Headwaters Fall 2013: Energy

-

Upload

colorado-foundation-for-water-education -

Category

Documents

-

view

218 -

download

1

description

Transcript of Headwaters Fall 2013: Energy

H e a d w a t e r s | F a l l 2 0 1 3 1

Colorado Foundation For Water eduCation | Fall 2013

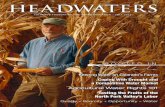

The energy IssueColorado’s Shifting Energy Mix

The Risks and Rewards of Oil and Gas Drilling

Power and Energy in the Water Market

Water = Cooling + Hydropower

C o l o r a d o F o u n d a t i o n f o r W a t e r E d u c a t i o n | y o u r w a t e r c o l o r a d o . o r g

Helping Colorado’s water managers by providing affordable,

real-time wireless monitoring and remote control for:

Surface Water, Groundwater, Water Meters, Automated Gates

w w w . a m c - w i r e l e s s . c o m

Sales 303.588.7504Office 303.279.2002 ext. 1206

A Colorado CompanyAmerican Millennium Corporation, Inc.

H e a d w a t e r s | F a l l 2 0 1 3 1

CFWE Mission in Motion

Correction to Headwaters Summer 2013 Story The article, “The Rio Grande Compact,” which appeared in the Summer 2013 is-sue of Headwaters on page 18, misstat-ed the impact to Colorado’s Rio Grande Compact apportionment that could be wrought by critical habitat designation for the southwestern willow flycatcher in New Mexico. Although some worry critical habitat designation could change Colorado’s water delivery requirements to New Mexico, the U.S. Fish and Wildlife Service says that it cannot use the des-ignation to require the delivery of more water downstream. If any extra water is required, or changes in delivery made, it will be under the terms of the compact. Find additional coverage on this topic online at blog.yourwatercolorado.org.

H e a d w a t e r s | S u m m e r 2 0 1 3

1

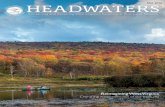

Colorado Foundation For Water eduCation | Summer 2013

Valley

The San Luis Valley’s Groundwater Crisis

Capitalizing on Limited Reservoir Storage

Holistic Land Management Gains Ground

Tracing the San Luis Valley’s Ancient Paths

Water = Community + Legacy + Reclamation

wiTh A ViewRenewing the Future of the Rio Grande Basin

GROWinG CaPaCiTy

MillerCoors Support and Happy Hour CFWE is thrilled to announce a new part-nership with MillerCoors beginning in late 2013. We will kick off the “Watershed Hap-py Hour” series at the Golden Brewery later this year. MillerCoors will host a gathering of their employees and other CFWE sup-porters to honor our work, strengthen rela-tionships and toast water stewardship with a Colorado-made brew! MillerCoors’ gen-erous financial support will go a long way towards helping all Coloradans “speak flu-ent water.” Thank you!

CulTivaTinG PaRTiCiPaTiOn

Colorado’s Water Plan Colorado has arrived at an unprecedented point in water history, one where dialogue and consensus among water leaders is leading to a comprehensive plan to address our state’s water challenges. CFWE is proud to support understanding of Colorado’s Water Plan and the Basin Implementation Plans through our facilitation of the Public Education, Participation and Outreach workgroup of the Interbasin Compact Com-mittee. To further support participation in a secure water future, expect to see ad-ditional activities from CFWE over the coming year, including:

3 Special communications pieces representing a diversity of perspectives on channels such as the “Your Water Colorado” blog and “Connecting the Drops” radio series

3 Relevant speakers and topics at CFWE programs and events, such as Headwaters magazine receptions and our annual Legislative Lunch

3 Cross-promotions of CWCB communications and social media

Read more about Colorado’s Water Plan and sign up for regular updates at www.coloradowaterplan.com.

STREnGTHEninG lEaDERSHiP

Water Educator network We’re making water education better and easier! CFWE’s all-new Water Educator Net-work is bringing you tools, training and resources to increase the amount and quality of water education in Colorado. Through this network, with generous support from Xcel Energy, CFWE will improve the understanding of Colorado water issues within youth and adult audiences by becoming the premiere resource for Colorado water educators to learn, share and connect with each other. There’s a lot to look forward to. Be sure to grab the next issue of Headwaters magazine, hitting mailboxes in January 2014—the entire issue will focus on water education and civic engagement. What better way to launch a new network? Stay tuned to yourwatercolorado.org for upcoming trainings, meetings, resources and more.

GROWinG CaPaCiTy

Welcome new StaffCFWE continues to grow and change in or-der to best meet the water education needs of Colorado. We are happy to welcome Alicia Prescott as our new Development Director. Alicia moved to Colorado in July with her husband and two dogs, and started at CFWE in September. She’s ready and excited to continue her development career in Colorado water! Previously, Alicia has worked in uni-versity fundraising, campaign development, grant writing, special event planning, and volunteer management across the American South. She graduated from the University of Southern Mississippi with a bachelor’s de-gree in marketing and a master’s in business administration. Please help us welcome Ali-cia to CFWE and Colorado by buying her a sweet tea when you meet her!

Alicia Prescott

2 C o l o r a d o F o u n d a t i o n f o r W a t e r E d u c a t i o n | y o u r w a t e r c o l o r a d o . o r g

CFWE Mission in Motion

CREaTinG KnOWlEDGE

The Great Citizen’s Guide GiveawayFor a limited time, nonprofits and educational groups can receive up to 100 free CFWE Citizen’s Guides! The Citizen’s Guides are a series of high-quality reference booklets on Colorado water topics. Educate your staff, volunteers, board, students and constitu-ents, and boost their understanding of Colorado’s water resources. To be considered, you must submit an outreach plan by November 22. Learn more at yourwatercolorado.org or by contacting CFWE intern Abby Kuranz: [email protected].

inCREaSinG aWaREnESS

Connecting the Drops CFWE is on the air, bring-ing you quality report-ing on the radio and the web. We’ve partnered with community radio stations from Greeley to Durango to create regu-lar water programming for the next year, with the potential of reaching hundreds of thou-sands of listeners across Colorado. Tune in for monthly segments that complement and build on what you’re reading in Head-waters. And visit yourwatercolorado.org to access archived stories from our radio spot: “Connecting the Drops.”

ColoradoFoundationfor Water Education

Board Members

Gregg Ten Eyck

President

Justice Gregory J. Hobbs, Jr.

Vice President

Rita Crumpton

Past President

Eric Hecox

Secretary

alan Matlosz

Treasurer

Becky Brooks

nick Colglazier

lindsay Cox

lisa Darling

Steve Fearn

Rep. Randy Fischer

Greg Johnson

Pete Kasper

Dan luecke

Trina McGuire-Collier

Kate Mcintire

Kaylee Moore

Reed Morris

Sen. Gail Schwartz

andrew Todd

Chris Treese

Reagan Waskom

Staff

nicole SeltzerExecutive Director

Kristin MahargProgram Manager

Caitlin ColemanProgram Associate

Jennie GeurtsAdministrative Assistant

alicia Prescott Development Director

Mission Statement the mission of the Colorado Foundation for Water education is to promote better understanding of water resources through education and information. the Foundation does not take an advocacy position on any water issue.

Acknowledgments the Colorado Foundation for Water education thanks the people and organizations who provided review, comment and assistance in the development of this issue.

Headwaters Magazine is published three times a year by the Colorado Foundation for Water education. Headwaters is designed to provide Colorado citizens with balanced and accurate information on a variety of subjects related to water resources. Copyright 2013 by the Colorado Foundation for Water education. iSSn: 1546-0584 edited by Jayla Poppleton. designed by emmett Jordan.

1580 logan St., Suite 410, denver, Co 80203

303-377-4433 • www.yourwatercolorado.org

H e a d w a t e r s | F a l l 2 0 1 3 3

Want to share your support of Headwaters with over 10,000 readers each edition? Call Alicia at 303-377-4433 for sponsorship and advertising opportunities!

“I feel so old. It’s great!” You don’t often hear people in their 30s and 40s rejoicing in their maturity, but at the 2013 Sustaining Colorado’s Watersheds Conference in October I heard it numerous times. The Colorado Foundation for Water Education is proud to be a partner in this annual event that draws a large number of college students, budding water professionals and nonprofit vol-unteers. It is gratifying to sit in a room full of young energy, hearing them challenge their assumptions, promote their good work and learn from those who are now (hopefully) a bit wiser than they were 10 or 20 years ago. And I had more fun than I should have dressed up as “Captain Cutthroat” thanks to the

Roaring Fork Conservancy. (Check out photos on CFWE’s Facebook page.)

