GUIDELINES FOR VALUE ENGINEERING (VE) - SAVE International

Transcript of GUIDELINES FOR VALUE ENGINEERING (VE) - SAVE International

M A R C H / A P R I L 1979 Volume 2 No. 6

WORLD T E C H N I C A L P U B L I C A T I O N F O R

GUIDELINES FOR VALUE ENGINEERING (VE)

Prepared by: TASK FORCE #19

Subcommittee on New Highway Materials AASHTO-AGC-ARTBA Joint

Cooperative Committee

Members of Task Force «19

James L. Pierce—Georgia Department of Transportation, Chairman Philip G. Gosher—Virginia Department of Highways and Transportation

E. Darwin Spartz—California Department of Transportation Michael N. Zabych—Corps of Engineers, Department of Defense Edward D. Johnson—Federal Highway Administration, Secretary

INSIDE - V. E. in H I G H W A Y CONSTRUCTION-GUILDLINES

ALSO: Putting Sell in Suggestions

A Tool for Upstream Value Engineering The SAVE 1979 International Conference

The V.E. Present of a Lifetime

Now!—A book that shows you how to make the Value Management Concept work!

VALUE MANAGEMENT

FOR CONSTRUCTION

By Manuel C. Macedo, Jr., Paul V. Dobrow, and Joseph J . O'Rourke

This book introduces and defines the Value Management concept, and lays out the principles and practices that make the Value Management concept work. It concerns itself with the management of the total project value as opposed to the traditional value engineering /analysis methodology—although the traditional methodology is not totally abandoned.

For the graduate engineer, manager or administrator, the complexity of a program causes expensive mistakes in the earliest planning. Without prior years of exposure and experience, it is difficult to envision the Value Management techniques that can save time and acquisition dollars in the planning and organization stages as well as the opportunities to reduce costs of operations and support during the design and engineering phases. This book provides the insights by explanation and practical case examples for the broad as well as specific Value Management process.

Value Management for Construction brings together the current thinking on Value Management. It explains what is happening in the industry and what is expected to happen in the near future. Its intent is to start an industry-wide dialogue on the Value Management Concept. There is no attempt to develop an inflexible methodology. Nor is this considered the final word on Value Management. The experience of the recent past has proved the validity and usefulness of the Value Management Concept, but the next several years will see the concept revised and perfected into a classic management tool.

Value Management for Construction has been written at the management and decision-making level. The subject is developed in the book with practicing managers in mind. Its contents are aimed at executives, construction managers, value managers, project managers, architect-engineers, general contractors, and others involved with the planning, designing, constructing, operating and financing of building projects.

390 pp. (0471-03166-6) 1978 $25.00

W I L E Y - I N T E R S C I E N C E A DIVISION OF JOHN WILEY & SONS, INC. 605 THIRD AVENUE NEW YORK, N.Y. 10016

Mail to: WILEY-INTERSCIENCE a division of John Wiley & Sons, Inc., Dept. 092, 605 Third Avenue, Mew York, N.Y. 10016 (Att: Mat Bodian)

Please send me a copy of VALUE MANAGEMENT FOR CONSTRUCTION by Manuel C. Macedo, Jr., Paul V Dobrow, and Joseph J. O'Rourke. (0471 -03166-6) • Bill me. • Bill firm-<« $25.00 per copy (plus postage/handling).

Name .

Affiliation

Address

City

State/Zip A3659-51

P U B L I S H E R

Society of American Value Engineers

A SOCIETY OF A M E R I C A N

V A L U E ENGINEERS 220 N . STORY RD. , SUITE 114

I R V I N G , T E X A S 75061

Managing Editor Carlos Fallon

10 Quail Hol low Drive

Southport, N . C . 28461

Contributing Editor — A S P I A L E X P E T C H K U R O W

C O L L I N S R A D I O G R O U P (MS 402-231) R O C K W E L L I N T E R N A T I O N A L

1200 N. A L M A R O A D R I C H A R D S O N , T X 75080

Contributing Editor — NASS J U D Y C O R B I N

N A T I O N W I D E M U T U A L I N S U R A N C E 246 N. H I G H ST.

C O L U M B U S , O H I O 43216

Production Editing and Printing Triangle Press P.O. Box 407

Grand Prairie, T X 75051

E D I T O R I A L A D V I S O R Y B O A R D

Arnold Skromme Deere & Co. Moline, I L

Oliver Hallett Executive Secretary NASS

Paul M. Bailey Pacific Gas & Electric

Art Mudge Joy Mfg. Co .

Thomas D. O'Connor West Point, P A

Harry Coffin Schwinn Bicycle Chicago, I L

V A L U E W O R L D Volume 2 No. 6 March/April 1979

Magazine for

A M E R I C A N SOCIETY FOR PERFORMANCE I M P R O V E M E N T 790 Broad Street, Newark, NJ 07102

and

N A T I O N A L ASSOCIATION OF SUGGESTION SYSTEMS 435 North Michigan Ave., Chicago, I L 60611

and

SOCIETY OF A M E R I C A N V A L U E ENGINEERS 220 N . STORY RD. , SUITE 114

I R V I N G , TEXAS 75061

THIS MONTH'S FEATURES: Page

The V.E. Present of a Lifetime By H. K. van Heerden, Pr. Eng.,CVS 3

Putting Sell in Suggestions By Robert A Schwarz 5

V.E. in Highway Construction-Guidelines Material supplied by: Kempter-Rossman International, Excerpts by Carlos Fallon-Managing Editor 7

A Tool for Upstream Value Engineering Reprint of Naval Engineering Journal 11

The SAVE 1979 International Conference By Donald Parker, General Chairman 17

COLUMNS FEATURES:

Carlos Fallon 2 Opportunities 16

SUBSCRIPTIONS — Single Issue $2. Yearly rate: U.S. $12 10 SAVE Members, (included in unual membership dnes rale). Non-members and Foreign Countries $14. Technical Society and organization bulk rates and overseas air mail rates are available upon request. Make all checks payable to SAVE in U.S. dollars.

IN THIS ISSUE

EDITORIAL

Meet our new Managing Editor-Carlos

Fallon

p.2

Putting Sell In Suggestions by Robert A . Schwarz

p.5

NAVAL ENGINEERS JOURNAL

A Tool for Upstream Value Engi neering

p . l l

1

OUR NEW MANAGING

EDITOR

Carlos Fallon

Editorial

PRODUCTIVITY

The word productivity and its diverse meanings seriously affects production. To enhance productivity, in a lasting way, the value disciplines seek to increase return on investment while at the same time making the work more pleasant for the actual producers. This is new?...

Not in the countries that compete most successfully with the United States. In Sweden, Volvo has conducted extensive experiments on making the work more interesting for the workers. Sweetness and light? Not at all. They are a very practical people. The standards of living in Sweden surpassed that of the United States in 1978. To last, and to increase, productivity must be good for the producers themselves as well as for the customer and the enterprise.

In Japan, industry takes an active interest in the welfare of its workers, and the workers take an active interest in the success of their companies.

It was no accident. The Japanese had paid the price that we are paying now. They found out that hostility is expensive, that the class struggle is wastefull. A warrior-based feudal system that exalted hostility had dominated Japanese culture for 700 years. But they had been learning; first, f rom the Chinese, as the Romans had learned f rom the Greeks; and then, they saw foreign warships silencing their forts and steaming against the tide without any wind.

A l l the Japanese people seem to have reached a collective decision: (1) they would have to abandon the hostility-steeped feudal system in favor of a cooperative national government, and (2) they would learn to make machines. The M e i j i Restoration was implemented by a number of imperial rescripts. One of these said, in effect,

Carlos Fallon

"We are learning too fast." In learning to make machines, Japan was falling heir to the social turmoil of the industrial revolut ion. Western in dustrialization left little room for certain basic Japanese values. The imperial court then stepped in with the Educational Rescript of 1890 which added ethics and loyalty to the mainly economic motivation of Western industry. Powerful feudal families became powerful, industrial families. In line with the Educational Rescript, the Japanese built upon their own culture. Their concept of productivity rests on a balanced loyalty among employers, employees, and the community.

