Hard Factsthe tank will withstand this load, we use the formula 5 x 72 psf=360 psf’ 5 inches Hg is...

Transcript of Hard Factsthe tank will withstand this load, we use the formula 5 x 72 psf=360 psf’ 5 inches Hg is...

Hard FactsN e w s l e t t e r

Precast Concrete Association of Virginia

Fall 2006 - November Vol. 9, No. 2

President’s Letter

Hank GottschalkPCAV President

Every traveler Italk with these dayshas a story abouttheir recentadventure flying ourfriendly skies.Although thelocations, names andspecifics change,every one of themseems to have aconsistent underlyingtheme. Life is seldom

played out exactly as you would haveplanned, is it? This is true in our travel plansand also in our everyday lives.

Sometimes life appears to be a sadisticbaseball pitcher, just waiting to catch uswith an unexpected curve ball or that cruelknuckle ball. The successful seem to takethis challenge in stride. Their skill is evidentbecause they know when to swing away,when to hold back, and when to step outof the batter’s box to avoid getting hit withthe ball.

Our association is up against this verysame challenge. No matter how detailed weset our course, things don’t always playout exactly as planned. We, too, need toknow when to swing away, and when holdback. The final outcome is directlydependent on our ability to make thatdecision when the pitch is thrown, and theability to execute the decision at the correcttime. And these decisions do not belongsolely to your Board of Directors.

The challenges faced by PCAV can bemet with dedicated members. I would likeeveryone to consider this question: How

Vacuum Testing: Why?

Continued on page 3

We live at the bottom of a deep sea ofair. Just as submarines can be crushed bydeep water, the air exerts a crushingpressure on everything around us. Whenwe draw the air out of a structure, thedifference in pressure between inside andoutside exerts a force on the structure thattries to crush it. At sea level, the air pressesus with 15 pounds of pressure per squareinch (actually about 14.7 psi). Air pressurevaries with changes in the weather andchanges in altitude. On beautiful, dry,sunny days the air pressure is high.Weathermen report this as inches ofmercury (Hg). A good day may show a

pressure of over 30 inches of Hg. Ahurricane may show a very low pressurearound 29 inches of Hg. For our purposes,we use 30 inches of Hg as one atmospherewhich is about 15 psi of pressure. Since 30inches Hg equals 15 psi, one inch of Hgequals 0.5 psi.

Further, since a square foot is 144square inches, one inch of Hg equals 72pounds per square foot (psf). Using avacuum pump, we draw air out of a structureand measure the effect in terms of inches

Table of Contents

Message from the President ..............1Tech Brief: Vacuum Testing ................1PCAV Happenings ...........................2PCAV Board .......................................2Marketing: Targeting ............................3Tech Brief: Butyl .........................5Annual Conference Recap ............. 62006 Calendar of Events .................8Member Companies..........................8

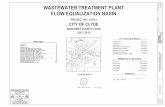

10 inches of Hg applies a load of 720 psf toWinchester Building Supply septic tank.

Continued on page 4

of Hg pressure difference. Total vacuumwould read 30 inches of Hg on a gauge. Itnever happens. Septic tanks are usuallytested for water tightness at 4 inches of Hgand perhaps 7-12 inches to demonstratestructural integrity.

Soil weights vary by type, and watercontent. Obviously wet soil weighs morethan dry soil. Again, let us take a rule ofthumb weight of 120 pounds per cubic foot.Three feet down this soil exerts 360 psf.Ten feet deep it is 1,200 psf. Knowing thesefacts, we can test structures to simulatevarious loads. For example, most septictanks are never buried more than three feetdeep, so an anticipated load on the top ofthe tank would be 360 psf. To test whetherthe tank will withstand this load, we usethe formula 5 x 72 psf=360 psf’ 5 inches Hgis exactly the right load.

ASTM C-1227 is the standard appliedto septic tanks and it tells how to test forwater tightness and structural soundness.To test for water tightness, ASTM C-1227allows either a water test, where the tank isfilled with water (to what level is vague)and let stand for 24 hours. When checked,

www.gopcav.com 888.503.4800

Page 2

Continued on page 3

P C A V O f f i c e r sPresident

Hank GottshalkHanson Pipe & Precast, Inc.

Vice PresidentAlex Mason

Americast - Ashland Plant

Secretary-TreasurerCarissa Alexander

Hanson Pipe & Precast, Inc.

Associates DirectorMarie Derby, Essroc Cement

P C A V D i r e c t o r sStephen Rodgers

Contractors Precast Corp.