From a more diverse and enthusiastic audience show-ing up at traditionally staid water meetings to the numerous phone calls and emails CFWE gets asking how to help with our work, I see widespread evidence of a burgeoning inter-est in water. I am grateful for this attention, and my hope is that the professional water community can find ways to welcome and embrace it.

In my opinion, Colorado is more than halfway through its transition from what author George Sibley, in a 2009 ar-ticle for Headwaters magazine, called an “adversarial and litigious ‘every man, or city, for himself’ culture” to a more democratic process where diverse interests sit at the same table and come to mutually beneficial agreements. The dif-ficulty I see, however, is what exactly the role of “the public” is in managing and protecting water in Colorado, given the importance of honoring private property rights. As those young conference attendees become the leaders of tomor-row, they will have a chance to wrestle with this question,

and I look forward to where their vision will take us.But as I look forward, I also need to remember to look back. This Headwaters is the last of 2013, a year

of tremendous change for me personally, for CFWE and for the state of Colorado. Having recently traded my long commute for a house in Denver, I am now a bona fide “city girl.” I get to wear my high heels more often, but I do miss the rural landscape of northern Boulder County. I drove by my old house in Longmont yesterday for the first time since the September floods and marveled at the changes in the St. Vrain River. My thoughts are with those who are dealing with tremendous personal loss, and those who are working tirelessly to fix the ruined transportation, energy and water systems our communities rely upon.

At the Foundation, we continue to make great progress toward our goal of helping all Coloradans “speak fluent water.” In the past year, we increased staffing levels by bringing Caitlin Coleman on full-time and hiring our first Development Director. This additional staff capacity has allowed us to broaden our reach and try some new things, such as the “Connecting the Drops” monthly radio series. We’re also hosting our first energy-focused tour in the Weld County area on Nov. 8. Join us if you are able!

I am excited by the direction we are moving at CFWE, and am gratified by the moral and financial support we continue to get from you, our supporters. In 2014, look for more new programming includ-ing professional development support for water educators funded by Xcel Energy.

Finally, I hope you and your loved ones have a safe and happy holiday season (which apparently is already in full swing if you judge by the seasonal aisle at Target). May 2014 bring you happiness and lots of snow!

Executive Director

Nicole Seltzer

ContrIbutorsAllen Best has written about oil and gas issues in Colo-rado since 2008, and about water issues for decades. He grew up in the South Platte Valley, where it was his family’s eternal hope that oil would be found on his grandparents’ farms, though it never happened. His work has appeared in publications as diverse as High Country News, Telluride Watch, Colorado Biz Magazine and The New York Times, among others. He publishes Mountain Town News, which can be found at mountaintownnews.net.

Joshua Zaffos writes from Fort Collins, where he also teaches journalism and natural resources communi-cations at Colorado State University. His stories have been published by High Country News, Wired, Scientific American, Nature Conservancy Magazine, and many other outlets. His work is online at joshuazaffos.com.

Caitlin Coleman is a writer and program associate for the Colorado Foundation for Water Education. Originally from New York State, writing about water for energy, a prominent but often polarizing topic country-wide, was enlightening, she says.

Matthew Staver is an independent documentary and commercial photographer based in Denver. Every proj-ect is different, but his approach is constant: creating visual permanence in a world of relentless motion. His work can be found at matthewstaver.com.

Kevin Moloney is a Colorado native and freelance pho-tojournalist who has covered the western energy boom since 1996 for the New York Times and other publications throughout Europe and the United States. He is a frequent contributor to Headwaters. His work can be found at kev-inmoloney.photoshelter.com.

Charles Chamberlin is a freelance graphic designer liv-ing in Boulder. Some examples of his work can be found online at cdcgraphics.blogspot.com.

4 C o l o r a d o F o u n d a t i o n f o r W a t e r E d u c a t i o n | y o u r w a t e r c o l o r a d o . o r g

ContentsFall 2013

The Power (and Energy) of Water

By Joshua ZaffosThe state’s energy portfolio is in transition, which may yield water-saving gains, even as the state braces for a growing population and the forecasted impacts of more persistent drought.

Do Oil and Water Mix?

By Allen BestOil and gas production in Colorado is at near-record highs, with no signs of slowing. But public concerns are growing and the jury’s still out on the safety of practices such as hydraulic fracturing. How will the state balance development with adequate protections?

Power in the Marketplace

By Caitlin ColemanFrom leasing water rights to diversifying water supply portfolios, both power providers and energy companies are in the market for water. The demand has contributed to higher prices—and some creative arrangements.

7 CoolingWater converted into steam to turn turbines must be cooled back to its liquid state; When it comes to water use and efficiency, cooling technologies vary; Options for cooling solar plants.

8 HydropowerHydropower ranks low for overall electricity generation, but its contribution is growing; Reducing hydro’s impact on rivers; The power potential of small projects.

Water Is…

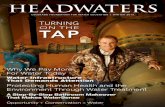

On the Cover: The Ft. Saint Vrain Generating Station, owned by Xcel Energy, lights up the sky near Platteville, Colo. Once Colorado’s only nuclear facility, it was decommissioned in 1989 and re-powered as a natural gas plant. Photo by Kevin Moloney.

10 16 24

Emm

ett J

orda

n (2

), Ke

vin M

olon

ey (p

ower

pla

nt),

Blue

Wat

er R

esou

rces

(can

al),

Rich

ard

Sten

zil (P

uebl

o Re

serv

oir)

surely it came as a surprise to many when it was reported by the U.S. Energy In-formation Association early in October that the United States is poised to eclipse Russia and Saudi Arabia for oil and gas production by the end of the year. Fueling the domestic boom in production is the ability to tap oil and gas from shale deposits where it was previously uneconomical to recover. Hydraulic fracturing, or fracking, is the technology that has received most of the hype, both for the bountiful production it has enabled, as well as for the controversy it has sparked among wary citi-zens concerned about air and water quality and other disturbances.

In Colorado, one of the top-10-producing states for both oil and gas, the center of activity has closed in on populated areas in the northern Front Range, further heightening residents’ alarm. Now there’s plenty of NIMBYism (Not In My Back Yard) to go around, and I can’t say I blame people. September’s floods on the Front Range and associated oil spills magnified the fact that despite our precautions, accidents happen, with consequences we have yet to fully realize. And still there is the unignorable fact that we are a society heavily reliant on the resource being provided. Increased oil independence could also arguably improve national security and smooth tensions abroad.

Dialogue over safety issues in the public arena has been obscured by the lack of consistency in language. Often, when the public refers to concerns about hydraulic fracturing, they’re roping in the entire process of well development, whereas industry and regulators narrow the definition to the underground fracturing “treatment” of the shale formation. For the dialogue to be effective, we all need to get on the same page. In this issue, we attempt to clear up some of the misunderstandings.

From a water availability standpoint, concerns have been raised about the amount of water re-quired in the fracking process. Yet the numbers are miniscule when looking at the big picture in Colorado: Only 0.04 percent of the water removed from streams and aquifers is used for fracking. But when that demand is focused in a few targeted locales where oil and gas development is con-centrated, the local impacts become more significant.

The argument is similar when it comes to power generation. Of course a reliable power supply is integral to our day-to-day lives, and we certainly want to make sure our power suppliers are ad-equately stocked with the water they’ll need to keep our power lines humming. But it’s difficult to make the case that statewide water requirements for power generation are a mighty strain on the resource in the midst of the much, much larger demands stemming from agriculture and municipal use. Still, in the face of population growth and escalating water demands from every sector, every drop counts. Hence the advantage of water-saving technologies and fuel choices when it comes to generating power.

Join us in exploring the dual topics of energy development and power production in this issue. As with all Colorado water matters, it’s important to consider and address the concerns of all Colo-radans. Here’s to a bright future in Colorado,

P.S. Remember to look for our “Floo-uhnt” water facts, and get a leg up in your ability to “speak fluent water.” We also encourage you to jump on the opportunities we’ve provided to “Take the Next Step” in your water education journey, highlighted throughout this issue.

Tenthings to Do In this Issue:

1 Tune in to the “Connecting the Drops” radio program for additional coverage on water and energy issues (page 2).

2 get a crash course in technologies used for cooling steam at power plants (page 7).

3 stay current on trends in hydropower development in Colorado (page 9).

