GROUP 139 INDEXABLE MILLING CUTTERS

Transcript of GROUP 139 INDEXABLE MILLING CUTTERS

INDEXABLE MILLING CUTTERSGROUP

139

Page284

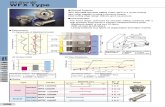

HELIDO H490 End Mills & Face MillsThe new HELIDO H490 ANKX rectangular inserts have fourhelical right-hand positive cutting edges. They were designedin cutting edge lengths of 9, 12 and 17 mm. Insertconstruction is very thick and strong; clamped into a dovetailinclined pocket which provides a very rigid clamping and hasa wiper which leaves an excellent surface finish. Due to itsstrong construction, unique chip deflector with positivecutting angles and excellent grade combinations, this newfamily features high durability, low cutting forces and longtool life. Our most advanced SUMO TEC grades ensureexcellent performance and reliability. The new HELIDO toolscan be used for machining steel, stainless steel and castiron at very high machining parameters. HELIDO's state-of-the-art of milling insert design, enables excellentperformance and extremely high productivity.H490 - A new family of double-sided inserts with four helicalcutting edges.

H490 E90AX... -09 End MillsEnd Mills with double-sided inserts, diameter range 16 - 40mm.

Dimensions Order Code OfferDesignation D Z H L d Shank Type Inserts ISC-139 Price/1

H490 E90AX D16-2-C15-09-B 16 2 40 150 15 C -4530C £175.69H490 E90AX D16-2-C16-09 16 2 26 90 16 C -4530M £161.73H490 E90AX D16-2-W16-09 16 2 26 85 16 W -4531J £161.73H490 E90AX D20-2-C19-09-B 20 2 40 160 19 C -4531S £187.46H490 E90AX D20-2-C20-09 20 2 26 110 20 C -4532C £174.95H490 E90AX D20-2-W20-09 20 2 26 90 20 W -4532S £174.95H490 E90AX D20-3-C20-09 20 3 26 110 20 C -4533C £183.04H490 E90AX D20-3-W20-09 20 3 26 90 20 W -4533S £183.04H490 E90AX D25-3-C24-09-B 25 3 40 200 24 C -4534G £219.80H490 E90AX D25-3-C25-09 25 3 26 120 25 C -4534S £203.63H490 E90AX D25-3-W25-09 25 3 26 95 25 W H490 ANKX 0904… -4535C £203.63H490 E90AX D25-4-C25-09 25 4 26 120 25 C H490 ANCX 0904... -4535S £213.92H490 E90AX D25-4-W25-09 25 4 26 95 25 W -4536C £213.92H490 E90AX D32-4-C31-09-B 32 4 40 200 31 C -4536W £261.70H490 E90AX D32-4-C32-09 32 4 30 130 32 C -4537C £241.85H490 E90AX D32-4-W32-09 32 4 30 110 32 W -4537M £241.85H490 E90AX D32-5-C32-09 32 5 30 130 32 C -4538C £255.10H490 E90AX D32-5-W32-09 32 5 30 110 32 W -4538S £255.10H490 E90AX D40-5-C32-09 40 5 38 130 32 C -4539M £264.64H490 E90AX D40-5-W32-09 40 5 38 110 32 W -4539S £264.64H490 E90AX D40-6-C32-09 40 6 38 130 32 C -4540C £277.14H490 E90AX D40-6-W32-09 40 6 38 110 32 W -4540S £277.14

Dimensions Order Code OfferDesignation D Z L da Arbor Style Inserts ISC-139 Price/1

H490 F90AX D032-4-16-09 32 4 35 16 A -4548C £233.04H490 F90AX D032-5-16-09 32 5 35 16 A -4548M £246.27H490 F90AX D040-5-16-09 40 5 40 16 A -4548S £263.92H490 F90AX D040-6-16-09 40 6 40 16 A H490 ANKX 0904… -4548V £276.40H490 F90AX D050-6-22-09 50 6 40 22 A H490 ANCX 0904... -4549C £302.14H490 F90AX D050-7-22-09 50 7 40 22 A -4549M £322.72H490 F90AX D063-8-22-09 63 8 40 22 A -4549S £381.53H490 F90AX D063-9-22-09 63 9 40 22 A -4549V £401.37

H490 F90AX... -09 Face MillsFace Mills with double-sided inserts, diameter range 32 - 63mm.

