GUJARAT TECHNOLOGICAL UNIVERSITY, AHMEDABAD, …in rear axle assembly, 3e.Analyse and Rectify...

Transcript of GUJARAT TECHNOLOGICAL UNIVERSITY, AHMEDABAD, …in rear axle assembly, 3e.Analyse and Rectify...

Auto Transmission –Mechanism Diagnosis and Testing Course Code: 3360202

GTU/ NITTTR Bhopal/14 Gujarat State

GUJARAT TECHNOLOGICAL UNIVERSITY, AHMEDABAD, GUJARAT

COURSE CURRICULUM

COURSE TITLE: AUTO TRANSMISSION-MECHANISM DIAGNOSIS AND

TESTING

(COURSE CODE: 3360202)

Diploma Programme in which this course is offered Semester in which offered

Automobile Engineering Sixth

1. RATIONALE

This course is designed to develop the deeper understanding in the students about the

troubles occurring in automobile transmission and chassis system and its probable

causes. They will be exposed to systematic method of working using standard trouble

shooting procedure rather than taking adhoc remedial measures. This will make the

learning more interesting and would develop desired skills for proper maintenance of

different component of auto transmission mechanisms.

2. COMPETENCY

The course content should be taught and implemented with the aim to develop required

skills in the students so they can acquire the following competency:

Remedy automobile transmission systems based on diagnosis and testing

using suitable instruments and tools.

3. COURSE OUTCOMES

The theory should be taught and practical should be carried out in such a manner that

students are able to acquire different learning outcomes in cognitive, psychomotor and

affective domain so that they can demonstrate the following course outcomes.

i. Identify probable faults/troubles and their causes in automobile transmission systems.

ii. Use suitable instruments, tools and service manuals for diagnosis and testing of

automobile transmission systems

iii. Remove automobile units by using proper tools and procedures: gear box, brakes,

suspension, final drive, etc.

iv. Disassemble, inspect, and repair various automobile units by using proper tools and

procedures: gear box, differential, brakes, suspension, steering, etc.

v. Follow safety rules for repair and maintenance of various transmission systems of

automobile vehicle.

Auto Transmission –Mechanism Diagnosis and Testing Course Code: 3360202

GTU/ NITTTR Bhopal/14 Gujarat State

4. TEACHING AND EXAMINATION SCHEME

Teaching Scheme

(In Hours)

Total Credits

(L+T+P)

Examination Scheme

Theory Marks Practical Marks Total

Marks

L T P C ESE PA ESE PA 150

4 0 2 6 70 30 20 30

Legends: L-Lecture; T – Tutorial/Teacher Guided Student Activity; P - Practical; C – Credit; ESE - End

Semester Examination; PA - Progressive Assessment.

5. COURSE CONTENT DETAILS

Unit Major Learning Outcomes

(in Cognitive domain) Topics and Sub-topics

Unit – I

Trouble

Shooting of

Clutch

1a.Identify various troubles

in clutch unit and fluid

coupling,

1b.Analyse and Rectify

various troubles in clutch

unit

1c.Explain overhauling of

Clutch

1.1 Troubles in clutch units, its causes

and rectification

1.2 Inspection procedure and

rectification

1.3 Reconditioning of clutch

components

1.4 Clutch adjustment

1.5 Lubrication of clutch units and

linkages

1.6 Troubles in fluid coupling, its

causes and remedies

Unit – II

Inspection,

Testing and

Overhauling of

Gear Box.

2a.Identify various troubles

in gear box

2b.Analyse and Rectify

various troubles in gear

box

2c.Explain overhauling of

Gear box

2.1 Troubles in gear box unit, their

causes and remedies

2.2 Inspection of components of gear

box

2.3 Rectification of various troubles in

components

2.4 Overhauling of gearbox

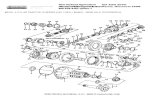

Unit– III

Inspection and

Trouble

Shooting of

Propeller Shaft

- Universal

Joint & Rear

Axle Assembly

3a.Identify various troubles

in propeller shaft,

3b.Analyse and Rectify

various troubles in

propeller shaft

3c.Explain Inspection

procedure of propeller

shaft

3d.Identify various troubles

in rear axle assembly,

3e.Analyse and Rectify

various troubles in rear

axle assembly

3f.Explain Inspection

procedure of rear axle

3.1 Troubles in propeller shaft

assembly

3.2 Inspection procedure

3.3 Rectification of various troubles

3.4 Alignment of propeller shaft

3.5 Troubleshooting of Constant

Velocity Joint

3.6 Troubles in rear axle assembly and

their probable causes

3.7 Inspection procedure for rear axle

assembly

3.8 Rectification of troubles in rear axle

assembly

3.9 Procedure for road testing for

proper performance of rear axle

Auto Transmission –Mechanism Diagnosis and Testing Course Code: 3360202

GTU/ NITTTR Bhopal/14 Gujarat State

Unit Major Learning Outcomes

(in Cognitive domain) Topics and Sub-topics

assembly assembly

Unit– IV

Trouble

Shooting of

Front Axle and

Steering System

4a.Identify various troubles

in front axle and steering

system

4b.Analyse and Rectify

various troubles in front

axle and steering system

4c.Explain Inspection

procedure of front axle

4d. Describe the procedure

of Wheel alignment

4.1 Troubles in front axle and steering

system, and their probable causes

4.2 Inspection procedure for front axle

4.3 Rectification of various troubles

4.4 Procedure of testing for proper

performance

4.5 Wheel alignment procedure

4.6 Troubles, its causes and remedies in

power steering system (Hydraulic and

Electronics)

4.7 Troubleshooting of various steering

gear box

Unit– V

Trouble

shooting of

Braking System

& Service of

Wheels and

Tyres

5a.Identify various troubles

in different braking

system,

5b.Analyse and Rectify

various troubles in brake

5c.Explain brake

performance test

5d.Identify various troubles

in wheels,

5e.Analyse and Rectify

various troubles

5f. Describe the procedure

of tyre rotation and

Wheel balancing

5g. Explain the procedure

of tyre retreading

5.1 Troubles in Mechanical, Hydraulic

and Air braking system and their

causes

5.2 External checks of braking system

5.3 Internal checks of system

5.4 Rectification of various troubles

5.5 Brake performance test

5.6 Trouble shooting of sub assemblies

of various brake systems like Master

Cylinder, Vacuum Booster and

Unloader Valve.