4 Find out how different types of power factor into Colorado’s energy mix (page 14).

5 Calculate how your energy use measures up via the national geographic personal energy meter (page 15).

6 Learn which counties are Colorado’s hot spots for oil and gas production (page 17).

7 Trace water’s path through the process of hydraulic fracturing, oil and gas recovery and waste fluid disposal (page 20).

8 search the Colorado Oil and gas Conservation Commission’s database for information on wells drilled in your area (page 22).

9 see how much water is used to power the average home in Colorado (page 29).

10 sign up to receive updates on Colorado’s Water Plan (page 1).

H e a d w a t e r s | F a l l 2 0 1 3 5

Jayla PoppletonEditor

Jayla Poppleton, Editor

Water is Colorado

Cooling > Hydropower

Photo by John Wark

the 1,426-megawatt Comanche Generating Station sits southeast of Pueblo, where its three coal-fired generating units produce more power than any other plant in Colorado. operational since 1973, the plant added a second unit in 1975 and a third in 2010. the third unit is the most efficient coal plant in the state, producing more power with less fuel. it also employs a hybrid system that uses ambient air temperature to

aid cooling, reducing the plant’s water use by half.

6 C o l o r a d o F o u n d a t i o n f o r W a t e r E d u c a t i o n | y o u r w a t e r c o l o r a d o . o r g

H e a d w a t e r s | F a l l 2 0 1 3 7

Boiler Water

Turbine

Condenser

Heat Source

Cooling Tower

Boiler

Generator Fans

High-Pressure Steam ➠ Low-Pressure Steam ➠

Electricity

Makeup Water

➠➠

➠

➠➠

➠➠

➠

WARM Cooling Water ➠

COOL Cooling Water

➠

➠

Evaporation

Water Source

Closed-Loop System

A mbient A

ir

Water Fuels Powerin Colorado, less than 0.5 percent of water tapped from rivers and aquifers is used for power generation. it seems insignificant, but here’s a look at water’s crucial role in Colorado’s power play. —Rebecca L. Olgeirson

When it comes to power generation, the reliance on fossil fuels and resulting air quality issues generally garners the most attention. However, here in arid Colorado it’s also important to understand how water fits into the power picture.

Thermoelectric power relies on heating water to create steam and then using that steam to spin turbines. The spinning turbines generate electric-ity. This part of the process is the same across all types of thermoelectric power plants. What varies is the type of fuel used to heat the water—coal, natural gas, nuclear, concentrating solar, even geothermal or biomass—and the water cooling method employed.

The water heated in the power generation pro-cess must be cooled in order to condense it from a vapor state back to liquid form before it can be

reused by the plant or returned to its source. Water resource issues such as drought, water

rights and water quality regulation all factor into power generation, as they affect water availability and plant operation. As a result, industry represen-tatives say they weigh the costs and benefits of different technologies’ water usage carefully. Still, decisions aren’t made in a vacuum. Often less water-intensive cooling technologies are also less efficient, requiring more fuel for the same amount of energy produced, increasing fossil fuel reliance.

“Upstream” water demands related to fuel choice impact overall water use as well. Coal, for example, which supplies 67 percent of Colo-rado’s electricity, requires 20 to 60 gallons per megawatt hour of electricity produced before it ever gets to the power plant, according to the

U.S. Department of Energy. This water is used for mining, washing and transporting the coal. Developing natural gas requires 30 gallons per megawatt hour if hydraulic fracturing is used, or 5 gallons for conventional drilling. Natural gas cur-rently supplies 20 percent of the state’s electricity.

Stacy Tellinghuisen, senior energy/water policy analyst at Western Resource Advocates, says Colo-rado’s energy sector is more water conscious than other parts of the nation. But given water scarcity and future drought issues, the power sector’s water needs must continue to be considered in decision-making. “Looking forward, with Colorado’s growing population and climate change, we need to keep in mind water demands as we make energy choices: ‘Are the water supplies there? Are we allowing flex-ibility in how we use water in the future?’”

technology Keeps it CoolWater use in Colorado is tallied in two ways—withdrawal and consumption. Withdrawal is how much a water user removes from a water source, some of it temporarily. And consumption is the amount of water “permanently” removed from the system, some of which evaporates into the atmosphere only to rain down somewhere else.

When it comes to generating power in Colorado, most plants consume the vast majority of the water they withdraw—90 percent on average. By comparison, agriculture, which withdraws nearly 200 times as much water as the state’s power plants, is 43 percent consumptive on average, accord-ing to Colorado’s Division of Water Resources.

Operating in an environment of relative water scarcity, Colorado power

plant operators have developed cooling systems accordingly. Of the three main types—once-through systems, closed-loop systems and dry-cooled systems—Colorado power providers rarely use once-through systems due to their higher water demand.

Once-through systems, which cycle cooling water through only one time, withdraw the most water from natural sources, but consume less because most of the water used for cooling is later returned to the water source. Dis-charge temperatures, regulated on a per-plant basis by the Colorado Water Quality Control Division, must be low enough to protect fish and the envi-ronment, although they can still raise water temperatures by as much as 25 degrees Fahrenheit.

Wonder what makes water such an effective cooling agent? Attributed to the strength of their hydrogen bonds, water molecules have a very high specific heat compared to other substances, meaning they are capable of absorbing large quantities of heat with only a slight change in their own temperature.

Recirculating, Closed-Loop Cooling

Water is Cooling

Continued on page 8

HO O

In 2010, Colorado produced more than one and a half million megawatt hours of electricity using hydropower. While this accounted for less than 4 percent of total electrical gen-eration in the state, technological advances and streamlined regulations are improving the outlook for adding more of this energy source to Colorado’s power mix.

Colorado has more than 60 hydropower units collectively capable of producing 1,160 megawatts of power at any given time. One quarter of that installed capacity comes from three dams on the upper Gunnison River—the Crystal, Morrow Point and Blue Mesa dams of the Aspinall Unit, which collectively produce up to 288 megawatts. These dams were constructed in the early 1960s to store water for the upper Colorado River Basin; adding hydropower became an incidental purpose, says Bureau of Reclamation hydrologist Dan Crabtree. Today, that power—enough to supply as many as 100,000 homes—is sold to municipalities, public utilities and governmental agencies in Colorado and surrounding states through the Western Area Power Administration.

Large facilities like the Aspinall Unit are unlikely to be built today, however. “Ecological damage basi-cally restricts development of large-scale hydropower, especially on mainstem rivers,” says Crabtree.

New projects are much smaller—and take advantage of existing infrastructure. Reclamation cur-rently has several new hydropower projects underway in Colorado: The Dallas Creek Project on Ridg-way Dam on the Uncompahgre River and the South Canal Hydroelectric Project downstream near Montrose will each generate close to 8 megawatts, together providing enough electricity to power more than 5,000 homes annually. Affordable construction loans and power purchase agreements with Aspen and Tri-State Generation and Transmission made the projects feasible.

Typical impediments to hydropower development include expensive start-up costs, although hy-dropower has a longer economic life and costs less to maintain and operate than other renewable energies, says Brad Florentin, senior engineer with AMEC, a consulting firm that works on energy projects worldwide.

Acquiring power purchase agreements can also be difficult, as well as securing necessary per-mits—but that recently became easier with the passage of two bills signed into law by President Obama in August 2013. The Hydropower Regulatory Efficiency Act, introduced by Colorado Rep. Diana DeGette, and the Bureau of Reclamation Small Conduit Hydropower Development and Rural Jobs Act, introduced by Colorado Rep. Scott Tipton, should shorten regulatory timeframes, as well as expedite small hydropower development at existing Reclamation-owned canals, pipelines, aque-ducts and other waterways. Moving more quickly than many expected, the Federal Energy Regula-tory Commission approved its first application, for a project in Idaho, under the new legislation in October 2013—a promising sign to small hydro advocates.

In 2011, Reclamation identified 37 additional sites where hydro facilities could be installed on ex-isting dams in Colorado. Tapping those resources could generate another 242,000 megawatt hours of electricity per year, says Reclamation’s senior advisor for hydropower Kerry McCalman. In 2012, the agency identified an additional 28 sites on the state’s irrigation canals with the potential for gen-erating 100,000 megawatt hours annually. Together, the retrofits could supply 40,000 homes.