Craig WhittenEast Jordan Iron Works, Inc.

Greg OuimetteFrederick Precast Concrete Inc.

Don WurstelMack Industries

John D. McConnellNansemond Pre-Cast Concrete

Frank GrubbsA.L. Patterson, Inc.

Mimi Rainero ColesPermatile Concrete Products Company

Mike BargRinker Materials

Paul ShermanRotondo Precast

James CampbellWinchester Building Supply Co.

Associates RepresentativeWeldon Mitchell, NPC Inc.

NECSA RepresentativeEd Wiles, Roanoke Cement Co.

Promotional PartnerNortheast Cement Shippers Association

General CounselJames D. Fullerton, Fullerton & Associates

Managing ConsultantMark I. Singer, Advocates of Virginia

1108 East Main Street, Suite 1200Richmond, VA 23219

PH: 804.346.1020 FX: 804.346.8287 Toll Free: 888.503.4800

E-mail: [email protected]

PCAV Happenings

Mark SingerPCAV Exec.Director

As this newsletter goes to press, thePCAV is coming off another successfulannual conference. A large crowd ofmembers attended the Wintergreenconvention, and participated in numerousbusiness and social events designed toenhance the value of membership in thePCAV.

Conference DetailsAttendees heard reports from the

association’s standing committees, andpresentations by nationally knownspeakers. The PCAV Board of Directors metand discussed a broad range of issuesaffecting the membership. President HankGottschalk (Hanson), Alex Mason(Americast), and Carissa Alexander(Hanson) were unanimously re-elected tosecond-year terms as the officers of thePCAV. Congrats to all three!

Sandwiched in between thesemeetings were numerous networkingopportunities including a golf outing,reception, dinner and a concludingluncheon. It was a great meeting forlearning, both in the meeting room and overa meal. PCAV would like to thankConference Chair Marie Derby for onceagain making this event a very successfuland informative gathering of the precastconcrete industry in Virginia.

Committee DoingsThe association’s committees continue

to work hard and productively. TheEducation Committee is planning twotraining sessions for this fall, aimed asspecifiers and contractors which willprobably he held in the Northern Virginiaand Tidewater areas of the state.

The Marketing Committee continuesto ensure that the PCAV has a strong

presence at industry-related eventsthroughout the state, and just finishedattending and providing a sponsorship atthe Virginia Engineer’s Conference inWilliamsburg.

The Pipe Committee is working on aPowerPoint presentation for localgovernments designed to provide themwith guidance on both when, and how, toinitiate and conduct a video pipeinspection.

The Drainage and SanitaryStructures Committee continues to workwith VDOT on that VDOT’s intention tomove to a 30-inch clear opening ondrainage system access points, and ameeting will be held on this importantsubject before year’s end. In addition, workcontinues with our VDOT partners toestablish a Precast Concrete and ConcretePipe Certification School to be up andfunctioning before 2007.

The Box Culvert and BridgesCommittee is working with VDOT on aprecast certification for the procurementof materials and is seeking agreement on acommon program for LRFD designs.

New Directory/Marketing SupportAside from all of this committee

activity, members were also pleased torecently receive newly printed copies ofthe 2006 PCAV Directory. And both theassociation’s immediate Past President(Steve Rodgers – Contractors PrecastCorp.) and current President (HankGottschalk – Hanson Pipe and Products,Inc.) drove to BWI Airport in August tomeet with representatives of NECSA (theNortheast Cement Shippers Assoc.) tomake a presentation on behalf of the PCAVfor continued NECSA support of theassociation’s ongoing promotional efforts.The membership thanks both gentlemenfor their time on this important matter.

In order to assist in maximizing ourrelationship with NECSA, your Board ofDirectors is requesting that individualmember firms endeavor to route theirpurchasing of promotional materialsthrough the PCAV office. For more

Page 3

www.gopcav.com 888.503.4800

Continued from page 2PCAV Happenings

deep in the bench can play be successful?Are you willing to step up to the plate andhelp your PCAV be successful?

Every producer, manufacturer, designfirm and municipality is faced with the needto accomplish more with less—less time,less money and less resources. This is agiven, and a requirement, if one is to besuccessful. It is the single element commonto every business; the dilemma is that thisobjective can directly affect whether weare successful.

As an association, can we deepen ourbenches with more involvement in ourcommittees? Perhaps we can share theburden that is often placed on the shouldersof our teammates—to hit us that homerun—by adding a few strategically placedbase hitters in our line up.

