic resistance and power assessment isone of the most important aspect to evaluate in HSCdesign during preliminary phase. The method appliedherein to build the mathematical model is based on slenderbody theory for wave resistance and flat plate theory tofrictional resistance.Moraes et al. (2004) researched and compared the

slender body theory and the 3D theory results. A broad-spectrum analysis was carried out to compare wave

ARTICLE IN PRESS

Fig. 2. A typical terminal in Macapa.

0

5

10

15

20

25

30

35

1940 1960 1980 2000 2020

Year

Sp

eed

(kn

ots

)

Fig. 3. Passenger boat speed in Amazon region.

Fig. 1. A poor ‘‘terminal’’ in Rondonia.

H.B. Moraes et al. / Ocean Engineering ] (]]]]) ]]]–]]] 3

ARTICLE IN PRESS

HSCat Preliminary Design(Module II)

- Volume and Weights - Areas- Hydrostatic Parameters - Power Preliminary Evaluation

Cost Analysis

(Module IV)

Terminal Preliminary Design

(Module III)- Area - Equipment- Number of Docks

Requirements(Module I )

- Distance - Time- Physics and Operational Constraints - Number of Passengers, etc...

Fig. 4. HSCat river transportation preliminary design diagram.

H.B. Moraes et al. / Ocean Engineering ] (]]]]) ]]]–]]]4

resistance for different models. Monohull and catamaranmodels were tested to determine the interference phenom-enon. Even though research is in place, the slender bodyapplication theory was applied in preliminary design phaseto select a suitable model. The 3D theory models are morecomplex and time consuming. They use a CFD approachand in the author’s point of view should be reserved toadvanced design phases.

3.1.1. Slender body theory (wave resistance)

The wave resistance (Rw) evaluation using the slenderbody theory is based on the wave energy behavior. Themethod was developed by Michell (1889).

The interaction effect between the twin catamaran hullsis considered by using the image method that is equivalentto assess a monohull resistance when displacing along thechannel center line. An algorithm was implemented inSLENDER Fortran program by Williams (1994).

3.1.2. Flat plate theory (frictional resistance)

Frictional resistance is important when the hull isoperating at low speed. In some cases the frictionalresistance can achieve 80% of total resistance.

Following Froude (1872) flat plate hypothesis, manyformulations were proposed establishing that the shipfrictional resistance is approximately the same as a flatplate with the same wetted area.

The ITTC—International Towing Tank Conference(1957) proposed the line to be used in the HSCatmathematical model. Eqs. (1)–(3) present the frictionalresistance coefficient proposed by ITTC.

Cf ¼0:075

ðlog10Rn� 2Þ2, (1)

Rn ¼VLrm

, (2)

Rf ¼1

2rAmV2Cf . (3)

3.2. Weight Model

Weight evaluation is a fundamental part of preliminaryship design. In special for HSCraft the weight estimates areimportant and can make a difference in performanceassessment. There is few data available to develop astatistical model for high-speed catamaran hull weightevaluation although the importance of establishing areliable weight approaches. The HSCat weight is dividedin lightweight (structure, equipment, engine propulsion),operational (oil, lube, water, crew and food) and cargoweight (passenger, luggage and vehicles).

3.2.1. Lightweight—structure weight

The structure weight is evaluated by mathematical modelof Karayannis et al. (1999). It includes the hull structureand superstructure weights.Karayannis et al. (1999) works present a mathematical

model based on catamarans with 100, 75 and 50m long,twin hull separation ratio (S/L) with range varying from0.20 to 0.26 and limited to aluminum HSCat.The model is also based on Lloyds Register of Shipping

Classification Society—Rules for the classification of specialservice craft (1997). The model uses equipment numeral ‘‘E’’developed by Watson and Gilfillan (1977) for displacementships. This method has been investigated to HS crafts withrelative success. Eq. (4) shows the ‘‘E’’ numeral formula:

E ¼ 2Lðbþ TÞ þ 0:85LðD� TÞ þ 1:6LðB� 2bÞ, (4)

ARTICLE IN PRESSH.B. Moraes et al. / Ocean Engineering ] (]]]]) ]]]–]]] 5

where

B ¼ S þ b, (5)

D ¼ 4þ 0:44B. (6)

Eqs. (7) and (8) present the structural weight as functionof ‘‘E’’ number.