As in Japan, the idea of productivity, in Scandinavia, goes beyond "more units of product per unit of cost." In the same way that the Japanese built upon their native values, the Scandinavians have built upon their ice-age heritage-what Northerners in this country call "Yankee ingenuity."--an urge to improve. Vardeanalys in Scandinavia is as much concerned with better products as it is with economy and efficiency.

I am now revising my book Value Analysis to Improve Productivity and I came across a passage in which I asked a Danish client why he needed a U.S. consultant when productivity in his country was rising faster than in the U.S.

"Because, " he told me, "you have a problem with increasing costs, yes; but not with productivity."

This was a revelation. "We have no problem with productivity?"

My host laughed, serving me smoked salmon and pouring cold aquavit. "Your productivity is nearly perfect. That is why it is hard to improve. We are winning the race with costs because we still have room to improve our productivity. That is why we invite North American consultants to help us bring our productivity up to the near-perfect level of yours."

He plopped a gigantic slice of smoked salmon on my plate. "This is a different kind of salmon," he explained. "The other one was smoked just like he comes out of the sea. This one is jellied before he is smoked. "

I picked uneasily at the fish. "You see, " my host was explaining,

"our factory-floor productivity will soon be approaching the level of yours, leaving little room for improvement; yet our workers will demand and deserve higher wages. When we can no longer improve the ways of making the product, we want to be ready to work on the product itself, using vardeanalys."

Now I was eating the fish with enthusiasm. I knew that most customers are not getting what they really want. Give it to them and the product earns a better price. The customers have the money to pay for it out of the wage increases that industry has been paying them. Productivity has increased because the workers are turning out a better product for the same cost. The results of their labor and their imagination are worth more than the results of their labor alone.

F u l l use o f the i n i t i a t i v e , resourcefullness, and ingenuity of all the working force makes the work more interesting for the actual producers and more competitive too.

J. J. Kaufman, Gardner-Denver's Director of Value Programs, uses a practical measure for this kind of productivity. You wil l read about it in these pages after it is published in the NEWSLETTER OF SJVE (Society of Japanese Value Engineers). They gave Jerry Kaufman an assignment to write a column for them. I have already written Akira Kodama, Secretary General of SJVE for permission to use the article.

2

VALUE IN ENERGY

& CONSERVATION The V.E . Present of a Lifetime

Votoe Engineers

Value Aft**3-

dear

real

ar o » « "Tare * * * " l l rea"? Spfeu*. WH\'"a vfe»- f e W V E / V A

rVS ueerden, ^ r ^

By writing to:

The Co-ordinator Value in energy & Conservation International Conference P.O. Box 12027 Clubview Republic of South Afr ica , 0014

airmail (31 cents), you wil l let us know who to keep posted with infoi 111:11 ion. We wil l be exhibiting at the 1979 SAVE International Conference in Washington D.C. where we hope to meet you.

The executive and members of VEMSSA join me in festive greetings to you and your families.

Figure 1

Honeywell wins national Suggestion System award 4th consecutive year

Suggestion System Special Issue

^ ^ ^ ^ Dec. 12, 1977

FOR T H E F O U R T H Y E A R IN A ROW, Honeywell s ECR/suggestion system won the top national award tor companies its size. From left: Leo Kirk, Residential; Bob Schwarz AvD DSD-Gerry Axmark, Residential; Frank Perry, AvD, DSD; Bob Kilby, AvD, DSD; Bert Caswell' A v D '

Honeywell won the top n a t i o n a l a w a r d f o r i t s M i n n e a p o l i s O p e r a t i o n s ECR/Suggestion System program for the fourth year in a row.

The "Excellence of Performance" award for companies with over 6.000 eligible employes was awarded to Honeywell by the N a t i o n a l A s s o c i a t i o n of Suggestion Systems (NASS) at its 25th annual conference in N o v e m b e r 1977 in New Orleans.

"Minneapolis Operations

Honeywellers have had an excellent program participation record for years" said Bob Schwarz, A V D / D S D Manager and Leo K i r k , Residential Manager of the S T E P program.

In order to win the award, the f o l l o w i n g c r i t e r i a were judged: the highest number of suggestions received per 100 eligible employes: Ihe highest number of employes submitting suggestions per 100 eligible employes: and the highest percentage of suggestions accepted.

In winning the a w a r d , Honeywell's system was judged as having the best overall per formance in a l l three categories.

Honeywell competes with the suggestions systems of R C A . Western Elec tr i c . Genera l Motors, J B M . G T & E , and Firestone.lo name a few. Well over 500 companies belong to NASS and compete for the two top awards (one for companies over 6.000 emplo_\es. one for those with less than 6,000).

p f j ^ ? ? ? R.1!DY

P E R P ' C H presents Martin Kroska, Residential Coil Winding, with the State "Suggester of the Year-award along with a personal commendation.

WHY H O N E Y W E L L E R S WON T H E 1976 N A T I O N A L S U G G E S T I O N

S Y S T E M A W A R D

Ideas: 159 ideas were submitted for every I00 Honeywellers.

Number*: 3,040 Honeywellers submitted E C R s , which is 39.4 percent of eligible employes.

Percentage*: 6.327 E C R s were accepted, which was 49.X percent of all processed E C R s .

Average: The average award for the year was $21.02.

Total: Total amount awarded for E C R s in I976 was SI32.9X9.

T E N Y E A R A W A R D T O T A L

l he I C R total amount awarded to Honeywellers in the last 10 jcars is SI.7I6.XX6.

Martin Kroska Wins State Award Already "Suggester of the

Year" for his division. Martin Kroska, group leader. Residential Coil Winding, went on to win the state suggester award sponsored by the Twin City Chapter of the National Association of Suggestion Systems.

Martin's idea made it possible to slice and press the transformer from the smoke detector

on our -28 machines saving more than $47,000 per year. This is the highest savings achieved from an idea sub-mil ted by a R e s i d e n t i a l employe.

Kroska was selected as the Division's "Suggester of the Year" on the basis of the number of ideas he submitted, percent accepted and the dollar

amounts of savings and awards. "Suggesters of the Year"

from eight other companies participated in the competition, including Honeywell's Avionics and Defense Systems Divisions, Buck bee-Mears Co . , Peavey Co. , Magnetic Peripherals Inc., Sperry U n i v a c , Whir lpool Corp., Winnebago Industries, and the State of Minnesota.

C H A R L E S HOLM, MARTIN K R O S K A

Win ' Suggesters of the Year9

C H A R L E S HOLM, Suggester of the Year'

A D G ' s Charles Holm and Residential's Martin Kroska were named Ihe Suggestion System's "Suggesters of the Year" for their divisions.

The total number of E C R ideas submitted, the percentage accepted, and the total dollars awarded and savings generated by each accepted idea are factors in determining the winner.

Holm's best idea last year was lo use a less expensive Arklone "P" freon instead of FC-77 freon saving Honeywell S10.265

annually. His awards for the year totaled $1,154.

Martin Kroska submitted 10 ideas with awards totaling $ 1 , 0 3 0 a n d s a v i n g s for Honeywell totaling $47,233 (see related story this page).

Both men were presented N a t i o n a l A s s o c i a t i o n of Suggestion System certificates for their accomplishments. The presentation was made ul a Twin Cities luncheon bv Slate Attorney Genera l Warren Spannaus.

Note: This article, submitted by our NASS contributing editor seems to bridge the gap between NASS and ASPI, two of our supporting societies. No problem. In many an orginazation that gap has to be bridged. Improving our ability to work well together among the improvement disciplines is one of the aims of this publication.-Editor.

The views and comments by the author in this article do not necessarily constitute the endorsement or opinion of Honeywell, Inc.

PUTTING SELL IN SUGGESTION by Robert A. Schwarz, Honeywell Inc.

We in the suggestions system business need to borrow f r o m the industrial psychologists. We also need to use the effective techniques used by our sales department. We must provide the motivation and recognition vital to achieving and maintaining a successful and profitable suggestion system program.

We operate our overall motivation program under the title of "STEP-Strive Toward Error-Free Performance." Our suggestion system, a part of STEP, uses an "ECR~Error Cause Removal" as the basic suggestion submission. I wi l l refer to STEP and ECR in this paper.

