Evaluation and Selection of the Precooling Stage for LNG ...

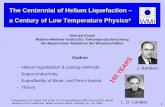

Helium refrigeration and liquefaction using a liquid ... · HeliumRefrigerationandLiquefactionUsing...

Transcript of Helium refrigeration and liquefaction using a liquid ... · HeliumRefrigerationandLiquefactionUsing...

fEc : '60

NBSPB 151398

ecUnlcai ^lote

j$oulder laboratories

92o. 39

HELIUM REFRIGERATION AND LIQUEFACTIONUSING A LIQUID HYDROGEN REFRIGERATORFOR PRECOOLING

BY D.B. CHELTON, J.W. DEAN, T.R.STROBRIDGE, B.W. BIRMINGHAM

AND D.B. MANN

U. S. DEPARTMENT OF COMMERCENATIONAL BUREAU OF STANDARDS

THE NATIONAL BUREAU OF STANDARDS

Functions and Activities

The functions of the National Bureau of Standards are set forth in the Act of Congress, March

3, 1901, as amended hy Congress in Public Law 619, 1950. These include the development andmaintenance of the national standards of measurement and the provision of means and methods for

making measurements consistent with these standards: the determination of physical constants and

properties of materials: the development of methods and instruments for testing materials, devices,

and structures; advisory services to government agencies on scientific and technical problems: in-

vention and development of devices to serve special needs of the Government; and the development

of standard practices, codes, and specifications. The work includes basic and applied research,

development, engineering, instrumentation, testing, evaluation, calibration services, and various

consultation and information services. Research projects are also performed for other government

agencies when the work relates to and supplements the basic program of the Bureau or when the

Bureau's unique competence is required. The scope of activities is suggested by the listing of

divisions and sections on the inside of the back cover.

Publications

The results of the Bureau's work take the form of either actual equipment and devices or pub-

lished papers. These papers appear either in the Bureau's own series of publications or in the journals

of professional and scientific societies. The Bureau itself publishes three periodicals available from

the Government Printing Office: The Journal of Research, published in four separate sections,

presents complete scientific and technical papers; the Technical News Bulletin presents summary

and preliminary reports on work in progress; and Basic Radio Propagation Predictions provides

data for determining the best frequencies to use for radio communications throughout the world.

There are also five series of nonperiodical publications: Monographs, Applied Mathematics Series,

Handbooks, Miscellaneous Publications, and Technical Notes.

Information on the Bureau's publications can be found in NBS Circular 460, Publications of the

National Bureau of Standards ($1.25) and its Supplement (SI.50), available from the Superintendent

of Documents, Government Printing Office, Washington 25, D.C.

NATIONAL BUREAU OF STANDARDS

technical ^lote39

January 27, I960

HELIUM REFRIGERATION AND LIQUEFACTION USING

A LIQUID HYDROGEN REFRIGERATOR FORPRECOOLING

by

D. B. Chelton

J. W. Dean

T. R. Strobridge

B. W. Birmingham

D. B. Mann

NBS Technical Notes are designed to supplement the Bu-reau's regular publications program. They provide a

means for making available scientific data that are of

transient or limited interest. Technical Notes may belisted or referred to in the open literature. They are for

sale by the Office of Technical Services, U. S. Depart-ment of Commerce, Washington 25, D. C.

DISTRIBUTED BY

UNITED STATES DEPARTMENT OF COMMERCE

OFFICE OF TECHNICAL SERVICES

WASHINGTON 25, D. C

Price $ .50

TABLE OF CONTENTS

*

Abstract 1

Introduction 2

General Discussion 2

Hydrogen Refrigerator 5

Helium Refrigerator 10

Helium Liquefier 21

Bibliography 31

Helium Refrigeration and Liquefaction Using

a Liquid Hydrogen Refrigerator for

Precooling

by

D. B. Chelton

J. W. Dean

T. R. Strobridge

B. W. Birmingham

D. B. Mann

ABSTRACT

Consideration is given to the use of a hydrogen refrigerator to

assist in the production of temperatures below those obtained with

hydrogen. A hydrogen refrigerator is used to maintain a precooling

evaporator at or near 21 K in a helium gas circuit. The helium

circuit may be arranged to produce liquid for external use or to pro-

duce refrigeration between 21 K and 4. 2 K in a closed system.

Charts have been developed that show the requirements of the

composite helium - hydrogen system and the effect of heat exchanger

performance. The relative quantities of refrigeration (hydrogen and

helium) at various temperature levels have been determined.

INTRODUCTION

At the present time, a number of hydrogen refrigerators and

liquefiers are being used to maintain experimental apparatus at lowtemperatures. For example, several 21-27 K hydrogen refrigerators

are used for continuous refrigeration of liquid hydrogen bubble cham-bers* » 2. Refrigeration at this temperature level is also being planned

for experimental apparatus associated with nuclear reactors andelectromagnets. Certain applications may require temperature belowthose obtainable with hydrogen.

Hydrogen refrigerators can be used for the production of lowertemperatures by using a hydrogen evaporator to precool a stream of

helium gas in an additional circuit. In some instances, it may befeasible to convert a hydrogen liquefier to perform the function of a

refrigerator for this precooling.

This paper discusses a relatively simple method of using a

hydrogen refrigerator to assist in the production of temperaturesfrom 21 K to liquid helium temperature. With proper considerations

it should be possible to operate the hydrogen precooled helium systemat any temperature within these limits. Consideration in the text is

also given to the production of liquid helium for external use. Cycleinformation is presented with text only sufficient to define the parti-

cular conditions or assumptions upon which the calculation is based.

GENERAL DISCUSSION

A schematic arrangement of the composite helium-hydrogenlow temperature apparatus is shown in Figure 1 . Symbols indicated

on the schematic are used throughout the text. The automatic control

of such a unit has been discussed elsewhere and will not be considered

here. Both the helium and the hydrogen circuits use liquid nitrogen

precooling at 65 K, although 78 K is considered in a few instances.

The liquid nitrogen required as precoolant is given in liters per hoursince, for most applications, it will be supplied as liquid from an ex-

ternal source. It is further assumed that the nitrogen will be supplied

to the unit as saturated liquid at 2 atmospheres.