"B" Suffix cylindrical shank which may be shortened.

Designation Grade Order Code OfferISC-122 Price/1

H490 ANKX 090408PNTR IC808 -4512C £9.90

H490 ANKX Double-Sided Insert -4 cutting edges

Insert Grade Descriptions

IC808 A tough submicron substrate, improved TiAIN PVDcoated grade for better chip flow. Designed for machining

heat resistant alloys, austenitic stainless steel, hard alloys andcarbon steel at medium to high cutting speeds, interrupted cut andunfavourable conditions. Excellent notch wear and built-up edgeresistance.

IC808

H490 - A New Family of Double-SidedInserts with 4 Helical Cutting Edges

200% MORE

PRODUCTIVITY

CU

TTIN

G T

OO

LS

Page285

INDEXABLE MILLING CUTTERSGROUP

139

H490 F90AX - 12 Face Mills Face Mills with double-sided inserts,diameter range 40 - 100mm.

Dimensions Order Code OfferDesignation D Z L Da Pitch Arbor Type Inserts ISC-139 Price/1

H490 F90AX D040-4-16-12 40 4 40 16 A -4550C £256.55H490 F90AX D050-3-22-12 50 3 40 22 A -4550S £261.70H490 F90AX D050-5-22-12 50 5 40 22 Fine Pitch A -4550V £290.37H490 F90AX D063-4-27-12 63 4 50 27 A

H490 ANKX 1205…-4551M £327.86

H490 F90AX D063-6-27-12 63 6 50 27 Fine Pitch AH490 ANCX 1205...

-4551S £348.45H490 F90AX D080-5-27-12 80 5 50 27 B -4552C £420.48H490 F90AX D080-7-27-12 80 7 50 27 Fine Pitch B -4552M £448.43H490 F90AX D100-6-32-12 100 6 50 32 B -4553C £507.24H490 F90AX D100-9-32-12 100 9 50 32 Fine Pitch B -4553S £578.53

Dimensions Order Code OfferDesignation D Z L H d Shank Type Inserts ISC-139 Price/1

H490 E90AX D25-2-C25-12 25 2 110 35 25 C -4541S £197.75H490 E90AX D25-2-W25-12 25 2 110 35 25 W -4542C £197.75H490 E90AX D32-3-C32-12 32 3 110 40 32 C -4543C £234.50H490 E90AX D32-3-W32-12 32 3 110 40 32 W H490 ANKX 1205… -4543H £234.50H490 E90AX D40-4-C32-12 40 4 130 40 32 C H490 ANCX 1205... -4544C £257.29H490 E90AX D40-4-W32-12 40 4 115 40 32 W -4544H £257.29H490 E90AX D50-5-C32-12 50 5 130 50 32 C -4545C £283.03

H490 E90AX . . . 12 End Mills

End Mills with double-sided inserts, diameter range 25 - 50mm.

Designation Grade Order Code OfferISC-122 Price/1

H490 ANKX 120504PNTR IC830 -4514M £10.70H490 ANKX 120508PNTR IC808 -4515C £10.70H490 ANKX 120508PNTR IC830 -4515M £10.70H490 ANKX 120510PNTR IC830 -4516M £11.54H490 ANKX 120512PNTR IC830 -4517M £11.54H490 ANKX 120516PNTR IC830 -4518M £11.54H490 ANCX 120508PDR IC808 -4510C £13.67H490 ANCX 120508PDR IC830 -4510M £13.67

H490 ANKX Double-Sided Insert -4 cutting edges.

Insert Grade Descriptions

IC808 A tough submicron substrate, improved TiAIN PVDcoated grade for better chip flow. Designed for machining

heat resistant alloys, austenitic stainless steel, hard alloys andcarbon steel at medium to high cutting speeds, interrupted cut andunfavourable conditions. Excellent notch wear and built-up edgeresistance.

IC830 An improved PVD TiAIN coated tough grade withbetter chip flow. Suitable for milling stainless, high

temperature alloys and other alloy steels. Recommended forinterrupted cut and heavy operations.