Continued from page 1President’s Letter

information on why this is important, andhow it can be easily accomplished, give mea call.

Legislative Non-actionFinally, our industry continues to be

disappointed by state legislators’continued failure to enact a program thatensures a long-term, adequate andsustainable funding stream for Virginia’stransportation infrastructure. StateDelegates and Senators failed toaccomplish this goal during the regularwinter session of the General Assembly,and failed again in a special legislative

session called by the Governor specific-ally for this purpose. Anotherspecial session may be called this fall aslegislators try one last time to reachagreement on ways to provide sufficientfunding to meet Virginia’s ever-growingtransportation needs. PCAV members willbe supporting that effort.

As you can see, PCAV memberscontinue to work hard on a broad range ofactivities that support greater usage andacceptance of precast concrete products.If you are not already actively engaged inthis process, call the PCAV office and findout how you can assist.

~Mark Singer

As a designer, can you deepen yourbenches by enlisting the help of the PCAV?Perhaps a few well-placed pinch hitters canhelp your lineup. The PCAV is alwaysready, willing and able to help designerswith their needs.

As a contractor, can you deepen upyour benches by ordering precast, insteadof on-site construction? The speed, agilityand dependability of using precastconcrete could give that much-neededcompetitive edge.

As an owner, can you deepen yourbenches by demanding dependable precastconcrete? Precast is ready to serve as astructure the very day that it arrives onsite.

I challenge you to consider how youcan help promote precast concrete andcontribute to the PCAV.

~Hank Gottschalk

“Some men dream of worthy accomplishments,while others stay awake and do them.”

~Anonymous

5 Steps to Targeting YourMarketing Message

To win at the game of business, a com-pany needs a good plan. This can be donein-house, with a marketing consultant, orwith a marketing firm. Here are five steps todeveloping and implementing a good mar-keting message:

1. Determine your company’sstrengths and weaknesses.Before you can tell others who you

are and what you do, you need to knowabout yourself. Gather your employees to-gether and brainstorm a list of yourcompany’s strengths and weaknesses.Write everything down that is said and waitto evaluate it until you have exhausted allof the ideas.

Next, review each item on the list anddecide if this is appropriate to be on thelist, or if it can be eliminated. It’s likely youwill find several that can be combined soyou end up with a relatively short list ofstrengths and weaknesses. You can alsodevelop a short survey and ask your cus-tomers and vendors what they think yourstrengths and weaknesses are. Their an-swers may surprise you!

2. Research your target market/customer.Next, analyze your sales from the past

three years. What products or services aremost profitable for you? Who are your cus-tomers? What can you conclude aboutyour customers? What is similar aboutthem? Based on your profitability evalua-tion, should you be targeting a certain typeof customer, or changing your current strat-egies? How do these customers make theirbuying decisions? How can you influencethose decisions?

Consider such things as:• Location• Size business (either sales dollars

or number of employees)• Industries/types of businesses• Type of ownership (sole

proprietor, corporation, etc.)• Who are the decision makers,

influencers and gatekeepers?

3. Investigate your competitors.Continued on page 6

Page 4

www.gopcav.com 888.503.4800

if there is no water loss, the tank is declaredwater tight; if the water has dropped, it isrefilled and checked an hour later, if it stillholds the water without loss it passes. Or

the tank can be subjected to 4 inches Hgand if it holds the vacuum with less than a10 percent loss over two minutes it passes.Vacuum testing is faster and easier tocomplete. Total test time may be less thanten minutes, instead of the 24-hour watertest.

What are the dangers?

Concrete tanks can fly into a pieces asthe air crushes a heavily loaded tank. Plastictanks crush and collapse, fiberglass tankscan fly into pieces too. There’s not muchwarning. The typical top-seam concrete

Continued from page 1Vacuum Testing

tank is not dangerous until vacuums of over7 inches Hg occur. Mid-seam tanks arestronger. Still, care should be taken to stayaway from any tank under vacuum loading.

No matter what the load. It is a good ideato place the test tank in among other tanks,so that flying chunks of concrete arecontained. I personally have testedhundreds of tanks and never had anychunks fly off, but I know it can happenand I am careful.

