Hoover Portapower Vacuum Repair, Vacuum Tips & Vacuum Maintenance

Heat Balance of the Vacuum Distilation Column_Startiev

-

Upload

luciano-renteria -

Category

Documents

-

view

10 -

download

0

Transcript of Heat Balance of the Vacuum Distilation Column_Startiev

-

HEAT BALANCE OF THE VACUUM DISTILLATION COLUMN

KEY FOR IDENTIFICATION OF THE REASON FOR LOW HEAVY VACUUM GAS OIL YIELD

Dicho Stratiev1, Ivelina Shishkova, Petya Dermatova

1Lukoil Neftochim Bourgas R&D Department, 8104 Bourgas, Bulgaria,

e-mail: [email protected]

KEY WORDS: Atmospheric resid vacuum distillation, heavy vacuum gas oil, heat

balance

ABSTRACT

Estimation of heat balance of the vacuum distillation column of atmospheric resid in the Lukoil Neftochim Bourgas identified the reason for a decrease in the heavy vacuum gas oil yield. The hypothesis of a leakage of the heavy vacuum gasoil draw tray was rejected and it was found that the hydraulic resistance in the heavy vacuum gas oil pump around did not allow an increase of its flow rate and taking away the heat required for condensation of heavy vacuum gas oil, contained in atmospheric residue.

Atmospheric residue vacuum distillation process economics is favored by

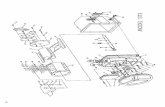

heavy vacuum gas oil (HVGO) yield increase [1]. Therefore, all over the world many designs leading to reconstruction of atmospheric residue vacuum distillation columns in order to increase end boiling point resulting in HVGO yield growth are realized [2,3]. Two vacuum distillation columns for distillation of atmospheric residue produced via crude oil fractionation are included in Lukoil Neftochim Bourgas, Bulgaria crude oil processing scheme. The typical feed of these vacuum columns is atmospheric residue distilled from Ural crude oil (Table I). Within 2006 it has been established that at VD-2 (atmospheric residue vacuum distillation unit - 2) HVGO yield decreases as the unit rate increases. The principle process diagram of VD-2 unit is shown at Figure 1. The vacuum column consists of 4 structural Seltzer packing layers and includes four recycle refluxes, down recycle reflux (DRR); down sharp recycle reflux (DSRR), upper recycle reflux (URR) and upper sharp recycle reflux (USRR). The atmospheric residue is fractionated to light vacuum gas oil (LVGO)(side recovery), heavy vacuum gas oil (HVGO)(side recovery) and vacuum residue, and minimum quantity light diesel fraction (LDF) is drawn out from the column top. VD-2 is wet vacuum column since superheated steam is fed at the bottom to strip entrained lighter hydrocarbons from the vacuum residue. The vacuum column K-101 process parameters and material balance has been recorded as well as produced product physical-chemical parameters have been determined at different rates in order to identify the cause of HVGO yield decrease as the VD-2 rate is increased within April 2006 (Tables II-IV).

44th International Petroleum Conference, Bratislava, Slovak Republic, September 21-22, 2009 1

-

Figure 1 Process diagram of VD-2

44th International Petroleum Conference, Bratislava, Slovak Republic, September 21-22, 2009 2

-

Table I Density and TBP of atmospheric residue, obtained at Ural crude oil distillation (feed for VD-1 and VD-2 units)

Density, d420 0.934

TBP distillation range, OC % recovered % recovered

IBP - 380 10.30 10.30 380-400 4.75 15.05

400-430 8.83 23.88 430-470 14.59 38.47

470-490 6.36 44.83 490-510 4.47 49.30

510-540 6.48 55.78 Over 540 42.73

Table II VD-2 unit vacuum distillation column process parameters Parameters

13.04.2006

14.04.2006

17.04.2006

Rate, t/h 289 274 282

Column K-101 inlet temperature, o C 386 386 382

Temperature beneath 1st packing,

o C 203 196 194

Temperature beneath 2nd packing,

o C 270 268 257

Temperature beneath 3rd packing,

o C 359 355 338

Temperature beneath 4th packing,

o C 366 368 364

Bottom temperature, o C 367 366 364

Top temperature, o C 84 90 90

URR flow, m3/h 111 114 113

USRR flow, m3/h 68 70 70

DRR, m3/h 102 104 102

DSRR, m3/h 13 13 12

LVGO, t/h 15

HVGO flow, m3/h (t/h) 167 (135.5) 167 (135.5) 167 (135.5)

LDF, t/h 1,5 1,5 1,5

Darken product, m3/h (t/h) 7 (6)

URR temperature, o C 73 73 73

USRR temperature, o C 173 173 173

DRR temperature, o C 94 94 94

DSRR temperature, o C 285 285 285

Stripping steam quantity, kg/h 960 960 960

Top residual pressure, mmHg 60.8 47*

Residual pressure at column feeding area, mmHg

68.4

52.5*

Residual pressure at the bottom, mmHg

98.8

148*

* The residual pressure has been measured by absolute pressure gauge with accuracy of 1 mmHg