IC808

IC830

Rampdown

Rampdown

H490 - A New Family of Double-SidedH490 - A New Family of Double-SidedInserts with 4 Helical Cutting EdgesInserts with 4 Helical Cutting Edges

200% MORE

PRODUCTIVITY

CU

TTIN

G T

OO

LS

INDEXABLE MILLING CUTTERSGROUP

139

Page286

XP-90C ‘APT’ 90° Shell Mills90° approach with centre screen clamping. Utilising the APKT 1604inserts. Produces square stepless shoulders, wide slots and deepprofiles.

Insert size: APKT 1604 PDTR

‘Hi Shear’ 45°45° approach face mill utilising square inserts, with centre screwclamping to give a steep rake geometry for a smooth cutting actionand excellent chip evacuation.

Insert size: SEHW 1204 AFTN-05

Top Brand Milling Bodies & Top Brand InsertsAll tools on this page supplied complete with 1 or 2 SETS* of carbide inserts, in coated grades for steels and general use applications.EXCLUSIVE UNBEATABLE VALUE. Inserts supplied will vary according to availability. (*Sets = Number of teeth per cutter x1 set for ‘Tri Square 90° and Octagon Face Mill and x2 sets for all the others). SEE FOLLOWING PAGES FOR FURTHER PRODUCT INFORMATION

XP-45C ‘Face Hog’ 45° Shell Mills45° approach face mill which uses square inserts with top clamping.Ideal for use in particularly heavy operations where a solid insert isan advantage. The high shear geometry reduces cutting forcesextending tool life.

Insert size: SEKN/R 1203 AF_N

XP-90C ‘4 Square’ 90° Shell MillsHas centre screw clamping for improved chip evacuation and utilisessquare inserts for the added economy of the extra insert edge. The cutter provides an 89° shoulder at the edge of a milled face.

Insert size: SDMT 12T308

Dia. Order Code List Offer(mm)

d zPRO-139 Price/1 Price/1

63 22 5 -7600K £249.99 £94.9980 27 5 -7620K £299.99 £129.99100 32 6 -7640K £329.99 £144.99

Dia. Order Code List Offer(mm)

d zPRO-139 Price/1 Price/1

63 22 5 -7500K £199.99 £94.9980 27 6 -7520K £249.99 £124.99100 32 7 -7540K £299.99 £149.99

Dia. Order Code List Offer(mm)

d zPRO-139 Price/1 Price/1

50 22 4 -3920K £202.99 £69.9963 22 6 -3940K £273.99 £89.9980 27 7 -3960K £333.99 £99.99100 32 8 -3980K £387.99 £124.99

APKTinserts

Supplied with2 sets of

SDMTinserts

SEKN/Rinserts

Supplied with2 sets of

Dia. Order Code List Offer(mm)

d zPRO-139 Price/1 Price/1

63 22 5 -7400K £269.99 £99.9980 27 6 -7420K £289.99 £129.99100 32 6 -7440K £349.99 £139.99160 40 8 -7460K £499.99 £199.99

For APKT 10 Inserts

For APKT 16 Inserts

XP-90C ‘APT’ Weldon End MillsUsed for profiling, slotting and facing. First choice for profiling work. Available indiameters from 10 to 40mm and utilising a long edge APKT style insert for deep profiles.

Dia. Order Code List Offer(mm)

d zPRO-139 Price/1 Price/1

10 10 1 -4800K £105.99 £39.9912 12 1 -4820K £127.99 £39.9916 16 2 -4860K £144.99 £49.9920 20 3 -4900K £168.99 £54.99

Dia. Order Code List Offer(mm)

d zPRO-139 Price/1 Price/1

20 20 1 -5000K £143.99 £44.9925 25 2 -5020K £147.99 £54.9932 32 3 -5040K £183.99 £59.9940 32 4 -5060K £269.99 £69.99

‘Tri Square’ 90° Shell MillsUses top clamping triangular inserts to produce a 90° shoulder at theedge of a milled face. When taking a number of cuts across a facethe shoulder produced is without steps. 80mm diameter.

