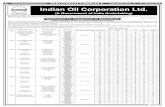

Gujarat Refinery Indian oil Corporation Limited...Gujarat Refinery Indian oil Corporation Limited...

Transcript of Gujarat Refinery Indian oil Corporation Limited...Gujarat Refinery Indian oil Corporation Limited...

Gujarat Refinery

Indian oil Corporation Limited

Dated: 18.01.2013

The heater charge pumps (M/s Flowserve pump model no. 8HED16 DS) bearing

tag number 2095-P-01A/B/C were installed in Delayed Coker Plant at Gujarat Refinery and commissioned in April 2011. These pumps were creating repeated problems since commissioning.

On 11.01.2013, the turbine driven pump i.e., 2095-P-01A was started after stoppage of about 3 days due to shortage of steam; the pump could deliver only 120m3/hr flow at 32 kg/cm2 pressure. It was suspected that there might be coke up inside the pump in impeller eye and pump was opened on 17.01.2013 and the following were the observation

Observation:

1. Heavy erosion of metal on casing and casing covers. 2. Coke crusher vanes were totally broken 3. Impeller and impeller vanes are heavily eroded and vane tips are totally

gone. 4. All the casing wear rings are badly eroded.

Photographs: Casing cover on NDE side

Fig.1 a: casing cover on NDE side