Heat Exchangers1 Chapter 11 Heat Exchangers (11.1-11.3)

-

Upload

marvin-henry -

Category

Documents

-

view

253 -

download

1

Transcript of Heat Exchangers1 Chapter 11 Heat Exchangers (11.1-11.3)

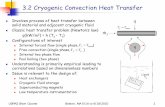

Heat Exchangers 1

Chapter 11

Heat Exchangers (11.1-11.3)

Heat Exchangers 2

Case Study: Milk Pasteurization

• Every particle of milk or milk product must be heated to a specific temperature for a specified period of time to inactivate bacteria that may be harmful to health and cause spoilage.– Public Health aspect

– Quality Considerations

• The extend of microorganism inactivation depends on the combination of temperature and holding time.

• Ontario regulations: – Milk: 63° C for not less than 30 min., 72° C for not less than 16 sec.

– Frozen dairy dessert mix (ice cream or ice milk, egg nog): at least 69° C for not less than 30 min; at least 80° C for not less than 25 sec;

– Milk based products- with 10% mf or higher, or added sugar (cream, chocolate milk, etc) 66° C/30 min, 75° C/16 sec

Heat Exchangers 3

Methods of Pasteurization

• Batch Method:

Uses a jacketed vat, surrounded by circulating water, steam, or heating coils of water or steam.

Heat Exchangers 4

Methods of Pasteurization

• Continuous process: HTST (High temperature short time) pasteurization

Heat Exchangers 5

Continuous Process

Heat treatment is accomplished using a plate heat exchanger.

Heat Exchangers 6

Heat Exchangers

• A heat exchanger is used to exchange heat between two fluids of different temperatures, which are separated by a solid wall.

• Heat exchangers are ubiquitous to energy conversion and utilization. They encompass a wide range of flow configurations.

• Applications in heating and air conditioning, power production, waste heat recovery, chemical processing, food processing, sterilization in bio-processes.

• Heat exchangers are classified according to flow arrangement and type of construction.

All principles that we have learned previously apply. In this chapter we will learn how our previous knowledge can be

applied to do heat exchanger calculations, discuss methodologies for design and introduce performance parameters.

Heat Exchangers 7

Concentric Tube Construction

Parallel Flow CounterflowParallel Flow Counterflow

• - :• :

Parallel Flow CounterflowParallel Flow Counterflow

Heat Exchangers 8

Cross-Flow Heat Exchangers

Finned-Both FluidsUnmixed

Finned-Both FluidsUnmixed

Unfinned-One Fluid Mixedthe Other Unmixed

Unfinned-One Fluid Mixedthe Other Unmixed

Heat Exchangers 9

Shell-and-Tube Heat Exchangers

Baffles are used to establish a cross-flow and to induce turbulent mixing of the shell-side fluid, both of which enhance convection.

The number of tube and shell passes may be varied

One Shell Pass and One Tube Pass

One Shell Pass,Two Tube Passes

Two Shell Passes,Four Tube Passes

Heat Exchangers 10

Compact Heat Exchangers

• Widely used to achieve large heat rates per unit volume, particularly when one or both fluids is a gas.

• Characterized by large heat transfer surface areas per unit volume (>700 m2/m3), small flow passages, and laminar flow.

Heat Exchangers 11

Heat Exchanger AnalysisRecall from Chapter 8 • Expression for convection heat transfer for flow of a fluid inside a tube:

)( ,, imompconv TTcmq

• For case 3 involving constant surrounding fluid temperature:

lms TAUq )/ln( io

iolm TT

TTT

Heat Exchangers 12

Heat Exchanger Analysis

In a two-fluid heat exchanger, consider the hot and cold fluids separately:

)(

)(

,,,

,,,

icoccpcc

ohihhphh

TTcmq

TTcmq

lmTUAq and

Need to define U and Tlm

(11.1) (11.2)