Our program, at Honeywell, M i n neapolis, recognizes two significantly important elements: recognition o f the employee, and the opportunity to win something. Let's deal with them separately.

Recognition

We have been successful in providing recognition primarily aimed at hourly employees. First, each department has an ECR submission record. This particular technique focusses on the quantity of submissions and ties into a recognition award program which provided gif t items we wil l discuss later.

The persons submitting high dollar award ECR's are singled out for special treatment. During a given year, we wi l l recognize approximately 80 individuals for their suggestion idea and the award that they have received. We feel that this technique offers support to team building because of the conversation about achievement and the problem solutions that it generates. I t also tends to share some o f the ideas between buildings and divisions of the company, resulting in added savings through expanded use of good suggestions. We always share some additional copies of these posters with the employees involved and i f we fai l to do so, we are usually reminded by the employee.

Our newspaper, the Honeywell Circulator (Figure 1), is used to carry articles about individual awards, usually with group pictures showing an individual getting his award with fellow employees.

The ECR winner of the year for Honeywell Division receives state-wide recognition. This includes meeting the Governor, an appropriate certificate, and it is another eagerly sought honor. Pictures of the winner of the year are also published, utilizing either the newspaper insert or our bulletin boards.

Other internal newsletters exist that are parochial to the specific divisions in our geographic area. Here again, we provide them with copy and pictures on significant ECR accomplishment. These twice-monthly newsletters regularly carry articles providing visibility to the program and recognition to the high achievers.

Another utilization of ECR recognition is our employee Open House which we hold on alternate years. Here we utilize a picture of the employee, a summary of the accomplishment, and a statement of the award magnitude. These pictures tend to reinforce the importance of the program and the benefits to the employee with the employee's family. Here again, we had a high response to the program and a high interest in being selected for one of the posters.

Recognition aimed at peer group visibility is gained when the Supervisor or Manager makes presentation of the check in an appropriate employee group. Here the employee is presented the ECR Award check with appropriate fe l low employees and management , and we usua l ly photograph for reprint use.

con't on page 6

5

Putting Sell In Suggestions con't from page 5

Figure 2

Winning

Winning is the other aspect that we feel is of importance.

A l l of us are motivated to feel that winning something is important. I t seems to be a basic part of the American way of l i fe . I am sure each of you, like myself, has been to a gathering where prizes were offered for some kind of game. A l l of us compete aggressively to win these; and frequently they represent little cash value, but provide a sense of having been the winner. We feel that the utilization of nominal gi f t awards is a significant enhancement, and i t helps accomplish the savings our ECR programs provide.

Let's look at a means of stimulating the quantity of ECR's submitted. Specifically, at the level of 3 ECR's, the suggesters can select any of the items they want f rom Figure 2.

The two programs, one for Quality of ECR's and the other for Quantity of ECR's reinforce our objective of having a large f low of good ECR's that provide us a favorable level of savings.

The cash awards which are based on one sixth of our first year's savings, with maximum award of $1500, are major goals for the employees. We have many employees who exceed 25 ECR's in a given year. We also have many employees who exceed $1500 in awards, through the submission of many ECR's, each winning significant awards.

We carefully select award items that are desirable. We want the employees to eagerly compete for them. People walking out the door with a cutting board, weed trimmer, or a set of wrenches are going to be noticed by their fellow employees. The fact that

somebody else has W O N something tends to be a significant stimulant to those who have not.

The fact that the employee is carrying out an award makes the winner extremely obvious. The nature of the carefully selected and desirable awards tends to make the others a little bit jealous. We provide a wide selection of awards so that the people can select something that they already do not have—and something they really want.

Our program remains extremely successful with our participation rates high, at around 330 ECR's per 100 employees per year. Our acceptance rate is extremely high—between 45% to 50% acceptance of all ECR's submitted. We feel the program generates quality awareness, productivity, and a team spirit. These add up to an increased competitive position for Honeywell.

6

Editor's Note: Kempter-Rossman International, Value Engineering consultants to a number of State Highway Commissions, graciously sent us the material from which we took the excerpts below

This document is disseminated under the sponsorship of the Joint Committee of the American Association of State Highway and Transportation Officials, Associated General Contractors, and the American Road & Transportation Builders Association (AASHTO-AGC-ARTBA) in the interest of information exchange based on the combined technical expertise of each Task Force member. As such, the opinions and conclusions implied or expressed herein do not necessarily reflect the official views or policies of the Joint Committee or its member organizations.

EXCERPTS FROM

Guidelines For Value Engineering (VE)

Prepared by

TASK FORCE #19

Subcommittee on New Highway Materials AASHTO-AGC-ARTBA Joint Cooperative Committee

Members of Task Force #19

James L . Pierce—Georgia Department of Transportation, Chairman Philip G. Gosher—Virginia Department of Highways and Transportation

E. Darwin Spartz—California Department of Transportation Michael N . Zabych—Corps of Engineers, Department of Defense Edward D . Johnson—Federal Highway Administration, Secretary

D E F I N I T I O N Value Engineering is defined by the

Society of American Value Engineers as: The systematic application of recognized techniques which identify the function o f a product or service, established a value for that function, and provide the necessary function reliably at the lowest overall cost. In all instances the required function should be achieved at the lowest possible life-cycle cost consistent with requirements for performance, maintainability, safety, and esthetics.

W H A T V A L U E E N G I N E E R I N G ISN'T

Value Engineering is not just "good engineering." I t is not a suggestion program and it is not routine project or

plan review. I t is not typical cost reduction in that it does not "cheapen" the product or service nor does it "cut corners." I t simply answers the questions "What else wil l accomplish the purpose of the product, service, or process we are studying?"

It stands to reason that any technique so useful should be applied to every project and at each stage in the normal day-to-day development of a highway project. This is not the case. The practice of VE entails a certain amount of expense which must be justified by potential cost savings. Accordingly there must be a recognized need for change and a distinct opportunity for financial benefit to warrant the added cost of a VE effor t .

F U N C T I O N A L A P P R O A C H

A buyer purchases goods or ser-vicesbecause they wil l provide certain functions at a cost he is willing to pay. To Obtain good value, the many functions in an item or service must first be carefully defined so that costs of each can be determined. The buyer is then able to analyze his prospective purchase, see exactly what he is obtaining f o r his money, and el iminate undesirable or unnecessary functions and their costs.

First attempts to define the functions of an item wil l usually result in several concepts described in many sentences. The rule in VE is that the basic func-

con't on page 9

8

con'I from page 8

t ion should be defined in only two words, a verb and a noun. The verb answers the question, "What does it do?" The noun answers the second question, "What does it do it to?" By reducing the basic function definition to two words we:

(1) force conciseness, (2) avoid defining more than one sim

ple function, and (3) Achieve the broadest point of

view.

This apparent oversimplification accomplishes a true goal of the VE process: that of stripping the subject under scrutiny to its bare essentials in order to more clearly appreciate its function.

In some instances, it wi l l be determined that the function is unnecessary and that the item or process can be eliminated. We next classify the many secondary functions of the goods and services as to whether they are answering the question, "What must it do?" We must then identify those secondary functions which are unwanted and eliminate them. In this way, we are able to simplify the design of a product or process to that which provides the buyer's basic need.

We can now set about the task of developing new alternatives that perform the basic function defined, and select the one giving the best value.

V A L U E E N G I N E E R I N G P E R S O N N E L

Note the emphasis on good human relations in all phases of this plan. Persons assigned to do VE must be carefully selected.

Along with diversified experience, personnel should be carefully selected on the basis of their creativity and challenging approach to their daily work and to specific problems. Disciplines other than engineering provide greater objectivity to a team effor t .

Sensitivity to the problems involved in gathering information and ability in presenting and promoting alternatives is essential in personnel selected. The ability to think through and present ideas clearly along with a moderate amount of perseverance is essential in team members.

Specific training in the concepts, application and techniques of VE is

essential for those working as VE team members.

Freshness and enthusiasm are positive elements in a VE effort and assignments in VE should generally be for a definite period.

I t takes more than just a recommendation to cause a change. Personal prejudices, apathy, fear of change and even jealously combine to create formidable opposition ot implementation of VE recommendations in some cases. The overcoming of such opposition may require more effort than the study itself. Value Engineers must be prepared to perservere over long periods of time i f necessary. They should not be disappointed i f the required change does not happen immediately.