5.7 Trouble shooting of Antilock

Braking System.

5.8 Different troubles and probable

causes in Wheels and Tyres

5.9 Inspection of rim and tyres

5.10 Remedial Operation

5.11 Rotation of tyre

5.12 Tyre Retreading procedure

5.13 Various troubles, causes and

remedies in alloy wheels

5.14 Wheel balancing procedure

Unit– VI

Inspection,

Servicing and

Repair of

Suspension

System &

Chassis Frame.

6a.Identify various troubles

in suspension system

6b.Analyse and Rectify

various troubles in

suspension system

6c. Identify various

troubles in chassis frame,

6d. Analyze and Rectify

various troubles in

chassis and frame

6e. Explain repair and

6.1 Various troubles and their probable

causes in suspension system

6.2 Inspection procedure

6.3 Remedial operation

6.4 Lubrication of coil spring and leaf

spring

6.5 Various troubles and causes in

chassis frame

6.6 Inspection procedure

6.7 Remedial operation

6.8 Repairs and alignment of frame

Auto Transmission –Mechanism Diagnosis and Testing Course Code: 3360202

GTU/ NITTTR Bhopal/14 Gujarat State

Unit Major Learning Outcomes

(in Cognitive domain) Topics and Sub-topics

alignment procedure of

frame

6.9 Schedule for chassis lubrication

6.10 Types of instrument used

6. SUGGESTED SPECIFICATION TABLE WITH HOURS & MARKS

(THEORY)

Unit

No.

Unit Title

Teaching

Hours

Distribution of Theory

Marks

(Duration – 56 Hours)

R

Level

U

Level

A

Level

Total

1. Trouble Shooting of Clutch 08 02 04 04 10

2. Inspection, Testing And Overhauling

of Gear Box. 09 02 05 04 11

3. Inspection and Trouble Shooting of

Propeller Shaft - Universal Joint &

Rear Axle Assembly 11 04 04 06 14

4. Trouble Shooting of Front Axle and

Steering System 08 02 04 03 09

5. Trouble shooting of

Braking System & Service of Wheels

and Tyres 12 04 04 06 14

6. Inspection, Servicing and Repair of

Suspension System & Chassis Frame. 08 04 04 04 12

Total 56 18 25 27 70

Legends: R = Remember; U = Understand; A = Apply and above levels (Bloom’s

revised taxonomy)

Note: This specification table shall be treated as a general guideline for students and

teachers. The actual distribution of marks in the question paper may vary slightly from

above table.

7. SUGGESTED LIST OF EXERCISES/PRACTICALS

The practical should be properly designed and implemented with an attempt to develop

different types of skills (outcomes in psychomotor and affective domain) so that

students are able to acquire the competencies/programme outcomes. Following is the

list of practical exercises for guidance.

Sr.

No.

Unit

No.

Practical Exercises (Any Seven)

(Outcomes’ in Psychomotor Domain) Hours

(Total 28 hrs)

1 I Perform servicing of clutch 4

2 II Perform servicing of gear box 4

3 II Perform servicing of gear shifting mechanism 4

4 II Perform servicing of automatic transmission 4

5 II Perform servicing of fluid coupling 4

6 III Perform servicing of final drive 4

7 IV Perform servicing of steering system 4

8 V Perform servicing of braking system 4

Auto Transmission –Mechanism Diagnosis and Testing Course Code: 3360202

GTU/ NITTTR Bhopal/14 Gujarat State

9 V Perform bleeding of hydraulic braking system

and pedal adjustment

4

10 V Perform servicing of air brake system 4

11 V Perform wheel alignment and balancing 4

12 VI Wash and service the car. 4

8. SUGGESTED LIST OF STUDENT ACTIVITIES

Following is the list of proposed student activities like: course/topic based seminars,

internet based assignments, teacher guided self learning activities,

course/library/internet/lab based mini-projects, Demonstration, Industrial Visits, Video

collection, Chart or Model preparation by students etc. These could be individual or

group-based.

9. SPECIAL INSTRUCTIONAL STRATEGIES (If any) i. Case studies of typical maintenance problems in different makes of automobiles

and problem based learning

ii.Arrange expert lectures of maintenance executives of different automobile

companies.

iii.Visit to authorize workshop of two wheeler, three and four wheeler.

iv.Collection of animation or video clips and presentation using same.

v.Chart or Model preparation by students

10. SUGGESTED LEARNING RESOURCES

A) List of Books

Sr.No. Author Title of Books Publication

1 R. B. Gupta Automobile Engineering Satya Prakashan, New Delhi

2 W.H.Crouse &

D.L. Anglin

Automotive Mechanics Tata Mc-Graw Hill

Publishing Co. Ltd.

3 Ernest A. Venk,

Edward Dale

Spicer & Irving

Augustus Frazee

Automotive maintenance

and trouble shooting

American Technical Society,

1963

4 Anthony E.

Schwaller

Total Automotive

Technology

Cengage Learning, 2004

5 Tim Gills Automotive Service:

Inspection, Maintenance,

Repair

Cengage Learning, 2011

6 R.C. Mishra, K.

Pathak

Maintenance Engineering

And Management

PHI Learning Pvt. Ltd., 2004

7 C.P. Nakra Automobile Engineering Dhanpat Rai Publication Co.

(P) Ltd.

8 N.K.Giri Automotive Technology Khanna Publication Co. (P)

Ltd.

B) List of Major Equipment/ Instrument with Broad Specifications

a. Tool Box (2 sets atleast for Intake of 60 students.), Container for Oil Drain.

Auto Transmission –Mechanism Diagnosis and Testing Course Code: 3360202

GTU/ NITTTR Bhopal/14 Gujarat State

b. Measuring instruments and gages like Vernier caliper, Micrometer, Filler gauge,

Thread gauge etc.

c. Various charts for safety slogan, servicing & overhauling of various systems.