To begin

1. Select tanks that have sufficientage for testing.

2. Examine the tanks before testingto look for flaws that may indicatea problem

3. Seal all entries except the onethrough which the equipmentdraws a vacuum

4. If the top of the tank is rough , useCS-367 sealant under the test plate

5. It is good to have two gauges,one verifies the other.

6. Gauges with large displays areeasier to read, a range of0–10 inches is ideal.

During the test

1. Do not rush the process. It is betterto slowly raise the vacuum load. If thetank is leaking, decide how to fix it.

7. Most often, the leak is wherethe equipment seals at entries.

8. If you cannot hear the leak,spray soapy water all over the insideand repeat the test 10. Staying insideto look for bubbles while the test isrun will probably kill you!

11. To test for structural loading graduallyincrease the load.

12. Stop when the ultimate load isachieved. There is no need to holdthe pressure.

13. Achieving the high load withoutcracks or fracture is sufficient.

Keep records

1. Take pictures to documentyour process.

Diehl Vault, Orangeville, Pa., loads septic tank with 77,500 lbs. on top. A 22-inch vacuum could loadthe top just as much, but it would also load the sides.

ConSeal CS-367 Seals openings air- and wa-ter-tight. Later, the cover is easily removed.

Continued on page 6

Page 5

www.gopcav.com 888.503.4800

Where Do You Put The Butyl?

There are more wrong answers to thisquestion floating around than there shouldbe. So, if anyone tells you where to put thebutyl, ask how he knows. Before extensivetesting ConSeal had it wrong too. Not now.

Here’s the KeyIn order for ConSeal to work, you need

compression. How much? It’s never beenfully tested, but experience shows that atleast 50 percent compression always works.Will 30 percent compression work? Maybe.Probably.

Can you put too much in the joint?No. It’s just that simple: No. If there isexcess sealant, it will squeeze out of thejoint. In very cold conditions it will takeawhile to compress, but eventually it willsettle to the ideal amount of sealant versusthe weight of the structures and the shapeof the joint. You cannot squeeze it all out.When you see the ConSeal squeezing outof the joint, think “full” not empty.

I actually had an engineer say thatthe sealant had all squeezed out. This iseasily disproved. Take two pieces of steel,a wad of ConSeal, and a vice. Assembleand squeeze. When you try to take the steelpieces apart you will understand theconcept.

Getting the Right CompressionDetermining how much to use to get

the 50 percent compression is a matter ofmeasuring. If there is a ¾-inch gap between

structures then 1½- inch sealant is calledfor. If you cannot easily measure the gap,perform a “bitewing” test. Put some butylstrips across the joints at strategic locationsand assemble the structures. To preventsticking, wet the area or use talcum powder.Let the structure rest for a few minutes anddisassemble. The compression pattern willtell what you need to know.

Put the sealant where the fit is tightest,use a sufficient amount, and watertightstructures are assured. Knead the endstogether to make a continuous bead ofsealant. Cut the ends on a 45-degee angle,or overlap, or overlay, it doesn’t matter; solong as the butyl is kneaded together tomake a continuous gasket.

Box culverts and pipes present theirown challenges. It has been the custom to

put half of the sealant on one piece andhalf on the other. Because without primer itis often difficult to make the sealant “hang”on the face of the concrete while it is beinghandled. Unfortunately, this has led tomistakes. If the ConSeal is placed at theback of the female (bell) and at the back ofthe male (spigot), the gasket is notcontinuous.

Where to Place the SealantIt is perfectly alright to place sealant

at either “inside” or“outside” locationson pipe and culvert.Just do not mix thetwo. No matter whereyou put it, select theright size and qualityof sealant. Be careful

if it is not ConSeal, because there areseveral sizes of the “same size” sealanton the market! This is because ASTM hasremained silent on the subject of sealantsizes. The opportunity to cheat is too muchfor some to resist. Measure the sealant tosee if you got what you paid for. The chartbelow illustrates the point. Theseundersizes have been found at precaster’sacross the Northeast. “One inch” refers tothe equivalent of a round one-inch crosssection. So, a round cross section willmeasure .79 square inches in area.ConSeal’s full size computes to Thecompression pattern will tell what you needto know.

Focus on DetailsPrecast is a very technical business.

Attention to detail makes the differencebetween high and low quality. So what doyou do when you find a joint that is tightsome places and not so good in otherplaces?

First, this indicates that the pallets areoff. Something slipped; there may be astone under one corner of the form;hardened concrete has built up and warpedthe pallet, etc.; for sure something is wrong.You will fix it, but just now you have todeliver a box with an uneven joint and itcan’t leak! Double up the ConSeal in thebad area. Stack sealant upon itself until youhave room to achieve the 40 percentcompression. If stacking is not practical,twist several pieces of sealant uponthemselves to form a rope the size you need.