Still, Colorado hydropower will never compare to a state like Washington, whose Grand Coulee Dam on the Columbia River alone produces more than 10 times the amount of hydropower of all that is gen-erated here—Colorado streamflows simply can’t compete with such a massive river. —Sharon Sullivan

Keeping it CoolContinued from page 7

Closed-loop or recirculating systems, which use water to cool steam back into a liquid state before returning it to the steam cycle, withdraw less wa-ter but have a 70 to 80 percent consumption rate in Colorado, according to Xcel Energy. These are the most common systems employed here. These systems move water from the steam cycle through pipes called cooling towers, where a large volume of cool water falls over the tower, lowering the tem-perature of the water within before cycling it back into the system.

According to Jordan Macknick, environmental analyst at the National Renewable Energy Labo-ratory (NREL) in Golden, once-through cooling technologies withdraw 10 to 100 times more water per unit of power generation than cooling tower technologies, yet cooling tower technolo-gies can consume twice as much water as once-through systems.

Finally, dry-cooled systems use no water, but rely on tremendous volumes of air current and re-quire more energy to operate, trading lower water use for increased fuel consumption. These sys-tems are also quite expensive to build and depend on ambient air temperature for efficiency—working great on cold days, less so in the heat of summer or in the desert. However, some facilities, includ-ing an Xcel plant in Pueblo, have installed hybrid systems that utilize water for cooling only when air temperatures are too high for dry cooling. Xcel says its new hybrid system cuts water consump-tion by 50 percent.—Rebecca L. Olgeirson

Water for solar When talking solar, most people think of the thin, black panels sitting on a rooftop or in a field. This type of photovoltaic (PV) solar collector requires very little water.

But there’s another kind of solar energy, and a wide chasm separates it from its cousin when considering water use. Concentrating solar power (CSP) consists of massive installations of mirrors that direct sunlight to one spot, where it heats a working fluid into the steam used to produce electricity, just as at a conventional power plant. The big difference? CSP plants do it without fos-sil fuels.

If outfitted with a typical closed-loop, recircu-lating water tower cooling system, however, CSP plants consume between 725 and 1100 gallons of water per megawatt hour of electricity produced, according to a recent report by the National Re-newable Energy Laboratory. CSP plants require water for washing the mirrors, but most of their water usage is attributed to cooling, the same as at a conventionally powered plant.

An added concern is site location—the best sites for CSP plants are often in desert-like conditions where water is already scarce. As a result, most new CSP plants proposed in dry regions would be dry-cooled, despite the higher cost and reduced efficiency rate of the waterless technology. —Rebecca L. Olgeirson

Water is Cooling Water is Hydropower

Hydropower in Colorado

8

Built in 1981 as part of the Fryingpan-Arkansas Project, the Mt. Elbert Power Plant near Leadville is capable of producing 200 megawatts of electricity. This pumped-storage hydro plant helps meet peak power demands by pumping water uphill from Twin Lakes Reservoir during times when demand is low, then releasing it to drop through the plant’s turbines when demand is high.

Colorado’s renewable energy targets exclude existing large hydropower projects of more than 30 megawatts from qualifying as renewable, as well as new projects, coming online after 2005, of greater than 10 megawatts.

Water is Hydropower

reducing Hydro’s ImpactHydropower accounts for nearly two-thirds of all renewable energy gener-ation in the nation, according to the U.S. Department of Energy. Generally considered a “clean” energy source because there is no fuel combustion and little air pollution compared with generating energy using fossil fuels, hydropower facilities still have their drawbacks.

Large dams, for example, have significantly impacted rivers by altering their flow patterns, in some cases virtually wiping out native species. Un-der natural conditions, high springtime flows inundate floodplains, providing both nursery areas and quiet water habitat for adult fish prior to spawning, says Patty Gelatt of the U.S. Fish and Wildlife Service Western Colorado Field Office.

In 2010, Reclamation began implementing new operating strategies for its 288-megawatt Aspinall Unit to help endangered fish and critical habitat, in-

creasing water releases in the spring to mimic the river’s natural seasonal flow, though such efforts have come at a cost to total power generation.

Fish, which need well-oxygenated water, can also be impacted by the oxygen-reducing effect turbines have on flowing water. Oxygen is restored naturally when water flows over rapids, or ripples. In some cases, engineer-ing structures are installed in rivers to replicate that re-aeration effect. Other mitigation efforts include fish passages and ladders to help migrating fish navigate over dams and electronic fish barriers to prevent fish from swimming into areas where they risk being struck by turbines.

To be considered, and certified, “low-impact” by the Low Impact Hydro-power Institute, projects must meet criteria for minimizing these types of impacts. Such certification, the institute notes, could be a selling point for marketing power from hydro projects. —Sharon Sullivan

Hydropower in Colorado

big Potential for small HydroAlthough the days of building new, large-scale hydropower projects are likely limited, possibilities abound in Colorado to install power-producing turbines on existing infrastructure. Such “micro-hydro” technology captures the energy of water moving through the state’s irrigation and municipal systems, often in order to power on-site operations.

The Colorado Department of Agriculture has hired Applegate Group, a Colorado-based engineering and consulting firm, “to create a roadmap for the Department to successfully support the development of small agricultural hydropower,” says Applegate water resources engineer Lindsay George. One notable success is a project on the Wenschhof cattle ranch in Meeker, where Applegate assisted with securing funding, permitting, construction and commissioning of a 23-kilowatt hydropower system that provides for all of the ranch’s electrical needs—at a projected savings of $350,000 in utility costs over 30 years.

Applegate also worked with the Colorado Energy Office on the recently published Colorado Small Hydropower Handbook. The handbook is a resource for utilities, farmers and ranchers, and others inter-ested in developing the resource, focusing on projects of 2 megawatts or less. Good prospective sites for adding small hydropower are characterized by existing infrastructure, such as dams and pipelines, consistent water flows, and at least 15 to 20 feet of “head,” or water level difference, says George.

Grand Junction is one municipality that has utilized the technology, developing micro-hydropower at its Kannah Creek Water Treatment Plant a few years ago. Utilities manager Terry Franklin helped design a 30-kilowatt system that generates enough electricity to run the facility, saving $8,000 a year in energy costs. Payback for the $50,000 project was just over six years. —Sharon Sullivan

The Towoac-Highline Canal delivers irrigation water to the Ute Mountain Ute Tribe near Cortez, capturing 360 kilowatts of power as it passes the Carver Drop.

Water is Hydropower

H e a d w a t e r s | F a l l 2 0 1 3 9

Cou

rtes

y Te

llurid

e En

ergy

1 0 C o l o r a d o F o u n d a t i o n f o r W a t e r E d u c a t i o n | y o u r w a t e r c o l o r a d o . o r g

For five decades, the Cherokee Generating Station,on the north side of Denver, ran on western Colorado coal and cheaply powered the population boom of Colorado’s Front Range. Its four coal-fired, steam-electric generating units produced up to 717 megawatts, enough electricity for more than half a million homes. The plant—one of the largest operated by Xcel Energy in the state—also emitted many thousands of tons of pollutants annually, including nitrogen oxides, sul-fur dioxides and carbon dioxide, contributing to poor air quality, smog and climate change. As for water, Cherokee was more innovative. The plant requires up to 10 million gallons or 30 acre feet per day to operate, but its water supply for years has been recycled wastewater from the same households purchasing its power.

Cherokee may embody the good, the bad and the ugly of energy de-velopment and power generation, but for the last two years, this cor-nerstone Colorado power facility has been undergoing a $530 million makeover to replace coal with more efficient natural gas. Xcel has al-

ready demolished Cherokee’s two oldest coal-fired units, and will shut-ter another by 2015. In their place, construction is now underway on a new 569-megawatt natural gas-fired, combined-cycle plant, which uses gas and steam turbines to run on fuel as well as waste heat that would otherwise be lost as exhaust. The last 352-megawatt coal-fired unit will be converted to run on natural gas by 2017.

The retrofit is the keystone of Colorado’s strategy to slash Front Range air pollution, including reducing smog-causing ozone levels by 86 percent. The 2010 Clean Air-Clean Jobs Act, signed into law by then-Governor Bill Ritter, serves as a roadmap to bring the state into compli-ance with federal air quality standards by phasing out older coal-fired power plants and replacing them with more efficient and less polluting gas-fired facilities and renewable energy. The law also helps Colorado prepare for anticipated federal greenhouse gas regulations to address climate change.

THE POWEr(anD EnErgy)

OF WaTErby Joshua Zaffos

The Cherokee Generating Station along the South Platte River in Denver uses water recycled from the adjacent Metro Wastewater treatment plant (foreground).