C) List of Software/Learning Websites

Sr.No Topic / Video Title URL Address

1 1 Connecting brake lines with a

compression fitting

http://youtu.be/rF9p0KoYU4E?list=PLPvqV

A0h0J6ib8WNSsv1lTOQKOMAQVHNz

2 2 Checking a pressed in lower ball

joint for wear

http://youtu.be/RWZq9WapzrM?list=PLPvqV

A0h0J6ib8WNSsv1lTOQKOMAQVHNz

3 4 Changing a vehicle brake line http://youtu.be/1ltBpXORbhU?list=PLPvqVA

0h0J6ib8WNSsv1lTOQKOMAQVHNz

4 5 Car O Liner Mark 6 Frame

Alignment Bench

http://youtu.be/w-

j6T_Yj18g?list=PLPvqVA0h0J6ib8WNSsv1l

TOQKOMAQVHNz

5 6 Bench bleeding a brake master

cylinder

http://youtu.be/KglpDbSI2F8?list=PLPvqVA

0h0J6ib8WNSsv1lTOQKOMAQVHNz

6 7 ABS Brakes & More How to

Troubleshoot ABS Disc Brakes

http://youtu.be/CqXmrex-

DD4?list=PLPvqVA0h0J6ib8WNSsv1lTOQ

KOMAQVHNz

7 9

8

1998 Ford Ranger Rear

Differential Reassembly

http://youtu.be/tQQ6OorGI4E?list=PLPvqVA

0h0J6ib8WNSsv1lTOQKOMAQVHNz

8 9 1998 Ford Ranger Rear

Differential Disassembly

http://youtu.be/ISqhuAh8Eus?list=PLPvqVA

0h0J6ib8WNSsv1lTOQKOMAQVHNz

9 3D Wheel Alignment Manatec

FOX 3D

http://youtu.be/iA327NEjwYw?list=PLPvqV

A0h0J6ib8WNSsv1lTOQKOMAQVHNz

10 Wheel balancing http://youtu.be/yRoXUI3UR0k?list=PLPvqV

A0h0J6ib8WNSsv1lTOQKOMAQVHNz

11 Wheel balancer http://youtu.be/Hl6Oy6jViEs?list=PLPvqVA0

h0J6ib8WNSsv1lTOQKOMAQVHNz

12 Wheel Alignment Why cars need

four wheel alignment

http://youtu.be/59aJ3YERo_I?list=PLPvqVA

0h0J6ib8WNSsv1lTOQKOMAQVHNz

13 Symptoms of unbalanced tires http://youtu.be/m9f63m31bVs?list=PLPvqVA

0h0J6ib8WNSsv1lTOQKOMAQVHNz

14 Symptoms of a worn wheel

bearing while driving the vehicle

http://youtu.be/3ly_QReFOg0?list=PLPvqVA

0h0J6ib8WNSsv1lTOQKOMAQVHNz

15 Symptoms of a warped brake

rotor

http://youtu.be/F5Epq1wZ5Do?list=PLPvqV

A0h0J6ib8WNSsv1lTOQKOMAQVHNz

16 MGB Differential Repair Part 2 http://youtu.be/xA6kA09XTlY?list=PLPvqV

A0h0J6ib8WNSsv1lTOQKOMAQVHNz

17 How To Test, Troubleshoot,

Remove & Replace a Power

Steering Gear Box

http://youtu.be/QsbNTjqSjpk?list=PLPvqVA0

h0J6ib8WNSsv1lTOQKOMAQVHNz

18 How to Perform an Alignment

on Your Car at Home

http://youtu.be/C8lnafFxtE4?list=PLPvqVA0

h0J6ib8WNSsv1lTOQKOMAQVHNz

19 How To Diagnose A Clutch

Problem

http://youtu.be/eqrFtnSZlMU?list=PLPvqVA

0h0J6ib8WNSsv1lTOQKOMAQVHNz

20 How to connect brake lines with http://youtu.be/kBwQPoHWmyE?list=PLPvq

Auto Transmission –Mechanism Diagnosis and Testing Course Code: 3360202

GTU/ NITTTR Bhopal/14 Gujarat State

new fittings & a union VA0h0J6ib8WNSsv1lTOQKOMAQVHNz

22 How to bend brake lines with a

pulley

http://youtu.be/-

T7pxl2RtpQ?list=PLPvqVA0h0J6ib8WNSsv

1lTOQKOMAQVHNz

23 Troubleshooting brake chamber http://youtu.be/9r1b1_9T7L4?list=PLPvqVA0

h0J6ib8WNSsv1lTOQKOMAQVHNz

24 What Are Typical Steering and

Suspension Problems

http://youtu.be/vdmdGQcbh50?list=PLPvqV

A0h0J6ib8WNSsv1lTOQKOMAQVHNz

Complete Playlist URL

http://www.youtube.com/playlist?list=PLPvqVA0h0J6ib8WNSsv1lTOQKOMA

QVHNz

11. COURSE CURRICULUM DEVELOPMENT COMMITTEE

Faculty Members from Polytechnics

Prof. M. J. Pathak, H.O.D., Auto.Dept. Sir Bhavsinhji Polytechnic Inst., Bhavnagar.

Prof. S.V. Trivedi, H.O.D., Automobile Department, Parul Institute of Technology,

Waghodia, Vadodara.

Prof. D. J. Gohel, Lecturer, Automobile Department, C.U. Shah Polytechnic,

Surendranagar.

Prof. A. C. Suthar, Lecturer, Automobile Dept. MLIDS Polytechnic, Bhandu

Coordinator and Faculty Members from NITTTR Bhopal

Dr. K.K. Jain, Professor, Department of Mechanical Engineering

Dr. C. K. Chugh, Professor, Department of Mechanical Engineering

SUBJECT: AUTOMOBILE TRANSMISSION MECHANISM DIAGNOSIS AND TESTING

ASSIGNMENT - 1 TROUBLE SHOOTING OF CLUTCH

1 Explain various types of clutch adjustment2 Explain following terms with reasons & remedies. (1) clutch shudder (2) clutch chattering3 Mention various defects occur in a clutch unit & explain any one with causes and remedies.4 Write short note on servicing of clutch unit.5 Describe the procedure of securing alignment of clutch components with reference to fly

wheel, while refitting the clutch assembly6 What are the different causes and remedies of troubles in clutch systems7 Write short note on Clutch Dragging & Clutch Chattering.

SUBJECT: AUTOMOBILE TRANSMISSION MECHANISM DIAGNOSIS AND TESTING

ASSIGNMENT – 2 INSPECTIONS, TESTING AND OVERHAULING OF GEAR BOX

1 Write Various types of noises produced in different parts of gear-box & also give causes of each

2 Explain following terms with reasons & remedies with reference to Gear-box.(1) hard shifting (2) slipping of gear

3 Explain procedure of overhauling of gear-box and state precautions to be taken while fitting gear-box on bell-housing

4 Write short note on gear box over hauling5 Give causes and remedies of “Power not transmitted by gear box”.6 Mention the troubles arise in gear box due to defective shifting mechanism7 What are the checks and adjustments normally carried out while assembling a three speed

synchromesh gear box.