Insert size: TPKN 1603

Dia. Order Code List Offer(mm)

d zPRO-139 Price/1 Price/1

80 32 5 -6330K £279.99 £89.99

SEHWinserts

Supplied with2 sets of

TPKNinserts

Supplied with1 set ofSupplied with

2 sets of

APKTinserts

Supplied with2 sets of

XP XTRA PLASMA

COATED BODY

XP XTRA PLASMA

COATED BODY

XP XTRA PLASMA

COATED BODY

XP XTRA PLASMA

COATED BODY

XP XTRA PLASMA

COATED BODY

CU

TTIN

G T

OO

LS

EXTENDEDRANGE

Page287

INDEXABLE MILLING CUTTERS

GROUP

139

(K20) Micrograin uncoated. For cast irons, aluminiumalloys, other non-ferrous materials including titaniums andnickel alloys.

(P25) Uncoated. For medium and finish milling of steels.

(P10-P35) CVD coated. Milling grade for steels and somestainless steels.

(P40) Uncoated. For rough medium and finish milling oftough steels and stainless steels including interruptedcutting.

Insert Grade Description

Designation Grade To SuitOrder Code List OfferYML-120 Price/1 Price/1

K20 -4517V £10.17 £6.92SEKN 1203 AFTN QP25 Face Hog -4527P £10.33 £7.02

QP40 -4527S £10.45 £7.11

SEKR 1203 AFTNK20

Face Hog-4617V £10.20 £6.94

QP25C -4627W £11.45 £7.79

Application Range

K20 K20

QP25QP25

QP25CQP25C

QP40QP40

Inserts

XP-45C ‘Hi Shear’ Milling Cutters

Super Positive 45° approach milling cutter, angle decreases cutting forces and allows a quick feed in a limited capacity machine. Torx screws allow for good chip evacuation. Plasma Ion coating offers longer tool life and greater hardness that is more resistant to wear. Through coolant as standard.

(K20) Micrograin uncoated. For cast irons, aluminiumalloys, other non-ferrous materials including titaniums

and nickel alloys.

(P10-P35) CVD coated. Milling grade for steels and somestainless steels.

K20 K20

QP25CQP25C

Inserts Insert Grade Description

Designation GradeOrder Code List OfferYML-120 Price/1 Price/1

SEHT 1204 AFTNK20 -4430V £9.79 £6.66QP25C -4430W £11.52 £7.83

SEHW 1204 AFTN-05K20 -4445V £11.35 £7.72QP25C -4445W £13.24 £9.00

Dia Order Code List Offer(mm) D1 d F Z IND-139 Price/1 Price/1

63 75 22 50 5 -7400K £173.63 £104.1880 92 27 50 6 -7420K £198.11 £118.87100 112 32 50 6 -7440K £261.56 £156.94160 172 40 63 8 -7460K £465.23 £279.14

Spares to suit

Order Code KEN-603Offer

Price/1

-0220D £7.09

Order Code IND-107Offer Offer Offer Offer

Price/1 Price/1 Price/1 Price/1

-5353K £3.44-5354K £1.83-5356K £3.14

-5352K £3.05

-5358K £3.68

Arbor Screw Clamp Screw Driver

XP XTRA PLASMA

COATED BODY

Feed Per Tooth (mm)

0.05 - 0.20

See Page 290 for Cutting Speed Information

CU

TTIN

G TO

OLS

Dia Order Code List Offer(mm) D1 d L Z IND-139 Price/1 Price/1

63 76 22 50 5 -7600K £161.39 £96.8380 93 27 50 6 -7620K £220.37 £132.22100 113 32 50 6 -7640K £288.27 £172.96125 138 40 63 7 -7660K £331.67 £199.00160 173 40 63 8 -7680K £440.75 £264.45

Application Range

Spares to suit

Order Code KEN-601Offer

Price/1

-1400K £20.67

Order Code IND-107Offer Offer Offer Offer

Price/1 Price/1 Price/1 Price/1

-5353K £3.44-5354K £1.83-5356K £3.14 -4960K £3.72 -5284K £0.87 -5290K £9.41

--5358K £3.68

Arbor Screw Shim Shim Screw Clamp Screw Hex Key

XP XTRA PLASMA

COATED BODYFeed Per Tooth (mm)

