High productivity with ELECTRIC ARC · PDF fileScrap preheater furnaces DC furnaces 1 Steel...

Transcript of High productivity with ELECTRIC ARC · PDF fileScrap preheater furnaces DC furnaces 1 Steel...

ELECTRIC ARC FURNACESHigh productivity with ELECTRIC ARC FURNACES

Steelmaking Plants

SMS Demag has been supplying the necessary plant and equipment since theearly beginnings of industrial electric steel-making.

Experienced DESIGN

Until today, we have designed, built andcommissioned over 1275 electric arc fur-naces, worldwide in all sizes and for alarge variety of requirements.

TAILOR-MADE SOLUTIONS

Based on this, we can claim to rankamong the most experienced and suc-cessful plant engineering and manufactur-ing companies supplying the electric steel-making sector. Both, customer feedbackand continuous research and develop-ment, ensure state-of-the-art technologyof electric arc furnaces, resulting in:

Production efficiencyQuality improvementCost reduction

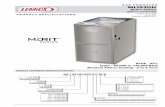

Electric Arc FurnacesSMS Demag

FURNACE TECHNOLOGIESSMS Demag - your partner forFURNACE TECHNOLOGIES

2

AC EAF

CONARC® Scrap preheater

DC EAF

� � �

� � �

� �

3

CONTENT

2 3 Furnace technologies

4 5 Design features

6 7 AC and DC furnaces

8 9 CONARC® furnaces

10 11 Scrap preheating systems,

CONTIARC® furnaces for

cast iron production

12 13 Technology components,

Process control and

visualisation

14 15 Engineering services and

know-how transfer,

TrainingCONTIARC®

� Carbon steel� Special steel� Stainless steel� Cast iron / Hot metal

�

Electric Arc FurnacesSMS Demag

DESIGN FEATURESDESIGN FEATURES

4

SMS Demag Electric Arc Furnaces areknown worldwide for their availability androbustness. Our furnace design reflectsconstant improvements and responds toour customers’ demands.

High productivityLow production costReliable operationLow maintenance

4 2 1 8 7

2

5

6

3

� Power Conducting Arms(PCA) Power-conducting electrode arms, madeof copper-clad steel or aluminium fea-ture low impedance for high powerinput.

� Roof lifting armsThe roof lifting arms are arranged in V-form for three-point roof lifting. Onearm is shorter than the other, so thatafter automatic uncoupling of the rooflift hooks, the gantry with lifted armscan be slewed off with the off-gaselbow still on the roof. With such anarrangement, the complete roof can bereplaced within a short time, resulting inhigh productivity and low downtime.

Top view.

Sectional view.

5

� Water-cooled panelsThe newly designed tube-gap-tube steelpanels ensure a long service life due toexcellent slag retaining conditions.

Reduced slag-door tunnel The new small tunnel depth reduces theamount of scrap in the door area.

Exchangeable shellAn exchangeable shell can be installed.This allows a short production stop anda higher plant availability.

� EBT tapping systemThe pneumatic taphole cylinder is locat-ed below the EBT corner and directlyactivates the selfcleaning taphole open-ing mechanism resulting in a reliableoperation and secures the opening ofthe taphole.

� Large bearing for roof and electrode slewingKingpin and wheels with rail arereplaced by a large bearing as knownfrom a caster turret. This bearing isarranged outside the furnace centerline,thus allowing shortest possible elec-trode arms resulting in less electricallosses thus reducing production cost.

Mast guidingThe electrode masts are aligned andguided during their stroke motion byfour guide roller assemblies. The provensystem allows for easy alignment andlow maintenance cost.

View of EBT side.View of slag doorside.

The SMS Demag AC furnace has provenits capability worldwide at many installa-tions since the beginning of the electricsteelmaking process. Over the years, theAC furnace has been improved in designand further developed. Today’s AC fur-naces are ultra high-powered furnaceswith specific transformer ratings up toand more than 1 MVA/t.

HIGH-IMPEDANCE furnace

Today, high-impedance furnaces are stateof the art. High-impedance furnaces areprovided with low reactances on the sec-ondary side and an additional reactor onthe primary side of the furnace trans-former.