Those employing VE have certain advantages and opportunities that are not afforded to those working solely in the de s ign , c o n s t r u c t i o n or maintenance.

Abil i ty to work in all disciplines, and not be restricted to certain specific activity by organizational boundaries.

Authority to spend the time required to study a problem thoroughly.

Access to help f rom persons having expertise in many specialties.

It should be emphasized that Value Engineering is not intended to compete with anyone. On the contrary, those working with the problem being studied are considered part of the team. Their help is essential to the success of VE effort . VE is designed to supplement the efforts being made, not to replace them.

P R O C E D U R E S FOR E S T A B L I S H I N G AN IN-HOUSE

V E P R O G R A M

A n effective VE Program wil l not result simply f rom deciding that value engineering is something that should be done in the course of normal work. To achieve any meaningful results, the VE program needs the wholehearted commitment and support of executive management. Management should further develop a policy on where, when, how and what specific areas of highway work the VE effort should be directed. It should also establish a trained team of value analysts and a systematic training program. When appropriate, consideration should be given to employing a VE consultant.

T H E R O L E O F E X E C U T I V E M A N A G E M E N T

It is of utmost importance that the executive management of the organization both understand and support the VE effort .

Management must be familiar enough with VE to be able to recognize the area where this tool can be most effective. Value engineering, like any other management tool, has certain limitations and should not be viewed as a panacea for problems.

V A L U E E N G I N E E R I N G T R A I N I N G

Formal VE training is essential for those who are to be members of the VE Team. As a minimum, this should be in the form of a 40-hour workshop. Once all team members have completed a few successful studies, they will be in a position to design similar or abbreviated programs for in-house presentation. The more widespread the VE concept becomes within an organization the easier, it is to have the study results accepted and implemented. Overall organizational understanding also facilitates information gathering and reduces some of the resistance to change, which in turn, increases the capability and effectiveness of the VE Team. Short orientations of what VE actually is and some results of its application should be presented to persons who wil l be contacted by the team making the VE study.

U S E O F V A L U E E N G I N E E R I N G C O N S U L T A N T S

While the VE Team wil l be able to completely analyze most of the projects selected for study, occasionally an unusual project may require "outside" assistance. Value engineering consultants can be beneficial in these circumstances and have also proven valuable in helping to organize the overall VE Program and working with the VE Team to get the program o f f to a good start. "Outsiders" may be able to examine an item or process with greater objectivity than the agency's own personnel; and subsequently, their recommendations may be more open to acceptance.

A TOOL FOR UPSTREAM VALUE ENGINEERING

Reprinted by permission of the

NAVAL ENGINEERS JOURNAL

The view expressed herein are the personal opinions of the authors and are not necessarily the off icial views of the Department of Defense or any military department thereof.

W E I G H T DISTRIBUTION C A T E G O R I Z A T I O N

FOR M I L I T A R Y V E H I C L E S

T H E A U T H O R S

Dr . Sidney Teitler, after receiving his Ph.D. in Physics from Syracuse University, joined the Staff of the Naval Research Laboratory INRL) where he carried out studies in various areas of experimental and theoretical Physics. He is a Fellow of the American Physical Society and from 1966 until 1967 spent a Sabbatical Leave at the Niels Bohr Institute in Copenhagen, Denmark. At present he divides his time between technical and management activities as Head of the Program and Resource Analysis Office at NRL.

Mr. Robert E . Proodian received his BS degree in Plastics Technology from the Lowell Technological Institute and is currently enrolled in the Graduate School (Center for Technology and Administration) at The American University. He joined the Non-Metallic Materials Branch of the Naval Ship Engineering Center INAVSEC) in 1968 where he was engaged in the technical management of R&D for new polymer systems for the Navy. In 1974. he joined NRL as a Program Liaison Officer for the Chemistry Division and in 1976 he was transferred to his present position in the Laboratory's Program and Resource Analysis Office.

A B S T R A C T

The paper presents a compact method for displaying vehicle weight distributions and utilizes this in a discussion of design "trade-offs" for military vehicles.

INTRODUCTION

I ^ J O T LONG AGO, Dix AND R I D D E L L [1] utilized data from previously built successful military vehicles to formulate a relatively simple framework for assessing performance, cost, and technology characteristics of vehicle concepts. An important ingredient in their discussion is the distribution of non-structural weight (the available weight, W ^ ) into payload weight (Wp), propulsion weight (Wp), and fuel weight (Wp).

Wp + W E + Wp = W A (1)

In this paper a compact method for displaying the weight distribution of vehicles is presented and utilized in a discussion of design "trade-offs" for military vehicles.

T H E W E I G H T FRACTION DISTRIBUTION TRIANGLE

In discussing "trade-offs" in the distribution among the component parts of W ^ , it is useful to deal with

dimensionless weight fractions, namely, the payload weight fraction fp = W p / W ^ , the propulsion system weight fraction fp = W p / W ^ , and the fuel weight fraction fp = W p / W ^ . Clearly, from Equation (1):

fp + f E + fp = 1 (2)

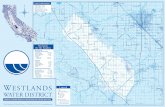

The condition imposed by Equation (2) makes it possible to display the weight fractions in a symmetric way by means of an equilateral triangle coordinate system. Such a system is shown in Figure 1. It is designated The Weight Fraction Distribution Triangle. Every point within the triangle is identified by a unique triad of weight fractions (fp, fp, fp). For example, the point (0.5, 0.3, 0.2) is shown in Figure 1. The individual weight fractions can vary in the range 0 to 1 subject to the constraint imposed by Equation (2).

An optimum product point of two weight fractions is defined to be the point at which the product of the two is maximum when the third weight fraction is held fixed. From the condition imposed by Equation (2), it follows that such a maximum occurs when the two factors in the product are equal. An optimum product line is the sequence of optimum product points that occurs as the fixed value of the third weight fraction is allowed to vary throughout the full range of 0 to 1.

The three possible optimum product lines are shown in Figure 1. Dix and R I D D E L L have already used the concepts of the optimum productivity line (equivalent here to the sequence of max. [(fpfp), fixed fp] and the optimum capacity line (equivalent here to the sequence of max. [(fpfp), fixed f p ] . The symmetry of the present description leads one to add the optimum deliverahility line which is the sequence of max. [(fpfp), fixed fp].

It may be observed that fp is related to payload, fp is related to speed, and fp is related to range. Then the optimum productivity line corresponds to an optimum payload-speed product which is a transportation parameter usually expressed in "ton-miles per hour." Similarly, the optimum capacity line corresponds to an optimum payload-range product which is a logistics parameter usually expressed in "ton-miles." Finally, the optimum deliverability line corresponds to an optimum range-speed product which is an interceptor parameter expressible in "(miles)2 per hour."

It may be noted that an individual optimum product line is a line that includes a vertex and the midpoint of the opposite side of the triangle. Thus, it divides the equilateral triangle into two equal parts. For the triangle

WEIGHT DISTRIBUTION CATEGORIZATION/MILITARY VEHICLES TEITLER/PROODIAN

OPTIMUM CAPACITY LINE

OPTIMUM -DELIVERABILITY LINE

(0 .5 ,0 .3 ,0 .2)

OPTIMUM PRODUCTIVITY

^0.4 LINE

Figure 1. The Weight Fraction Distribution Triangle.

configuration chosen in Figure 1, the partitions formed by the optimum product lines may be characterized as follows:

1) The optimum deliverability line ( 0 < fixed f p < 1): To the right, f p is traded off for f E ; to the left, f E is traded off for f p .

2) The optimum capacity line ( 0 < fixed f E <; 1): Above, f p is traded off for f p ; below, f p is traded off for f F-

3) The optimum productivity line (0 < fixed f p < 1): Below, f p is traded off for f E ; above, f E is traded off for f p .

The cumulative effect of the three optimum product lines is to divide the equilateral triangle into six equal parts or regions. These triangular regions all meet at the intersection of the three optimum product lines, namely the point (1/3, 1/3, 1/3). This common point becomes the natural reference point for the consideration of

"trade-offs" in weight fraction distribution as revealed by vehicle placement in the triangle. The nature of the six regions which meet at point (1/3, 1/3, 1/3) is described hereafter and summarized in TABLE 1.