0.05 - 0.20

See Page 290 for Cutting Speed Information

XP-45C ‘Face Hog’ Milling Cutters

Super Positive 45° approach milling cutter, angle decreases cutting forces and allows a quick feed in a limited capacity machine. Clamp style insert pocket with shim seats to protect the body in case of accident. Plasma Ion coating offers longer tool life and greater hardness that is more resistant to wear. Through coolant as standard

INDEXABLE MILLING CUTTERS

GROUP

139

Page288

SDMT

90°

Application Range

To SuitOrder Code OfferKEN-601 Price/100

Clamp Wrench (Insert 1603) -1400K £20.67Clamp Wrench (Insert 2204) -1500K £34.54

(K20) Micrograinuncoated.

For cast irons, aluminiumalloys and other non-ferrousmaterials including titaniumsand nickel alloys.

(P25) Uncoated. Formedium and finishmilling of steels.

(P40) Uncoated. Forrough medium and

finish milling of tough steelsand stainless steels includinginterrupted cutting.

(P20-P40 M20-M30)Coated. Turning

grade for steels, cast steelsand stainless steels. A goodgeneral purpose steel gradefor roughing.

‘Tri Square’ 90° Shell MillsUses top clamping triangular inserts to produce a 90° shoulder at the edge of a milled face. This is of major benefit when taking a number of cuts across a face as the shoulder produced is without steps.

Inserts

Designation Grade To Suit Order Code List OfferYML-120 Price/1Price/1

TPKN 1603 PPR K20 Tri-Sq -8428V £5.91 £4.02

TPKN 1603 PPTRQP25 -8438P £8.24 £5.60QP40

Tri-Sq-8438S £8.24 £5.60

TPKN 2204 PDR K20 Tri-Sq -8458V £9.19 £6.25

TPKN 2204 PDTRQP25 -8468P £11.75 £7.99QP40

Tri-Sq-8468S £11.75 £7.99

SDMT 12T308 QX530 4 Sq -4280E £11.21 £7.62

Insert Grade Selection

TPKN

Hexagon Keys

For TPKN 1603

For TPKN 2204

Application Range

K20 K20

QP25QP25

QP40QP40

XP XTRA PLASMA

COATED BODY

Feed Per Tooth (mm)

0.04 - 0.30

See Page 290 for Cutting Speed Information

XP-90C ‘4 Square’ 90° Shell Mills for SDMT 12 inserts

Dia Weight Order Code List Offer(mm) d F L3 Z each IND-139 Price/1 Price/1

63 27 50 13 4 655g -3400K £183.65 £110.1980 32 50 13 5 1200g -3420K £211.47 £126.88

100 40 50 13 6 1746g -3440K £273.80 £164.28

Spares to suit

Order Code IND-107Offer Offer Offer Offer Offer

Price/1 Price/1 Price/1 Price/1 Price/1

-5354K £1.83-5355K £1.26 -5360K £3.42 -5362K £0.44 -0050K £0.83 -0440K £0.73-5357K £7.14

Arbor Screw Shim Shim Pin Clamp Screw Clamp Ring

Dia Weight Order Code List Offer(mm) d H Z each IND-139 Price/1 Price/1

63 22 40 5 459g -7500K £162.50 £97.5080 27 50 6 999g -7520K £220.37 £132.22

100 32 50 7 1669g -7540K £288.27 £172.96125 40 63 7 3533g -7560K £340.58 £204.35

Spares to suit

Arbor Screw Shim Shim Pin Clamp Screw Driver

Dia Weight Order Code List Offer(mm) d F L3 Z each IND-139 Price/1 Price/1

100 40 50 18 5 1546g -3460K £273.80 £164.28125 40 63 18 6 2777g -3480K £365.06 £219.04