The hydrogen gas is further cooled, after liquid nitrogen pre-cooling, in a final heat exchanger and expanded at the hydrogen throttle

valve to produce liquid in the evaporator. The evaporator can be a

reservoir as shown, or a bundle of heat exchanger tubes. Hydrogenevaporator temperatures from 21 K (1.23 atm) to 1 5 K (0.13 atm) arestudied.

CM

I

LIQUID NITROGENEVAPORATORS

( PRECOOLANT )

H2 Throttle Valve

LIQUID HYDROGENEVAPORATOR

( PRECOOLANT)

He Throttle Valve

Q2 or-x->

HELIUM RESERVOIRor EVAPORATOR

Figure I. schematic arrangement of low

TEMPERATURE CYCLE

The helium gas, after liquid nitrogen precooling, is passedthrough a counterflow heat exchanger and further cooled in the liquid

hydrogen evaporator. The temperature of the gas is still further

reduced in a final heat exchanger and expanded at the helium throttle

valve where liquid can be formed. Liquid formed in the expansionprocess can be evaporated in the reservoir, as in a refrigerator, or

can be extracted from the reservoir, as in a helium liquefier. If

refrigeration is required at temperatures above liquid helium, the

final heat exchanger is partially by-passed. The quantity of by-passedgas determines the operating temperature of the refrigerator.

If a hydrogen refrigerator is available, the method describedabove is a very simple way of producing temperatures lower than that

obtainable with hydrogen. An alternate method for the final stage

cooling of the helium gas stream would utilize an expansion engine as

indicated by the dotted lines of Figure 1. The expander inlet temp-erature could range from the temperature of the hydrogen evaporator

to some lower temperature. This method requires the use of an ex-

pansion engine operating at low temperatures, but it substantially

increases the thermodynamic efficiency of the cycle. Additional

improvement in the thermodynamic efficiency of the cycle can be

obtained by replacing the helium throttle valve with an expansionengine. Use of such an expander is limited to temperatures abovethat of liquid helium if condensation in the expander is to be avoided.

The performance of this alternate cycle must be computed for the

refrigeration temperature desired. These more extensive calcula-

tions have not been considered in the present paper.

Small capacity refrigeration systems do not necessarilyrequire a high thermodynamic efficiency. Often the simplest cycle is

desirable for reliability and ease of operation. For any cycle,

however, it is desirable to produce refrigeration with a minimum ex-

penditure of energy, since the cost of gas compression equipmentmaterially affects the total capital investment. Compression equip-

ment may account for 20-40 percent of the total system cost.

Sufficient information is presented later to determine the per-formance of a practical helium refrigeration or liquefaction systembased on the cycle indicated by the solid lines in Figure 1. A conven-ient reference is the theoretical performance based on a heat exchanger

efficiency of 100 percent. For the final heat exchangers in the cycle

under consideration, this corresponds to AT = AT. = 0. The design

parameters considered are:

5

1) heat exchanger efficiency (presented as

functions of AT through AT )

1 5

2) liquid nitrogen consumption

3) mass flow

4) power required for compression

The power required reflects only that necessary for compression of

the gas in each circuit. A 65 percent isothermal compressionefficiency is used for the calculations. With the aid of the designcharts presented, it is possible to determine the quantity of refrigera-

tion (Q ) required at liquid hydrogen temperature for a given quantityI;

of refrigeration (Q_) at lower temperatures or for a given quantity of

helium liquefied (x).

All helium calculations are based on the thermodynamic pro-'s A 5

perties presented by Mann and Stewart , Keesom and Zelmanov a

The hydrogen calculations are based on the properties given byWoolley, Scott and Brickwedde . The results of the calculations havebeen smoothed where necessary since they require greater accuracythan obtainable from the above properties.

HYDROGEN REFRIGERATOR

Hydrogen refrigerators usually operate from 21 K to 27 K.

For efficient operation of the helium refrigerator or liquefier, it is

desirable to maintain the hydrogen evaporator as low in temperatureas possible. In fact, it would be desirable, on this basis, to operatethe evaporator at a reduced pressure. Practical considerationsusually limit the precooling temperature to about 15 K (0. 132 atm),

slightly above the triple point of hydrogen. Operating the hydrogenevaporator at a reduced pressure results in a substantial increase in

the work of hydrogen compression although there is a considerablereduction in the work of compression for the total cycle in Figure 1.

Figure 2 shows the work of hydrogen compression (kw) required perunit (kw) of refrigeration at the evaporator temperature for theore-tical performance (100 percent efficiency) of the final heat exchanger.Minimum work occurs for an inlet high pressure near 120 atmospheresand this pressure has been used throughout the remainder of the calcu-

lations. The power required to compress 1 scfm (1 atm, 20 C) of

hydrogen gas from 1 atmosphere to 120 atmospheres is equal to 0. 37

kw„ Compression from 0. 132 atm requires 0. 52 kw per scfm (1 scfm=0. 04 gm/sec).

The refrigeration available as a function of heat exchangerperformance is shown in Figure 3. It is observed that the quantity of

refrigeration is reduced because of finite temperature differences,

by 5 percent per degree K for 65 K precooling and by 6.7 percent per

degree K for 78 K precooling.

The liquid nitrogen required in the precooling evaporator is

affected by both AT and AT.. A lower limit is imposed on the value

of AT. because of the variation in the specific heat of hydrogen. This

limit can be seen in a cooling curve analysis . The quantity of

nitrogen is shown in Figure 4 in units of liters per hour per watt of

refrigeration (Q ) at the hydrogen evaporator. Both Figure 3 and 4

are independent of the hydrogen evaporator temperature.

Since it is thermodynamically advantageous to reduce the

temperature (and pressure) of a hydrogen evaporator, it is of

interest to determine the effect of a reduced pressure on the perfor-

mance of a hydrogen refrigerator not specifically designed for suchoperation. The reduction in temperature (and pressure) will require

that the heat exchangers operate under conditions other than the

original design. The important design parameters influenced byreduced pressure operation are the heat exchanger efficiency and the

pressure drop across the heat exchangers. The heat exchangerefficiency is affected by both the quantity of heat transferred and the

heat transfer coefficients within the heat exchanger.