R E G I O N 1 is to the right of the optimum deliverability line, and above both the optimum capacity and optimum productivity lines. In this region, subject to the constraint imposed by Equation (2), the weight fractions have the following ranges: 1/3 < f p < 1, 0 < f E < 1/2, 0 < f p < 1/3. Hence, with respect to the reference point (1/3, 1/3, 1/3), the principal emphasis for vehicles with weight fraction distribution in this region is payload, the second is the propulsion system, and the third is fuel.

R E G I O N 2 is to the right of the optimum deliverability line, above the optimum capacity line and below the optimum productivity line. In this region, subject to the constraint imposed by Equation (2), the weight fractions have the following ranges: 0 < f p < 1/2, 1/3 < f E < 1, 0 < f p < 1/3. Hence, for vehicles with weight fraction distribution in this region, the principal emphasis is the

TEITLER/ PROODI AN WEIGHT DISTRIBUTION CATEGORIZATION/MILITARY VEHICLES

T A B L E 1

C H A R A C T E R I S T I C S F O R W E I G H T FR A C T IO N REGIONS

Region Ranges of Weight F r a c t i o n s

subject to

f P + f E + f F " 1

Order of Eaphasls

1 1/3 S f p < 1, 0 < f E < 1/2, 0 < f p < 1/3

payload propulsion a y s t e a f u e l

2 O S f p S 1/2, 1/3 < f R < 1, 0 < f p < 1/3 propulsion system payload

f u e l

3 0 < f p < 1/3, 1/3 < f g < 1. 0 < f p < 1/2 propulsion system

f u e l payload

4 O W p S 1/3, 0 < f E < 1/2, 1/3 i f F < 1 f u e l propulsion system payload

5 0 < f p < 1/2, 0 < f E < 1/3, 1/3 < f p < 1 f u e l payload propulsion system

6 1/3 < f p < 1, 0 < f E < 1/3, 0 < fp < 1/2 payload f u e l propulsion system

propulsion system, the second is payload, and the third is fuel.

R E G I O N 3 is to the right of the optimum deliverability line, and below both the optimum capacity and the optimum productivity lines. In this region, subject to the constraint imposed by Equation (2), the weight fractions have the following ranges: 0 < f p < 1/3, 1/3 < f p < 1, 0 < f p < 1/2. Hence, for vehicles with weight fraction distribution in this region, the principal emphasis is the propulsion system (as it is in R E G I O N 2), the second is fuel, and the third is payload.

R E G I O N 4 is to the left of the optimum deliverability line, and below both the optimum capacity and the optimum productivity lines. In this region, subject to the constraint imposed by Equation (2), the weight fractions have the following ranges: 0_< f p < 1/3, 0 < f p < 1/2, 1/3 < f p < 1. Hence, for vehicles with weight fraction distribution in this region, the principal emphasis is fuel, the second is the propulsion system, and the third is payload.

R E G I O N 5 is to the left of the optimum deliverability line, below the optimum capacity line, and above the optimum productivity line. In this region, subject to the constraint imposed by Equation (2), the weight fractions have the following ranges: 0 < f p < 1/2, 0 < f p < 1/3, 1/3 < f p < 1. Hence, for vehicles with weight fraction distribution in this region, the principal emphasis is fuel (as it is in R E G I O N 4), the second is payload, and the third is the propulsion system.

R E G I O N 6 is to the left of the optimum deliverability line, and above both the optimum capacity and the optimum productivity lines. In this region, subject to the

constraint imposed by Equation (2), the weight fractions have the following ranges: 1/3 < f p < 1, 0 < f p < 1/3, 0 < f p < 1/2. Hence, for vehicles with weight fraction distribution in this region, the principal emphasis is payload (as it is in R E G I O N 1), the second is fuel, and the third is the propulsion system.

W E I G H T F R A C T I O N D I S T R I B U T I O N FOR T Y P I C A L

M I L I T A R Y V E H I C L E S

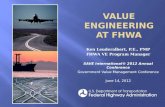

Now that the Weight Fraction Distribution Triangle has been introduced and characterized, it is worthwhile to display weight fraction distributions for typical existing military vehicles in order to develop criteria by which future vehicle concepts may be evaluated. Fortunately, Dix and R I D D E L L [2] have collected a great deal of relevant data which are readily transposed to a Weight Fraction Distribution Triangle. Tehis transposition is shown in Figure 2.

The three weight fractions exemplify the military need to deliver payload (fp) in a timely manner ( fp) at the proper place (fp) . I t is interesting to observe the "tradeoffs" which are forced by mission requirements on the one hand and by the realities of vehicle characteristics on the other. Types of vehicles fall into relatively small areas of the triangle. Interceptors are clustered close to the point (1/3, 1/3, 1/3) consistent with their need for speed and action at relatively short distances. Fighters must give up payload fraction and some propulsion system fraction to gain range (fp) . Attack Aircraft " t rade-off speed ( fp) relative to fighters to gain payload ( fp) . Penetrating Bombers clearly emphasize range with their large f p . The F-lll stands out for its " t rade-off of f p for f p when compared to Fighters and for its " t rade-off of f p for f p when compared to Bombers. Its placement is indicative of the compromises made to establish its dual role as Fighter and Bomber.

The only vehicle types in Figure 2 to fall into a high f p region (namely Region 6) are the Helicopters (Helos) and Naval Escorts. Vehicles of both types are inherently limited by design factors. Despite these limitations, their high payload fraction, and for Helos their unique capability, make these vehicles militarily important. Also, it may be noted that both Helos and existing Naval Escorts (non-nuclear) have propulsion systems that are technologically mature. This has led to a clustering of each type about a particular f p which has proven most effective by experience. Thus, for these vehicles, the "trade-offs" are primarily between payload (fp) and range ( fp) .

The vehicles shown in Figure 2 all have non-nuclear propulsion systems. Nuclear powered vehicles have negligible expendable fuel so they lie on or near the f p — 0 line. (Except for their independence of it, f p is not a meaningful parameter for nuclear vehicles since it is not related to vehicle range.) For nuclear vehicles, there is simply a " t rade-off between f p and f p . Since data are not readily available, one cannot determine whether any nuclear vehicles fal l in R E G I O N 1. Certainly some must fall in R E G I O N 2. In any event, the payload fraction probably ranges from a high for an Aircraft Carrier, to a

W E I G H T D I S T R I B U T I O N C A T E G O R I Z A T I O N / M I L I T A R Y V E H I C L E S T E I T L E R / P R O O D I A N

4 NAVAL ESCORTS SHIPS

18 HELOS

B-52H

5 ATTACK AIRCRAFT

B-1

9 INTERCEPTORS . 4

.3 12 — FIGHTERS

Figure 2. The Weight Fraction Distribution for Some Military Vehicles.

medium level for a Carrier Escort, to a low for Submarines. Of course, there is a complementary range for the propulsion system fraction.

In general, vehicles of a type do fal l in a rather limited area of the Weight Fraction Distribution Triangle. One would expect follow-on vehicles to fal l not far from these areas since new vehicles must be integrated into the operations of present vehicles. Therefore, new vehicles usually only represent an iteration on present vehicles. Thus one does not expect dramatic changes in weight fractions. However, as Dix and R I D D E L L point out, mission requirements, substantial improvements in technology, or budget limitations may provide reasons for a change in weight distributions of future vehicles.

An example of a possible change due to mission requirement is provided by the recent NAVY interest in high speed vessels such as the Surface Effect Ship (SES). Such ships borrow heavily from aircraft technology and probably will not fall in R E G I O N 6 where other Naval Escorts lie. Rather, they would most likely have to trade off payload for fuel so as to fall in R E G I O N 5. Although such

a "trade-off ' may be considered justified by the need for surface speed in a N A V Y mission, it may also lead to the rejection of the SES as a viable military vehicle.