~Ed Pennypacker, Jepco Sales

Sealant placed “inside” will show when youlookdown into the joints from the insides of thepipe or culvert. For a continuous gasket this iswhere to put the butyl.

Sealant placed “outside” will show when you lookin the joint from outside the structure. Note thatthe ConSeal is placed on the leading edge of thebell and the back shoulder of the spigot.

Page 6

www.gopcav.com 888.503.4800

The 2006 Annual Convention for thePCAV was held on September 12–14 at theWintergreen Resort. The convention waswell-attended by our Producers,Associates and VDOT.

Golf Outing FunDespite the fact that we traded

sunshine for fog, the golfers were still ableto play at the Stoney Creek golf course in

the valley. Many thanks to Golf ChairmanJim Richmond of Americast for hispatience and persistence to reorganize ourgolfers due to the weather conditions. Ourgroup dinner was concluded with SteveBrogan, a ventriloquist, performing a greatshow.

Day TwoThe next day began with the

Associates meeting and then our generalsession. We were enlightened and amusedby Dr. Ken Hover from Cornell University.He not only educated our group but madethe science of concrete entertaining. Hisspeech was very informative and allcomments were excellent. During themeeting, our committee chairs alsopresented brief reports about the pastyear.

Several folks from VDOT attended theconference, and PCAV greatly appreciatestheir support. Mal Kerley, Chief Engineer

PCAV Annual Conference Recap

Ventriloquist Steve Brogan performs at AnnualConference.

Brogan and his dummy “talk” to Don Wagner,Hanson Pipe and Precast.

2. Write down the results.3. Repeat the process.

Note that a single test is not enoughto predict how all of your tanks will perform.At least three tests before a trend isindicated.

~Ed Pennypacker, Jepco Sales

Continued from page 4Vacuum Testing

Who are your main competitors?When you lose a sale, why does this hap-pen? Which competitor generally makes thesale? What is better about your competi-tors’ products and services? Why do yourprospects choose a competitor instead ofyou? What are the annual sales figures foryour competitors? What do they spend ontheir advertising and marketing efforts?(Your industry periodicals and associationscan help you determine this.)

4. Differentiate yourself.How are you better than your com-

petitors? What is different about your com-pany? Is your product or service a higherquality than your competitors’? Is it lessexpensive? Do you have better customerservice? Does your product last longer?Require fewer repairs? Why do your cus-tomers choose you instead of your com-petitor?

What problems do you solve? Make alist of your product’s features and benefits.Are they different than those of your com-petitors?

Try to describe your business in oneshort and succinct “tagline,” or position-ing statement. This should be a clear state-ment of what you do and what you standfor in no more than eight or ten words.Coca-Cola, for instance, says Coke is “TheReal Thing.” Once you create this shortpositioning statement, create your 30-sec-ond sound bite, also known as your “el-evator speech,” to use when you introduceyourself in public. This is also what youwill use to help you focus your marketingefforts.

5. Create a marketing planand execute it.Now that you know who you are, who

your competitors are and how you are bet-ter than them, you can create a roadmap tofollow—a marketing plan for your com-pany. Remember to include measurableshort- and long-term goals, specific strate-gies, and appropriate tactics to reach yourgoals. Then, put your plan into action andevaluate the results, making adjustmentsas required.

~Lois Carter Fay,MarketingIdeaShop.com

Continued from page 3Marketing

at VDOT, offered some brief remarks towardthe end of the convention, and PCAVPresident Hank Gottschalk of Hanson

Pipe and Precast delivered the closingremarks.

Gottschalk also welcomed everyone toour send-off luncheon. Not only did thistrip provide terrific education but a goodtime was had by all!

Please mark your calendars forWintergreen in 2007. Our convention willbe held on September 18-20, 2007.

~Marie DerbyPCAV Associates Director

Essroc Cement

Page 7

www.gopcav.com 888.503.4800

(LtoR) Carissa Alexander (Hanson Pipe andPrecast), Marie Derby (Essrock) and JimRichmond (Americast). Alexander won thelongest drive. (Not pictured): The winner of theLongest Putt was Scott Lander.

And The Winners Are . . .

In the picture at the left are: Conference Speaker Ken Hover (Cornell University),Jim Richmond (Americast), Paul Lewis (Engineered Wire), Mary Beth Rainero(Permatile Concrete Products), Adam Wilkerson (VDOT), Don Anger (Americast).