By considering the basic equations of heat transfer, it can beshown that the heat transfer coefficients will remain approximatelythe same for a given flow rate regardless of pressure. The changein efficiency of a heat exchanger will therefore be determined by the

additional heat removed and its effect on the log mean temperaturedifference. However, for the case considered this effect has beencalculated and found to be insignificant. Thus, neither the change in

the heat transfer coefficients nor the quantity of heat transferred hasan appreciable effect on the heat exchanger efficiency.

The pressure drop across a heat exchanger, for a given flow

rate, is proportional to the specific volume of the process fluid. Fora given heat exchanger, the pressure drop in a 1 5 K hydrogen refrig-

erator will be approximately 10 times the pressure drop in a 21 Krefrigerator. Therefore, the lowest attainable operating temperatureof the evaporator will usually be dictated by the heat exchangerpressure drop. However, the actual value must be determined for

each heat exchanger design and cannot be computed on a generalizedbasis.

E

o

LUor

COC/)

LUtrQ.

XO

a: o

CM

LU

D

Ll

•J9*d2H m>|/aa>| • N0ISS3ddlAI00 ZH JO >JHOM

Af\ -1U - p>.

c - Precoo in a TemD.«j w i ii ^

.

~ **--*-.. 65 ° < " _r iz**- "tjO ""''" !"»«i-</) *""«;\ Q _y - - — _________

*"+- ------o _ ______£

Q _ ~_ _Oll 1

_lflO « ..^*' - Precoo 1

1

1 i a Tfim d, * B -» 7 3° <—' 7 -"-*_Li— r * Bi -»^

^r *•- =^i *>>- -

•

u_i i GLLu ©/VQu

AT3 iK

Figure 3. hydrogen refrigerator

refrigeration available

H CD

CL or

5 CM3 XCO"Z. •*-

o oo $N

CM k_z .c

*~\ \L_J

V)^3 CD

O .t:

N2 Precooling Temp. = 65 °K

t j

1

ftOC 1Utb 1

.

A 4= 15 K „---""— ^** "T*

i~ ^^w^m^** 9 ^

m m m mmOCA "^UeiH-

i 1

1 T "" X1 |

1 1

•

1

'

!

1 1

1 1

C\0 O ''ii

VtLeL .^ "A"Vi=m°k ' 1i LL_L44-+M

I

£S 4 - \\J r\j j_li_—H""TT I

I I

j j

L- ^"^"e^^^* *

^m^ m mmmmm^^~ m

... |

i MAOA ' ; i _[__ _, .UdO i i I

I i

I

I

. __ _, L _4_1__L , J _, I

! I

I I

i

_j_ __ __u J ,_ -n_ 4_,_ .. J L j_ _L;

iI

A|Q I I I I • I 1 ,UltJ A 4- - «. J .—+—'""^ATa = 5 °K I

, ,.,—>--" ^

-Li-^+* "^Ti—J^^H 1

I—" m^**^^»*1

I ! 1

1 !i

nin ' !1

1

!

'; 1

iUloI

Ml ,;

|

1

11 ' 1

i

!'

;

1 ! ! ! 1 1 1 I II! 1 1 ! II 1 1iq1

II hi i ! i i ! I ! I :

i

i !

'

!

i . i i i !

AT3 , °K

Figure 4. hydrogen refrigerator

liquid nitrogen consumption

10

HELIUM REFRIGERATOR

The performance of a helium refrigerator with liquid hydrogenprecooling has been calculated on the basis of the assumptions set

forth in the General Discussion. The design charts presented(Figures 5 through 12) are applicable to refrigeration temperaturesfrom the temperature of the liquid hydrogen evaporator to the temp-erature of liquid helium.

Figure 5 shows the work of compression (kw) required perunit (kw) of refrigeration at the helium evaporator temperature for

theoretical performance of the final heat exchanger, AT_ - 0.

Minimum work occurs for an inlet high pressure near 30 atmospheresand this pressure has been used throughout the remainder of the cal-

culations. The compression of 1 scfm (1 atm, 20 C) of helium gasfrom 1 to 30 atmospheres requires 0.274 kw (1 scfm = 0.0835 gm/sec).

As previously indicated, the quantity of helium refrigeration

(Q_) available is substantially influenced by the hydrogen precooling

temperature. Theoretical refrigeration as a function of the precooling

temperature is shown in Figure 6. It can be seen that an increase in

refrigeration of 80 percent is achieved by reducing the precooling

temperature from 21 K to 1 5 K when the return helium stream is at

a pressure of one atmosphere. An increase in the low pressure of

the system will decrease the available refrigeration but will also

decrease the power of compression. A low pressure of 5 atmospheresresults in a decrease in the work of compression of 47 percent (30

atmospheres high pressure) while the theoretical refrigeration avail-

able is decreased by 20-25 percent. Thus, operation at a slightly

elevated low pressure may be beneficial if refrigeration temperaturesabove liquid helium are desired. If refrigeration is required nearthe normal boiling point of helium (4. 2 K), it is important to keep this

pressure as low as practicable.

Applying the First Law of Thermodynamics to the processshown in the schematic of Figure 1 shows that AT. affects the final

quantity of refrigeration (Q_) and that AT affects the relationship of

Q to the quantity of refrigeration required in the hydrogen evaporator

(Q- ). Figures 7 and 8 indicate the ratio of refrigeration, Q /Q , as a

function of both AT and AT for 21 K and 15 K precooling, respec-tively. The temperature difference at the warm end of the final heliumheat exchanger (AT ) has a profound influence on the refrigeration

available - considerably greater than the influence of AT . In fact,

when AT = 1. 9 K with 21 K precooling, no refrigeration is available

below the hydrogen evaporator temperature. The point of zero refrig-eration with 1 5°TC precooling occurs when AT. = 3. 1°K.

11

The basic assumption of theoretical refrigeration, AT = 0,

requires further consideration for the helium refrigeration cycle. Bya cooling curve analysis , for the conditions under consideration, a

violation of the Second Law of Thermodynamics is observed. Toavoid this difficulty, a modification to the schematic shown in Figure1 must be made for the portion of the helium circuit below the

hydrogen evaporator. This modification is shown in Figure la below.