The additional reactance on the primaryside of these furnaces features:

Reduction in electrode currentReduction in operation costReduction in the disturbances to the electrical supply network

POWER CONDUCTINGARMS (PCA)

This development has been proven bythe use of:

Copper-clad electrode armsAluminium electrode arms

These furnaces have advantages such as:Increased power input (i.e. in connec-tion with reconstructions)Fewer secondary conductor losses

AC FURNACE TECHNOLOGYsuitable for:

Single furnacesTwin-shell furnacesCONARC® furnacesScrap preheater furnaces

MAIN FEATURES of AChigh-impedance furnaces

Reduced energy consumptionReduced electrode consumptionFewer electrode breakagesStable arc operationFewer mechanical forces acting onthe electrodes and electrode armsFewer network disturbances

Electric Arc FurnacesSMS Demag

AC AC furnaces

6

AC furnace.

7

SMS Demag is the world leader in DCtechnology as proven by the most produc-tive furnaces in the world. SMS DemagDC EAFs can be equipped with pin-typebottom electrode systems or billet-typebottom electrode systems. Today, SMSDemag furnaces have proven their capa-bility worldwide in a large number ofinstallations.

MAIN FEATURES of SMS Demag DC furnaceoperation

Reduced electrode consumptionReduced energy consumptionImproved thermal and metallurgicalhomogenisation of the meltIntensified stirringLower network disturbances com-pared to AC furnacesPossibility of connecting to weak elec-trical networksComputer simulation for avoiding arcdeflection resulting in perfect bus barrouting

DC TECHNOLOGY suitable for:

Single furnacesTwin-shell furnacesCONARC® furnacesScrap preheater furnaces

DC DC furnaces

1 Steel cylinder2 Electrode sealing ring3 Copper cylinder4 Cooling chamber5 Thermocouple6 Insulation

DC furnace.

Pin-type

bottom electrodes

� Lowest operating cost� Air-cooled bottom electrode� Bottom electrode featuring

a large number of simplesteel pins

� Large contact surface� Life time exceeds refractory

life time of lower shell� No intermediate repairs

Billet-type

bottom electrodes

� Spray-water-cooled bottomelectrode for intensive cooling

� Bottom electrode featuring asteel/copper combination forthermal balance

� Monitoring and control of eachbottom electrode, with thepossibility of individual currentsetting for each electrode

The SMS Demag CONARC® furnace com-bines the conventional CONverter processwith electric ARC steelmaking in a furnacewith two identical shells. The furnace isequipped with one set of electrodes whichare connected to a transformer and can beslewed alternatively to each of the twoshells. Oxygen is injected through a water-cooled top lance which can also be slewedfrom one shell to the other.

The process is split into two stages:The converter process, during which theliquid iron is decarburised by injection ofoxygen through the top lance.The electric arc process, during whichthe electrical energy for melting of thesolid charge and for superheating of thebath to tapping temperature is used.

The typical process starts with the charg-ing of hot metal into a “liquid heel”; asmall part of the previous melt is kept inthe furnace. After the top lance has beenbrought into position, the oxygen blow isinitiated.During the converter phase, the contentsof carbon, silicon, manganese and phos-phorus in the bath are reduced. Thesereactions are exothermic, i.e. they gener-ate heat. Cold material like DRI or scrap isadded to the furnace to utilise this energyand to avoid overheating of the bath.

After completion of the decarburisationprocess, the top lance is slewed away andthe electrodes are brought into operatingposition. In the arcing phase, the remain-ing solid charge material like scrap orsponge iron is fed into the bath until thedesired tapping weight is reached.

The temperature of the bath is thenincreased to the required value, where-upon the heat is tapped into a ladle.