Order Code IND-107

Offer Offer Offer Offer OfferPrice/1 Price/1 Price/1 Price/1 Price/1

-5357K £7.14 -5361K £3.42 -5380K £0.44 -0060K £0.98 -0500K £0.86

For InsertsSee Below

Insert Size Feed Per Tooth (Fz) mm

TPKN 16 0.05 - 0.20

TPKN 22 0.10 - 0.30

See Page 290 for Cutting Speed Information

Order Code KEN-603

OfferPrice/1

-0150D £6.36

QX530 QX530

Order Code IND-107

Offer Offer Offer Offer Price/1 Price/1 Price/1 Price/1

-5354K £1.83-5354K £1.83

-2490K £3.05 -1570K £3.24 -3400K £1.42-5356K £3.14-5357K £7.14

SDMT 12

CU

TTIN

G TO

OLS

XP-90C ‘4 Square’ 90° Shell Mills

Positive 90° cutter with an exact angle of 90°, square insert allowing depth passes and high feed per teeth. Torx style insert pocket with shim seats to protect the bodyin case of accident. Plasma Ion coating offers longer tool life and greater hardness that is more resistant to wear. Through coolant as standard.

Page289

INDEXABLE MILLING CUTTERS

GROUP

139

Order Code KEN-603

Offer Price/1

-0080D £5.58-0150D £6.36-0150D £6.36

XP-90C ‘APT’ 90° Shell MillsPositive 90° approach milling cutter, using size 16 inserts allowing depth passes and high feed per teeth. Torx screw allows for good chipevacuation. Plasma Ion coating offers longer tool life and greater hardness that is more resistant to wear. Through coolant as standard.

(K20) Micrograin uncoated. For cast irons,aluminium alloys, other non-ferrous

materials including titaniums and nickel alloys.

(K15-K30) Coated. For milling cast irons.

(P10-P35) PVD coated. Milling grade forsteels and some stainless steels.

Insert Grade Description

Insert Grade Selection

XP-90C ‘APT’ 90° Shell Mills

Positive 90° approach milling cutter, using size 10/16 inserts allowing depth passes and high feed per teeth. Torx screw allowsfor good chip evacuation. Plasma Ion coating offers longer tool life and greater hardness that is more resistant to wear. Through coolant as standard.

C

D

L

H

XP-90C Shell Mills For APKT 16 Inserts

D z B C L InsertsOrder Code List OfferIND-139 Price/1 Price/1

50 4 22 10.4 50 -3920K £210.36 £126.2263 5 22 10.4 50

APKT1604-3940K £296.06 £177.64

80 6 27 12.7 50or

-3960K £368.40 £221.04100 7 32 14.4 63

APXT1604-3980K £431.84 £259.10

Designation Grade To SuitWeight Order Code List Offereach YML-120 Price/1 Price/1

APKT 1003 PDRQK25C APT 27g -0028X £9.84 £6.69QP30P Shell Mills 35g -0028W £9.84 £6.69K20 Combination 85g -0031V £9.55 £6.49

APXT 1604 PDTR QK25C End, APT 92g -0030X £11.40 £7.75QP30P Shell Mills 85g -0030W £11.40 £7.75

XP-90C End Mills For AP_T 10 Inserts

D z H C L InsertsOrder Code List OfferIND-139 Price/1 Price/1

10 1 20 10 80 -4800K £122.43 £73.4612 1 20 12 80

APKT1003-4820K £148.03 £88.82

16 2 25 16 90or

-4860K £168.06 £100.8420 3 25 20 110

APXT1003-4900K £189.21 £113.53

XP-90C End Mills For AP_T 16 Inserts

D z H C L InsertsOrder Code List OfferIND-139 Price/1 Price/1

20 1 37 20 115 -5000K £166.95 £100.1725 2 40 25 117

APKT1604-5020K £171.40 £102.84

32 3 40 25 126or

-5040K £212.58 £127.5540 4 50 32 136

APXT1604-5060K £309.41 £185.65

To Suit Order Code IND-107

Offer Price/1 Offer Price/1 Offer Price/1

10-20 Dia (APKT 10) - -5240K £3.02 -20-25 Dia (APKT 16) - -5270K £3.10 -5150K £2.4232-40 Dia (APKT 16) - -5270K £3.10 -5150K £2.42