HighPressure

LowPressure

I

EVAPORATOR

SECONDARYTHROTTLEVALVE

SECONDARYPRESSURE

HX I

Figure la ModifiedSchematic for HeliumRefrigerator

hx n

12

The final helium heat exchanger of Figure 1 is subdivided

into two heat exchangers by the addition of a secondary throttle valve.

The inlet temperature of this valve and the resulting down streampressure is selected to prevent a violation of the Second Law of

Thermodynamics. A cooling curve for this arrangement is shown in

Figure 9. For a 30 atmosphere high pressure and the precooling

temperatures under consideration, a secondary pressure of 5-10

atmospheres is sufficient.

To be consistent with the Second Law of Thermodynamics, if

provisions for the two throttle valves are not made, the minimumvalues of AT are 0. 5 K for 21 K precooling and 1.7 K for 15 Kprecooling. These temperature differences are sufficient to providea AT = at the cold end of the final heat exchanger. The effect of

this AT. can be seen from Figures 7 and 8.

Additional design parameters are given in Figures 10 and 11.

From these figures, it is possible to determine the helium flow rate

and the consumption of liquid nitrogen for a helium refrigerator.

The liquid nitrogen consumption shown in Figure 11 is independent of

the hydrogen evaporator temperature.

The effect of eliminating the nitrogen evaporator in the heliumcircuit is shown in Figure 12 for a 21 K hydrogen evaporator. Theratio of the quantity of helium refrigeration to the quantity of

hydrogen refrigeration is greatly reduced, conclusively indicating the

desirability of this precooling in the helium circuit.

As indicated in the General Discussion, the installation of anexpansion engine across the final helium heat exchanger, as shown bythe dotted line in Figure 1, adds substantially to the thermodynamicefficiency of the cycle. Preliminary calculations indicate that the

addition of an expansion engine having a 21 K inlet temperature andan 85 percent isentropic expansion efficiency will decrease the workof compression by at least a factor of 2 and will increase the avail-

able refrigeration (Q ? ) by a considerable factor. The optimum highpressure, based on work of compression, is reduced to about 15

atmospheres.

13

0)

OC

X

-ST

inenUJrrgl

ooa>

X

rro

Low Pressure = 1 atmAT2 =

.

ac\c\ vbUU \i_ i

vA i

\\ "i

L-

i, rrecooiing lemp.- . _ \ 21 K :

'i

i ~1 . V

I.XCW i-/AA VHKJKJ V ^

\ *^^ j?

Sfc. *?^^* m —J^*^| i L "1—

1

~ +" ~n~ " ~^~

i

_l _. q

v rrecoo ling i e m p.~

~~...

~ S^ : 15 < : . .

^ *- *^^ *^**

200 ~i T"*J """

_

i j

>-v

10 20 30 40

HIGH PRESSURE , atm

Figure 5. helium refrigerator

work of helium compression

14

—rr t r - 1 - ''

i1

™

iT r 1± : ± ±4- .

^ X i 1

• yi ts: r te I

1.4 | V0) " "L _S~ "" '" *

|i

T* S !

s cLI

£ ""''

""" \ " ± X ..' "

.

m- +- " ^rt 4- '" '

o X u . . .-i ._»-/ -+- \</} 1

- V^

1 \1 ^

(/)*~

^^ \

* . -|

,

t

o 1.2 ~ x __ ^v' •

•* - -4 \0, .> X Ji -. CoxX -T - - - V^fc -

* V j*

VO*. --» -^ . -t . . VO/^2 ± . V^ n

O X i_ X ^>0± V/i ._X - X- Xi -Xl x-xv it1— - s K X .__ ±i

. ± SStv .... _. 'it- -h

^-r ^ k. Sl^rv<L V VJVr I

fX 4 - S^ \*o - ^xIX. ^ -sr^G xxlit v \PUs X 4iLU X •— -04-V -

N^ -CO i n V \.t- -1- ^v-/ I.U V*~~

VI

n" -j s r«-1 IS.

Li_ - -- -ps 5s.-j-

-x ~ _ " ss^ .^4~ 5-" \ \J x ^ X

OC J. X it. _.SSL-

<V^4- sl/^> _

H ^J7 / ~k

iX X- 4X 7t sv<n k.

-d - slu£t.<r . _ .it __ . . V^ N7t - 7 ^ V j<S

Sc '

(J X 4_X , , ... _n sm/ /? ^L./^C* 4- 3 tso i? r ^.

I— I: ~ " _"

SSL°V?X S^ -+-4-

i n ft sl°^/r "^ _ sli 1 u.o s ^ ^^- srv X "" "'X _ it "

.. -s^7v^- jr --^ ^r ±"- !-t \i^ , Vr>> 1 _ 4K\J £ ^ . Ik

III i

^kv ^ .LUx

VI— ___ ___x_ _ _x v

%i. 1

^vX .c

4xt s ». 47 7tV_L+__4_4_ ._ I" "" I|_ j_ i V i

>». i

J.j _i-4 ,-- "

~ -!--.^sj. xixr - x ~"

'

r» «? i i

i_l.

~'S !

u.t> _L4-i-L -X _... ' _ 4 ^ Sk

4XQXJ X X '

11^ '

7P4X J... .. _ t j 1- n -' '

"'" ^ '_ "„ ±'"_x_^il . ,

'

'4-i . |_ „. X-. J t i illTi t r X ^ -J

f++7- X

i 1 1 i

15 16 17 18 19 20 21

precooling temperature , °k

Figure 6. helium refrigerator - theoretical

REFRIGERATION

15

:_x "" "

:-F-

• -^- TI

ix

_ X iHx.

! /i '/

4*

i x1

*i

[y // /!

; ! S'f'

!I

1 / /y l/i y [ /\

l/ \ / '11 /' 'v> ./1 >' ,/ j

j1

I

i

!I

1 cK / i/

_*n^ y^ ' #M jT- X /

<> y /1

! '

, !

| >T 1 ,' 1 f\|

i

!Ml

j* j/l /

i

1 II 1 IN' /\

1 i 11

|L/l

|

1 1 l>" >' !