Technology can also be very important, particularly in determining propulsion system and fuel fractions. For example, advances in structural material may serve to lower the total vehicle weight and hence, to reduce requirements on the propulsion system and, thereby, f g . Similarly, the propulsion system itself may be made of lighter material. On the other hand, an improvement in vehicle design or in the propulsion system efficiency could serve to lower f p . Further, technology status may be valuable in assessing a vehicle concept. For example, an anomalous weight fraction distribution might be addressed by oncoming advances in technology. I f applicable advances are likely for the new vehicle candidate, then the concept is viable. I f not, then the candidate should be rejected until prospects for the new technology improve.

Budget limitations may be the most fundamental factor in the present era. They can readily remove a vehicle

W E I G H T D I S T R I B U T I O N C A T E G O R I Z A T I O N / M I L I T A R Y V E H I C L E S T E I T L E R / P R O O D I A N

4 NAVAL ESCORTS SHIPS

18 HELOS

PRACTICAL DELIVERABILITY BOUNDARY

-PRACTICAL PRODUCTIVITY BOUNDARY

B-52H

5 ATTACK AIRCRAFT

F - l l l

.9 INTERCEPTORS

1.4

12 -FIGHTERS

.PRACTICAL CAPACITY BOUNDARY

A C K N O W L E D G M E N T

The authors are grateful to Professor P. Mandel and Drs. F . R. Riddell and D . M . Dix for their helpful comments, in particular, the concept o f "practical boundaries," as shown in Figure 3, suggested by Drs. RiddeUVand Dix.

R E F E R E N C E S

(1) Dix, Donald M . and Fred R. R i d d e l l , " P r o j e c t i n g C o s t -P e r f o r m a n c e T r a d e - o f f s f o r Mi l i t a ry Vehicles," Astronautics

and Aeronautics, Vol.14, N o . 9 (1976) pp. 40-50

(2) Ib id , p.46, Figure F-4.

Figure 3. Practical Boundaries

concept f rom consideration i f i t is too costly even though it integrates well into present operations and/or satisfies a major new mission requirement. On the other hand, one may be able to compromise on both operations integration and mission requirements to build an affordable vehicle. The Weight Fraction Distribution Triangle may help to establish the limits of such compromises.

Finally, i t should be noted that a vehicle's vulnerability may also remove it f rom consideration. For example, one might consider a dirigible-type vehicle. Such vehicles, although faster than surface ships, have small propulsion system requirements and modest fuel needs. Hence, they would undoubtedly fal l in R E G I O N 6, a high payload region. However, the general belief that air buoyant vehicles are vulnerable to the vagueries of nature as well as enemy attack tends to remove them from consideration.

SUMMARY

The Weight Fraction Distribution Triangle has been introduced and shown to provide a compact graphical display of the distribution of the available weight of a

for Petroleum Fueled Vehicles. vehicle. I t has been used to reemphasize the Dix and R I D D E L L observation that weight distributions of existing military vehicles fal l into reasonably well-defined categories. Indeed, these categories are so well-defined that one could postulate that there are practical boundaries in the design of petroleum fueled vehicles (see ACKNOWLEDGMENT) . Such boundaries are shown in Figure 3. The "practical productivity boundary" is seen to be the line, f p / f p = 1.5. Similarly, the "practical deliverability boundary" is seen to be the line f p / f p =

1.5. The "practical capacity boundary" corresponds to the line f p / f p = 3.0. Hence, the net effect of past experience for petroleum fueled vehicles is to indicate that the range of weight distribution fractions for general purpose military vehicles is limited by practical considerations. Of course, these practical boundaries could be crossed in the design of special purpose vehicles.

In general, the Weight Fraction Distribution Triangle may be used as a tool in evaluating new vehicle concepts and "trade-offs" in a historical context. However, before their acceptance, any conclusions concerning a new vehicle must be subjected to a determination of vehicle cost as well as an evaluation of vehicle vulnerability in military operations.

14

Society o^me/tican^aCueSngmGG/tg N A T I O N A L O F F I C E P . O . B O X 210887 D A L L A S , T E X A S 75211

COMPENDIUM OF VALUE

The 1979 SAVE Compendium of Value gathers together and presents by Subject Group Books, all the papers on value technology pertaining to each Subject Group, as published in the SAVE Annual Proceedings f rom 1963 through 1978. These are individual books for each Subject Group, as shown on this order fo rm, containing exact reprints of the entire papers presented for each subject, taken f rom the SAVE Annual International Conference Proceedings. For Example: The Construction Book, No. 6, contains f u l l reprints of over 60 papers presented on value technology in Construction.

Take advantage of this opportunity to augment your Library of Value Technology with a set of books dedicated to the particular Subject Groups of personal interest to you or your company. Send in the handy order form now, for immediate fast delivery of your Books.

Book No. of Book No. of

Subject Group No. Pages Price Subject Group No. Pages Price

Administration 1 65 $ 4.75 Life Cycle Cost 22 15 3.50

Application 2 510 12.85

Applications (Unique) 3 136 9.75 Maintenance 23 30 3.75 Management 24 226 12.95

Commercial 4 47 4.25 Manufacturing 25 80 5.75

Computer 5 69 4.75 Marketing 26 62 4.75

Construction 6 373 17.50 Contractual Aspects 7 177 10.25 New Products 27 33 3.75 Cost. Design To 8 60 4.75

A i/\ Cost Effectiveness 9 130 9.50 Organization 58 62 4.75 Cost to Produce 10 25 3.50 Creativity 11 94 6.25 Personnel 29 37 4.00

Philosophy 30 152 9.75 Data Sources 12 25 3.50 Professionalism 31 66 4.95 Department of Defense 13 92 6.25 (Value) Program Measurement 32 168 10.25 Design 14 82 5.75 Programs 33 69 4.75

Purchasing 34 20 3.50 Education 15 104 6.50

Software 35 59 4.75

Fast 16 70 5.5U Standards 36 22 3.50 Function 17 57 4.75 Systems Effectiveness 37 24 3.50 Fundamentals of V.E. 18 II 3.50 Support (See Maintenance) 38 30 3.75

Government Agencies - (Other than DoD) 19 58 4.75 Techniques 39 298 14.25 Training 40 104 6.50

Inlcrdiscipline 20 45 4.25 International 21 85 5.75

Tear Off Form To Mail -

SEND COMPLETED ORDER FORM TO: S O C I E T Y O F A M E R I C A N V A L U E ENGINEERS, INC.

P. O. Box 210887 • Dallas. Texas 75211

Please send to my attention the following items:

Quantity Book No. Price Quantity Book No. Price

Add: Postage & Handling • $1.25 per book

(1st Class $2.50; Air Mail $4.00 per book)

Enclosed please f i n d Check D Money Order •

in the amount of $

Name _

Address

City

State _Zip .

P A Y M E N T / N U.S. F U N D S

M U S T A C C O M P A N Y A L L O R D E H S

15

OPPORTUNITIES Here is a list of possible V E job open

ings that Russ Brennen, S A V E fellow, has put together for us. If interested, write Russ at:

R. C . Brannen plus Associates 2817 Osborn Road

Bay Village, Ohio 44140

and indicate the location in which you are interested.

JOB OPPORTUNITIES

C A L I F O R N I A . Manager and Value Engineers, $18,000 - $28,000.

C O L O R A D O . Manager, Manufacturing and Value Engineering, $28,000 -$32,000.

C O N N E C T I C U T . Value Engineer, Manufacturing and Value Engineering, $25,000 - $28,000.

I L L I N O I S . (2) Managers, Value Engineers, Design, Manufacturing and Value Engineering, $28,000 -$30,000 plus.

MAINE. Manager, Value Engineering, Manufacturing and Value Engineering, $20,000 - $25,000.

M I C H I G A N . Manager and Value Engineers, Manufacturing and Value Engineering, $18,000 -$25,000.

MINNESOTA. Value Engineer, Design and Value Engineering, $18,000 -$25,000.

OHIO. Director, Value Engineering, $28,000 - $38,000. Value Analyst, Value Engineering, Manufacturing, $18,000 -$24,000.

RECRUITING OPPORTUNITIES

Suggestion System Administrator with 20 years' experience seeks position with company desiring to set up a program or update and revitalized an existing program. Will relocate for right opportunity. Please reply to Box B. National Association of Suggestion Systems, 435 North Michigan Avenue, Chicago, Illinois 60611.