SUBJECT: AUTOMOBILE TRANSMISSION MECHANISM DIAGNOSIS AND TESTING

ASSIGNMENT – 3 INSPECTIONS AND TROUBLE SHOOTING OF PROPELLERSHAFT -UNIVERSAL JOINT & REAR AXLE ASSEMBLY

1How will you inspect following(1) bearing(2) thrust washer (3)rear axle (4) pinion (5)differential gear

2 Explain effect of following.(1) Low level of lubricating oil in differential (2) poor maintenance of propeller shaft, universal joint and slip joint.

3 Explain inspection procedure of propeller shaft.4 Describe any five typical contact pattern with neat sketch between crown wheel and drive

pinion and give causes for each pattern.5 Explain troubles in rear axle assembly .Also give Causes and Remedies6 Write the procedure in brief for removing, dismantling, checking and refitting of propeller

shaft of any vehicle

SUBJECT: AUTOMOBILE TRANSMISSION MECHANISM DIAGNOSIS AND TESTING

ASSIGNMENT – 4 TROUBLE SHOOTING OF FRONT AXLE AND STEERINGSYSTEM

1Write causes and remedies for following.(1) hard steering (2) front wheel shimmy(3) excessive play in steering column (4) Front wheel wobble at high speed

2 Explain the procedure for obtaining the proper “toe-in” of a given vehicle and give all preliminary checks required for performing wheel alignment job.

3 Write problems arise due to faulty steering system with remedial measure of each4 State preliminary checks required while checking wheel alignment.5 What are causes and remedies for front wheel wobble at all speed?6 Write Causes & Remedies for Excessive looseness in the Power Steering system7 Write down various troubles arise in Front Axle8 State the effects of wrong castor and uneven camber on the steering mechanizing9 State the procedure of checking and adjusting of “ Toe” in a Heavy motor vehicle

SUBJECT: AUTOMOBILE TRANSMISSION MECHANISM DIAGNOSIS AND TESTING

ASSIGNMENT – 5 TROUBLE SHOOTING OF BRAKING SYSTEM & SERVICE OFWHEELS AND TYRES

1Explain reasons & remedies for following with reference to brake.(1)spongy brake (2) brake pulling (3)noisy brake

2 Explain total service of drum type braking system3 Give characteristics of brake-fluid. Also state the procedure for bleeding the hydraulic

braking system. 4 Explain common problems of following with reason.

(1) air assisted hydraulic brake (2) mechanical brake5 Write short note on (1) Tire retreading. (2) General schedule for chassis lubrication6 Mention various troubles with causes of air assisted hydraulic brakes.7 Write short note on Wheel Balancing Procedure.8 List various troubles & causes in Wheel & Tyre.9 What are common troubles and their remedies of “Air-brake”10 List various troubles & causes in Wheel & Tyre

SUBJECT: AUTOMOBILE TRANSMISSION MECHANISM DIAGNOSIS AND TESTING

ASSIGNMENT – 6 INSPECTION, SERVICING AND REPAIR OF SUSPENSIONSYSTEM& CHASSIS FRAM

1Write advantages of independent suspension system and state the ill effects of unbalanced wheel in this type of suspension

2 State the causes of wheel cracks and misalignment of car chassis3 Describe following.

(1)reasons for noise from leaf spring (2)testing of telescopic shock absorber4 What are the causes and remedies for hard rigid suspension?5 Explain various method for repair and alignment of frame6 List the various check points necessary for inspection of a leaf spring assembly on a

vehicle

Laxmi Institute of Technology, SarigamApproved by AICTE, New Delhi; Affiliated to Gujarat Technological University, Ahmedabad

Academic Year 2018-19

Centre Code: 691 Examination : MID – I ExaminationBranch: automobile Semester: 6th Sub Code:3360202Sub: ATMDT Date: 29/01/2019 Time: 10:30 to 11:30 Marks: 20Note: write any four of it1 Write short note on servicing of clutch unit. 52 Write short note on Clutch Dragging & Clutch Chattering. 53 Explain following terms with reasons & remedies with reference to Gear-box.

(1) hard shifting (2) slipping of gear

5

4 Give causes and remedies of “Power not transmitted by gear box”. 55 How will you inspect following

(1) bearing(2) thrust washer (3)rear axle (4) pinion (5)differential gear

5

6 Explain inspection procedure of propeller shaft. 57 Write short note on gear box over hauling 5

Laxmi Institute of Technology, SarigamApproved by AICTE, New Delhi; Affiliated to Gujarat Technological University, Ahmedabad

Academic Year 2018-19

Centre Code: 691 Examination : MID – I ExaminationBranch: automobile Semester: 6th Sub Code:3360202Sub: ATMDT Date: 29/01/2019 Time: 10:30 to 11:30 Marks: 20

Note: તતેમમમાંથથ કકોઈપણ ચમર લખકો1 ક્લચ યયુનનિટનિથ સનરર્વિનસમાંગ પર ટટમાં કથ નિનોંધ લખકો. 52 ક્લચ ડડતે નગમાંગ અનિતે ક્લચ ચતેટરરમાંગ પર ટટમાં કમ નિનોંધ લખકો 53 નગયર-બકોક્સ સમાંદરર્ભે કમરણકો અનિતે ઉપમયકો સમથતે નિથચતેનિથ શરતકો સમજારકો. (1) હમડર્વિ નશનફટમાંગ (2) સ્લથનપમાંગ નગયર 5

4 નગયર બબૉક્સ દમરમ પમરર નિમ ટડ મન્સમથટ થમઈ " એનિમ કમરણકો અનિતે ઉપમયકો આપકો. 55 તમતે નિથચતેનિયુમાં નનિરથક્ષણ કતેરથ રથતતે કરશકો

(1) બતેરરમાંગ (2) થ્રશ રકોશર (3) પમછળનિકો એક્સલ (4) નપનનિયનિ (5) રડફરન્ટ નગયર5

6 પકોપતેલર શમફટનિથ નનિરથક્ષણ પરક્રિયમ સમજારકો. 57 નગયર બકોક્સ પર ટટમાંકમ નિનોંધ લખકો 5