PstructðtÞ ¼ 0:00064E1:7 for ðEo3025Þ, (7)

PstructðtÞ ¼ 0:39E0:9 for ðEX3025Þ. (8)

3.2.2. Lightweight—equipment weight

According to Karayannis et al. (1999), the equipmentweight is a function of HSCat length and breadth. Servicearea weight (Pserv) is estimated between 80 and 100 kg/m2.The following equations are to calculate the equipmentweight.

Ap ¼ðL� BÞ � 138

0:91ðm2Þ, (9)

As ¼ Ap=1:3ðm2Þ, (10)

Npass ¼ As=0:75. (11)

Adopting 90 kg/m2, service area weight (Pserv) isestimated as per Eq. (12) and remaining weight (Prest)calculated as per Eq. (13).

Pserv ¼ Ap � 90� 10�3ðtÞ, (12)

Prest ¼ 0:03� L� B� 10�3ðtÞ. (13)

0 5000 10000 1

Pow

0

10

20

30

40

Eng

ine

Wei

ght (

t)

MTU

CATERPILLAR Engine

WARTS

Main Eng

Fig. 5. Power between 1

The equipment weight (Pequip) is

Pequip ¼ Pserv þ PrestðtÞ. (14)

3.2.3. Lightweight—propulsion weight

Karayannis et al. (1999) propulsion weight modelconsiders main engine, gearbox and waterjet.

Main engine: Fig. 5 shows power and associated weightfor Karayannis et al. (1999) model and several main-engines weight (MTU, Carterpilar, Zvezda, and Wartsila)were plotted for comparison purposes. Generic gas turbinewas also included in Fig. 5. Data was selected from high-speed marine transportation, Jane’s Book (1996–1997) andengine catalog.Fig. 5 shows that up to 5000 hp, results are very similar

and Karayannis et al. (1999) model presents goodcorrelation. Eq. (15) shows the diesel engine mathematicalmodel. Eq. (16) shows the gas turbine model and Eq. (17)the gear box weight mathematical model.

Diesel engine

(Powerp14000 kW or 18800 hp),

PdieselengineðtÞ ¼ 6:82PotðkWÞ

nðrpmÞ

� �0:85

ðtÞ. (15)

Gas turbine

(Power between 6000 kW (8000 hp) and 25 000 kW(33 500 hp))

PgasturbineðtÞ ¼ 3þ 0:00056PotðkWÞðtÞ. (16)

5000 20000 25000 30000

er (HP)

Engine

DIESEL EngineKarayannis Model

ILA Engine

ine Weight x Power

Gas TurbineKarayannis Model

000 and 30,000 hp.

ARTICLE IN PRESSH.B. Moraes et al. / Ocean Engineering ] (]]]]) ]]]–]]]6

Gear box

(Power46000 kW or 8000 hp),

PgearboxðtÞ ¼ 0:00348PotðkWÞ0:75ðtÞ. (17)

3.2.4. Waterjet weight

Fig. 6 presents the waterjet weight as a function ofdelivered power. Kamewa, Nigata and MJP waterjet wherecompared with Karayannis et al. (1999) model (powerbetween 500 kW (670 hp) and 12 000 kW (16 000 hp)). Thegraph proves a good correlation between mathematicalmodel and the waterjet data. Eq. (18) presents the waterjetweight formula.

PwaterjetðtÞ ¼ 0:00018PotðkWÞ1:18ðtÞ. (18)

Other propulsion weights

Karayannis et al. (1999) proposed 55% of engine, gearand waterjet weights to consider other related propulsionweights (Eq. (19)).

Pother ¼ 0:55� ðPdieselengineðor PgasturbineÞ þ Pgearbox þ PwaterjetÞ.

(19)

3.3. Operational weight

The operational weight is a function of distance andtime. It consist of the sum of crew, luggage, fuel, lube oil,fresh water and food. All operational weights are presentedin Eqs. (20)–(25).