Jona

than

Wat

erm

an/L

ight

haw

k

H e a d w a t e r s | F a l l 2 0 1 3 1 1

This shift is providing another important environmental advantage. “The retirement of coal plants and the movement toward natural gas is an important step [for addressing air pollution and carbon emissions], but the side effect is water use reduction,” says Kristen Averyt, director of the Western Water Assessment and associate director for science at the Cooperative Institute for Research in Environmental Sciences (CI-RES) at University of Colorado Boulder. Planned nationwide retirements of coal plants, generating 51,000 megawatts, will eliminate 4 trillion gal-lons, or more than 12 million acre feet, in water withdrawals annually. That’s even after replacing them with more water-efficient power sta-tions, according to a July 2013 report by the Union of Concerned Sci-entists. “[The reduced water use] is not intentional, but it’s a co-benefit, and I think that’s important to think about,” says Averyt.

With Colorado’s—and the nation’s—energy portfolio in transition, the intersection of water and energy is becoming less of an after-

thought. From underground coal seams to sky-high wind currents, planners and policymakers are increasingly evaluating energy sources based on their water use and looking at how their choices can help ad-dress growth, climate change and other issues. And with its full menu of energy options, Colorado is “ground zero,” Averyt says, for testing the local impacts of national energy policies and influencing how the country powers its future.

revamping the energy MixFew states rival Colorado when it comes to energy resources. Impres-sive reserves of oil, gas and coal underlie parts of every corner of the state. Rivers and dams provide hydroelectricity on large and small scales. Uranium deposits in Paradox Valley and elsewhere could fuel nu-clear plants. With 300 days of sunshine, solar energy potential abounds, and the eastern plains, where gusts can blow a lofty average of 20 miles

1 2 C o l o r a d o F o u n d a t i o n f o r W a t e r E d u c a t i o n | y o u r w a t e r c o l o r a d o . o r g

per hour, are ideal for wind energy. Geothermal heat beneath the San Luis Valley and other ar-eas holds energy potential too.

Colorado has relied on coal as its dominant power source since settlement due to local abundance, including wide-ranging deposits across the Western Slope, which makes it an especially affordable fuel. Coal powered more than 90 percent of the state’s net electricity generation as recently as 1995. Today, about half of U.S. electricity generation comes from coal, while Colorado relies on the fossil fuel for 67 percent of its power.

During the 1990s and early 2000s, as Col-orado’s population swelled from 3.3 million to 5 million, federal air quality violations and concerns about pollutants from existing and new coal power kicked off a discussion on the state’s energy mix. In 2004, voters approved Amendment 37, establishing a renewable en-ergy portfolio standard that mandated utilities tap renewable energy sources for 10 percent of their power by 2015.

Since Amendment 37 passed, the state leg-islature has revised the target renewable stan-dard several times, most recently in June 2013. Now investor-owned utilities, of which Xcel is the largest in the state, are required to provide 30 percent of electricity from renewable sourc-es by 2020, one of the highest benchmarks in the nation. Under the same timeline, city utili-ties must move to 10 percent renewables, and large rural electric cooperatives will have to reach 20 percent—a percentage doubled un-der the 2013 legislation. Many rural providers believe reaching that target in seven years is going to be incredibly difficult, if not impos-sible—in part due to the need for new trans-mission lines to connect renewable sources in their far-flung service areas.

And yet, the statewide proliferation of pho-

tovoltaic solar panels and wind turbines is evidence of the change underway. Solar pow-er systems now generate 270 megawatts of electricity in Colorado, although Environment Colorado and industry trade group Colorado Solar Energy Industries Association want to boost that total to 3,000 megawatts by 2030. So far, solar development has relied heavily on tax credits, exemptions and rebates from federal, state and local government and utili-ties in order to be price-competitive with coal or gas power. But installation costs for solar projects here have been decreasing, a prom-ising sign of improving pricing equality with other energy sources.

Wind energy has developed even faster, with

2,300 installed megawatts of capacity as of late 2012. Ten years ago, Xcel supplied less than one percent of its electricity from wind energy, says Jack Ihle, the company’s director of environ-mental policy. Today, Xcel’s figure is 17 percent and growing, accounting for most of the state’s wind energy resources. As with solar, the federal renewable electricity production tax credit sub-sidizes wind, geothermal and biomass energy development to achieve competitive prices with fossil fuels. The increasing affordability and effi-ciency of wind turbines have also contributed to wind power prices nearing all-time lows in 2012, according to an August 2013 report by the U.S. Department of Energy’s Lawrence Berkeley Na-tional Laboratory.

© 2013 Xcel Energy Inc.

xcelenergy.com

DIVERSE ENERGY. There are a variety of sources from which we generate your energy—coal, natural gas, wind, solar and hydro power. A diverse mix makes your energy more a�ordable, reliable and cleaner.

Discover your energy mix at xcelenergy.com

PROVIDINGENERGY MIXwith a

7.375x3.33_HeadwatersMag_4c.indd 1 10/1/13 2:21 PM

There are 65 electric and natural gas utilities serving Colorado: 51 provide electricity only, eight provide only gas, and the remaining six provide both. The large number is, in part, a legacy of the 1936 Rural Electrification Act, which accounted for Colorado’s large size and required service to more remote, rural locations. Source: Colorado Governor’s Energy Office

Water Withdrawals in Colorado

• 86% Agriculture• 8% Municipal• 2.5% Recreation & Fisheries• 1.5% Industrial/Commercial• 1% Augmentation• 1% Recharge

0.80% Large Industry

0.07% Commercial

0.45% Thermoelectric Power Generation

0.04% Hydraulic Fracturing

0.03% Solar, Coal, Natural Gas & Uranium Development

0.03% Snowmaking

Source: Colorado Division of Water Resources Cumulative Yearly Statistics 1996-2008

H e a d w a t e r s | F a l l 2 0 1 3 1 3

Colorado’s utilities are meeting renewable goals, says Joshua Epel, chair of the state’s Public Utilities Commission. “No one else is doing anything else like Colorado, in terms of its renewable portfolio standard and Clean Air-Clean Jobs.” In addition to solar and wind de-velopment, Epel points to recent initiatives to capture and use methane from coal mines and to process and burn forest waste for bioenergy as promising test programs. “The strategies adopted have tremendous potential to propel Colorado forward,” Epel says.

While the Clean Air-Clean Jobs Act is spur-ring the reduction of coal power, the shift is also fueled by the natural gas boom. The advance-ment of horizontal drilling technology and hy-draulic fracturing—used to obtain oil and gas from once-unobtainable deposits—have sky-rocketed gas production around Colorado, the United States and the world.

The surge in hydraulic fracturing, or fracking, and gas drilling has lowered prices and made it a much more cost-effective fuel for power, Ihle says. Under Clean Air-Clean Jobs, Xcel plans to reduce its coal energy output from 69 to 45 per-cent of its total fuel mix by 2018, while ramping up gas energy from 17 to 35 percent. To pay for its Cherokee project, Xcel estimates rates for its customers will rise by just 2 percent.

Tri-State Generation and Transmission, a co-op which serves 44 smaller providers, says coal is still a more affordable fuel choice for its rural customers. Referencing a 2013 report by the American Coalition for Clean Coal Electric-ity, Tri-State’s water resources policy advisor Laura Chartrand says, “Striving for affordability is especially important to the 907,000 Colora-do households earning less than $50,000 per year who devote an estimated 19 percent of their after-tax income to energy.”

Although nothing is currently slated for Colora-do, nuclear power could factor into energy plan-ning as a low-carbon source of electricity on par with the cost of power generation using other fu-els. The Fort St. Vrain Generating Station in Weld County was Colorado’s only nuclear facility, but it was shut down in 1989 and is now operated by Xcel as a gas-fired plant. Few people support siting a nuclear plant near communities, based on fears of spills and meltdowns, and reactors are very costly to build. Nuclear power, includ-ing uranium processing and production, is also extremely water-intensive, requiring more water per megawatt-hour than fossil fuels. But techno-logical breakthroughs, such as the use of treated sewage water at Arizona’s Palo Verde nuclear plant—the country’s largest nuclear facility—are already changing how planners and some mem-bers of the public view nuclear energy.