1/3

Seat No.: ________ Enrolment No.______________

GUJARAT TECHNOLOGICAL UNIVERSITY DIPLOMA ENGINEERING – SEMESTER – VI(NEW) • EXAMINATION – WINTER - 2018

Subject Code: 3360202 Date:06-12 - 2018

Subject Name: AUTO TRANSMISSION-MECHANISM DIAGNOSIS AND TESTING

Time: 02:30 PM TO 05:00 PM Total Marks: 70 Instructions:

1. Attempt all questions.

2. Make Suitable assumptions wherever necessary.

3. Figures to the right indicate full marks.

4. Use of programmable & Communication aids are strictly prohibited.

5. Use of only simple calculator is permitted in Mathematics.

6. English version is authentic.

Q.1 Answer any seven out of ten. દશમ ાંથી કોઇપણ સ તન જવ બ આપો. 14

1. Write the principle of clutch.

૧. ક્લચનો સસધ્ ાંત જણ વો.

2. Why compressed air is not to be used to remove dust from clutch plates?

૨. ક્લચ પ્લેટ પરથી રજકણો દૂર કરવ કોમ્પ્રસે્ડ એરનો ઉપયોગ શ મ ટે કરવ મ ાં આવતો નથી?

3. Write the function of Detent spring in Gearbox.

૩. ગીયર બોક્ષમ ાં ડીટેન્ટ સ્રીંગનનાં ક યય જણ વો.

4. Can we use engine oil in gearbox? Why?

૪. આપણે ગીયર બોક્ષમ ાં એન્ીન ઓઇલ ઉપયોગ કરી સકીએ? શ મ ટે?

5. Give reasons for the leakage of gear oil.

૫. ગીયર ઓઇલ લીકેજ થવ ન ક રણો જણ વો.

6. How “Whipping” of propeller shaft can be controlled?

૬. રોપેલર શ ફ્ટન “વ્હીપીંગ” એક્શનનન સનયત્રણ કેવી રીતે કરી શક ય?

7. What is “Torque Steer” in case of rear axle assembly?

૭. રીયર એક્શલન અનનસાં્ ને “ટોકય સ્ટીયર” શનાં છે?

8. Explain servicing of constant velocity joint.

૮. કોન્સ્ટાંટ વેલોસીટી જોઇન્ટનનાં સવીસીંગ સમજાવો.

9. Draw tyre rotation pattern for six wheeler.

૯. છ પૈડ વ ડ વેહીક્લ મ ટે ટ યર રોટેશન દોરો.

10. What is meaning of sprung and unsprung weight?

૧૦. સ્રાંગ વેઇટ અને અનસ્રાંગ વેઇટનો અથય સમજાવો.

Q.2 (a) Explain causes and remedies for clutch dragging. 03

રશ્ન. ર (અ) ક્લચ ડે્રગીંગ મ ટેન ક રણો અને ઊપ યો જણ વો. ૦૩

OR

(a) Give causes and remedies for clutch judder. 03

(અ) ક્્ચ જડરની ખ મી મ ટેન ક રણો અને ઊપ યો જણ વો. ૦૩

(b) Write reasons for slipping of clutch. 03

(બ) ક્લચ સ્લીપ થવ ન ક રણો જણ વો. ૦૩

OR

(b) Write short note on Clutch adjustment 03

2/3

(બ) ટૂાંકનોં્ લખો. ક્લચ એડજ્સસ્ટમેંટ. ૦૩

(c) Write inspections way to gear box parts. 04

(ક) ગીયર બોક્ષન પ ર્ટનનું ઇંસ્પેક્શન કરવ ની રીત જણ વો. ૦૪

OR

(c) Explain bleeding of clutch hydraulic system. 04

(ક) હ ઇડ્રોસલક ક્લચ સીસ્ર્ટમનનાં બ્લીડીંગ સમજાવો. ૦૪

(d) Write procedure for reinstallation of clutch. 04

(ડ) ક્લચને ફરી તેની જગ્ય એ ફીટ કરવ ની રીત લખો. ૦૪

OR

(d) Write short note on Gearbox overhauling. 04

(ડ) ટૂાંકનોં્ લખો.ગીયર બોક્ષ ઓવરહોલીંગ ૦૪

Q.3 (a) Explain following terms with reasons & remedies with reference to gear-box.

(1) Hard shifting (2) slipping of gear. 03

રશ્ન. 3 (અ) ગીયર બોક્ષ મ ટે નીચેન ન ાં ક રણો અને ઉપ યો જણ વો.

(1) હ ડય સશફ્ટીંગ (2) ગીયરનનાં સ્લીપીંગ

૦૩

OR

(a) Describe the gear box removal procedure. 03

(અ) ગીયર બોક્ષ રીમનવ કરવ ની રીત સમજાવો. ૦૩

(b) Write short note on overhauling of transaxle. 03

(બ) ટૂાંકનોં્ લખો. ટ્ર ન્સએક્ષલનનાં ઓવર હોલીંગ ૦૩

OR

(b) Give causes and remedies for “ hard gear shifting”. 03

(બ) “હ ડય ગીયર સશફ્ટીંગ” ન ક રણો અને ઉપ યો જણ વો. ૦૩

(c) Write the inspection procedure for propeller shaft. 04

(ક) રોપેલર શ ફ્ટની તપ સ કરવ ની રક્રીય લખો. ૦૪

OR

(c) State various types of joints used in propeller shaft with their purpose. 04

(ક) રોપલેર શ ફર્ટમ ાં વપર ત જનદ જનદ જોઇન્ટન ન મ તેન હેતન સ થે લખો. ૦૪

(d) State causes and remedies for noisy rear axle. 04

(ડ) રીયલ એક્ષલમ ાંથી અવ જ આવવ ન ક રણો અને ઉપ યો જણ વો. ૦૪

OR

(d) Enlist troubles arises in rear axle. 04

(ડ) રીયર એક્ષલમ ાં ઉદભવતી ખ મીઓ જણ વો. ૦૪

Q.4 (a) Explain the steps of overhauling of differential. 03

રશ્ન. ૪ (અ) ડીફ્ર્નન્શીયલનનાં ઓવરહોલીંગ કરવ ન પગથીય ાં જણ વો. ૦૩

OR

(a) List different contact patterns between crown wheel and drive pinion and explain