�

Crew and luggage weight (Ptrip)Pcrew ¼ Ptp �N tripðtÞ. (20)

0 5000 10000

Power (HP

0

4

8

12

16

Wat

erje

t W

eigh

t (t

)

Waterjet Wei

WATERJET KAMEWA

WATERJET NIIGATA

W

Fig. 6. Waterjet weight Karayannis et al. (199

Fuel weight (Pfuel)

�Pfuel ¼ Power � SPF� Tn � 1:10=1000ðtÞ. (21)

Fuel to auxiliary engine can be evaluated by 10%, asshown in Eq. (21).Time between ports (Tv) can be evaluated by

Tv ¼ Dist=ð1:852� V Þ. (22)

�

Lub weight (Plub)Plub ¼ 0:05� PfuelðtÞ. (23)

�

Fresh water weight (Pfw)Pfw ¼ Cfw � ðNpass þN tripÞ � ðTn=24Þ=1000,

Cfw ¼ 30 l=person=day. ð24Þ

�

Food weight (Pfood)Pfood ¼ Cfood � ðN trip þNpassÞ � ðTn=24Þ=1000ðtÞ,

Cfood ¼ 6 kg=person=day. ð25Þ

The total operational weight (Poper) by trip is

Poper ¼ Ptrip þ Pfuel þ Plub þ Pfw þ Pfood. (26)

3.4. Cost assessment

High speed, smooth hull lines and passenger apprecia-tion are some of the major challenges for catama-ran designers. It is common to see high costs in most ofhigh-speed vessel design. New technology is always more

15000 20000

)

ght x Power

ATERJET MJP

KARAYANNIS Model

9) model and waterjet data.

ARTICLE IN PRESSH.B. Moraes et al. / Ocean Engineering ] (]]]]) ]]]–]]] 7

expensive and high speed is always associated with higheroil consumption.

In HSCat preliminary phase is necessary to assess somecosts, such as: investment, operational and infrastructure.

3.4.1. Building cost

Karayannis et al. (1999) proposed to split the investmentcosts in the following items: structure, equipment andengine.

Structure cost (Cest)

The structure cost is the sum of the structure materialcosts and man/hour fee required for HS craft building. Themathematical model also considers additional 10% formaterial losses. The proposed equation is the following(US$):

Cest ¼ ½Pest �M � 1:10� þ ½Pest � L�H�. (27)

Equipment cost (Cequi)

Karayannis et al. (1999) proposed that equipment costscan be assessed based on equipment weight (Pequi) (US$):

Cequi ¼ 22:000� Pequi. (28)

�

Main engine cost (Cmaq)Total main engine cost comprehends main engine,gearbox and waterjet units. Eqs. (29)–(32) present themathematical model based on equipment catalog.

� Diesel engine cost (Cmd) (US$):Cmd ¼ ð0:262� PotÞ � 103. (29)

�

Gas turbine cost (Ctg) (US$):Ctg ¼ ð0:35� ðPotÞ � 3� 10�6 � ðPotÞ2Þ � 103. (30)

�

Gear box cost (Crv) (US$):Crv ¼ ð57þ 0:0214� ðPotÞ � 3� 10�7 � ðPotÞ2Þ � 103.

(31)

�

Waterjet cost (Cwj):Cwj ¼ ð0:468� ðPotÞ0:82Þ � 103US$. (32)

The total cost considers an additional 40% to otherequipments associated with main engine and man/hourcosts to install all main engine equipment.

Cma ¼ ½Cmdðor CtgÞ þ Crv þ Cwj� � 1:40. (33)

The craft total acquisition cost (CTA) is modeled as perEq. (34).

CTA ¼ Cest þ Cequi þ Cma. (34)

The total cost per trip is modeled as per Eq. (35).

CTAV ¼ CTA=Nva. (35)

The number of trips per year is modeled as per Eq. (36).

Nva ¼ 330=ðTn þ 2TpÞ. (36)

3.4.2. Operational cost

Operational cost comprehends the following items:repairing and maintenance, crew salary and taxes, food,vessel insurance and administration costs.

�

Repairing and maintenance (Crm)Repairing and maintenance costs are estimated as 6% ofcraft total acquisition cost (CTA).

Crm ¼ 0:06� CTA (37)

�

Crew salary and taxes (Csal)Salary and taxes vary from country to country. Anaverage value was adopted (sm) and 14 workers wereconsidered.

Csal ¼ 12� sm �N trip � ð1þ encÞ. (38)

�

Food cost–crew (Calim)Calim ¼ N trip � Alim � 365. (39)

�

Hull insurance (Cseg)The mathematical model considers the insurance cost inBrazil as 3% of craft total acquisition cost (CTA).