THE FIRST-PLACE TEAMJohn McConnell (Nansemond Precast), Mike Barg (Rinker Materials)Ed Pennypacker (Concrete Sealants), Marie Derby (Essrock), RickTerrill (USF Fabrication), Jim Richmond (Americast)

THE SECOND-PLACE TEAMEd Plucinski (Hanseon Pipe and Precast), Jerry Mativa, Winches-ter Building Supply,Marie Derby (Essrock), Bob Swope (SwopeAssociates), Jim Richmond (Americast), John Rainero (PermatileConcrete Products)

Fun For All At Annual Conference

“We are what we repeatedly do. Excellence,then, is not an act but a habit.”

~Anonymous

Jim Fullerton (Fulleron & Associates), Adam Wilkerson (VDOT), BrianDeChirico (BASF Admixtures), and Rollie and Marilyn Walk (Universal Sales).

Page 8

1108 East Main Street, Suite 1200Richmond, Virginia 23219

MONTH EVENT/LOCATION

Jan. 9 PCAV/VDOT MeetingBoard MeetingHoliday Inn Koger CenterRichmond, Va.

July 17 PCAV/VDOT MeetingBoard MeetingHoliday Inn Koger CenterRichmond, Va.

Sept. 18-20 PCAV Annual Conference/Wintergreen

Hard Facts is a publication of the Precast Concrete Association of Virginia for its members. Submis-sions, story ideas, member kudos, letters to the editor and comments are welcomed. Contact theeditor, Lois Carter Fay, at 800.203.8660 or [email protected].

Newsletter Designer/Editor: Lois Carter Fay, MarketingIdeaShop.com Website Designer: Mike Doung, ICNS

PCAV Past PresidentsBill Tichacek, Americast 1991-1993Jim Richmond, CP&P 1993-1995Kirby O’Malley, Hydro Conduit 1995-1996Don Anger, CP&P 1996-1997Richard Rotondo, Rotondo Precast 1997-1999Scott Crumpler, Americast 1999-2001Mimi Rainero Coles, Permatile 2001-2003Stephen Rodgers, Contractors Precast Corp. 2003-2005

2007Calendar of Events

P C A V MissionThe Precast Concrete Association ofVirginia is dedicated to the growth of theprecast concrete industry. We pursuethat purpose by educating and partneringwith specifiers, installers and end us-ers on the advantages and proper utili-zation of our products and systems. Theassociation will represent its membersin the Commonwealth of Virginia

PCAV MembersProducer MembersAmericast - Division of

Valley Blox, Inc.Contractors Precast Corp.Frederick Precast

Concrete, Inc.Hanson Pipe & Precast, Inc.Mack IndustriesNansemond Pre-Cast

Concrete Co. Inc.Permatile Concrete

Products Co.Rinker MaterialsRotondo Precast/

Oldcastle PrecastWinchester Building

Supply Co., Inc.

Government MembersCity of Chesapeake

Associate MembersA.L. Patterson, Inc.A-LOK Products, Inc.Boral Material Technologies,

Inc.Capital Foundry of Virginia, Inc.CDS Technologies, Inc.Concrete Sealants, Inc.Dayton Superior Corp.East Jordan Iron Works, Inc.Engineered Wire Products, Inc.Essroc CementFullerton & Knowles, P.C.Hamilton Form CompanyHamilton Kent LLCInsteel Wire ProductsIvy Steel & WireKaufman Products, Inc.La Farge North AmericaLehigh Portland Cement Co.

Luck Stone CorporationM.A. Industries, Inc.Martin Marietta AggregatesMaster BuildersMeadow Burke ProductsNPC Inc.Press-Seal Gasket Corp.Roanoke Cement CompanySeaboard Asphalt Products Co.Spillman CompanySt. Lawrence Cement Corp.Swope & Associates, Inc.The Euclid Chemical CompanyThe SEFA GroupUniversal SalesU.S.F. FabricationVulcan Construction MaterialsW.R. Grace & Co.

Not a member? What’s stopping you? Join now!Call 888.503.4800 or visit www.gopcav.com.

PCAV/VDOT MeetingsAt the PCAV/VDOT meetings listed

above, there will also be numerouscommittee meetings held in conjunctionwith these meetings. These meetings willrun from 9:00 a.m. to 1:30 p.m. Pleasenote these dates on your calendars.Further information on these meetingswill be sent out 30 days in advance ofeach meeting.

Check out the PCAV website!www.gopcav.com