any one with neat sketch. 03

(અ) ક્ર ઉન વ્હીલ અને ડ્ર ઇવ પીનીયનન કોન્ટેકની ત્રણ પેટનય આકૃસત સ થે સમજાવો. ૦૩

(b) Give causes and remedies for “front wheel wobble at high speed.” 04

(બ) ફ્ર્નન્ટ વ્હીલ વોબલ એટ હ ઇસ્પીડસ્પીડન ક રણો અને ઉપ યો જણ વો. ૦૪

OR

(b) State preliminary checks required while checking wheel alignment. 04

(બ) વ્હીલ એલ યમેન્ટ દરમ્પ્ય ન કરવી પડતી ર થમીક ચક સણી વણયવો. ૦૪

3/3

(c) Write short note on Hydraulic Brake Bleeding. Why it is necessary? 07

(ક) ટૂાંકનોં્ લખો.હ ઇડ્રોલીક બ્રેક બ્લીડીંગ. તે શ મ ટે જરુરી છે ? ૦૭

Q.5 (a) List various troubles in wheel & tyres. 04

રશ્ન. ૫ (અ) વ્હી્સ અને ટ યરમ ાં આવતી જનદી જનદી ખ મી જણ વો. ૦૪

(b) Explain how to retreading the tyres. 04

(બ) ટ યર રીટ્રેડીંગ કરવ ની રીત જણ વો. ૦૪

(c) Mention the defects arise in chassis-frame and its causes. 03

(ક) ચેસીસ ફે્રમની ખ મીઓ જણ વી તેન ક રણો જણ વો. ૦૩

(d) State the method for testing telescopic shock absorber. 03

(ડ) ટેલીસ્કોપીક શોક એબ્શોબયરની તપ સ રક્રીય જણ વો. ૦૩

************

1/3

Seat No.: ________ Enrolment No.______________

GUJARAT TECHNOLOGICAL UNIVERSITY

DIPLOMA ENGINEERING – SEMESTER – 6(NEW) • EXAMINATION – SUMMER 2018

Subject Code: 3360202 Date: 08-May-2018

Subject Name: Auto Transmission-Mechanism Diagnosis And Testing

Time: 10:30 AM TO 01:00 PM Total Marks: 70 Instructions:

1. Attempt all questions.

2. Make Suitable assumptions wherever necessary.

3. Figures to the right indicate full marks.

4. Use of programmable & Communication aids are strictly prohibited.

5. Use of only simple calculator is permitted in Mathematics.

6. English version is authentic.

Q.1 Answer any seven out of ten. દશમ ાંથી કોઇપણ સ તન જવ બ આપો. 14

1. What do you mean by clutch pedal pulsation?

૧. ક્લચ પડલલ પ્સડસન નો મતલબ ું ાં ડે

2. Give reasons for the leakage of gear oil.

૨. ગીયર ઓઈલ લીકેજ થવ ન ક રણો આપો.

3. How “Whipping” of propeller shaft can be controlled?

૩. પ્રોપડલર શ ફ્ટન “વ્હીપીંગ” એકશનન ાં નનયાંત્રણ કેવી રીતડ કરી શક ય

4. What is “Torque Steer” in case of rear axle assembly?

૪. રીયર એક્સલ ન અન સાંધ નડ “ટોકક સ્ટીયર” ું ાં ડે

5. How to check bend or twisted axle beam?

૫. બેંલ અથવ ટ્વીસ્ટ થયડલી એક્સલ બીમ કેવી રીતડ ચ ડક કરવી

6. What is braking efficiency? What are the factors governing it?

૬. બ્રડકીંગ એફીસીયાંસી એટલડ ું ાં તડનડ નનયાંત્રણમ ાં ર ખત મ દ્દ ઓ જણ વો.

7. What is tyre rotation? Why it is necessary?

૭. ટ યર રોટેશન એટલડ ું ાં એની જરૂરીઆત શ મ ટે ડે

8. What is backlash? Name the device used to measure it.

૮. બડકલડશ એટલડ ું ાં તડન ાં મ પન કરવ મ ાં વપર ત સ ધનન ાં ન મ આપો.

9. What do you mean by “sagging” of springs? What is its effect on vehicle

driving?

૯. સ્પ્રીંગ્સ ન ાં “સડગીંગ” એટલડ ું ાં તડની વડહીકલ ન દ્ર ઈવીંગ ઉપર શી અસર થ ય ડે

10. Name the instruments used for checking misaligned chassis frame?

૧૦. વ ાંકી વળી ગયડલી ચ ડસીસ ફે્રમની ચ ક સણી કરવ મ ટે વપર ત સ ધનન ન મ લખો.

Q.2 (a) Give causes and remedies for clutch judder. 03

પ્રશ્ન. ર (અ) “ક્લચ જલર” ની ખ મી મ ટેન ક રણો અનડ ઉપ યો આપો. ૦૩

OR

(a) Give causes and remedies for “ hard gear shifting” 03

(અ) “હ લક ગીયર શીફટીંગ” ન ક રણો અનડ ઉપ યો જણ વો. ૦૩

2/3

(b) Write the inspection procedure for propeller shaft. 03

(બ) પ્રોપડલર શ ફ્ટની તપ સ કરવ ની પ્રક્રિય લખો. ૦૩

OR

(b) List different contact patterns between crown wheel and drive pinion and

explain any one with neat sketch.

03

(બ) િ ઉન વ્હીલ અનડ ડ્ર ઈવ પીનીયનન ાં દ ાંત વચ્ચ ડ સાંપકક સ ધવ થી મળત પડટનકની ય દી આપો અનડ કોઈ પણ એક સ્વચ્ે આક્રુનત સ થડ સમજાવો.

૦૩

(c) Write short note on clutch adjustment. 04

(ક) ક્લચ એલજસ્ટમેંટ ઉપર ટ ાંક નોંધ લખો. ૦૪

OR

(c) Write short note on Gear box overhauling. 04

(ક) ગીયર બોક્ષ ઓવરહોલીંગ ઉપર ટ ાંક નોંધ લખો. ૦૪

(d) Give causes & remedies for different troubles in propeller shaft. 04

(લ) પ્રોપડલર શ ફ્ટમ ાં ઉદભવનત જ દી જ દી ખ મીઓન ક રણો અનડ ઉપ યો જણ વો.