Cseg ¼ 0:03� CTA. (40)

�

Administration cost (Cadm)Administration cost is considered as 15% of thefollowing cost:

Cadm ¼ 0:15� ðCsal þ Calim þ Crm þ CsegÞ. (41)

3.4.3. Trip cost

Trip cost comprehends the following items: oil andlubricant costs.

�

Oil cost (Ccomb)Ccomb ¼ Prcomb � Pc (42)

�

LUB cost (Club)Club ¼ Prlub � Plub. (43)

Using all the formulae above, the total cost per trip(CTOT) is determined by Eq. (44).

CTOT ¼ ðCTA � FRCÞ þ Crm þ Csal þ Calim þ Cseg þ Cadm þ Ccomb þ Club.

(44)

The mathematical model for a preliminary HSCat designcan be solved by an optimization procedure. Goalprogramming was used as an optimization technique.

ARTICLE IN PRESS

Table 1

Formulation procedure for the achievement function

H.B. Moraes et al. / Ocean Engineering ] (]]]]) ]]]–]]]8

In the next section a goal programming method overview ispointed out.

Objective Procedure

GiXbi minimize ni

Gipbi minimize pi

Gi ¼ bi minimize (ni þ pi)

4. Optimization model goal programming

The multi-objective goal programming method isbased on the simplex linear programming that wasdeveloped during World War II. The method wasdeveloped to solve military strategic problems. The simplexmethod provides a procedure to optimize linear mathe-matics problems with one objective function. Ignizio (1976)presents a linear and non-linear goal programming as anextension of the simplex method. In the multi-objectivegoal programming approach it is necessary to follow threesteps:

Step1: Identify the decision variables (xj).Step 2: Formulate mathematical model objectives (Gi).Step 3: Formulate achievement function (ak).

All the mathematical model constraints are convertedinto goals in the goal programming procedure withmultiple objectives. The following criteria define theobjectives:

(1)

Designer criteriaExample: Minimize construction costs, maximize tankvolume, minimize forces and tensions, minimize mo-tion, etc.(2)

Resource limitationExample: Material, cost, etc.(3)

All remaining constraints that could affect the decisionvariables.Example: Physic constraints (decision variable non-negative, size constraints in the shipyard, etc.)(4)

The mathematical formulas of the goals (Gi) arefunction of the decision variables (fi(x)):Gi ¼ f iðxÞ. (45)

All objectives are associated to a value (bi) in the righthand side of the equation:

f iðxÞ ¼ ðbiÞ, (46)

where b is the value the objective needs to fulfill.Finally, we can write the goals as

Gi ) f iðxjÞ þ ni � pi ¼ bi; i ¼ 1; 2; 3; . . . ;m

ðm objectivesÞ,

j ¼ 1; 2; 3; . . . ; k ðk variablesÞ,

ð47Þ

where ni and pi are the negative and positive deviationvariables , respectively, from the objective.

Table 1 shows formulation procedure for the achieve-ment function.

For the achievement function is necessary to assign thepriority level (P1, P2,y) for each objective. We can writethe mathematical model asminimize

a ¼ fP1½g1ðn; pÞ�;P2½g2ðn; pÞ�; . . . ;Pk½gkðn; pÞ�g, (48)

where gk(n,p) is the linear function of the deviationvariables, Pk is the function gk(n,p) priority kpm (numberof objectives).Finally, the mathematical model can be written in a

short form, as follows:Find x0 ¼ ðx1; x2; . . . ;xjÞ to minimize

a ¼ ða1; a2; . . . ; akÞ (49)

where

a1 ¼ g1ðn; pÞ

a2 ¼ g2ðn; pÞ

ak ¼ gkðn; pÞ

for,

f iðxjÞ þ ni � pi ¼ bi; i ¼ 1; 2; . . .m ðobjectivesÞ,

j ¼ 1; 2; . . . k ðvariablesÞ ð50Þ

and

x0; ni; pip0.

4.1. Non-linear goal programming

Griffith and Stewart (1961), presented a procedure fornon-linear models using Taylor series expansion. The goalprogramming they used takes the two first terms of theTaylor expansion to approximate the goal functions nearthe test point. Smith et al. (1987) incorporated the thirdterm of Taylor expansion in their goal optimizationprocedure.We can write the nonlinear goal function using the

mathematical model presented in Eq. (51) and in lineariza-tion procedure (52):

Gi ) f iðxjÞ þ ni � pi ¼ bi; i ¼ 1; 2; 3; . . . ;m

ðm objectivesÞ,

j ¼ 1; 2; 3; . . . ; k ðk variablesÞ.