! LLf li!' i m I 1 >T \jf

.^.^r M \

Xj?*\ * 'n ^

'

i ' >^i Mm 1>+Tj !>n !

''

1 ! U^T ' M>f II i

! _> fTI '; T ^M[\ II" in.**^

i III! :

j^xt! ^ !

l Mlo^T ! ^^

•^ ui

: LU"^ ' / 1

%• ^ ' i

; Vn .

' .?

n o 1 M L^ y*

III! | 1 | _>>^ ^r I y— «fi !

i

!

i

' LL-rTl M "!

ii

'.uh i #

f\l IA «-> 1 J*^" i U^ 1 1 !

i

| ] i/ 1^ **>! 1 lO^-M

:! I 1 ! 1

|1

1 II-*^ /

" " I

1 O ' '

:' I'm 1 I _^* 1

;

\ f\'^^^M1 1 jH

f\ ^m^ -— l ' /O- 'v^ Mi ±**^£ £ \ ir 1 Li- ,

Ti '

I

;j m !

1 "1/K^ I

'

'

c c1 1

O M _^«**T^ il'l MM 1 r«f|a> © «— v_***f i mm

11

' •" :

1— •—ftJ O >"f

i

i -.'*'1

i 1

c^ ll !

!%J* **• ~ O --

i

C C -I

j -"i

l^+0*

O O i -- -4- ^?o ft ____: _zji =- -^—

'iO O i

| *«"a> a> ^^^-' wrr^- *- lO -4""""q_ q.

U,!---"T _

CM CMT ^ '

-1- ^ > 1

1 j1

i!ii

i'

i

i '

i

1 1 1 'III i !'

'|

i' 1 !

!

1

i

' '

I i

_l_ _l LI t ! II II 1 II 1 INI i 'Ii I i i 1 J - ... _-

XUJ

e)z<

00 io

UJ

— Si— To\ Ll

CO co o Z6 <J _l

Li. 58UJ |L

tr ll.Lu

COXUJI

Q.

o IT ^y;*-

6 l±_'

1- CMUJcc

UJ UJa>X**-

o Li-

Li

z<

o a: or

CVJ

d1-

<or

2D

2orLU

_l a.

<M

>1<*

IIV

UJ

I

UJo:

D

Ll

16

1

1 1

1

u1

!

' Mil1

i

i j

1

i i

i

i

V ^^i L

^ J/^ /1

^ -^ ^ > !

>*'' >*^ ? d ! if

.^ _*^ ! X r^i* x / ' / '

X ^^ j/1

./in * / ' /

+ ** ** ^ 4

^ *^ V JO _ >^ _V .r

^ ^ ^ -^'

>T l>

lO -"^ rd ± y

£r

_i> i

ov* • '

I

jfv^ ^ ^^^ o in 32 p *

~X-p *

lO •" T— <£>

ii ii

• •

a. a. ie c o +*C t<D <D C\J_1— 1—

1

9 o»• C ""

_ *—

O /-iS 2o O1o o _

: ±1

n nLL U>

CM CMX z.

j

^ ^L —

CD

d

d

d

CM

d

CM

o

LJor

CMX

UJor

CD

X

o

Oh-<or

UJ

z<

UJ

— h-

3 UJ

I ^

CM

>!, 'IV

U.

o

&LlLLUJ

a:

UJ

LLUJIT

D-IUJ

I

CO

UJ

D

Ll

Ul

LlT

uz<

£UJQl

17

LlI

<LUQ_

LU

HIGH PRESSURE

LOWPRESSURE SECONDARY

PRESSURE

hxh \

HEAT TRANSFERRED

Figure 9. helium refrigerator -cooling

CURVE FOR MODIFIED CYCLE

18

q —-—n— n r !

° ±T i- -4- -i -a L . -+. lu l U MMi

1

'

1 !i i

j1+ t

i1 !

ih

1i

1

''

I1 1 1

i

''

i. — — [ | i i

i i . .-+--+----; i : !

| |""" 4""

"! I i M

! MM 1

1

1

i

'!

1

!

1

i

1

11 1

i1

!1

1

T~i ^ h l| ', Miq- - Ml 1

i{

ff

1 !

1Ml' til '

'

1

!

!Mi, iji mi

jJ

|

IIIc m ' J '

: M i i

j

i

;

1b M / '

ii \

''

' ' M' Pf a/> nn linn Tom n T p ;

! Ml i i

:

i i !*4— l|| 1rTCVsUUIIiiy ICIMJJ. i

0) ?| °K /i M II 1

^3 || ! fc. 1 r\ / I I I | || | j

0-i

! 1 1 j 1 1 j

I

1 1

*» T i

1 / j

I

j'

'

I1 ! I

11

]

"T" ' ' ' / |i i M i

i M i

•*•j

j

ji 1 j

i i i

j| | i |

|

*i/ 1

i

!

'

i

j

• H !

i

o i 1 / 1i

zr 1i

'

' / i I

'

I! !

'

'

$ In i

j

!i

i

ji I

\ " 1 ^ 1 y ji ; ,

j

c /i !"^ ^ "^

1 / '

i

"^ li'M*— ~r

i

i i f ! n ii

««- / 1 I'Mn \/ < II MlilM*» i' M 1 M 1

(/) /j'

•* cxLU / 1 UUJ /

|1 |

j | | | ]

1— /i

Sr / I M<* / MM/v- iy M i

ii

Q- y^r/> y i i ii> ' ^ i ^n~ztO O ^ '

' J*~j ^ • ' '

i^."^ '

1 _*^ i^''LL- ^f' ^^T

jdrf^*' Irf^^

CD *** m**^'

x "^ .—'" I ~l

i= 1 l~1

j* - """ -Yeeoolina TemD '

- --«-" **"". |«n oiv-^t-----"* IO «A

1

l

l~

1

| |

^ - , , , . .1....

I 2

AT2 f°K

Figure IO. helium refrigerator - helium

flow rate

19

N2 Precooling Temp .= 65 °K

__ _ _j_ TT'TT ""^TT"-j MX— "' "'

.

ltti

i

i

i

J® no ^ -j_ 1

-r- .08 ^"""»~v_L 1 >\-r'"

!|

'

-1- ta->--^L *iie - iH h *»-M_l? ' 5 o^ , _+_ _L _j_

t- ^ TH-M-aL KC !^-»H* —

1 L |

*-1 TrH-, f

11H— 1 --«.. 1O |

*"**-L</> 11

! TT*- 1

>s I

1

i

1

V.1C 1

I'"*-

!