It is seen from these data that vacuum residue density at 13.04.2006 is

lower (0.95) as compare to typical values of that product (about 1.0). The vacuum residue lower density supposes higher content of HVGO which

44th International Petroleum Conference, Bratislava, Slovak Republic, September 21-22, 2009 3

-

complies with HVGO lower recovery. When the unit rate has been decreased from 289 t/h to 274 t/h, it is established that HVGO recovery increases that corresponds to the higher density of vacuum residue sampled at lower rate. Obviously, the column rate has effect on the extent of deriving HVGO from vacuum residue. One of the primary suppositions for the HVGO low yield has been that HVGO product collective tray is leaky. Table III VD-2 products density data

D4

20

13.04.2006

14.04.2006

Vacuum residue 0.9502 0.9984

HBGO 0.9136 0.9096

LVGO 0.882 0.882

LDF 0.856

Table IV Distillation data of LVGO, HVGO and LDF sampled at 3.04.2006

Distillation, % v/v HVGO, ASTM D-1160

LVGO, ASTM D-86

LDF, ASTM D-86

IBP 254 279 147

5 362 291 184

10 380 298 196

20 394 306 219

30 407 315 234

40 417 323 248

50 432 332 261

60 444 340 275

70 459 349 291

80 474 361 308

90 497 345

95 518 354

98 363

Recover up to 3600, % v/v

79

In order to check this supposition material and heat balances of

sections from which LVGO and HVGO are drawn out has been calculated (Tables V and VI).

44th International Petroleum Conference, Bratislava, Slovak Republic, September 21-22, 2009 4

-

Table V Material and heat balance calculations of the LVGO sampling loop

1st packing material balance Vapor quantity at 1st packing inlet Vin

Vin = LVGO + USRR + steam + LDF = 15 + 54 + 0.96 + 1.5 = 71.5 t/h (1)

Vapor quantity at 1st packing outlet Vout

Vout = steam + LDF = 0.96 + 1.5 (2)

Liquid quantity leaving 1 packing Lout Lout = USRR 1st packing heat balance LVGO vapor enthalpy 106 kcal/kg* Superheated steam enthalpy 675 kcal/kg LDF enthalpy - 91 kcal/kg* LVGO liquid enthalpy 16.74 kcal/kg* LVGO specific heat capacity 0.5 kcal/kg0C* Inlet heat quantity - Qin Qin = 15 000 106 + 54 000 106 + 960 675 + 1500 91 = 8 098 300 kcal/h

(3) Heat quantity released from 1st packing with vapors Qvapour out

Qvapour out = 1500 91 + 960 675 = 784 300 kcal/h (4)

Heat quantity released with USRR, LVGO and URR - Qliquidout

Qliquidout = 54 000 X 16.74+15000 X16.74 + 95000 X 0.5 X (203-73) = 7 329 825 kcal/h

(5) According the heat balance Qin = Qvapour out + Qliquidout

Qvapour out + Qliquidout = 7 329 825 + 784 300 = 8 114 125 kcal/h (6)

Difference between total Qvapour out + Qliquidout and Qin is 15 825 kcal/h and 0,19% of Qin. Hence, there is no rupture of the collective tray from which LVGO is drawn out. *Enthalpy and the specific heat capacity values are calculated by the help of software simulator ChemCad and use of the Lee-Kesler model, that is suitable for hydrocarbon systems [4]

44th International Petroleum Conference, Bratislava, Slovak Republic, September 21-22, 2009 5

-

Table VI HVGO and LVGO drawing out loop material and heat balance calculations

3rd packing material balance

3rd packing inlet vapor quantity Vin is:

Vin = HVGO + DSRR + LVGO + steam + LDF =

= 135.5 + 9.8 + 15 + + 0.96 + 1.5 = 216.7 = 162.7 t/h. (7)

Vapor quantity, computed by software simulator Chemcad at column feeding rate of 289 t/h atmospheric residue has been 165t/h. The phase equilibrium constants have been computed according to Chao-Seader model [5] The vapor quantity computed by equation 7 and by Chemcad is in good compliance.

3rd packing heat balance

LVGO specific heat capacity 0.433 kcal/kg0C* 3rd packing inlet heat - Qin is: Qin = 32.64 X 10

6 kcal/h (Computed by use of ChemCad simulator) Heat quantity, released by DRR QHVGO is:

QHVGO = 86 400 X 0,433 x (359-94) = 9 913 968 kcal/h (8)

Heat quantity, released by URR QLVGO is:

QLVGO = 95 000 X 0.500 X (203-73) = 6 175 000 kcal/h (9)

Heat quantity, released by LVGO QLVGO is: QLVGOprod = 251 049 kcal/h Heat quantity, released by HVGO QHVGOprod is: QHVGOprod = 17 X 10

6 kcal/h Total released heat quantity Qout is:

Qout = QHVGOprod + QLVGOprod + QLVGO + QHVGO =

=17 X 106 + 251 049 + 6 175 000 + 9 913 968 = 33.3 X 10

6 kcal/h (10)

Difference between Qin and Qout, is 0,66.106 kcal/h and is 2%, therefore it is considered as negligible. Hence, the tray from which HVGO is drawn out is not leaky and can not be considered as cause for HVGO low yield.