ð51Þ

Considering the function fi(xj) continuously differenti-able and assuming xs one solution for the objectives, the

ARTICLE IN PRESS

Table 2

Belem-Macapa (route data)

Distance 309 miles/574 km

Fleet 6

Fleet age 5Yrs

Time Conventional boat—22h

High speed vessel—12h

Ticket price (average) US$ 27

Passenger capacity (average) 396

Table 3

Belem-Manaus (route data)

Distance 889 miles/1646km

Fleet 11

Fleet age 15 years

Time Conventional boat—100 h

Ticket price (average) US$ 40

Passenger capacity (average) 316

Stops: Breves, Gurupa, Almerim,

Prainha, Monte Alegre, Santarem,

Obidos, Parintins and Itacoatiara

8

H.B. Moraes et al. / Ocean Engineering ] (]]]]) ]]]–]]] 9

function approximation is giving by

f iðxÞ ¼ bi � ni þ pi ¼ f iðxsÞ þXJ

j¼1

qf ðxsÞ

qðxjÞðxj � xs; jÞ,

i ¼ 1; 2; 3; . . . ;m. ð52Þ

The non-linear goal programming optimization techniquewas developed and implemented in a FORTRAN code.

HScat preliminary design mathematical model and goalprogramming optimization technique are added to studytwo passenger transport cases in Amazon area. The first isa Belem-Macapa route and the second case a very longroute Belem-Manaus. Following case studies are presentedand results shown.

5. Case studies

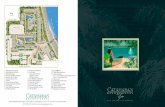

The Amazon area in Brazil (Fig. 7) was selected topresent two case studies. Belem-Macapa line, presented inTable 2, correspond to a short line (574 km–300miles) nostop. Belem-Manaus line, presented in Table 3, represents along line (1646 km–890 miles) with many intermediatescales.

5.1. Case study 1: Belem-acapa route

Belem-Macapa is a line where high-speed vessels havebeen used for passenger transportation since 2001. Theoperation generally is made no stop and through rivers andnatural channels that surround the south of Marajo Islandin Para state (see Fig. 7). The total number of passengersusing this line is around 180,000 on an annual basis.

Preliminary design requirements establish a 400 passengervessel to achieve the current demand. Speed was defined

Fig. 7. Amaz

around 30 knots. Many aspects should be considered beforespeed set up. Experience with existing high speed vesseloperating in Belem-Macapa route indicates speed limit ataround 35 knots. Brazilian Navy determines the speed limitto operate in shallow channels around Marajo Island. Thepresence of small fishing and passenger boats in the sameroute requires a reduced speed. Another aspect that should beconsidered to establish reduced operation speed is thepresence of objects in the river as tree-trunks and small sandislands. Many accidents involving large floating objects withcommercial boats have often been described.

on area.

ARTICLE IN PRESS

Table 4

Four hundred passenger catamaran

Variable V ¼ 25 knots V ¼ 30 knots V ¼ 35 knots

Length (m) 35.41 36.13 37.52

Twin hull breadth (m) 3.91 3.99 3.88

Draft (m) 1.31 1.35 1.33

S/L ratio 0.28 0.27 0.25

0.00 100.00 2

C

Bre

adth

(m

)

2.00

3.00

4.00

5.00

6.00

7.00

Fig. 8. Breadth c

0.00 100.00 2

C

Co

st/p

ax (

US

$)

20.00

40.00

60.00

80.00

100.00

120.00

Fig. 9. Cost/pax

H.B. Moraes et al. / Ocean Engineering ] (]]]]) ]]]–]]]10

The preliminary design mathematical model was appliedand goal programming was used to find out a compromis-ing solution. Table 4 presents the main catamarandimensions for three different speeds.Figs. 8–11 indicate the convergence process during the

optimization phase. Fig. 8 shows the twin hull breadthconvergence for speed equals to 30 knots. The startingpoint was selected and the convergence reaches the value of3.99m for the twin hull breadth after 250 cycles.

00.00

ycles

300.00 400.00

onvergence.