Heat Exchangers 13

Overall Heat Transfer Coefficient

• For tubular heat exchangers we must take into account the conduction resistance in the wall and convection resistances of the fluids at the inner and outer tube surfaces.

oo

io

ii AhkL

DD

AhUA

1

2

)/ln(11

Parallel Flow CounterflowParallel Flow Counterflow

where inner tube surface

outer tube surface LDA

LDA

oo

ii

(11.3a)

ooii AUAUUA

111

Note that:

Heat Exchangers 14

Fouling• Heat exchanger surfaces are subject to fouling by fluid impurities,

rust formation, or other reactions between the fluid and the wall material. The subsequent deposition of a film or scale on the surface can greatly increase the resistance to heat transfer between the fluids.

• An additional thermal resistance, can be introduced: The Fouling factor, Rf. Depends on operating temperature, fluid velocity and length of service of

heat exchanger. It is variable during heat exchanger operation. Typical values in Table 11.1.

• The overall heat transfer coefficient can be written:

ooo

ofio

i

if

ii AhA

R

kL

DD

A

R

AhUA

1

2

)/ln(11"

,"

,

(11.3b)

Heat Exchangers 15

Fin (extended surface) effects• Fins reduce the resistance to convection heat transfer, by increasing

surface area.• Expression for overall heat transfer coefficient includes overall surface

efficiency, or temperature effectiveness, o, of the finned surface, which depends on the type of fin (see also Ch. 3.6.4)

hoho

hfconduction

co

cf

co

hhcc

hAA

RR

A

R

hA

AUAUUA

)(

1

)()()(

1

111

",

",

(11.3c)

where c is for cold and h for hot fluids respectively

Heat Exchangers 16

Tlm: 1. Parallel-Flow Heat Exchangers

where

Parallel Flow CounterflowParallel Flow Counterflow

lmTUAq

)/ln( 12

12

TT

TTTlm

ocoh

icih

TTT

TTT

,,2

,,1

T1 T2

Heat Exchangers 17

Tlm: 2. Counter-Flow Heat Exchangers

where

lmTUAq

)/ln( 12

12

TT

TTTlm

icoh

ocih

TTT

TTT

,,2

,,1

Parallel Flow CounterflowParallel Flow Counterflow

T1 T2

Heat Exchangers 18

Example 11.1A counterflow, concentric tube heat exchanger is used to cool the lubricating oil for a large industrial gas turbine engine. The flow rate of cooling water through the inner tube (Di=25 mm) is 0.2 kg/s, while the flow rate of oil through the outer annulus (Do=45 mm) is 0.1 kg/s. The oil and water enter at temperatures of 100 and 30°C respectively. How long must the tube be made if the outlet temperature of the oil is to be 60°C?

Heat Exchangers 19

Special Operating Conditions

Condenser: Hot fluid is condensing vapor (eg. steam)

Evaporator/boiler: Cold fluid is evaporating liquid

Heat Exchangers 20

Multipass and Cross-Flow Heat Exchangers

To account for complex flow conditions in multipass, shell and tube and cross-flow heat exchangers, the log-mean temperature difference can be modified:

CFlmlm TFT ,

where F=correction factor (Figures 11.10-11.13) and

icoh

ocih

TTT

TTT

,,2

,,1

Heat Exchangers 21

Correction Factor

where t is the tube-side fluid temperature

Heat Exchangers 22

Example 11.2A shell-and-tube heat exchanger must be designed to heat 2.5 kg/s of water from 15 to 85°C. The heating is to be accomplished by passing hot engine oil, which is available at 160°C, through the shell side of the exchanger. The oil is known to provide an average convection coefficient of ho=400 W/m2.K on the outside of the tubes. Ten tubes pass the water through the shell. Each tube is thin walled, of diameter D=25 mm, and makes eight passes through the shell. If the oil leaves the exchanger at 100°C, what is the flow rate? How long must the tubes be to accomplish the desired heating?