૦૪

OR

(d) State the reasons for changing both, ring gear and drive pinion together while

differential overhauling.

04

(લ) રીંગ ગીયર અનડ ડ્ર ઈવ પીનીયનનડ લીફે્રન્શીયલન ઓવરહોલીંગ વખતડ એક સ થડ બદલવ ન ક રણો લખો.

૦૪

Q.3 (a) Give causes and remedies for “front wheel wobble at high speed.” 03

પ્રશ્ન. 3 (અ) “ફ્ર્નન્ટ વ્હીલ વોબલ એટ હ ઈ સ્પીલ” ન ક રણો અનડ ઉપ યો જણ વો. ૦૩

OR

(a) Give causes and remedies of “front wheel shimmy”. 03

(અ) “ફ્રન્ટ વ્હીલ શીમી” મ ટે ક રણો અનડ ઉપ યો આપો. ૦૩

(b) State preliminary checks required while checking wheel alignment. 03

(બ) વ્હીલ અલ ઈન્મેંટ દરમ્ય ન કરવી પલતી પ્ર થમીક ચ ક સણી વણકવો. ૦૩

OR

(b) Write the procedure for strut rod adjustment. 03

(બ) સ્ત્રટ રોલ એલજસ્ટમેંટની પ્રક્રિય લખો. ૦૩

(c) State the effects of wrong caster and uneven camber on steering operation. 04

(ક) ખોટ કેસ્ટર તથ અનનયમીત કેમ્બર એન્ગલની સ્સ્ટયરીંગ મીકેનીઝમ ઉપર થ્તી

થ્તી

૦૪

થતી અસરો જણ વો. OR

(c) Write inspection procedure for front axle. 04

(ક) ફ્રન્ટ એક્ષલ તપ સ કરવ ની પ્રક્રિય જણ વો. ૦૪

(d) Write causes and remedies for excessive looseness in power steering system. 04

(લ) પ વર સ્સ્ટયરીંગ મ ાં વધ પલતી લ ઝનડસ મ ટેન ક રણો અનડ ઉપ યો જણ વો. ૦૪

OR

(d) Write procedure of wheel balancing. 04

(લ) વ્હીલ બડલડન્સીંગ કરવ ની પ્રક્રિય લખો. ૦૪

Q.4 (a) Write procedure of servicing drum brake. 03

3/3

પ્રશ્ન. ૪ (અ) ડ્રમ બ્રડકનડ સરવીસ કરવ ની રીત લખો. ૦૩

OR

(a) Give causes and remedies for “pedal goes to floor board” 03

(અ) “પડલલ ફ્લોર બોલકનડ અલી જાય ડે”. આ ખ મી મ ટે ક રણો અનડ ઉપ યો આપો. ૦૩

(b) Write short note on Tyre Retreading process. 04

(બ) “ટ યર ક્રરટે્રલીંગ” પ્રક્રિય ઉપર ટ ાંક નોંધ લખો. ૦૪

OR

(b) Define “over inflation” and “under inflation”. State ill effects of each. 04

(બ) “ઓવર ઈંફ્લડશન” અનડ “અંલર ઈંફ્લડશન” ની વ્ય ખ્ય આપી તડની આલ અસરો જણ વો.

૦૪

(c) Write short note on Hydraulic Brake Bleeding. Why it is necessary? 07

(ક) હ ઈડ્રોલીક બ્રડક બ્લીલીંગ ઉપર ટ ાંક નોંધ લખો. તડની જરૂરીઆત ું ાં ડે તડ જણ વો.

૦૭

Q.5 (a) Write causes and remedies for hard rigid suspension. 04

પ્રશ્ન. ૫ (અ) હ લક રીજીલ સસ્પેંસન ન ક રણો અનડ ઉપ ય જણ વો. ૦૪

(b) State the effect of misalignment of vehicle chassis while it’s running. 04

(બ) વ હનન ચ ડસીસની મીસ અલ ઈનમેંટ ની વ હન ન ચ લવ ઉપર થતી અસરો જણ વો.

૦૪

(c) State the method of testing telescopic shock absorber. 03

(ક) ટેલીસ્કોપીક શોક એબ્સોબકરની તપ સ પ્રિીય વણકવો. ૦૩

(d) What are the common troubles of “Air Brakes”. 03

(લ) “એર બ્રડક” સ થડ સાંકળ યડલી સ મ ન્ય ખ મીઓ કઈ ડે તડ જણ વો. ૦૩

************

1/3

Seat No.: ________ Enrolment No.______________

GUJARAT TECHNOLOGICAL UNIVERSITY DIPLOMA ENGINEERING – SEMESTER VI • EXAMINATION – SUMMER 2017

Subject Code: 3360202 Date:11-05-2017

Subject Name: Auto Transmission Mechanism Diagnosis and Testing.

Time: 10:30 AM TO 01:00 PM Total Marks: 70 Instructions:

1. Attempt all questions.

2. Make Suitable assumptions wherever necessary.

3. Figures to the right indicate full marks.

4. Use of programmable & Communication aids are strictly prohibited.

5. Use of only simple calculator is permitted in Mathematics.

6. English version is authentic.

Q.1 Answer any seven out of ten. દશમ ાંથી કોઇપણ સ તન જવ બ આપો. 14

1. What is meaning of sprung and unsprung weight?

૧. સ્પ્રાંગ અને અન સ્પ્રાંગ વજનનો અથથ સમજાવો.

2. Write function of antiroll bar.

૨. એન્ટીરોલ બ ર ન ાં ક ર્થ લખો.

3. What may be the faults in suspension system for rough ride?

૩. સસ્પ્પેન્સન સસસ્પ્ટમમ ાં કઈ ખ મીઓન લીધે રફ ર ઈડ હોર્ શકે?

4. What may be the faults in suspension system for vehicle pulls to one side?

૪. સસ્પ્પેન્સન સસસ્પ્ટમમ ાં કઈ ખ મીઓન લીધે વ હન એકબ જ ખેચ ાંર્?

5. Write four advantages of using air suspension.

૫. એર સસ્પ્પેન્સન વ પરવ ન ચ ર ફ ર્દ ઓ લખો.

6. Write probable faults for excessive brake pedal travel.

૬. વધ રે પડત ાં બે્રક પેડલન ટ્ર વેલ મ ટેની શકર્ ખ મીઓ લખો.

7. State parts of disc brake assembly.

૭. ડીસ્પ્ક બ્રેક એસેમ્બલીન ભ ગો લખો.