Spares Arbor Screw Clamp Screw Flag Torx Key

K20 K20

QP30PQP30P

QK25CQK25C

Driver

Order Code KEN-603

Offer Price/1

-0150D £6.36

To Suit Order Code IND-107 Order Code IND-107

Offer Price/1 Offer Price/1

50 & 63 Dia -5354K £1.8380 Dia (APKT 16) -5354K £1.83 -5270K £3.10

100 Dia -5355K £1.26

Spares Arbor Screw Clamp Screw Flag Torx Key Driver

XPXTRA PLASMA

COATED BODY

XPXTRA PLASMA

COATED BODY

Insert Size Feed Per Tooth (Fz) mm

APXT 10 0.05 - 0.20APXT 16 0.10 - 0.30

Feed Per Tooth (Fz) mm

0.10 - 0.30

See Page 290 for Cutting speed Information

For InsertsSee Below

CU

TTIN

G TO

OLS

INDEXABLE MILLING CUTTERS

GROUP

139

Page290

CU

TTIN

G TO

OLS

L

L1

d

L2

Insert Grade Selection

(P10-P35 M10-M30 K10-K30) Coated. An excellent general purpose grade for

medium roughing on steels, stainless and castirons.

(K10) Uncoated. Used in combination with a high rake geometry for machining

aluminium, plastics and other soft non-ferrousmaterials.

(QX500) (P10-P25 Cermet). For highspeed finishing and light roughing. Will

maintain a high class surface finish. Mainly usedon steels and can be applied to finishing somestainless steels and cast irons.

Feed Per Rev (mm)

0.02 - 0.10

Insert Grade Description

BrinellHardness

HB

Speed-M/Min

Materials

Colour defines similar machineability

TensileStrengthN/mm2

RockwellHardness

HRC K10

QX520

QX530

QX500

200-270 180-350 150-200

180-250 150-320 130-180

150-220 130-280 110-150

140-210 140-210 110-140

140-200 130-200 100-120

110-180 100-170 70-90

90-190 110-220

70-160 70-140 60-100

50-90

175-280 190-400

160-250 150-300

Mild, soft and free machining non-alloy low carbon steels

Non-alloy, case hardening, structural and low to medium carbon steels

Non alloy, plain and medium carbon steels and castings

Generally low to medium alloy steels and castings

Medium to high alloy steels, tool steels and steel castings

Heat treated high alloy steels and castings

Soft & generally easy to machine Ferritic & Martensitic stainless steels & castings

Medium strength & reasonable to machine Austenitic stainless steels & castings

Hard & generally difficult to machine Ferritic & Austenitic (duplex) stainless steels & castings

Grey cast iron Hardness - soft to medium

Grey cast iron Hardness - medium to hard

Malleable and Nodular irons - soft to medium 200-250

200-250

200-250 100-500

300-500 400-700

300-500 400-700

300-500 400-600

300-500

400-700

400-700

200-500

Malleable and Nodular irons - medium to hard

Copper

Brass (Alpha - long chip)

Brass (Beta - short chip) & soft Bronze

Unalloyed: Aluminium, Magnesium & Zinc

Aluminium alloys less than 5% Si Magnesium & Zinc alloys (long chip)

Aluminium alloys 5% to 10% Si

Aluminium alloys above 10% Si (short chip)

Thermoplastics

Thermo-setting plastics

Reinforced plastics & composite materials

-

-

up to 26

up to 26

from 26

up to 48

from 36

up to 48

up to 20

up to 30

up to 36

-

-

-

-

-

-

-

-

-

-

-

up to 130

up to 200

up to 260

up to 260

from 260

up to 340

from 340

up to 450

up to 230

up to 290

up to 340

up to 180

from 180

up to 300

up to 220

from 220

up to 300

-

-

-

-

-

-

-

up to 400

up to 700

up to 850

up to 850

from 850

up to 1200

from 1200

up to 1500

up to 800

up to 1000

up to 1200

up to 500

up to 800

up to 800

up to 150

from 150

up to 300

from 200

up to 500

from 200

up to 500

1.1

1.2

1.3

1.4

1.5

1.6

2.1

2.2

2.3

3.1

3.2

3.3

3.4

6.1

6.2

6.3

7.1

7.2

7.3

7.4

8.1

8.2

8.3

Dia. Order Code List Offer(mm)

