High-purity single-crystal monoisotopic silicon-28 for precise determination of Avogadro’s number

Transcript of High-purity single-crystal monoisotopic silicon-28 for precise determination of Avogadro’s number

ISSN 0012-5008, Doklady Chemistry, 2008, Vol. 421, Part 1, pp. 157–160. © Pleiades Publishing, Ltd., 2008.Original Russian Text © G.G. Devyatykh, A.D. Bulanov, A.V. Gusev, I.D. Kovalev, V.A. Krylov, A.M. Potapov, P.G. Sennikov, S.A. Adamchik, V. A. Gavva, A.P. Kotkov, M.F. Churbanov,E.M. Dianov, A.K. Kaliteevskii, O.N. Godisov, H.-J. Pohl, P. Becker, H. Riemann, N.V. Abrosimov, 2008, published in Doklady Akademii Nauk, 2008, Vol. 421, No. 1, pp. 61–64.

157

The Avogadro constant

N

A

is a physical constantthat relates the notion of mass unit kilogram to theatomic mass. Decreasing the error of determination of

N

A

at a constant atomic mass will make it possible toincrease the accuracy of determination of a mass unit.In addition, determination of the

N

A

value with the leastpossible error is required to refine other fundamentalphysical constants, such as Planck’s constant [1].

Initially,

N

A

was determined on the basis of ratios inmolecular kinetic theory of gases and liquids; since1941, crystals have been measured. Beginning in 1965,measurements have been carried out for high-purity per-fect silicon crystals [2]. The most precise values for theAvogadro constant were obtained in 2003 using the den-sity

ρ

, the lattice constant

a

, and the average molar mass

M

of silicon, measured in 1998 for a sphere producedfrom a high-purity structurally perfect single crystal [3]:

(1)

In these measurements, the Avogadro constant wasdetermined with a relative uncertainty of 3

×

10

–7

,

†

Deceased.

NA 8M/ρ( )a

3---------------.=

which is close to the ultimately achievable value for sil-icon of natural isotopic composition [4]. Isotopic inho-mogeneity of silicon—the error of determination of itsisotopic composition—is the main factor that limits theaccuracy of determination. Earlier, in [5], the authorsdescribe an attempt to refine the Avogadro constantusing isotopically enriched silicon-28 (99.02%). How-ever, it was impossible to decrease the uncertainty indetermining

N

A

as compared to measurements on natu-ral silicon due to an insufficient degree on isotopicenrichment and chemical purity of the material. TheInternational Council of Directors of State Institutes onMass Measurement of the European Commission(CIPM) has organized the AVOGADRO scientificproject with the goal to determine the Avogadronumber with an uncertainty of 2

×

10

–8

. TheAvogadro constant can be refined by using a highlyenriched, chemically pure, and structurally perfectsingle crystal of silicon-28. The high isotopic purity ofenriched

28

Si will make it possible to increase the accu-racy in determining the average molar mass

M

. Therequirements on the quality of the material for theAVOGADRO project are given in Table 1.

This work deals with the development of a methodand production of the material meeting the require-ments of the AVOGADRO project.

To achieve the required concentration of the silicon-28 isotope (>99.99%), a centrifugal method was usedfor producing stable isotopes, which was developed andused in Russia for the first time [6]. In view of techno-logical and economic efficiency, silicon tetrafluoride ofnatural isotopic composition was used as a compoundfor centrifugal enrichment of silicon-28. A special cen-trifugal setup and a technology for production of sili-con-28 tetrafluoride with extremely high concentra-tions were developed in the Tsentrotekh-EKhZ Scienceand Technology Center. As a result of this work, sili-con-28 tetrafluoride with a content of the main isotopeof 99.992–99.996% was produced in the required

High-Purity Single-Crystal Monoisotopic Silicon-28 for Precise Determination of Avogadro’s Number

Academician

G. G. Devyatykh

a

†

, A. D. Bulanov

a

, A. V. Gusev

a

, I. D. Kovalev

a

, V. A. Krylov

a

, A. M. Potapov

a

, P. G. Sennikov

a

, S. A. Adamchik

a

, V. A. Gavva

a

, A. P. Kotkov

a

,

Corresponding Member of the RAS

M. F. Churbanov

a

,

Academician

E. M. Dianov

b

,A. K. Kaliteevskii

c

, O. N. Godisov

c

, H.-J. Pohl

d

, P. Becker

e

, H. Riemann

f

, and N. V. Abrosimov

f

Received January 23, 2008

DOI:

10.1134/S001250080807001X

a

Institute of Chemistry of High-Purity Substances, Russian Academy of Sciences, ul. Tropinina,Nizhni Novgorod, 603650 Russia

b

Research Center of Fiber Optics, Russian Academy of Sciences, ul. Vavilova 38, Moscow, 116942 Russia

c

Tsentrotekh-EKhZ Science and Technology Center, pr. Stachek 47, St. Petersburg, 198096 Russia

d

VITCON Projectconsult GmbH, Otto-Schott-Str. 13, D-07747 Jena, Germany

e

Physikalisch-Technische Bundesanstalt, Bundesallee 100, 38116 Braunschweig, Germany

f

Institut für Kristallzucht, Max-Born-Str. 2, D-12489 Berlin, Germany

CHEMISTRY

158

DOKLADY CHEMISTRY

Vol. 421

Part 1

2008

DEVYATYKH et al.

amount. The content of impurities in it was determinedby high-resolution IR Fourier spectroscopy and gaschromatography and was as follows (mol %): Si

2

F

6

O,(2.0

±

0.6)

×

10

–1

; CO

2

, (1.0

±

0.3)

×

10

–2

; H

2

O, (6.0

±

1.0)

×

10

–3

; HF, (3.0

±

0.5)

×

10

–4

; hydrocarbons C

1

–C

4

,

10

–3

–10

–

5

(Table 2).

High-purity single-crystal silicon-28 was obtainedfrom silicon-28 tetrafluoride by the hydride method [7],which includes the synthesis and ultrapurification ofmonosilane, the production of polycrystalline silicon,and its additional purification and conversion to a sin-gle-crystal ingot by crucibleless zone melting. The tra-ditional scheme of the method was adapted for the pro-duction of monoisotopic material [8]. It was taken intoaccount that silicon tetrafluoride highly enriched in

28

Siwas used as a starting substance. This demanded adetailed study and control of the impurity and isotopiccomposition of silicon-containing substances at all

steps of the process, the selection of methods andequipment providing a high yield of the target product,and the absence of isotopic dilution.

Monoisotopic silane was produced by the reactionof

28

SiF

4

with CaH

2

[9]. Calcium hydride was synthe-sized from distilled calcium metal and hydrogen, whichwas purified by diffusion through a palladium mem-brane. A mixture of isotopically enriched silicon tet-rafluoride with hydrogen of grade A was passedthrough the calcium hydride layer. To reduce the con-tent of fluorine-containing impurities, silane was addi-tionally passed through the reactor with CaH

2

at 180

°

Cat atmospheric pressure. The yield of

28

SiH

4

was 89–92% of the theoretically possible one. The resultingmonoisotopic silane was purified from impurities bycryofiltration and periodic low-temperature rectifica-tion. Rectification was carried out in a metal rectifyingcolumn with a middle feeding reservoir in the discretemode of sampling of low- and high-boiling impurities.The degree of extraction was 0.003–0.006. The yield ofthe high-purity product during purification steps was90–92%.

The content of impurities in the produced monoiso-topic silane was monitored by gas chromatography andgas chromatography/mass spectrometry. The content ofhydrocarbon impurities (C

1

–C

4

) according to theresults of gas chromatography is given in Table 2.

A polycrystalline monoisotopic silicon-28 has beenproduced by heterogeneous decomposition of high-purity silane on the surface of a silicon-28 seed rod con-taining 99.99%

28

Si with a specific resistance of morethan 500

Ω

cm. The technique for production of seedrods was described in [10]. Thermal decomposition ofmonosilane was carried out in an ad hoc single-rodsetup (Steremat). The starting rod, 7 mm in diameter,was fixed between molybdenum current feedthroughsand heated by electrical current. The high-voltage startmethod was used for initial heating of the rod. Theoperating temperature of the rod substrate was 800

°

C,

Table 1.

