Gantry Cranes/Semi Gantry Cranes by V. M. Engineers Mumbai Mumbai

GULLCO GANTRY/BRIDGE SYSTEMScatalog.gullco.com/Asset/Gantry.pdfGullco Gantry System is equipped with...

Transcript of GULLCO GANTRY/BRIDGE SYSTEMScatalog.gullco.com/Asset/Gantry.pdfGullco Gantry System is equipped with...

GULLCO GANTRY/BRIDGE SYSTEMSCUSTOM ENGINEERED TO AUTOMATE WELDING/CUTTING OPERATIONS

Gullco Gantry Units are custom designed assemblies that are used in a variety of applications such as automated seam welding, fabricatedassemblies, stiffener seams and automated cutting operations such asstripping and edge preparation. Gullco will custom design a gantry/bridgeunit to meet your specific requirements. A wide variety of custom design features and efficient, high quality Gullco systems and components providecost effective, reliable solutions for your welding/cutting needs.

SPECIFICATIONS

®

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE

BULLETIN GBU-99 Campion PRINTED IN CANADA

KAT, MOGGY ,KATBAK & SAM are registered trademarks of Gullco Enterprises Limited

The custom engineered Gullco Gantry/Bridge unit shown above is designed to automate the welding ofaluminum stiffeners on trailer side walls. The system is programmed to automatically locate the stiffener

and then weld both sides simultaneously with dual torches. This unit is equipped with a touch screenIndustrial PC utilizing Citect HMI software

WWOORRLLDD LLEEAADDEERRSS IINN TTHHEE DDEESSIIGGNN,, MMAANNUUFFAACCTTUURREE && DDIISSTTRRIIBBUUTTIIOONN OOFF AAUUTTOOMMAATTEEDD WWEELLDDIINNGG SSYYSSTTEEMMSS

AANNDD AACCCCEESSSSOORRIIEESSCUT COSTS, IMPROVE QUALITY, AND

INCREASE EFFICIENCY...WITH THESE PROVEN GULLCO PRODUCTS

Contact Gullco or your Gullco distributor today for information on any of these quality products

KAT SYSTEMS

- Oscillators- Torch Indexers- Flex & Rigid KAT

Programmable Travel Carriages

- Seam Trackers- Bridge Units- Circle Cutting

System

WELD PREP

- Bevellers- Positioners- Grippers- Kamel Pipe Turning

Rolls

OVENS

- Flux Rebake- Flux Holding- Flux Hoppers- Electrode

Stabilizing- Dry- Pak Portable

Electrode Dispensers

MOGGY

- Trackless Fillet & Butt Welding

- Stitch welding control

- Radial Oscillation Control

- Also operates on 6” V-groove track

CERAMICS

- KATBAK Ceramic Weld Backing

- Impart uniform x-ray quality back beads

- Eliminate costly grinding & re-welds

- Knuckle joints for use on flat or curved surfaces

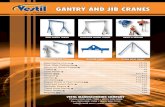

GANTRY BEAM-made fromheavy duty track sections.spans range up to 18 ft(mm).

WELDING GUN/CUTTINGTORCH OR TOOL MOUNTINGSYSTEMS- tailored to suitapplication requirementsincluding mounting SeamTrackers, etc.

GANTRY SUPPORT CARRIAGES- Equipped withtop lading, heavy duty cam-type roller bearing assemblies

LONGITUDINAL TRACK SECTIONS- interlocking designallows unlimited longitudinal travel.

X-AXIS TRAVERSE CARRIAGE-powered by Gullco “KAT”24volt,, low voltage gear headmotors.

Y-AXIS LONGITUDINAL DRIVE-powered by Gullco low voltage,heavy duty drive systems.

CROSS DRIVE SHAFT- directgear drive to each longitudinaltrack ensures accurate trackingof gantry.

CONTROL STATION- incorpo-rates a touch screen 9460industrial flat panel pc utilizingCitect HMI software to controlfunctions such as automaticforward/reverse travel, variablespeeds, automatic seam loca-tion/tracking and automaticoperation of weld guns.

BASIC COMPONENTS OF A GULLCO GANTRY/BRIDGE SYSTEM

GULLCO GANTRY/BRIDGE SYSTEMS

GULLCO GANTRGULLCO GANTRY/BRIDGE FEAY/BRIDGE FEATURESTURES

Touch screen industrial PC utilizing CitectHMI software.

Longitudinal track and cables are locatedunderneath table for protection.

Gullco Gantry System is equipped with dualtorches enabling simultaneous welds on bothsides of aluminum trailer sidewall stiffeners in one pass.

TYPICAL GULLCO GANTRY/BRIDGESYSTEM DESIGN

WELDINGWELDINGThis diagram shows a typical welding Gantry/Bridge unit design. The long tracks are locatedunderneath the table providing protection. This also allows the workpiece to be easily loaded atany point on the table as it is clear and easily accessible. The bridge unit can be equipped toautomatically position and clamp the parts to be welded. It can also be supplied with mechanical,electronic or laser seam tracking equipment.Gullco can custom design a Gantry/Bridge system tomeet your specific requirements.

LLLLEEEETTTT GGGGUUUULLLLLLLLCCCCOOOO EEEENNNNGGGGIIIINNNNEEEEEEEERRRR AAAANNNNDDDD BBBBUUUUIIIILLLLDDDD AAAA GGGGAAAANNNNTTTTRRRRYYYY////BBBBRRRRIIIIDDDDGGGGEEEE SSSSYYYYSSSSTTTTEEEEMMMM FFFFOOOORRRR YYYYOOOOUUUU

Seam Tracking is provided by Gullco designedvertical and horizontal tracking device.