Heat Exchangers & Waste Heat Recovery

Transcript of Heat Exchangers & Waste Heat Recovery

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

1/30

HEAT EXCHANGERS&

WASTE HEAT RECOVERYBY

R. SAHAYFOUNDER & CEO

eQube

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

2/30

Waste

Introduction

Type of waste heat recovery

Assessment of waste heat recovery

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

3/30

Introduction

Dumped heat that can still be reused

Value (quality) more important thanquantity

Waste heat recovery saves fuel

What is Waste Heat?

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

4/30

Introduction

Source and Quality Table: Waste heat source and qualityS. No Source of Waste Heat Quality of Waste Heat

1 Heat in fl ue gases The higher the temperature, the greater thepotential value for heat r ecovery

2 Heat in vapour streams As above but when con densed, lat ent heat

also r ecoverable 3 Convective & radiant heat lo st

from exterior of equipment Low grade if collected may be used forspace heating or air preheats

4 Heat losses in cool ing w ater Low grade useful gains if heat is exchangedwith incoming fresh w ater

5 Heat losses in pro vidingchill ed water or in thedispo sal of chilled water

1.High grade if it can be utili zed to reducedemand for refrigeration 2.Low gr ade if refrigeration unit used as aform o f Heat pump

6 Heat stored in prod uctsleaving the process

Quality depends up on temperature

7 Heat in gaseous & liq uideffluents leaving process

Poor if heavily contaminated & thus requiri ngalloy heat exchanger

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

5/30

IntroductionHigh Temperature Heat Recovery

Table: Typical waste heat temperature at high temperaturerange from various sources

Types of Devices Temperature ( 0C) Nickel refining f urnace 1370 1650

Alu mini um ref in in g furnace 650 760

Zinc refin ing furnace 760 1100

Copper refinin g furnace 760 815

Steel heating fu rnace 925 1050

Copper reverberatory fu rnace 900 1100

Open h earth furnace 650 700

Cement kiln (Dry process) 620 730

Glass melting f urnace 1000 1550

Hydrogen plants 650 1000

Solid waste incinerators 650 1000

Fume incinerators 650 1450

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

6/30

Introduction

Medium Temperature HeatRecovery Table: Typical waste heat temperature at medium temperature rangefrom various sources

Types of Devices Temperature ( 0C) Steam boiler exhaust 230 480

Gas tu rbine exhaust 370 540

Recipro cating engin e exhaust 315 600

Recipro cating engine exhaust (turbocharged)

230 370

Heat treatment furnace 425 650

Drying & baking ovens 230 600

Catalytic crackers 425 650

Anneal in g fu rn ace co ol in g syst ems 425 650

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

7/30

Introduction

Low Temperature Heat Recovery Source Temperature 0C

Process steam condensate 55-88

Cooling water from: Furnace doors 32-55

Bearings 32-88

Welding machines 32-88

Injection molding machines 32-88

Anneal in g fu rnaces 66-230

Forming dies 27-88

Air c ompressor s 27-50

Pumps 27-88

Internal combust ion engines 66-120

Air c ondi tion in g and refr ig erat ion con densers 3243

Liquid still condensers 32-88

Drying, baking and curin g ovens 93-230

Hot processed liqui ds 32-232

Hot processed solid s 93-232 T a

b l e :

T y p

i c a

l w a s t e

h e a

t t e m p e r a

t u r e a

t l o w

t e m p e r a

t u r e

r a n g e

f r o m

v a r i o u

s s o u r c e s

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

8/30

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

9/30

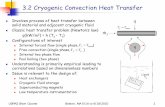

Type of Waste Heat Recovery

Commercial Waste Heat Recovery

Recuperators Heat exchange betweenflue gases and the air

through metallic/ceramicwalls

Ducts/tubes carrycombustion air forpreheating

Waste heat stream onother side

Inlet air f romatmosphere

Outsideducting

Tune plate

Preheatedair

Centre tube plate

Exhaust gasfrom process

Figure 1 : Waste heat recoveryusing recuperator, Source: SEAV

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

10/30

Type of Waste Heat Recovery

Commercial WasteHeat Recovery Metallic radiationrecuperators

F i g u r e 2

. M e t a l l i c R a d i a t i o n R e c u p e r a t o r

( H a r d t e c

h G r o u p

)

Simplest recuperator

Two metal tubes

Less fuel is burned per

furnace load Heat transfer mosly by

radiation

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

11/30

Type of Waste Heat RecoveryCommercial Waste Heat Recovery

Convectiverecuperators

Figure 3. Convective Recuperator

Hot gas throughparallel small diametertubes

Tubes can be baffledto allow gas to passover them again

Baffling increases heatexchange but moreexpensive exchangeris needed

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

12/30

Type of Waste Heat Recovery

Commercial Waste Heat Recovery Radiation/convectivehybrid recuperators

Figure 4. Hybrid Recuperator

Combinations of radiation &convection

More effective heat transfer

More expensive but less

bulky than simple metallicradiation recuperators

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

13/30

Type of Waste Heat Recovery

Commercial Waste Heat Recovery

Ceramic recuperators Less temperature limitations:

Operation on gas side up to 1550 C

Operation on preheated air side to 815 C

New designs

Last two years

Air preheat temperatures

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

14/30

Type of Waste Heat Recovery

Regenerator

Figure 5. Regenerator

Large capacities

Glass and steel meltingfurnaces

Time between the reversalsimportant to reduce costs

Heat transfer in oldregenerators reduced by

Dust & slagging on surfacesheat losses from the walls

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

15/30

Type of Waste Heat Recovery

Heat Wheels

Figure 6. Heat Wheel

Porous disk rotatingbetween two side-by-side ducts

Low to medium

temperature wasteheat recovery systems

Heat transferefficiency up to 85 %

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

16/30

Type of Waste Heat Recovery

Heat Pipe

Figure 7. Heat Pipe

Transfer up to 100 timesmore thermal energy thancopper

Three elements: -sealed container- capillary wick

structure -working fluid

Works with evaporationand condensation

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

17/30

Type of Waste Heat Recovery

Heat Pipe Performance and advantage Lightweight and compact

No need for mechanical maintenance, input power,cooling water and lubrication systems

Lowers the fan horsepower requirement andincreases the overall thermal efficiency of the system

Can operate at 315

C with 60% to 80% heat recovery

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

18/30

Type of Waste Heat Recovery

Heat Pipe Typical application

Process to space heating

- Transfers thermal energy from process exhaustfor building heating

Process to process- Transfers recovered waste thermal energy fromthe process to the incoming process air

HVAC applications- Cooling and heating by recovering thermal energy

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

19/30

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

20/30

Type of Waste Heat Recovery

Economizer Shell and tube heat exchanger Used when the medium containing waste heat is a

liquid or a vapor that heats another liquid

Figure 9. Shell & Tube Heat Exchanger

Shell contains thetube bundle, andusually internal bafflesto direct the fluid

Vapor containedwithin the shell

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

21/30

Type of Waste Heat Recovery

Plate Heat Exchanger

Figure 10. Plate Heat Exchanger

Parallel plates forming a thin flow pass

Avoids high cost of heat exchange surfaces

Corrugated platesto improve heattransfer

When directionsof hot and coldfluids areopposite, thearrangement iscounter current

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

22/30

Type of Waste Heat Recovery

Plate Heat Exchanger Run around coil exchanger

Figure 11. Run Around Coil Exchanger

Heat transferfrom hot to colder

fluid via heattransfer fluid

One coil in hotstream

One coil in coldstream

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

23/30

Type of Waste Heat RecoveryPlate Heat Exchanger

Waste heat boiler

Figure 12. Two-Pass Water Tube Waste Heat Recovery Boiler

Water tube boiler: hotexhaust gases passover parallel tubes withwater

Capacities: 25 m3 to30,000 m3 /min ofexhaust gas

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

24/30

Type of Waste Heat RecoveryHeat Pump

Figure 13. Heat Pump Arrangement

The vapour compressioncycle

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

25/30

Type of Waste Heat RecoveryHeat Pump

Developed as a space heating system

Can upgrade heat >2X the energy consumed by the device

Most promising when heating and cooling capabilities arecombined

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

26/30

Type of Waste Heat Recovery

Heat Pump Thermo compressor Compress low-pressure steam by very high-pressuresteam and reuse as medium pressure steam

Nozzle for acceleration of HP steam to a high velocityfluid.

Figure: Thermo compressor

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

27/30

Introduction

Type of waste heat recovery

Assessment of waste heat recovery

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

28/30

Assessment of waste heat recovery

Quality:

Higher temperatures = Higher quality = Lower heatrecovery costs

Quantity:

The amount of recoverable heat can be calculated as:

Heat Losses

Q = heat content in kCalV = the flow rate of the substance in m3/hr = density of the flue gas in kg/m3Cp = the specific heat of the substance inkCal/kg oC

T = the temperature difference in oCCp (Specific heat of flue gas) = 0.24 kCal/kg/oC

Q = V x x Cp x T

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

29/30

Heat Saving Calculation Example Saving money by recovering heat from hot waste water:

Q = m x Cp x T x

Discharge of the waste water is 10000 kg/hr at 75 C

Preheat 10000 kg/hr of cold inlet water of 20 C

A heat recovery factor of 58%

An operation of 5000 hours per year

The annual heat saving (Q) is:

Assessment of waste heat recovery

www.eqube.co.in, your energy partner

-

8/12/2019 Heat Exchangers & Waste Heat Recovery

30/30

Heat Saving Calculation Example m = 1000 kg/hr = 10000 x 5000 kg/yr = 50000000 kg/yearCp = 1 kCal/kg C

T = (75 20) C = 55 C

= Heat Recovery Factor = 58% or 0.58

GCV of Oil = 10,200 kCal/kg

Equivalent Oil Savings = 159500000 / 10200 = 156372 LCost of Oil = INR 60/L

Monetary Savings = INR 9382320/Annum

Q = 50000000 x 1 x 55 x 0.58= 1595000000 kCal/year

Assessment of waste heat recovery

www.eqube.co.in, your energy partner