HAZEMAG Horizontal Impact Crusher HHI - Siming · The impact roll crusher is fitted with a modern...

Transcript of HAZEMAG Horizontal Impact Crusher HHI - Siming · The impact roll crusher is fitted with a modern...

HAZEMAG Horizontal Impact Crusher | HHI

HAZEMAG HHI | heavy - duty crushing operations with horizontal material flow

Type Average Feed Material Size

[mm]

Throughput Rate[t / h]

Drive Capacity[t / h]

HHI 1515 1.000 x 1.400 500 - 1.800 160 - 500

HHI 1518 1.100 x 1.750 800 - 2.500 315 - 630

HHI 1521 1.100 x 2.000 1.000 - 3.000 500 - 630

HHI 1525 1.100 x 2.400 1.200 - 4.000 630 - 750

* values are variable and can be aligned to the particular requirements

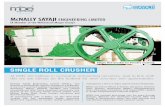

The horizontal crusher type HHI basically consists of two machine components: the crushing roll and the chain conveyor. The arrangement of the crushing roll above the horizontal chain conveyor permits the chain conveyor to be applied both as feed conveyor and as discharge conveyor. This system for crushing has proved successfully in innumerous applications in coal as well as in ore mining, above and underground, in natural stone and in recycling concrete and construction rubble.

This mode of operation of conveying the material to be crushed via the at-grade chain conveyor to a rotating impact roll, crushing and discharging it again is particularly suited for ambitious crushing operations.

Crushing in the horizontal material flow without any directional change is the basic principle of the HAZEMAG HHI and results in an extraordinary compact design with very high throughput rates.

The impact roll crusher is fitted with a modern control, which monitors the input power on the crushing roll as well as on the chain conveyor. This control automatically protects the plant from obstructions and in case of an overload, thus permitting a fully automatic operation of the plant. By means of a height adjustment and speed variation of the crushing roll as well as by changing the chain conveyor’s speed the final product may be influenced.

The HAZEMAG HHI series is a modular system aiming at fulfilling every task in the bulk goods industry. The machine’s equipment with the focus on its options may be modularly adapted to the respective require-ments and wishes of the operators.

Particular advantages of the HAZEMAG HHI series

Conveyor - compatible crushing of the feed material directly in the working area

At - grade material feeding

Crushing in tunnel situations

Erection without foundation

Further possible equipment variations

Feeding bin

Roller screen HRS integrated in chain conveyor

Variable length of chain conveyor

The following degrees of mobility are possible

Steel substructure with skids

With powerless crawler track assembly

With powered crawler track assembly

www.hazemag-group.com

+49 2594 77 - 0

+49 2594 77 - 400

HAZEMAG & EPR GmbH

Brokweg 75 · 48249 Dülmen, Germany

HAZEMAG | HHI– modular with a high throughput rate

HHI | Material situation inside the crushing chamber

1 10 100 1000

95

90

80

70

50

30

10

98

95

60

40

20

0,1 0,5 1,0

2,0 5,0

0,02

5

10

20

30

50

70

90

1

2

40

60

80

99,9 99,5 99,0 98 95

99,98

Grain Size (mm)

Pas

sing

(%

)

Ret

aine

d (%

)

HHI | Granulation Curve