>s

(/)i

i

Ti r\ri

i i ]

o> .UbI

^MI

._ '

_• !1 ' !

i""'— ! M 1 l

""••.^i

i

I

i

i Mi^""+4-* AT ' 'MM l

! M -T*-^'*! =? iA ' M-^i ^^"s-kr /0 °z^ '-J- J- _i L_!i r^"**H». a i

iiO i

!~"-»-4_1j

1 1

I

^*"1— J_i 1

1 ^"*^>_L 1

i_ — -h i- r ft n1

j1 r^",W».^

j

•' i i i

i II ; I r ^ !

0- Ml^ -txx X^X MM' r^ !^ I Mil ~^ "^ ~l T I'll !

""> rid ! '

ii 1

i!

7k -u^"i

1 MiCO t X X j 1 M Ml-7 ;

i

1

i

!2 1 1 ! !

Ii

J

!

r\ >i I

*-'i

'

1i

!

' Tio i

: r1 1 1

i i^^i

i

i i ji

I

i

'i

*M [..i

i

* -+»»-,_ ' 1 •

i M M ''

^ """-•L ! 1

|jl M!|| 1

I

"""»».. y\ t ' Mi MM •

"-^-r-L^f1

1 5 = e- ' Mil 1

(~\ ^"""4-4 r D °if' Ti ^***-hi_L_i '

•^— l rt""4»Lj""i X - . _|_ X

M*""4-)-.^'

'""

—

'

d r\r>*"^ ^^—1_w .Ot f" *"^ 5*1

i1

_l ! j

1 1i i

. 1-j i]

! !

!

' M!

1

i 1

| Ii! i

i ! 1 i ill III!

II! lilt MM

AT, , °K

Figure II. helium refrigerator - liquid

NITROGEN CONSUMPTION

20

H 2 Precooling Temp. = 21 °K

No N2 Precooling

AT2 =

<;u ^r

ie _ _ __lb

1

\\

.

%^^

\^%

.

10 \-£ '-- % ±

s_^^

If} £_i-i **%I"" s s<1 - s *_^ Q - _______ *-*,

***** s fc ^s^ "^

s ^*" *^ ~'* ^ *** s» * — » «l

Zl - - -*T

.08 .12 .16 .20

RATIO of He REF.to H2 REF. (Q2 /Q| )

Figure 12. helium refrigerator - effect of heat

exchanger performance ( no nitrogen precooling )

21

HELIUM LIQUEFIER

Essentially the same principles apply to the helium liquefier

that apply to the helium refrigerator discussed in the previous section.

However, for the pressures and temperatures considered, there is nodanger of violations of the Second Law of Thermodynamics. Althoughthe work of helium compression in a helium liquefier differs fromthat of a refrigerator, the level of optimum high pressure remainsthe same. This is shown in Figure 13 where the work of helium com-pression per unit of helium liquefied is presented as a function of the

high pressure. The liquid produced is calculated assuming theoreti-

cal performance of the final heat exchanger, AT. = 0, and a lowpressure in the cycle of one atmosphere. The remainder of the cal-

culations are based on the optimum high pressure of 30 atmospheres.The influence of the heat exchanger temperature difference (AT ) onthe quantity of liquid produced (fraction liquefied) is shown in Figure14. If liquid helium at one atmosphere is desired as an end product,

increasing the low pressure will both reduce the fraction liquefied

and cause flashing losses when the liquid is transferred from the

liquefier to an external storage container. It is particularly impor-tant therefore, to keep the low pressure as near one atmosphere as

possible. The pressure drop on the low pressure side of the heliumsystem must be carefully evaluated.

The ratio of helium liquefied to the quantity of hydrogen refrig-

eration required is shown in Figures 15 and 16. The effect of heat

exchanger performance can clearly be seen from these figures. With21 K precooling, no liquefaction occurs when AT. a 1 . 9 K. With15 K precooling, no liquefaction occurs when AT =3.1 K. Therequired helium flow rate and liquid nitrogen consumption are shownin Figures 17 through 20.

The effect of eliminating the liquid nitrogen evaporator in the

helium circuit is shown in Figure 21. The ratio of helium liquefied

to the quantity of hydrogen refrigeration required is greatly reduced,again indicating the desirability of this precooling in the heliumcircuit.

22

a>

+—a5

2400

2000

600

C/)

COUJ 1200rrQ.

SOoa>

800XH—O^cr 400

.... ,

1 !

|1

L\I

\"A~1

\~1

c* -. . rtl . _V 21 °K Drecoo inqi

. *\

L*IV

j

\]

iv J^I [j i A H

nljl—5r

W I ^r

N*_ rf**^^

'

i^ ^^ j

i ^^|

' ^W» w*^^*1 1 _l_ _l_ 1 _J , j_ _^_1

4- - -4T^t -C ^ti

i

!I

I 1

i

! 1

1 j

\S.""^W~j

T" it S -15 K Precoo ing z:

n**-L^ M L^-^-r^TNT"—Li Jj_44--rTi i

i

"— T!

'

!'

!

Il 1 1 !

|1 i ! i ' i

i

i! I...L 1

i

:

i i I i;

:

g 10 20 30 40

HIGH PRESSURE , atm

Figure 13. helium liquefier - work of

helium compression.

23

q x

?f\«-U vr>^

S^s.^^

^^s^O ^^

S. /^T1 I 1 1 c s,w '\S a . . ..."-1 .lb VV °JL.— 4 S si/T iCr*" _.

U_ ^.^/tv* -

nJT®*v. IPlu _ s*j>o M 41--* ^kt //^3 sJOn^» it it .. z^y^ HlT

-'^ ~ ~ x XS-*» r X_J _j T s s _.