Even with the rush toward natural gas, the push for renewables, and potential carbon emissions regulations, Ihle says Xcel—and Colorado—aren’t likely to fully divest from coal. Xcel is upgrading pollution controls at several coal plants to further limit smog and air pollution and keep the plants running and in compliance with Clean Air Act regulations. “We see value in balance even as certain driv-ers like emissions regulations will cause us to look harder at cleaner resources,” Ihle says. “Coal has been a very cost-effective resource and price-stable for a long time, and we’ll look for ways to make it as clean as we can.”

The utility also supports developing carbon capture and storage technologies to produce fewer and less harmful emissions. Carbon capture has its own water use implications, however: According to Averyt, the technology presently requires twice as much water as coal power without carbon capture.

The energy/water nexusIn the last decade, the nationwide economic recession has slowed Colorado’s population growth rate, while drought across the state has elevated the challenges facing utilities and resource managers. Looking ahead to 2040, state demographers and other planners forecast a more gradual 1.5 percent growth rate for Colorado. That’s still above the na-tional average and equivalent to 80,000 or more new citizens each year who will want re-liable and affordable electricity—and a beau-tiful place to live.

While improved air quality has driven energy policies, water conservation continues to get increasing attention from energy researchers and planners.

The “energy-water nexus” defines the mu-tual relationship between the two resources, with the acknowledgment that each affects the other’s availability. Water is essential to devel-oping and generating energy, and energy is es-sential to supplying and treating drinking water and wastewater. In the western United States, water providers are among the largest users of electricity, while power plants require a signifi-cant quantity of water to operate.

According to the Colorado Division of Wa-ter Resources, the state’s power plants with-draw 64,500 acre feet of water annually—and consume 90 percent of that. That’s enough

Denver

Grand Junction

Pueblo

Durango

Colorado Springs

14

19

172

159 12

10

13

2016

311 8

185

7

21

6

41

Water use by Power Plant

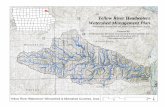

Colorado’s major power plants are strategically located near water sources and, with a few exceptions, near population centers to reduce transmission losses. Note: Circle sizes are based on estimated water consumption. Facilities consuming less than 100 acre feet per year are tallied but not shown. Source: Western Resource Advocates 2012 Data Sources: U.S. Energy Information Administration, National Renewable Energy Laboratory

Coal

Natural Gas

Other

Heat Source

Annual Water Consumption

Plant NameAcre Feet Per Year

1 Craig 16,400

2 Comanche 8,200

3 Cherokee 6,300

4 Hayden 5,900

5 Pawnee 5,700

6 Rawhide 3,700

7 Fort St Vrain 3,000

8 Rocky Mountain Energy 2,900

9 Ray D Nixon 2,800

10 Martin Drake 2,700

11 Valmont 1,900

12 Front Range Power Plant 1,300

13 Arapahoe 1,000

14 Nucla 800

15 W N Clark 400

16 Colorado Energy Nations 300

17 Lamar Plant 200

18 TCP 272 200

19 Williams Ignacio 100

20 Arapahoe Combustion 100

21 Brush Generation Facility 100

TOTAL 64,200

One megawatt (the same as 1,000 kilowatts) of electricity capacity can supply about 800 average homes in the United States or as many as 1,000 average Colorado homes. As of 2011, Colorado ranked 34th in the nation in energy consumption on a per capita basis. Source: U.S. Department of Energy

1 4 C o l o r a d o F o u n d a t i o n f o r W a t e r E d u c a t i o n | y o u r w a t e r c o l o r a d o . o r g

water to meet the needs of more than 350,000 people, although in exchange, these plants generate more than 87 percent of the electric-ity used in Colorado.

Natural gas plants, which are replacing most of the lost coal-powered megawatts, use less water and are more efficient. Based on re-search from the National Renewable Energy Laboratory (NREL), a new coal plant consumes about 500 gallons per megawatt hour (MWh) produced, while a combined cycle gas plant consumes about 200 gallons per MWh. Com-bined cycle gas plants also convert 50 percent of energy to electricity, while the efficiency rate of coal stations is closer to 33 percent.

That’s not to say the process of obtaining natural gas through drilling and hydraulic frac-turing doesn’t require its share of water, but according to Jordan Macknick, energy and environmental analyst for NREL, who has ana-lyzed different power sources’ water consump-tion across their entire “life cycle,” the oil and gas industry’s water use is mostly “up front” during the extraction process, compared with coal power, which requires water continually for mining, transporting and processing over the life of the mine.

Fracking’s water consumption has still been a major point of criticism from opponents. De-pending on the depth and location of a well, an operator may use from 2 million to over 5 million gallons—1 million gallons is about 3 acre feet—of water to initially drill and frack a site, a volume sig-nificantly greater than that used for conventional drilling. The process also typically contaminates

most of the water, rendering it unsuitable for fu-ture use, although more and more operations are testing and implementing treatment technologies that allow them to reuse and recycle water, which could provide benefits financially—and to sur-face flows and groundwater.

It’s all about tradeoffs, concludes Macknick. More gas-fired power will save water at the generation stations, but it does come with im-pacts on the ground at the shale plays where natural gas is extracted.

Water use also ranges across low-carbon and renewable energy sources. Wind power is unarguably the most “water-smart” alterna-tive, consuming a relatively negligible amount for operations and little else for its “fuel” pro-curement or power production. Photovoltaic solar panels also use a minimal amount of wa-ter to make power, but manufacturing equip-ment requires some water. Concentrated solar power, which uses mirrors or lenses to beam sunlight to run a heat engine, usually a steam turbine, can require more water than coal plants to cool facilities, depending on the type of technology employed.

Low water-use cooling technologies at pow-er plants also provide a way to conserve water. Dry cooling systems, for example, use air in-stead of water to cool the steam that passes through turbines, reducing a power facility’s water consumption by more than 90 percent compared with closed-loop, wet cooling pro-cesses. However, the technology has its trad-eoffs: Dry cooling has higher capital costs than the alternatives and lower efficiency. A gas

Jordan Macknick surrounds himself in solar research equipment at an NREL lab, where he studies the life-cycle water needs of different power sources.

68.1%

THERMOELECTRIC

COALTHERMOELECTRIC

NATURALGAS

Megawatts: 5,702 Gallons/MWh: 480

Cost/MWh:* $123 2010 MWh: 34,559,000 Considerations: Reliable, affordable, highest emissions; new technologies such as carbon capture and storage can shave emissions, but may increase water intensity.

CAPACITY

WATER INTENSITY

21.8%

Megawatts: 5,325 Gallons/MWh: 200 Cost/MWh:* $66 2010 MWh: 11,062,000 Considerations: Price volatility in past, but may be stabilizing; initial investment required if converting from coal plant; lower emissions than coal but not without impacts to air quality and warming.

CAPACITY

WATER INTENSITY

6.8%

CAPACITY

WATER INTENSITY

WIND

3.1%

Megawatts: 1,294 Gallons/MWh: 0 Cost/MWh:* $87 2010 MWh: 3,555,000 Considerations: Requires consistent wind. American Wind Energy Association reports 2,301 MW capacity as of 2012.

Megawatts: 1,225 Gallons/MWh: 0 Cost/MWh:* $90 2010 MWh: 1,578,000 Considerations: Larger projects can negatively impact rivers; evaporative water losses on reservoirs built specifically for hydro raise water intensity; new hydro projects are trending smaller and built on existing infrastructure.

CAPACITY

WATER INTENSITY

HYDRO

0.12%

Megawatts: 13 Gallons/MWh: 640

Cost/MWh:* $111 2010 MWh: 60,000 Considerations: Water requirements vary depending on whether biomass is captured waste, such as wood waste or landfill gas, or a byproduct of producing fuel such as ethanol, where the fuel originates as irrigated crops.

CAPACITY

WATER INTENSITY

BIOMASS

0.08%

Megawatts: 41 Gallons/MWh: 0 Cost/MWh:* $144 2010 MWh: 42,000 Considerations: Concentrated solar can have higher water intensity than coal; areas with greatest potential lack existing transmission. Environment Colorado reports 270 MW capacity as of 2012.