Suggestion Adminis trator Available—A bright, young, energetic individual with over three years' experience in suggestion related work is seeking a challenging position as a Suggestion Program Administrator of Suggestion Program Analyst. This individual has excellent qualifications, holds NASS Certificate and is willing to relocate. Please reply to Box C, National Association of Suggestion Systems, 435 North Michigan Avenue, Chicago, Illinois 60611.

Certified Suggestion System Administrator seeks challenge of setting up new, or revitalizing existing, Suggestion Plan. Six years of experience includes originating and managing suggestion and zero defects programs for multi-plant company. Has authored article published in professional journal, served as Director of the National Association of Suggestion Systems, and has instructed at the Suggestion System Administrator's Academy in Evansville, Indiana for the past two years. One and one-half years completed toward L L B degree. Please reply to Box A, National Association of Suggestion Systems, 435 North Michigan Avenue, Chicago, Illinois 60611.

SAVE 1979 INTERNATIONAL

CONFERENCE

May 23-26 Washington, D.C.

Conference Rates In addition to admission to the technical sessions and exhibit

area—

F u l l R e g i s t r a t i o n rates include all meal functions and one copy of the softbound conference proceedings.

D a i l y R e g i s t r a t i o n rate includes one luncheon and one copy

of the softbound conference proceedings.

S t u d e n t R e g i s t r a t i o n does not include meals but does

include a softbound copy of the conference proceedings.

Additional meal function tickets, tour tickets, and tickets for the cookout will be on sale at registration. Partner's program registration is ala carte.

H o t e l A c c o m m o d a t i o n s

Hotel accommodations should be arranged directly with the hotel. Be sure to mention the S A V E Conference to qualify for the special rates listed below. Hotel reservations should be made prior to the room block release dates listed. A hotel room reservation card will be mailed to you with confirmation of registration if time permits.

G o v e r n m e n t r a t e (ID must be presented) release date: April

24, 1979—

Singles: $ 3 2 Doubles: $ 4 4

Triples: $ 1 2 additional

C o n f e r e n c e r a t e release date: May 9, 1979—

Singles: $ 3 6 - 4 0 - 4 4 - 4 8 Doubles: $ 4 8 — 5 2 — 5 6 — 6 0 Triples: $ 1 2 additional Suites: $ 1 4 0 and up — 1 bdrm

$ 2 1 0 and up — 2 bdrm

H o t e l a d d r e s s The Capital Hilton

16th & K Streets, NW Washington, DC 20036

R e s e r v a t i o n P h o n e N o . —202—393-1000

Cance l la t ions—S u b s t i t u t i o n s may be made at any time. Cancellation of a confirmed registration may be made through May 15, 1979. Cancellations received after that date are subject to the full registration fee.

T a x Deduct ion— ( T r e a s u r y Reg. 1.162.5) An income tax deduction is allowed for expenses of education incurred to (1) maintain or improve skills required in one's employment or other trade or business or (2) meet express requirements of an employer or a law imposed as a condition to retention of employment, job status, or rate of compensation.

1979 SAVE International Conference Registration

Please confirm my conference registration to the following address:

Name: .

Position/Title:

Organization:

Address: .

City: _

Phone:

State: .Zip:.

Partner's Info:

Name for badge: :

Will you be staying the weekend? yes • no •

S e s s i o n s

Please check technical session you will most likely attend:

• Construction • Purchasing • Industry

Will you attend: • the Friday debate? yes • no • • a Saturday workshop? yes • no • • the Sunday cookout? yes • no • Please check rate applicable:

• $175— International (Indicate country )

• $175—Government (Indicate agency )

• $ 1 9 5 — U . S . S A V E member (Indicate chapter No. )

• $235—Non-member • $110—Daily rate (Indicate

day ) • $10—College student (Indicate

school )

This conference meets price guidelines established by the Office of Federal Procurement Policy, Office of Management and Budget.

Discount The Full conference rates may be reduced by $10 each for registration postmarked by April 16, 1979 when accompanied by full payment or an approved purchase order.

Does a discount apply? yes no

Payment Make checks payable to: 1979 SAVE Conference and Mail to:

Registration 1979 SAVE Conference PO Box 14265 Washington, DC 20044

Total amount enclosed— $ Paid by : Check • Purchase Order •

INTERNATIONAL CONFERENCE OF

WORLD VALUE

Society of American Value Engineers

J f i BOOK STORE ^

HARD COVER BOOKS

Quick Reduction of Costs by Creasy, 1971 The two-step functional approach

— a planned program of Value Engineering/Work Design assures quick reduction o f costs initially and fo r the long range e f for t .

Techniques of V.A. & V.E. (2nd Edition)

by Miles, L.D. 1972 This book , authored by the

originator o f Value Analysis and Engineer ing Techno logy , shows management and professional people specific steps to disciplined thinking, giving them 25-50 percent more efficiency-both in the quality and quantity o f their mental work.

Value Analysis by Gage, W. L., 1967 Written for business and industrial

managers responsible for developing new products and controlling product ion costs - explains with graphic examples, the basic steps in a value analysis program designed to identify and indicate ways o f reducing unnecessary c o s t .

Non-Member Member

$12.10 $10.50

19.50 18.50

14.00 13.00

V.E. in Manufacturing by A.S.T.M.E., 1967 A comprehensive reference book

that covers the theory, principles, application and administration o f value engineering and analysis — outstanding features include; meaning and analysis o f funct ion, V . E . principles, value and decision, scheduling o f V . E . activity, and management role in V . E .

V.E. in Construction Industry

by Dell'Isola, A. J., 1973 Presents a proven, organized ap

proach to reduce cost o f owenship of construction projects -educational facilities, hospitals, offices, apartments, laboratories. Applicable to public works projects - roads, sewage treatment plants , t ranspor ta t ion systems, dams.

V.E. in Federal Construction by National Academy of

Sciences, 1969 A very useful guide to application

o f the proven value engineering

technique in Federal Construction

Projects.

Non-Member

14.50

Member

13.85

18.75 16.35

3.95 3.60

Value Engineering by Mudge, A.E., 1971 The Value Engineering Systematic

Approach presented in three superbly organized parts - an in depth examinat ion o f the theory and fundamentals o f value engineering, application o f the Systematic Approach, and the magnitude/wide scope of uses o f the Systematic Approach.

17.50 17.00 Value Analysis in Design and Construction

by O'Brien, James J., 1976

A realistic no-nonsense guide to the enormous time and money saving opportunities made possible by applying value analysis throughout the entire cycle of any construction project.

16.50 15.00

• Tear Off Form To Mail -

SEND COMPLETED ORDER FORM TO: S O C I E T Y O F A M E R I C A N V A L U E E N G I N E E R S . INC. P. O. Box 210887 • Dallas, Texas 75211

Please send to my attention the fo l lowing items:

Q U A N T I T Y * DESCRIPTION U N I T COST T O T A L COST

A d d : Postage & Handling — $1.25 per book. (1st Class $2.50; A i r M a i l $4.00 per book) Overseas A i r m a i l $11.00 per book

•Certain items discounted when ordered in quantities of 3.0 or more. Information provided upon request.

18

Enclosed please f i n d Check • Money Order •

in the amount of $

Name _

Address

City

State _Zip_

P A Y M E N T I N U.S. FUNDS MUST ACCOMPANY ALL ORDERS

To qua l i fy for Member rates, show

Chapter Name:

C A L E N D A R O F E V E N T S

Value Engineered Design and Construction

30-6-06-8a L I F E L O N G L E A R N I N G

University Extension University of California

Berkeley, California 94720 a 40-hour workshop presented twice

April 9-13, 1979 and

November 12-16, 1979 Berkeley, California

Arthur Beard Engineers, Inc.

Announces more 40-hour workshops for 1979.

The program, which is approved by the Environmental Protection Agency, the Federal Highway Administration, the General Services Administration, the Society of American Value Engineers and the American Association of Cost Engineers, covers such topics as: Function Analysis; Life-Cycle Costing Procedures; Value Engineering Job Planning; How to Conduct a Value Engineering Study; and an Actual Project Study Analysis.