Requirements on the silicon-28 isotope for the AVOGADRO project

Parameter

28

SiF

428

Si polycrystal

28

Si single crystal

28

Si mass, g 7000 5300 5000

28

Si enrichment, % 99.99 >99.985, isotopic inhomogene-ity <10

–8

>99.985

Chemical purity, % >99.96 >99.9999 >99.9999

Impurity content, % Si

2

OF

6

< 0.05%C

x

H

y

< 0.01%C < 10

16

atom/cm,B < 2

×

10

14

atom/cm

3

, others (without H

2

) < 10

16

atom/cm

3

O, C < 2

×

10

15

atom/cm

3

,B < 2

×

10

14

atom/cm

3

,Others < 10

15

atom/cm

3

Size Rod: length 40–100 cm,diameter 40–80 mm

Diameter >104 mm

Note: Single crystal should have a specific resistance of no more than 80

Ω

cm.

Table 2. Concentrations of hydrocarbon impurities (106,mol %) in 28SiF4 and 28SiH4

Impurity 28SiF4

28SiH4 as syn-thesized

28SiH4purified

CH4 19 ± 4 2300 ± 300 <0.9

C2H6 7400 ± 700 5300 ± 500 <0.4

C2H4 6300 ± 600 4900 ± 500 <0.9

C3H8 26 ± 5 150 ± 20 <0.4

C3H6 27 ± 7 200 ± 20 <0.5

n-C4H10 34 ± 7 210 ± 30 <0.7

iso-C4H10 20 ± 4 130 ± 30 <0.7

DOKLADY CHEMISTRY Vol. 421 Part 1 2008

HIGH-PURITY SINGLE-CRYSTAL MONOISOTOPIC SILICON-28 159

which is optimal for the production of polycrystal-line silicon by pyrolysis of silane [11]. Calculationsof the gas dynamics in the reactor indicate that therate of the gas flow along the heated polycrystallinerod is 0.20–0.25 m/s. Due to intensive convectivemixing of the gas mixture in the reactor, the isotopesare uniformly distributed along the polycrystallinerod. At the ends of a 600-mm rod, the difference in theconcentration ratios of the 29Si and 30Si isotopes to themain 28Si isotope does not exceed 10–9. The depositionrate of polycrystalline silicon layers is 7 × 10–6 g/cm2 s.The yield of silicon at the given growth rate, deter-mined by comparison of the weights of the consumedsilane and produced silicon, was 95%.

First, a test sample of polycrystalline silicon-28 wasproduced in the form of a rod 24 mm in diameterweighing 440 g with a content of the main Si-28 isotopeof more than 99.99%. From this sample, a singlecrystal was grown, which was additionally purified bycrucibleless zone melting. The content of the carbonimpurity in the crystal did not exceed 1 × 1016 atom/cm3

and that of boron was no more than 5 × 1013 atom/cm3.The specific resistance of the crystal was 400–1000 Ω cm [12].

Our findings demonstrated that the above scheme,equipment, and modes of operation make it possible toproduce polycrystalline monoisotopic silicon fromsilane, with parameters meeting the requirements of theAVOGADRO project.

The above technique allowed us to obtain therequired amount (more than 7.5 kg) of high-purity

monoisotopic silane-28 with the following concentra-tions of impurities (106, mol %):

Using thermal decomposition, a sample of high-purity polycrystalline silicon-28 in the form of an ingot62 mm in diameter and 860 mm in length weighingmore than 5.9 kg was produced on the heated rod. The

Ar 1900 ± 400

Si2H6 200 ± 40

Si2OH6 10 ± 2CH4 <6

CHF3 <5

C2H6, iso-C4H10, n-C4H10 <3

C2H4, CO2 <2

C3H6, PH3, C2H5Cl <1

CH3SiH3 <0.9

C3H8, C2H5SiH3 <0.8

Si3H8, (C2H5)2SiH2 <0.6

AsH3, C2H3F, CH3Cl, trans-1,2-C2H2F2

<0.5

H2S, (CH3)2SiH2, cis-1,2-C2H2F2 <0.4

C2F4, C2HF3, (SiH3)2CH2, 1,1C2H2F2

<0.3

GeH4 <0.2

SF6 <0.09

Table 3. Content (at %) of silicon isotopes in silicon compounds

Isotope 28SiF428SiH4 Polycrystalline 28Si

28Si 99.9938 ± 0.0050 99.9930 ± 0.0017 99.99382 ± 0.0024029Si 0.006 ± 0.005 0.0064 ± 0.0014 0.005681 ± 0.00240030Si <0.005 <0.0006 0.000501 ± 0.000350

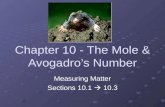

Target silicon-28 monocrystal for the AVOGADRO project (weight, 4530 g; length, 360 cm; maximum diameter, 98 mm).