CAPACITY

WATER INTENSITY

PHOTOVOLTAIC

SOLAR

Of Total Power Produced in Colorado

Of Total Power Produced in Colorado

Of Total Power Produced in Colorad

Of Total Power Produced in Colorado

Of Total Power Produced in Colorado

Of Total Power Produced in Colorado

GENERATION GENERATIONGENERATION GENERATION GENERATIONGENERATION

Median Water Consumption

Median Water Consumption

Median Water Consumption

Colorado Power Generation by Source, 2010

Mat

thew

Sta

ver

*Costs are projected national averages (in 2011 dollars), levelized to include construction and ongoing operation costs for new facilities coming online in 2018. Regional variations in fuel availability and operational costs could have significant impacts on prices.The U.S. Energy Information Administration reports that a 3-percentage point increase in the cost of capital was added to coal power without carbon capture and storage, accounting for possible future requirements to purchase allowances to offset their emissions.

plant with a dry system may need to burn more fuel to produce the same amount of electric-ity as a facility with wet cooling, while a solar plant would be producing less power with a dry versus wet system.

“Low carbon isn’t always low water,” says Averyt, “but it can be depending on the choic-es you make.” Water conservation isn’t driv-ing the rapid development of Colorado wind energy, but the savings are exactly the sort of unintentional byproduct that she identifies in energy policies.

Accounting for waterMoments of energy-water nexus serendipity aside, planners and analysts now recognize that water management and drought planning should become a more integrated element of energy policy.

“Most of our clean energy policies have not been driven by water issues,” says Stacy Tell-inghuisen, Western Resource Advocates senior energy/water policy analyst, “but I think as we see long-term drought affecting the Colorado River Basin and the region more broadly, we’re likely to see water issues become a bigger fac-tor in shaping our energy policy in the future.”

The threat of drought and climate change im-pacts lingers over Colorado. Climate models proj-ect summer temperatures will warm 2.5 degrees Fahrenheit by 2025 and 4 degrees by 2050. While precipitation shifts are less certain, a report from the Western Water Assessment and the Colorado Water Conservation Board points to a reduced water supply in the state by 2050 and more severe

and persistent drought conditions.Colorado officials are working on a state wa-

ter plan and climate action plan, both of which, leaders say, will address the linked relationship between energy and water. In the absence of national climate legislation, the state’s Clean Air-Clean Jobs Act also serves as preemptive action on climate change.

“Colorado is probably the leader in reduc-ing greenhouse gas emissions on a per-capita basis,” says Epel, the Public Utilities Commis-sion chairman.

“I think we’re on the right track, and Colo-rado is a leader in the region in terms of how they’re beginning to integrate water into en-ergy decisions,” Tellinghuisen adds. But she says more is possible, such as managing en-ergy supplies to be more resilient to drought.

Analysts, including Averyt and Macknick, working with Union of Concerned Scientists recently compiled a report, “Water-Smart Power,” highlighting risks and opportunities facing energy and water providers. Among the report’s conclusions: Our current strategy of replacing coal with natural gas as the domi-nant power source will reduce water withdraw-als for power by more than 80 percent and water consumption for power by more than 40 percent—but much of those savings won’t oc-cur until after 2030 because of rising demands from population growth and the continued use of fossil fuels over the next few decades.

Regarding climate, replacing coal-fired power with natural gas production has already contrib-uted to lower carbon emissions from electricity

generation, according to data from the U.S. En-ergy Information Administration (EIA). The En-vironmental Protection Agency figures gas-fired electricity emits only 40 percent of equivalent carbon dioxide compared with coal, even ac-counting for methane leakage and other factors. But despite the efficiency gains and water sav-ings associated with gas-fired power, computer models performed by the “Water-Smart Power” report’s authors and data from the EIA suggest using gas to supply 60 percent of U.S. power needs would minimally reduce the power sec-tor’s carbon emissions in the long-term, espe-cially as energy demands grow.

While there remains cause for concern, there is also reason for hope. Xcel and other utilities now consider the environment along with reliability and affordability in making de-cisions. Goals for renewable and alternative energy production are being met in Colorado. And even if energy policies don’t yet directly incorporate water planning here, the nexus is never far off in people’s minds.

“In the West, water is always a fundamen-tal part of the equation in every decision that is made,” says Averyt. “It’s built into our thinking.” q

H e a d w a t e r s | F a l l 2 0 1 3 1 5

Colorado Power Generation by Source, 2010

Estimate your carbon footprint and find out how your energy consumption measures up with National Geographic’s Personal Energy Meter. Find it by visiting www.nationalgeographic.com and searching for “Personal Energy Meter.”

68.1%

THERMOELECTRIC

COALTHERMOELECTRIC

NATURALGAS

Megawatts: 5,702 Gallons/MWh: 480

Cost/MWh:* $123 2010 MWh: 34,559,000 Considerations: Reliable, affordable, highest emissions; new technologies such as carbon capture and storage can shave emissions, but may increase water intensity.

CAPACITY

WATER INTENSITY

21.8%

Megawatts: 5,325 Gallons/MWh: 200 Cost/MWh:* $66 2010 MWh: 11,062,000 Considerations: Price volatility in past, but may be stabilizing; initial investment required if converting from coal plant; lower emissions than coal but not without impacts to air quality and warming.

CAPACITY

WATER INTENSITY

6.8%

CAPACITY

WATER INTENSITY

WIND

3.1%

Megawatts: 1,294 Gallons/MWh: 0 Cost/MWh:* $87 2010 MWh: 3,555,000 Considerations: Requires consistent wind. American Wind Energy Association reports 2,301 MW capacity as of 2012.

Megawatts: 1,225 Gallons/MWh: 0 Cost/MWh:* $90 2010 MWh: 1,578,000 Considerations: Larger projects can negatively impact rivers; evaporative water losses on reservoirs built specifically for hydro raise water intensity; new hydro projects are trending smaller and built on existing infrastructure.

CAPACITY

WATER INTENSITY

HYDRO

0.12%

Megawatts: 13 Gallons/MWh: 640

Cost/MWh:* $111 2010 MWh: 60,000 Considerations: Water requirements vary depending on whether biomass is captured waste, such as wood waste or landfill gas, or a byproduct of producing fuel such as ethanol, where the fuel originates as irrigated crops.

CAPACITY

WATER INTENSITY

BIOMASS

0.08%

Megawatts: 41 Gallons/MWh: 0 Cost/MWh:* $144 2010 MWh: 42,000 Considerations: Concentrated solar can have higher water intensity than coal; areas with greatest potential lack existing transmission. Environment Colorado reports 270 MW capacity as of 2012.

CAPACITY

WATER INTENSITY

PHOTOVOLTAIC

SOLAR

Of Total Power Produced in Colorado

Of Total Power Produced in Colorado

Of Total Power Produced in Colorad

Of Total Power Produced in Colorado

Of Total Power Produced in Colorado

Of Total Power Produced in Colorado

GENERATION GENERATIONGENERATION GENERATION GENERATIONGENERATION

Median Water Consumption

Median Water Consumption

Median Water Consumption

Sources: U.S. Energy Information Administration, National Renewable Energy Laboratory

Capacity (in megawatts—MW) represents the highest production capability at any given moment if facilities are running at full bore. Generation (in megawatt hours—MWh) represents the power produced over time, and is affected by outages or weather variability.

Do Oil andWater Mix?

Technology has produced a bonanza of oil

and gas. But many want assurances that

water resources are not being harmed.

by Allen Best

1 6 C o l o r a d o F o u n d a t i o n f o r W a t e r E d u c a t i o n | y o u r w a t e r c o l o r a d o . o r g

Emm

ett J

orda

n

Three drilling rigs operate in close proximity to each other east of Greeley in unincorporated Weld County.

Whatever you may think about oil and gas drilling, acknowledge

this much: The technology is jaw-dropping. A decade ago, library

shelves were sagging with books foretelling declined production

of oil and natural gas. Guess what? In July 2013, the International

Energy Agency announced that the United States will become the

world’s leading producer of natural gas in 2015 and the world’s lead-

ing producer of oil in 2017.The technology driving increased production

isn’t altogether new. Hydraulic fracturing was first used in Colorado in 1948. The application of water, sand and chemicals at high pressures to stimulate production is called by the industry and regulators a “frac.” To journalists, that spell-ing looks unkempt, so the news outlets call it a “frack.” To opponents, it’s a four-letter word no matter how you spell it. What’s different between those original fracks and those currently done an average of five times every day in Colorado is like the chasm between the first Apple com-puters and MacBooks today: the new versions are immensely more powerful—and more pre-cise. Instead of pumping fluids by the thousands of gallons, as the first fracturing jobs did, today

companies commonly use more than 5 million gallons of water to “shoot” deep rock layers and fracture them. Tiny fissures smaller than a follicle of hair are formed and propped open by sand particles and other “proppants,” allowing the oil and gas to escape out of the rock and into well casings. Fracturing chemicals, which constitute less than 1 percent of hydraulic fracturing fluid’s total volume, are used to improve effectiveness. Many are ordinary, benign household or industri-al substances, but some are known carcinogens and other toxins, raising concern about potential impacts to water quality.