00.00

ycles

300.00 400.00

convergence.

ARTICLE IN PRESS

Fig. 11. Design and average speed.

0.00 100.00 200.00

Cycles

Po

wer

(h

p)

300.00 400.00

0.00

5000.00

10000.00

15000.00

20000.00

25000.00

Fig. 10. Power convergence.

Table 5

Power and cost analysis

Speed (knots) 25 30 35

Power (hp) 3235 4780 6905

Speed gain 0 20 40

Power increased (%) 0 48 113

Cost increased (%) 0 20 49

H.B. Moraes et al. / Ocean Engineering ] (]]]]) ]]]–]]] 11

Fig. 9 presents the convergence process for cost/passenger design characteristic. After 250 steps theoptimization procedure reached a minimal cost/passenger(cost/pax) value of US$ 29.25 considering a 30 knots boatspeed.

Fig. 10 highlights the convergence process for vesselpower design characteristic. Table 5 shows a power studyfor all three speeds. Considering 25 knots as a base speed,table 5 indicates the increasing power and cost perpassenger to 30 and 35 knots. It is important to emphasizethat the model capacity of allowing a power versus costanalysis. Table 5 makes clear the necessity to input highpower and spend much more to achieve a speed higher than25 knots. In this example, the cost increase is almost linearwith speed, although power has a higher relationship.

Fig. 11 shows design and average speed correlation.Average speed considers the reduction of cruising speedduring the trip, due to: traffic near the cities, small boats(fishing and passenger) in the area for high speed craftnavigation, maneuvering, night navigation and very bigfloating objects as tree-trunks and sand islands, specially inthe Amazon River. In Belem-Macapa route 28% of thetotal trip is sailing under reduced speed because safety

reasons pointed out above. Fig. 12 presents the timenecessary to accomplish the total trip at different speeds.We see from the results the small gain in time when largespeed (over 20 knots) is applied in this particular casestudied Belem-Macapa route.

5.2. Case study 2: Belem-Manaus route

Case study two selected the largest Amazon route(1646 km). It is along the Amazon River. Passenger andcargo transport is performed at a very low speed with manystops (nine in the case study presented herein). Anotherimportant route aspect is the current effect (2 knots

ARTICLE IN PRESSH.B. Moraes et al. / Ocean Engineering ] (]]]]) ]]]–]]]12

upstream). Because the restricted area (at southeast ofMarajo Island in Breves) the cruising speed has alsoto be reduced to 16 knots in 167 km.Preliminary designrequirements establish a 300 passenger vessel to achieve thecurrent demand. Speed was established around 30 knots.The presence of small fishing and passenger boats in thesame route requires speed reduction. As indicated inBelem-Macapa route, reduced operation speed isnecessary due the presence of objects in the river as tree-

Fig. 12. Time

0.00 50.00 100.00

C

Tw

in H

ull

Bre

adth

(m

)

3.45

3.50

3.55

3.60

3.65

3.70

Fig. 13. Twin hull bre

Table 6

Three hundred passenger catamaran

Variable V ¼ 25 knots

Length (m) 34.25

Twin hull breadth (m) 3.49

Draft (m) 1.18

S/L ratio 0.25

trunks and small sand islands. The preliminary designmathematical model was applied and goal programmingwas used to find out a compromise solution. Table 6presents the main catamaran dimensions for three differentspeeds.Fig. 13 shows the twin hull breadth convergence for

speed equals to 30 knots. The starting point was selectedand the convergence process reaches the value of 3.56m forthe twin hull breadth.

� speed.

150.00

ycles

200.00 250.00

adth convergence.

V ¼ 30 knots V ¼ 35 knots

35.77 37.00

3.56 3.55

1.19 1.18

0.23 0.21

ARTICLE IN PRESS

0.00 50.00 100.00

Cycles

Co

st/p

ax (

US

$)

150.00 200.00 250.00

70.00

80.00

90.00

100.00

Fig. 14. Cost/pax convergence.

0.00 50.00 100.00 150.00 200.00 250.00

2800.00

3200.00

3600.00

4000.00

4400.00

4800.00

Cycles

Po

wer

(h

p)

Fig. 15. Power convergence.