8. State function of unloader valve used in air brake system.

૮. એર બે્રક સસસ્પ્ટમમ ાં વપર ત અનલોડર વ લ્વ ન ાં ક ર્થ લખો.

9. Write factors affecting braking efficiency.

૯. બ્રેકકિંગ ક ર્થદક્ષત ને અસર કરત ાં પકરબળો લખો.

10. Write reasons for spongy brake.

૧૦. સ્પ્પોંજી બ્રેકન ક રણો લખો.

Q.2 (a) Write parts to be checked in front axle assembly. 03

પ્રશ્ન. ર (અ) આગળન એક્ષલની એસેમ્બલીમ ાં ક્ય ક્ય ાં ભ ગો તપ સવ જોઈએ? ૦૩

OR

(a) How will you check bending and twisting of front axle? 03

(અ) આગળન એક્ષલન ાં બેંડીંગ અને ટ્વીસસ્પ્ટિંગ કેવી રીતે તપ સશો? ૦૩

(b) Explain free pedal adjustment with reference to clutch. 03

(બ) ફ્રી પેડલ પ્લે ન ાં એડ્જ્સ્સ્પ્ટ્મેંટ ચનલચન અન સાંધ ન મ ાં સમજાવો ૦૩

OR

2/3

(b) Write reasons for slipping of clutch. 03

(બ) ચનલચ સ્પ્લીપ થવ ન ક રણો લખો. ૦૩

(c) Write causes for excessive looseness in the power steering system. 04

(ક) પ વર સસ્પ્ટર્કરિંગસસસ્પ્ટમ વધ રે પડતી ઢીલી હોવ ન ક રણો લખો. ૦૪

OR

(c) Give causes and remedies for hard steering. 04

(ક) સખત સસ્પ્ટર્કરિંગન ક રણો અને ઉપ ર્ો લખો. ૦૪

(d) Write procedure for straightening the frame. 04

(ડ) ફે્રમ સીધી કરવ ની રીત લખો. ૦૪

OR

(d) Write reasons for sagging and twisting of frame. 04

(ડ) ફે્રમ વચ્ચેથી ઝૂકી જવ ન અને વળી જવ ન ક રણો લખો. ૦૪

Q.3 (a) State various types of joints used in propeller shaft with their purpose. 03

પ્રશ્ન. 3 (અ) રોપેલર શ ફ્ટમ ાં વપર ત જ દ જ દ જોઇન્ટન ન મ તેન હતે સ થે લખો. ૦૩

OR

(a) Write inspection procedure for constant velocity joint. 03

(અ) કોન્સટ્ન્ટ વેલોસસટી જોઇન્ટને તપ સવ ની રીત લખો. ૦૩

(b) Describe any three typical contact pattern with neat sketch between crown

wheel and drive pinion.

03

(બ) ક્ર ઉન વ્હીલ અને ડ્ર ઈવ સપસનર્નન કોન્ટેકની ત્રણ પેટનથ આકૃસત સ થે વણથવો. ૦૩

OR

(b) Write causes for noisy differential. 03

(બ) કડફે્રન્ન્શર્લમ થી અવ જ આવવ ન ાં ક રણો લખો. ૦૩

(c) Write procedure for alignment of propeller shaft. 04

(ક) રોપેલર શ ફ્ટન એલ ઇંમેંટની રીત લખો. ૦૪

OR

(c) Write causes and remedies of troubles in propeller shaft. 04

(ક) રોપેલર શ ફ્ટની મ શ્કેલીઓ ન ક રણો અને ઉપ ર્ો લખો. ૦૪

(d) State causes and remedies for noisy rear axle. 04

(ડ) કરર્ર એક્ષલમ થી અવ જ આવવ ન ક રણો અને ઉપ ર્ો લખો. ૦૪

OR

(d) Write procedure of replacing bearing and seal of rear axle assembly. 04

(ડ) કરર્ર એક્ષલ એસેમ્બલીન બેકરિંગ અને સીલ બદલવ ની રીત લખો. ૦૪

Q.4 (a) Write reasons for one side wear and uneven wear of tyre. 03

પ્રશ્ન. ૪ (અ) ટ ર્રન એકબ જ અને અસનર્મીત ઘસ ર ન ક રણો લખો॰ ૦૩

OR

(a) Explain tyre retreading procedure. 03

(અ) ટ ર્રન રીટે્રકડિંગની રીત સમજાવો। ૦૩

(b) Give reasons for gearbox oil leakage. 04

(બ) ગગર્રબોચનસમ થી ઓઇલ લીક થવ ન ક રણો લખો. ૦૪

OR

(b) Give reasons for hard gear shifting. 04

(બ) ગગર્ર સશસફ્ટિંગ હ ડથ થવ ન ક રણો લખો. ૦૪

3/3

(c) Give causes and remedial measures for

(1) Gear slipping (2) gear clash while shifting. (3) Noise from gear box

when vehicle is running on any gear.

07

(ક) નીચેન ન ક રણો અને ઉપ ર્ો લખો. (1) ગગર્ર સ્પ્લીપ થ ર્ છે. (2)ગગર્ર બદલતી વખતે અથડ ર્ છે.

(3) વ હન કોઈપણ ગગર્રમ ાં ચ લત ાં હોર્ ત્ર્ રે અવ જ આવે છે.

૦૭

Q.5 (a) Write procedure for reinstallation of clutch. 04

પ્રશ્ન. ૫ (અ) ચનલચને ફરી તેની જગ્ર્ એ સ્પ્થ પન કરવ ની રીત લખો. ૦૪

(b) How will you check performance of brake? 04

(બ) બે્રકન ાં ક મ કેવી રીતે તપ સશો? ૦૪

(c) Write procedure of lubrication of clutch unit and its linkage. 03

(ક) ચનલચ અને તેની ગલિંકેજને લ બ્રીકેટ કરવ ની રીત લખો. ૦૩

(d) Write use of following tools.

(1) Tyre thread depth gauge (2) tram gauge (3)coil spring compressor tool

03

(ડ) નીચેન સ ધનન ઉપર્ોગ લખો. (1) ટ ર્ર થે્રડ ડેપ્થ ગેજ (2) ટ્ર મ ગેજ (3)કોઇલ ન્સ્પ્રિંગ કોમ્રેસર ટલૂ

૦૩

************