The industry has proclaimed fracturing fluids safe for their intended use—thousands of feet underground—and Gov. John Hickenlooper in

2011 even sipped on a glass of Halliburton’s new “green” frack fluid, called CleanStim, as if it were a scotch and water. Not everybody’s buy-ing such assurances. If it’s so safe, say oppo-nents, why have companies for so long resisted disclosing the contents? The industry says it’s about maintaining that competitive edge; who can provide the most effective frack? In Colo-rado, but not all states, both chemicals and their relative proportions as a percentage of to-tal fluids injected during fracking are a matter of public record since 2012. Recipes for specific ingredients, however, remain private under laws that protect intellectual property.

Horizontal drilling has also enabled drillers to more efficiently extract the hydrocarbon resi-due of organic matter in ancient sands, muds and other sedimentary rock. It’s down, down you go, to 3,000, 5,000 and even 10,000 feet, and then slowly hook to the left or right into the unconventional deposits, so-called because they are so much more tightly compressed and cemented, the spaces between particles not even half as large as those of previous, or more conventional formations containing “reser-voirs” of oil and gas. Another key technological gain is 3-D seismic imaging, which allows ex-ploration teams to better visualize oil and natu-ral gas prospects, place wells more effectively,

2012 Colorado Oil & Gas Production Value By County (Millions of Dollars)

WeldMoffat

Mesa

Baca

Yuma

Las Animas

Routt

Gunnison

Lincoln

Garfield

Larimer

Bent

Kiowa

Logan

Rio Blanco

Elbert

Washington

Delta

Kit Carson

Jackson

Adams

Cheyenne

Prowers

Montezuma

Fremont

Morgan

Huerfano

Archuleta

Dolores

San Miguel

Phillips

Boulder

Arapahoe

La Plata

Sedgwick

Denver

Broomfield

Ratio of oil to natural gas production in Colorado's three leading counties

Oil

Natural GasWeld

Garfield

La Plata$0

$81.7

$5.2

$16

$271.3 $8.7

$4.6

$0.7

$3,997.2

$135.3

$655.2

$38.8

$47.6

$3.2

$95.3

$2.9

$9.9

$2,246.2

$0.8

$13

$16

$21.1

$19.8

$308.6

$37.1

$17.4

$116.5$0.2

$37.2

$50.7

$1,000.7

$21.6

$0.1

$6.9

$11.2

$25.5

$0.2

$2.3

$19.6

Jefferson

None

< $1 million

$1 - $10 million

$10 - $100 million

$100 - $1,000 million

> $1 billion

H e a d w a t e r s | F a l l 2 0 1 3 1 7

Sources: Colorado Oil and Gas Conservation Commission, Natural Gas Intelligence, U.S. Federal Reserve Economic Data

and reduce the number of dry holes.These technologies, backed by powerful

computers, converged with increased experi-ence and the incentive of higher prices to create something of a perfect storm for exploration in about 2003, and today supplies are bountiful. It’s been widely heralded as a game-changer. Manufacturers are returning, enabled by cheap chemical feedstock provided as part of natu-ral gas production. U.S. per-capita emissions of carbon dioxide have actually decreased in recent years as natural gas displaces coal for electrical production. Boosterish talk of national energy independence abounds. Some compa-nies even want to export natural gas abroad.

In Colorado, lower natural gas prices have meant lower heating bills: Average household energy costs here are 23 percent less than the national average, according to the U.S. Energy Information Administration. The surging oil and gas sector also delivers paychecks for 30,000 people in the state and contributes handsomely to tax coffers. Colorado’s severance tax in 2012 yielded $163 million, half of which was distribut-ed directly to local governments. A portion is also allocated to state water programs and loan funds via the Colorado Water Conservation Board. Dur-ing the 2012 fiscal year, the Colorado Founda-tion for Water Education received 40 percent of its revenue indirectly from state severance taxes.

For billionaire energy entrepreneur T. Boone Pickens, all this is good. “I want to get rid of ethanol. I want to get rid of OPEC. I want to get natural gas in transportation,” he said in August 2013 at the American Renewable Energy Days conference in Aspen. “I don’t think I am talk-ing to a group of people who are all that keen on drilling anything,” he added, but warned: “You’re going to have to deal with natural gas for 100 years. It’s going to be around that long. We have a lot of natural gas in this country.”

That, in the view of skeptics, is exactly the point. It’s an issue of scale—and costs. What do we really know about the impacts to wa-ter? That’s not to mention the round-the-clock clanging, incessant lights, rumbling trucks and pungent odors associated with oil and gas development, all of this sometimes literally in suburban backyards, in fields next to schools, and in pastures where cattle graze. If Colorado is to be such a major source for oil and gas, shouldn’t we get it right—and now, not later?

Trési Houpt was elected as a commissioner in Garfield County in 2002 as drilling rigs sprouted conspicuously in the Piceance Basin. The ba-sin arcs broadly from Carbondale through the Colorado River towns of Silt, Rifle and Battle-ment Mesa and toward one of Colorado’s oldest oil towns, Rangely. She says drilling companies weren’t communicating well with landowners then. That has improved. So have regulations intended to protect the environment and public health. But more, in her view, needs to be done.

“It could have happened to anybody,” she says of a spill of chemicals including the carcin-ogen benzene, a component of crude oil, found this year along Parachute Creek, a tributary to the Colorado River. “I think the contamination of Parachute Creek is just one more example of why we need to be extremely thoughtful about how we develop near waterways and whether we actually should.”

Houpt, who also served on the Colorado Oil and Gas Conservation Commission from 2007 to 2011, is among many Coloradans who be-lieve the implications of the oil and gas technol-ogy revolution have not been fully vetted. “Why not progress thoughtfully as we utilize this re-source and, at the same time, work on the tech-nologies that potentially could make it safer to drill in more populated or sensitive areas across the country?” she asks.

That is essentially the point Longmont is making, now followed by other cities along the Front Range, where citizen-based initiatives are seeking to put moratoriums on the use of hydraulic fracturing—and by extension, drilling altogether—within municipalities.

“Stop the fracking,” shouted one protester in May 2013 as Patty Limerick, noted historian at the University of Colorado Boulder, attempted to interview Gov. Hickenlooper at a forum in Boulder. Working to keep the session produc-tive for the other 450 people in attendance, Limerick ordered her out of the room, and soon another heckler was similarly dispatched. But such extremes only frame the edges of what has become a difficult conversation.

The Rise of Natural GasDrilling is hardly new in Colorado. In 1862, Colo-rado had a commercial oil well, thought to be second in the nation, near Florence, a few miles from Cañon City. Oil seeps led to development of a field north of Boulder in 1901, followed in 1920 by other fields near Fort Collins and Rangely. After World War II, the latter became one of the nation’s preeminent fields.

This post-war boom led to the creation of the Colorado Oil and Gas Conservation Commission (COGCC) in 1951. The agency initially set out to create order in the oil fields, to govern spac-ing in order to create more efficient extraction. The original mission of “preventing waste of the state’s oil and gas natural resources” has since expanded, most significantly in recent years, to include broader environmental protections,

Trési Houpt, former Garfield County commissioner

local vs. State authorityIn November 2012, 60 percent of Longmont voters enacted a ban on hydraulic fracturing within mu-nicipal borders, triggering a legal battle yet to be resolved. In effect, those voters—and others who have contemplated similar bans up and down the Front Range—find existing state regulations inad-equate, the risks to property values, public health and water supplies still too unclear.

In Colorado, federal, state and local govern-ments all have a say in regulating oil and gas activities, and about in that order. The broadest, most powerful laws governing water quality come from the federal government. Clean Water Act standards set by the U.S. Environmental Protec-tion Agency specify how much water produced by coalbed methane wells, for example, must be cleaned—and to what extent—before being released into creeks and rivers. EPA rules also govern the injection of “exploration and produc-tion” waste fluids into disposal wells under the Safe Drinking Water Act. In practice, much of the authority is delegated to two state agencies, the Colorado Department of Public Health and Envi-ronment and the Colorado Oil and Gas Conserva-tion Commission (COGCC).