Emphasis wi l l be placed on construction projects, relating primarily to: wa t e r ; was t ewa te r ; h i g h w a y s ; buildings; and power. Therefore, the workshops wi l l be of importance to planners, architects, engineers, contractors, designers and municipal officials.

For additional information, please

contact Larry Zi'rnmerman or Mary Ann Lewis at Arthur Beard Engineers, Inc., 6900 Wisconsin Avenue, Chevy Chase, M a r y l a n d 20015, 301/657-3660.

Minneapolis, Minnesota Apr i l 9-13, 1979

Boston, Massachusetts May 7-11, 1979

San Francisco, California September 10-14, 1979

Atlanta, Georgia October 15-19, 1979

Dallas, Texas November 12-16, 1979

Value Analysis, Inc. 4029 Westerly Place, #116

Newport Beach, California 92660 Telephone: (714) 548-8018

40-Hour Value Analysis/ Value Engineering Workshops

Battle Creek, Michigan (Systems & Procedures)

Apr i l 17-20, 1979

Portland, Oregon

(Hardware)

Apr i l 23-26, 1979

Detroit, Michigan (Hardware)

May 14-18, 1979 Cleveland, Ohio

(Hardware) June 12-22

Cleveland, Ohio (Systems & Procedures)

July 17-20, 1979

San Francisco, California (Systems & Procedures)

July 24-27, 1979 Birmingham, Alabama

(Hardware) August 21-24, 1979

Battle Creek, Michigan

(Hardware) September 18-21, 1979 Fort Wayne, Indiana

(Hardware) October 16-19, 1979

Rochester, New York

(Hardware) November 6-9, 1979

***FOR IMMEDIATE RELEASE

August 9-10, 1979

14th Annual Value Analysis & Value Engineering Manager's Conference, Carson Inn, Chicago, Illinois. For details, contact: Value Analysis, Incorporated, 4029 Westerly Place, Suite 116, Newport Beach, California 92660. Telephone: (714) 548-8018.

19

N A T I O N A L O F F I C E P . O . B O X 210887 D A L L A S , T E X A S 75211

BOOK STORE

e n *

1979 S A V E ENCYCLOPEDIA OF VALUE - ADDENDUM No. 1

This information filled 1 6 page booklet (8V2 x 1 1), is now available for immediate purchase from your SAVE Book store. The Addendum to the SAVE Encyclopedia of Value contains information on all branches of knowledge in Value Engineering as presented in the Society of American Value Engineers Annual Conference Proceedings from 1977 and 1978. Contents are presented in abstract form arranged alphabetically by subject.

To aid in the search for knowledge in Value Engineering, a primary subject index is provided for reference in identifying the works of various authors published under these major subject headings in the SAVE Annual Conference Proceedings. Abstracts include author identification, proceedings year of publication, and page number of the proceedings where full text of the referenced paper is presented.

Recognition and thanks is given to SAVE member O.J. Vogl of the SAVE Los Angeles Chapter who prepared the Abstracts for Addendum No. 1. This publication presents abstracts of over 65 papers contained in the 1977 and 1978 SAVE Annual Conference Proceedings.

ORDER YOUR PERSONAL COPY TODAY FOR ONLY $4.95 INCLUDING POSTAGE

- Tear Off Form To Moil -

Enclosed please f i n d Check • Money Order •

in the amount of $ SEND COMPLETED ORDER FORM TO: S O C I E T Y O F A M E R I C A N V A L U E ENGINEERS, INC. P. O. Box 210887 • Dallas, Texas 75211

Please send to my attention the following items:

Name

Address

City

1 9 7 9 S A V E Encyclopedia of Va lue Addendum No. 1

For only $ 4 . 9 5 including postage

State

P A Y M E N T I N U.S. FUNDS MUST ACCOMPANY A L L ORDERS

Zip

20

The "Pioneer Chapter" of the Society of American Value Engineers at Michigan State University would like to thank those S.A.V.E. members and their respective chapters and companies for the support they have given us in the past three years. Our special thanks go to the Detroit Chapter for the support that they have generously supplied to us.

Now i t is our turn to help you. As we all know, Value Analysis and Value Engineering are a growing and vital segment of the American Business Community. Since its conception in the late 1940's by Larry Miles, V . A . has proven itself a valuable tool . Good Value people are hard to come by. You either acquire them f r o m other organizations or you must train them yourself. We, of the Pioneer Chapter, have already had the equivalent of a 40 hour workshop plus the experience of doing our own special projects. Also by having the chance to talk to and experience the knowledge of noted value speakers such as Parks, Kaufman, Wilcock, Brandt and others, we have a good feel for current activities and needs of industry in Value work.

Should you need someone to f i l l a spot now or in the future, we would be a good place to start. Any inquires may be directed to Dr . John Polomsky, Dept. of Engineering, 234 Eng. Bid . M.S .U. East Lansing, Michigan.

Sincerely Yours,

Will iam J. Browne Jr. President, Pioneer Chapter.SAVE

Here is a list o f those graduating this year and part o f next year.

•David Beck Michale Beuche Richard Bolls Wil l iam J. Browne, Jr. Mark Byford Lawrence Bird Joseph Chambers Mark Deckert •Glenn Kevin Foster Daniel Ferrari Todd Grover Leslie Langnau Christopher Leavens Kevin Luedtke Will iam MacCreery Elizabeth Mart in Bruce Michel Gary Moss John Stein Peter Hubbard

Engineering Arts Engineering Arts Engineering Arts Engineering Arts Engineering Arts Engineering Arts Mechanical Engineering Engineering Arts Mechanical Engineering

Engineering Arts Engineering Arts Engineering Arts Engineering Arts Engineering Arts

Engineering Arts Engineering Arts Mechanical Engineering Engineering Arts Mechanical Engineering

Packaging & Eng. Arts

March 1979 June 1979 June 1979 March 1979 June 1979 June 1979 June 1979 June 1979 March 1980 June 1979 June 1979 June 1979 Dec. 1979 June 1979 June 1979 June 1979 June 1979 Dec. 1979 June 1979 June 1979

Value Engineering S l ide /Tape Presentat ion for Management

W e are p leased to announce the avai lab i l i ty date for the s l ide/ tape p resen ta t i on on the

Va lues of Va lue Eng ineer ing . This p resen ta t ion w i l l be ready for sh ipmen t February 2 2 ,

The 2 0 m inu te p resen ta t i on inc ludes 4 0 co lor sl ides ( 3 5 mm) accompan ied by a casse t te

tape w i t h the spoken message keyed to the v isual message of the sl ides. Th is p resen ta t ion

can be easi ly c o n d u c t e d w i t h a carouse l p ro jec tor and a casse t te player. This s l ide/ tape

package is a very usefu l too l to aid you and your g roups to i n t roduce the V .E . message to any

level of m a n a g e m e n t . A l l V .E . re ference l ibraries shou ld inc lude a copy of th is p resen ta t i on .

Order you rs t oday by send ing a check for $ 2 5 0 to the SAVE Nat iona l O f f i ce , 2 2 0 N. S to ry

Road, Sui te 1 1 4 , I r v ing , Texas 7 5 0 6 1 . Copies w i l l also be avai lable for shor t loan to SAVE

Chapters for specia l p rog rams .

1 9 7 9 .

Tear Off Kiirm To Mail

E n c l o s e d p lease f ind C h e c k Money O r d e r I 1

in the amount of $ S E N D C O M P L E T E D O R D E R F O R M T O : S O C I E T Y O F A M E R I C A N V A L U E E N G I N E E R S . I N C 220 N. Story Rd. Suite 114, Irving, Texas 75061

Please send lo my attention the following items: N a m e

A d d r e s s

City

V A L U E ENGINEERING, SLIDE/TAPE

PRESENTATION FOR M A N A G E M E N T

" T H E V A L U E OF V A L U E ENGINEERING"

State

P A Y M E N T I N U.S. F U N D S

M U S T A C C O M P A N Y A L L O R D E R S

Z i p

Society of American Value Engineers

220 N . Story R d .

Suite 114

Irving, T X 75061

Bulk Rate U . S . Postage Paid

Dal las , Texas

Permit No . 8293

A D D R E S S C O R R E C T I O N R E Q U E S T E D

c R , C V S , SR.. MEM

- . w e r d r i v e OH f S 3 3 H