Table 7

Power study

Speed (knots) 25 30 35

Power (hp) 1965 4017 5523

Speed gain 0 20 40

Power increase (%) 0 104 180

Cost increase (%) 0 47 70

H.B. Moraes et al. / Ocean Engineering ] (]]]]) ]]]–]]] 13

Fig. 14 presents the convergence process for cost/passenger design characteristic. After 200 steps theoptimization procedure reached a minimal cost/passenger(cost/pax) value of US$ 84.56 considering a 30 knots boatspeed.

Fig. 15 highlights the convergence process for vesselpower design characteristic. Table 7 presents a power studyfor all three speeds. Considering 25 knots as base speed,Table 7 shows the increasing of power and cost perpassenger for 30 and 35 knots. Table 7 makes clear theincrease in power and cost to achieve a speed higher than25 knots.

Fig. 16 shows design and average speed correlation.Average speed considers the reduction of the cruising speedduring the trip, due to the same reason as pointed out in

ARTICLE IN PRESS

Fig. 16. Design and average speed.

0

20

40

60

80

100

10 15 20 25

Speed (knots)

Tri

p t

ime

(h)

30 35 40

Fig. 17. Time� speed.

H.B. Moraes et al. / Ocean Engineering ] (]]]]) ]]]–]]]14

Belem-Macapa route: traffic near the cities, small boats(fishing and passenger) in the area of high speed craftnavigation, maneuvering, night navigation and, very bigfloating objects as tree-trunks and sand islands, specially inthe Amazon River. Fig. 17 presents the time necessary toaccomplish the total trip at different speeds. We see fromthe results the important gain in time when large speed(over 20 knots) is applied in this particular case studiedBelem-Manaus route.

6. Conclusion

The preliminary design model presented was developedas a design tool. The goal is to assist in HSCatamarandesign applied for passenger transport. The mathematicalmodel was initially developed for river transport but oceanvessels can also be considered.

Mathematical model applications were presented forboth case studies. The routes chosen for this research werein the Amazon area. The Belem-Macapa case study showeda cost/passenger price similar to that obtained for lowspeed vessels. This indicates a real possibility of changingthe low speed vessel (22 h trip) for a HSCat (13 h trip at 30knots).

Belem-Manaus case study, a long route example,presented many problems usual for inland navigation:speed constraints in many areas, strong current, many

stops and very long trip. As was indicated in the example,the average speed is lower than the cruising speed. Thecost/passenger and time reduced should be investigated inmore detail before an HSCat application is carried out.A large utilization of HSCatamaran is not feasible

because a useful preliminary design evaluation was notapplied.

Acknowledgements

The authors would like to thank the Brazilian NationalScientific and Technical Development Board (Conselho

Nacional de Desenvolvimento Cientıfico e Tecnologico,CNPq), Federal University of Rio de Janeiro and FederalUniversity of Para to supporting this study.

References

Froude, W., 1872. Experiments on surface friction. Bristish Association

Reports.

Griffith, R.E., Stewart, R.A., 1961. A nonlinear programming techniques

for the optimization of continuous processing systems. Management

Science 7, 379–392.

High-speed marine transportation. Jane0s Book, 291 edic- ao, 1996–1997.

Ignizio, J.P., 1976. Goal programming and extensions. Lexington Books,

Lexington, MA.

ITTC, 1957. International Towing Tank Conference.

ARTICLE IN PRESSH.B. Moraes et al. / Ocean Engineering ] (]]]]) ]]]–]]] 15

Karayannis, T., Molland, A.F., Williams, Y.S., 1999. Design data for

high-speed vessels. FAST-99.

Michell, J.H., 1889. The wave resistance of a ship. Philosophical Magazine

45 (Series 5), 106–123.

Moraes, H.B., Vasconcellos, J.M., Latorre, R.G., 2004. Wave resistance

for high-speed catamarans. Ocean Engineering 31 (17–18), 2253–2282.

Smith, W.F., Kamal, S., Mistree, F., 1987. The influence of hierarchical

decisions on ship design. Marine Technology 24 (2), 131–142.

Watson, D.G.M., Gilfillan, A.W., 1977. Some ship design methods.

Transactions of the Royal Institution of Naval Architects 119.

Williams, M.A., 1994. Hull form optimization of SWATH ships. M.Sc.,

Thesis, COPPE/UFRJ, Rio de Janeiro.

Further reading

Lloyds Register of Shipping, 1997. Rules for Classification of Special

Service Craft. Classification Society.