*^^—^ s^^- ^t~\

S|sV-> S.«HW s^1 AQ ». \,r— .Uo v n»j

( } s * fcv^ *<s<r ***».«-i -+- .s. . «-> __OC -+- 4- *% = </ o.tT *-h2 k a.t-L %>kL^ f^f '

-n/ rQr^ '

Hid '

s h_Tc°o/-• u^

i

"«<- W'//>^T*>sj ''O

^ sJj^^^fc^^

^s ^*^_^^

O" 1 Hi Mill II ill Mill Mill MM 1 Mil llmllll II II

AT2 , °K

Figure 14. helium liquefier - fraction

liquefied.

24

TTTT "TTT TTTT-! '-U

1]

|

_

;|

.

i

'

'

i. !

|

i ! '1 ;

1'

.^H-*"*^ n,.,,,! , , ! ,

1

ill

"X— L i . i . —-^ .awri - -

1—

.

,J—H-H-H—— \ <

\ -U —-~— 1}—\

:S::'CH-i-rTT:. .._...,-j-p

—

__^rr__g#ip[

|

i i

|'

. ' !

.'

'' ' 1 i<

—i -*^,

1 ,-** J/i 1

tmi

' 1 1 ]

v~ '|

I :i

1

11 ' III 1

1

_->^'r :

1o ' l

!

":..-*- f^T. "! -

...<-

r ~q

* ^ = No ° rHCO <o |

^:

:

Q. Q. -n

'

1

' ***^*

*- i- '+'-'-'-^

o* v :_^i".^ ,, ^^ .

r- e ir:

1

*->f-i

O O gM i: :

i: i

, :i

ii

i! .

j

!1 I

i i!

o !

i 1

''

'

Ii

; !

Of 1 1

l i

::' :';;:! L.

-i hi

.l^al-lkiliiijli_!~ 4444- u _

00O

toO

CM

O

CMO

>i< 'IV

UJ

Z<I

<*— u•— Xo

UJ£.

\ 1-

c < •

\ Ul

i_ ICO

u.z

• HLl_ u uLlI UJ UJor u. XOJ Li. dX UJ

1 *o*~ Xo UJ CMLJ u.

U_ UJ UJUJ _)

Z> a zO_i <

_l ?a> ^ q:X _>

•^ _i u.oUJ tr

o I UJ

V- •a.

<or

10

UJ

XDoLl

25

o5

XWOz<IoXUJ

- I

UJor

CMX

QUJ

UJ

O

CD

X

OOI-<a:

>1,* lIV

I-

UUJLlu_

Ul

XUJ

u.UJ

Dg_j

D_lUJ

I

CO

UJ

XD2

z_i

oouUJ

XQ.

o10

UJ

uz<

ou.

XUJ

0.

26

Precooling Temp.= 2l°K

80

Q)

0)

.2" 60

0)

o 40(A

UJi-<

o

<D

20

i I ZH i I lj lIIj i1

i ~l~ i I

I 2

AT2 , °K

Figure 17 helium liquefier - flow

rate (21° k precooling) .

27

Precooling Temp. = I5°K

o

a>

j= 4

Q>

(/)

- 3UJ

(Z

a> 2

, ,,

!

j

!

i

1

f

//

_J^~

. tf~

i

/]*

Jf

lAi

t

/j

f~

i

/_j

/j/]f

~i

f

/f

//w\

J'

i" /~i

¥/[

i

. /\/

J\ i

j Jf

/\j I

jr 'f:^r 1

\fJf

\J \

Jfs\

\a*'jr

J 1

j/^[x

^^—

-

1> ^!

! V^ i 1 1 '1

!

i i ^n ii M i

i ^.^ i

i II '

'

^rii ^-^r^^^

I

1

i

'!

i

!

!

1 |> Mil

1i

!

1 . 1 1 1 1

i_ I

!

! : 1 III IIi 'I'M ......

j

1 j !

1"'"

! E j ^•

i

I !

I

! '

iiIII | ;

r i T !i

i! i i i 1 1

i i i i i

(I{ j j _j ]

j |I 1

! 1 1 i 1 1

J_J1. \x ! 1 i i i,

i, i ;| :i LJJJJ

AT2 , °K

Figure 18. helium liquefier -flow

rate (15° k precooling) .

28

Q>

X

o(A

to

0.16

0.14

£ 0.12

o 0.10

h-Q.

^ .08

O

.06

H 2 Precooling Temp. = 21 °K

N2 Precooling Temp. = 65 °K

AT5 = 10 °K_______

-1- -

--__«_ . ATo - r\— — rn *"

"*T1

-J- """"------B..._T

*

1

_ A »•j "*—-— ** ? = n k 0.^

' M-t4-f U - 5 K__l_ . . _,_ .„rp ""-•i..^^^ * u

1

j 1

'1 1 r~

--«-„.„ AT« _-_ -

-"-, h=ti 1 ? °K 41

^™ H*^^^*4^_i_"" "**"_ m ^mm * mm ^mm

--__ AT - -~-:

^'p = 5 °w*•"»---1 1 _

CI , ,

""' \** ™ " — ——

1

„1

1 1

,---_____. „__ ... . _-__

-J- -\-i- -\- -4-

. _ ...

~T -J--L-

,—

1

1 1. „_r__.

3O- .04-1

I 2

AT, , °K

Figure 19. helium liquefier - liquid nitrogen

consumption (21° k precooling) .

29

H2 Precooling Temp. = 15 °K

N2 Precooling Temp. =65 °K

AT5 = 10 °K_p

r\ oq028 ---___ : A - = __

z ":'"f"::::::-\~ ii\j

^»

h- • 0,24 H-l i 441 y\\A 2=0

;

5 ^ff%m#ww^1 ._^ =p 4= H -

1? p it it ^ :+:._

r? c-r h- MMz S kl+HH irrmfTr °°K 111 llll4Ufflm\ 0.20 ^ ^=—+ +T"~=^=-r^ —»-

^ +"^ It111 lllllllllllllillAT? S fi °K

1| |

1

|'

|^. </>===-b----l.j

""TITT 11 ---' ~

Q <D n 1 c _ it^_ u. 1

—v — 4- it^ AT « ~ ~ '

O -—======== AT2 *2.:i°<— 11 11

-1 -- - - ___^« = =«L_±A lOU. 1 L.