160

DOKLADY CHEMISTRY Vol. 421 Part 1 2008

DEVYATYKH et al.

ingot contained 3.7 × 1015 atom/cm3 of carbon and6.1 × 1015 atom/cm3 of oxygen. The resulting carboncontent is significantly lower than the limit of its disso-lution in silicon (1017 cm–3), which provides an increasein the yield of structurally perfect single-crystal mate-rial by crucibleless zone melting. A comparative isoto-pic analysis of 28SiF4, 28SiH4, and the polycrystallinesilicon (Table 3) indicated that, within the error ofdetermination, they have the same isotopic composi-tion.

From the produced polycrystal, the target singlecrystal of silicon-28 for the AVOGADRO project wasgrown at the Institute for Crystal Growth (Berlin) bycrucibleless zone melting (figure). The monocrystalcontained impurities of 4.5 × 1013 atom/cm3 of boronand 5 × 1011 atom/cm3 of phosphorus. From thismonocrystal, two spheres 96 mm in diameter with amass of 1 kg were grown at the Australian Center forPrecision Optics (ACPO). These spheres will be usedfor measuring the density, lattice constant, and averagemolar mass of monoisotopic silicon-28.

ACKNOWLEDGMENTS

This work was supported by the International Sci-ence and Technology Center (project nos. 2630 and2980), the Presidium of the Russian Academy of Sciences(program no. 8), and the Council for Grants of the Presidentof the Russian Federation for State Support of Leading Sci-entific Schools (grant no. NSh–9614.2006.03).

REFERENCES

1. Cohen, E.R. and Taylor, B.N., CODATA Bull., no. 63,New York: Pergamon, 1986.

2. Volkov, N.F. and Trubnyakov, Yu.I., Tr. Metrolog. Inst.SSSR, 1979, nos. 234/294, pp. 10–13.

3. Fujii, K., IEEE Trans. Instrum. Meas., 2005, vol. 54,pp. 854–859.

4. Becker, P., Bettin, H., Danzebrink, H-U., et al., Metrolo-gia, 2003, vol. 40, pp. 271–287.

5. Becker, P., Bettin, H., De Bievre, P., et al., IEEE Trans.Instrum. Meas., 1995, vol. 44, no. 2, pp. 522–525.

6. Izotopy: svoistva, poluchenie, primenenie (Isotopes:Properties, Synthesis, Application), Baranov, V.Yu, Ed.,Moscow: Fizmatlit, 2005, vol. 1.

7. Devyatykh, G.G. and Zorin, L.D., Letuchie neorga-nicheskie gidridy osoboi chistoty (Ultrapure VolatileInorganic Hydrides), Moscow: Nauka, 1974.

8. RF Patent No. 2 155 158, Byull. Izobret., 2000, No. 24.9. Devyatykh, G.G., Dianov, E.M., Bulanov, A.D., et al.,

Dokl. Chem., 2003, vol. 391, nos. 4–6, pp. 204–205[Dokl. Akad. Nauk, 2003, vol. 391, no. 5, pp. 638–639].

10. Devyatykh, G.G., Bulanov, A.D., Gusev, A.V., et al.,Dokl. Chem., 2001, vol. 376, nos. 4–6, pp. 47–48 [Dokl.Akad. Nauk, 2001, vol. 376, no. 4, pp. 492–493].

11. Fal’kevich, E.S., Pul’ner, E.O., Chervonnyi, I.F., et al.,Tekhnologiya poluprovodnikovogo kremniya (Technol-ogy of Semiconductor Silicon), Moscow: Metallurgiya,1992.

12. Becker, P., Schiel, D., Pohl, H.-J., et al., Meas. Sci. Tech-nol., 2006, vol. 17, pp. 1854–1860.