ADVANTAGESHighest flexibility regarding materialinput. Scrap, hot metal or sponge ironpercentage can be fixed according tosteel quality and/or availibility and/or unitpricesUtmost flexibility with respect to energysources (electricity, coal, fuel, gas)Smooth network disturbances

Electric Arc FurnacesSMS Demag

CONARC®CONARC® furnaces

8

1st shell

2nd shell

9

SOLUTIONSCarbon steel Stainless steel

MODERN PROVEN EQUIPMENT

Oxygen-blowing top lance (BOF technology)State-of-the-art arcing process (EAF technology)

THE CONARC® PROCESSFEATURES:

Single-shell CONARC® furnacesTwin-shell CONARC® furnacesScrap preheating systemsOxygen top lancesOxygen/carbon injection systems

CONARC® process flow.

Hot metal charging. CONverter process. ARC process.

Electric Arc FurnacesSMS Demag

SCRAP PREHEATINGSYSTEMSSCRAP PREHEATINGSYSTEMS

10

The SMS Demag basic concept featuresa scrap preheating chamber with fingersets. Below the finger stage there is apost-combustion chamber serving as aninitial safety element of the scrap pre-heating concept. All conditions for chargematerial, e.g. scrap and hot metal, areflexible to meet customer’s demands.The basic requirement that the scrap becharged into the centre of the furnaceshell is assured.

PROCESS TECHNOLOGY

The process technology benefits fromthe basic scrap preheating concept:

The technology is convincingly logicalat ultra-low consumption figures forelectrical energy and electrodegraphite.The post-combustion chamber belowthe scrap chamber guarantees thecomplete combustion of all CO/CO2

gases generated in the furnace shell,so that a maximum quantity of heat istransferred to the scrap and the risk ofCO/CO2 explosions is minimised.

PROCESS EVALUATION

Considering the overall operating coststhe scrap preheating process is very cus-tomer specific. Only under special pre-conditions this process will provide costsavings. Therefore detailed feasibilityevaluation will be provided before follow-ing up this process route.

CIRCOARC®

Circular scrap preheating cham-ber on shell- DC applications- Highly efficient

scrap preheatingtechnology

- Industrialy provenreference fur-naces

MSP

Scrap preheatingchamber on shell- AC/DC application- Flexible use of

charge material - Industrial reliabili-

ty proven by anumber of refer-ence plants

SSP

Scrap preheatingchamber besideshell- AC/DC application- Flexible use of

charge material- Later-on installa-

tions possible- Furnace operation

without preheaterpossible

CONTIARC®

schematic diagram.

11

CONTIARC® CONTIARC® furnaces for cast iron production

Based on years of process know-howand experience, SMS Demag has creat-ed a completely new melting reactorwhich brings benefits through lowestproduction cost.

The CONTIARC® mainly consists of amelting reactor with an inner electrodeholding and guiding system inside a cen-tral water-cooled shaft, which serves toprotect the electrode.

The CONTIARC® is fed continuously withmaterial in a ring between the centralshaft and the outer furnace vessel,where the charged material is continu-ously preheated by the rising processgas in a counter-current flow, whilst thematerial continuously moves down.Located below the central shaft is a“free-melting volume” in the form of acavern.

In 2001 SMS Demag commissioned thefirst CONTIARC® furnace for the produc-tion of cast iron.

TECHNICAL DATA, REFERENCE PLANT

Type DC CONTIARC®

Tapping 60 tttt-time 55 minTransformer 100 MVADC power 65 MWDC current max. 130 kADC voltage max. 650 V

Lower shell.Charging materialdistribution system.

Charging materialfeeding system.

Off gas pipes

Inner vessel

Graphiteelectrode

Charging materialfeeding system

Bottomelectrodes

Chargingmaterialdistributionsystem

The state-of-the-art EAF are used todayonly as a melting machine. Besidedecaburisation and dephosphorisation, all metallurgical work is done in down-stream units.

The EAF itself should operate only as anefficiency melting unit for liquid steel.Therefore it is essential necessary to usethe best technology components, whichensure this modern steelmaking practice.For example the Acoustic Slag foamingControl (ASC) system makes it possibleto cover the electric arcs in an optimisedway with foaming slag by controlling thecarbon & oxygen injection unit.