'

^ l_3: . „, i__

AT, , °K

Figure 20. helium liquefier - liquid nitrogen

consumption (15° k precooling) .

30

cm

ii

Q.

e

o>c

ooo<D

X

1

o>c_or\

O<u

> O -

Q_ *-'

(M " .

^»Z (M.~ 1—° ^12 <J

:.. 1 i

oCM

CO CVI CO

*9», MV

111

JO4—

CD

zo •- <o IV.k. X£ UJ CD\ Z

oCD <

UJ

I

_l

nU. UJ

Li.

hi

Xa.

rr 1-z

CMX UJ

u.

UJ

CDro o U.

O*

UJ XQ 1 HUJ X 7l!

UJ

UJ U.3 UJ zo D

CMn a UJ

qco

X**-

o D

z<

Xo -1

UJ Ll.

<a:

I• UJ

CL_ CMo

UJ

xDCD

Ll

31

BIBLIOGRAPHY

1. B. W. Birmingham, D. B. Chelton, D. B. Mann and H. P.

Hernandez, n Cryogenic Engineering of Hydrogen BubbleChambers", ASTM Bulletin, No. 240, pp. 34-39 (1959).

2. D. B. Chelton and J. W. Dean, "Design and Construction of

a Liquid Hydrogen Temperature Refrigeration System",National Bureau of Standards Technical Note No. 38 (I960).

3. D. B. Mann and R. B. Stewart, "Thermodynamic Propertiesof Helium at Low Temperatures and High Pressures",National Bureau of Standards Technical Note No. 8 (1959).

4. W. H. Keesom, A. Bijl and L. A. J Monte, "Le Diagrammelog T, Sde l'helium, Leiden Communication, SupplementNo. 108c.

5. J. Zelmanov, "The Entropy Diagram for Helium at LowTemperatures", Journal of Physics (USSR), Volume 8,

Number 3, (1944) pp. 135-141.

6. H. W. Woolley, R. B. Scott and F. G. Brickwedde,"Compilation of the Thermal Properties of Hydrogen in Its

Various Isotopic and Ortho-Para Modifications", Journal of

Research, National Bureau of Standards, 41, 379 (1948)

RP 1932.

7. I. L. Zelmanov, Comptes rendus (Doklady) Acad. Sci. URSS,22, 25 (1939).

.S. DEPARTMENT OF COMMERCEFrederick H. Mueller, Secretary

NATIONAL BUREAU OF STANDARDSA. V. Astin, Director

THE NATIONAL BUREAU OF STANDARDS

The scope of activities of the National Bureau of Standards at its major laboratories in Washington, D.C., and

Boulder, Colorado, is suggested in the following listing of the divisions and sections engaged in technical work.

In general, each section carries out specialized research, development, and engineering in the field indicated by

its title. A brief description of the activities, and of the resultant publications, appears on the inside of the front

cover.

WASHINGTON, D.C.

Electricity and Electronics. Resistance and Reactance. Electron Devices. Electrical Instruments. Mag-netic Measurements. Dielectrics. Engineering Electronics. Electronic Instrumentation. Electrochemistry.

Optics and Metrology. Photometry and Colorimetry. Photographic Technology. Length. Engineering

Metrology.

Heat. Temperature Physics. Thermodynamics. Cryogenic Physics. Rheology. Molecular Kinetics. Free

Radicals Research.

Atomic and Radiation Physics. Spectroscopy. Radiometry. Ma6s Spectrometry. Solid State Physics.

Electron Physics. Atomic Physics. Neutron Physics. Radiation Theory. Radioactivity. X-rays. High

Eneigy Radiation. Nucleonic Instrumentation. Radiological Equipment.

Chemistry. Organic Coatings. Surface Chemistry. Organic Chemistry. Analytical Chemistry. Inorganic

Chemistry. Electrodeposition. Molecular Structure and Properties of Gases. Physical Chemistry. Thermo-

chemistry. Spectrochemistry. Pure Substances.

Mechanics. Sound. Mechanical Instruments. Fluid Mechanics. Engineering Mechanics. Mass and Scale.

Capacity, Density, and Fluid Meters. Combustion Controls.

Organic and Fibrous Materials. Rubber. TextUes. Paper. Leather. Testing and Specifications. Poly-

mer Structure. Plastics. Dental Research.

Metallurgy. Thermal Metallurgy. Chemical Metallurgy. Mechanical Metallurgy. Corrosion. Metal

Physics.

Mineral Products. Engineering Ceramics. Glass. Refractories. Enameled Metals. Constitution and Mi-

crostructure.

Building Technology. Structural Engineering. Fire Protection. Air Conditioning, Heating, and Refrigera-

tion. Floor, Roof, and Wall Coverings. Codes and Safety Standards. Heat Transfer. Concreting Materials.

Applied Mathematics. Numerical Analysis. Computation. Statistical Engineering. Mathematical Physics.

Data Processing Systems. SEAC Engineering Group. Components and Techniques. Digital Circuitry.

Digital Systems. Analog Systems. Application Engineering.

• Office of Basic Instrumentation. • Office of Weights and Measures.

BOULDER, COLORADO

Cryogenic Engineering. Cryogenic Equipment. Cryogenic Processes. Properties of Materials. Gas Lique-

faction.

Radio Propagation Physics. Upper Atmosphere Research. Ionospheric Research. Regular Propagation

Services. Sun-Earth Relationships. VHF Research. Radio Warning Services. Airglow and Aurora. Radio

Astronomy and Arctic Propagation.

Radio Propagation Engineering. Data Reduction Instrumentation. Modulation Research. Radio Noise.

Tropospheric Measurements. Tropospheric Analysis. Propagation Obstacles Engineering. Radio-Meteor-

ology. Lower Atmosphere Physics.

Radio Standards. High Frequency Electrical Standards. Radio Broadcast Service. High Frequency Im-

pedance Standards. Electronic Calibration Center. Microwave Physics. Microwave Circuit Standards.

Radio Communication and Systems. Low Frequency and Very Low Frequency Research. High Fre-

quency and Very High Frequency Research. Ultra High Frequency and Super High Frequency Research. Modula-

tion Research. Antenna Research. Navigation Systems. Systems Analysis. Field Operations.

NBS