*The specific heat capacity values are calculated by the help of software simulator ChemCad and use of the Lee-Kesler model [3].

44th International Petroleum Conference, Bratislava, Slovak Republic, September 21-22, 2009 6

-

Material and heat balances calculations show complete compliance

between calculated and real USRR and DSRR flows. That means that supposition for LVGO and HVGO collective trays rupture is not true. Hence, crux for HVGO low yield and 360oC minus fraction low content in LVGO (up to 360oC distilled 79 -80%) is another.

An experiment has been carried out on 14.04.2006 that consists of following: The DSRR quantity has been decreased from 13 to 0 m3/h and hence, DRR quantity increases from 102 to 104 m3/hv i.e. DRO + DSRR total flow decreases from 115 to 104 m3/h. At that H-105 pump pressure along the compressed line increases from 0.9 MPa to 0.95 MPa. That means that along the DRR line resistance exists and impedes DRR flow increase. Another experiment has been carried out on 17.04.2006 that consists of following: The DSRR flow has been increased from 12 to 21 m3/h and at that DRR flow decreases from 102 to 100 m3/h i.e. total flow increases from 112 to 121 m3/h. That once again shows that the reason for impossibility to increase DRR flow is not due to the H-105 pump capacity but to the resistance along DRR line. Because of that reason DRR possesses restricted resource for heat withdrawing out and for condensation of higher HVGO quantities. That is why as the K-101 rate is increased the HVGO drawing out decreases since it is not possible to keep high feed evaporation degree. On 17.04.2006 as the inlet temperature has been increased from 382 to 386oC the packing temperatures increase by about 10oC, HVGO drawing out does not increase but LVGO drawing out increases and vacuum residue drawing out decreases. The LVGO drawing out growth is due to the increase content of high boiling components in this fraction. If the yield of component distilled to 360oC is of 80% order in this fraction the last can not be used as feed for motor diesel fuel with sulfur content of 50 ppm production. It is established from carried out investigations by the research laboratory that among all middle distillate fractions produced from Ural crude oil processing at Lukoil Neftochim Bourgas-AD LVGD from VD is the most difficult to be hydrotreated [6]. That is why the smallest quality fraction worsening makes impossible production of diesel fuel with 50 ppm sulfur content when this fraction is included in the feed for hydrotreatment.

The conclusion may be derived from carried out investigation that crux for the unsatisfactory operation of VD-2 K-101 column at high rate is due to the insufficient resource for heat withdrawing out by DRR. This explains why at low rates HVGO drawing out and LVGO quality are satisfactory.

It has been established that DRR distribution device is damaged and part of it is broken and partially obstruct the line connecting DRR with distribution device within the VD-2 unit plan overhaul. Obviously because of this cause it has been impossible to increase DRR flow. As the DRR distribution device has been rehabilitated it becomes possible to increase its flow and at parameters of vacuum column shown in Table 1, at column rate of 288 t/h and all other equal conditions the DRR flow has been increase from 102 to 140 m3/h and as a result HVGO quantity increases from 135.5 t/h to 141 t/h.

44th International Petroleum Conference, Bratislava, Slovak Republic, September 21-22, 2009 7

-

CONCLUSIONS It is established that the narrow point of VD-2 vacuum column K-101 operation at high rate is restricted heat withdrawing by DRR. Because of that reason at high rates of order over 260 t/h the heat that may be withdrawn by DRR is insufficient for condensation of the all 360 -540 oC fraction quantity contained in atmospheric residue. At high rates the operation personnel is forced to keep lower atmospheric residue evaporation degree since otherwise that HVGO part that could not condensate because of restriction for heat withdrawing by DRR and could not be drawn as HVGO product, will be drawn as LVGO and may even be drawn as LDF because of considerable temperatures increase along the column height. This explains low HVGO drawing out and why part of it remains in the vacuum residue. The removal of hydraulic resistance along the DRR line within the plan overhaul allows HVGO drawing out increase of 2%. REFERENCE

1. S. W. Golden, G. R. Martin, Improve HVGO quality and cutpoint, Hydrocarbon Processing, November, 69 74,1991.

2. N. P. Lieberman, E. T. Lieberman, Design, Installation Pitfalls Appear In Vac Tower Retrofit, Oil&Gas Journal, Aug 26, 57-59, 1991.

3. S. W. Golden, A. W. Sloley, Simple methods solve vacuum column problems using plant data, Oil&Gas Journal, Sept. 14, 74-79, 1992.

4. B. I. Lee, M. G. Kesler, AIChE J.,21,510, 1975.

5. K. C. Chao, J. D. Seader, A General Correlation of Vapor-Liquid Equilibria in Hydrocarbon Mixtures, AIChE Journal, No4,7, 1961.

6. D. Dobrev, D. Stratiev, G. Argirov, T. Tzingov, A. Ivanov, Investigation on middle distillates ultra low hydrodesulphurization at Lukoil Neftochim Bourgas, Oxidation Communication, No3, 668-677, 2007.

44th International Petroleum Conference, Bratislava, Slovak Republic, September 21-22, 2009 8