TECHNOLOGY COMPONENTS

Clean steel automation package(Clean steel cook book)Slag free tapping / shrouded tapping(EBT with slag retaining device / inert-gas atmosphere)SULC automation package(Super Ultra Low Carbon processtechnology and automation package)Steel temperature tracking systemDigital electrode regulation system

Electric Arc FurnacesSMS Demag

TECHNOLOGY COMPONENTSTECHNOLOGY COMPONENTS

12

� Power conducting arms (PCA).

Top lance equipment. �

� Acoustic slag foaming control (ASC).

Oxygen and carbon injectors. �

Process control of the furnaces is basedon programmable logic controllers (PLC’s).All necessary open- and closed-loop con-trol functions are designed to meet bothprocess and safety requirements.

EAF’s today are operated and monitoredvia state-of-the-art Windows-based visuali-sation systems. Hardware platforms usedinclude industrial type PC’s or commercialoffice PC’s running under Windows NT.

The furnace process control system sup-plied by SMS Demag helps to make fur-nace operation efficient and comfortable.A hierarchical structure of clearly arrangedoperator displays as well as interlock dis-plays, alarm lists and trend displays allowfurnace operators to rapidly detect the cur-rent status of the furnace and to appropri-ately intervene.

Level 2 process control will assist the fur-nace operator to perform perfect and costoptimised production. The process modelsstarts at the scrap yard and follows up tothe tapped liquid steel.

The process models will serve either byindividual process dialog screens orthrough common HMI dialog mask servingfor level 1 (Basic automation) and Level 2(Process models)

13

PROCESS CONTROL VISUALISATIONPROCESS CONTROL andVISUALISATION

Conventional automation concept

Level 2 computer Level 2 computer

Level 2 terminal L1-HMI L1/L2-HMI

PCU PCU

SMS Demagintegrated automation concept

Operating screens.

Whenever SMS Demag receives anorder for steelmaking equipment, theengineering services and know-howtransfer are mutually agreed uponbetween both parties already in the proj-ect phase. Thanks to our experience,there is no question that we know thatthis is the fundamental basis for success-ful production equipment.

ENGINEERING/STUDIES

Modern engineering tools includingstress analysis enable SMS Demag todesign their equipment at the highestquality level.Further engineering services and/or stud-ies can be agreed for:

Layout and principal arrangement ofthe new equipmentOptimisation of material trackingInterface check with existing steelshop equipmentVerifying of production capacity, maintechnical indexesSimulation of existing production/material flow to optimise equipmentusageNetwork studies

Electric Arc FurnacesSMS Demag

ENGINEERING and KNOW-HOW ENGINEERING services and KNOW-HOW transfer

14

Class room training.

Training in referenceplant.

Engineering services.

15

TRAININGTRAINING

OFF-SITE TRAINING

The second step of the know-how trans-fer is an off-site training of the cus-tomer’s engineers, technicians andskilled workers.

Here, the key personnel are given theoretical and practical training by SMSDemag’s former customers as well astheir contract partners of today, whooperate similar equipment.

The theoretical and practical training willinclude:

Classification of scrap, alloys and slagagentsCalculation of charge mixPractical furnace operationMetallurgical steel quality performanceEBT tapping practiceSafety instructionsMaintenance trainingTrouble shooting

ON-SITE TRAINING

The main target of training on the cus-tomers’ site is to familiarise their person-nel with hands-on operation of the sup-plied machines and equipment. The oper-ators and maintenance personnel aretrained step by step to prepare them forsuccessful operation of the equipment.This training will start with the cold func-tion test and will end with start-up of liq-uid steel production, thereby attainingthe target production and performancefigures.

Training on site. Training in reference plant. Maintenance.

SMS DEMAG AG

Steelmaking and Continuous Casting Technology Division

Eduard-Schloemann-Strasse 4 · 40237 DüsseldorfP. O. Box 230229 · 40088 Düsseldorf

Phone: +49 (0) 211 881-0 Telefax: +49 (0) 211 881-6692

E-Mail: [email protected]: http://www.sms-demag.com

Germany

MEETING your EXPECTATIONS

H3/

303E

1500

/05/

2006

·ky·

Prin

ted

in G

erm

any