d L L1 L2IND-139 Price/1 Price/1

08 12 120 95 2510 12 120 95 25

-9010K £273.80 £164.2812 12 120 95 2516 16 120 95 25

Description To Suit Order Code OfferIND-107 Price/1

Insert Screw Quad -5240K £3.02T8 Torx Key Mill -5080K £2.26

Designation Grade To Suit Order Code List OfferYML-120 Price/1 Price/1

QX500 -0355A £6.11 £4.15CCMT060204-PM

QX520Quad Mill

-0355D £6.11 £4.15CCGT060202-AL K10 Quad Mill -0121N £8.23 £5.60CCGT060204-AL K10 Quad Mill -0131N £8.23 £5.60

Steel

Group

Speed & Feed Recommendations for Quad MillsSpecific feed rates may vary according to work material and machine conditions but the following can be used as a general guide.

QMC 06 Quad Milling Holder Set

Small diameter Indexable End Mills are taking a CCMT 06 insert. Ideal for use on manual and CNC milling machines where reach and clearance are required.

Uses CCMT 06/CCGT 06 inserts.

ApplicationRange

Spares

K10 K10

QX520 QX520

QX500QX500

Page291

INDEXABLE MILLING CUTTERS

GROUP

139

Speed Recommendations for Yamaloy Milling Inserts

Use the following table with the specific feed rates of the cutter used (found on the specific cutter page). Feed rates may vary according to work material and machine conditions but the following can be used as a general guide.

Steel Materials Brinell Rockwell Tensile Speed M/min

GroupColour Defines Similar Hardness Hardness Strength QP25/

Machineability HB HRC N/mm2 K20 QK25CQP30PQP30P QP40 QX530

1.1Mild, soft and free machining non-alloy

up to 130 - up to 400 - - 140 - 200 180 - 250 80 - 50 150 - 200low carbon steels

1.2Non-alloy, case hardening, structural and

up to 200 - up to 700 - - 130 - 180 150 - 230 75 - 110 130 - 180low to medium carbon steels

1.3Non-alloy, plain and

up to 260 up to 26 up to 850 - - 130 - 160 140 - 210 75 - 95 110 - 150medium carbon steels and castings

1.4Generally low to medium alloy steels

up to 260 up to 26 up to 850 - - 120 - 160 130 - 200 70 - 90 110 - 140and castings

1.5Medium to high alloy steels, tool steels from 260 from 26 from 850

- - 110 - 150 120 - 180 65 - 85 100 - 120and castings up to 340 up to 48 up to 1200

1.6 Heat treated alloy steels and castings up to 230 up to 20from 1200

- - 80 - 120 110 - 150 60 - 80 70 - 90up to 1500

2.1Soft and generally easy to machine ferritic

up to 290 up to 30 up to 800 - - 130 - 180 150 - 200 70 - 100 80 - 120and martensitic stainless steels and castings

2.2Medium strength and easy to machine

up to 340 up to 36 up to 1000 - - 120 - 170 130 - 180 70 - 100 60 - 100austenitic stainless steels and castings

2.3Hard and generally difficult to machine ferritic and

up to 180 - up to 1200 - - - 40 - 50 25 - 40 50 - 90austenitic (duplex) stainless steels and castings

3.1Grey cast iron from 180

- - 120 - 150 150 - 250 - - - -Hardness - soft to medium up to 300

3.2Grey cast iron

up to 220 - - 90 - 130 120 - 200 - - - -Hardness - medium to hard

3.3Malleable and nodular iron - from 220

- - 80 - 110 150 - 250 - - - -soft to medium to 300 max

3.4Malleable and nodular iron -

- - - 70 - 100 120 - 200 - - - -medium to hard

4.1Pure titanium

- - up to 700 200 - 300 - - - - -(also pure nickel)

4.2Titanium alloys of a medium

- - up to 900 50 - 80 - - - - -and hard nature

4.3Titanium alloys of a hard

- -from 900

20 - 50 - - - - -and very hard nature up to 1250

5.1Heat resistant super alloys including iron

- - up to 500 15 - 35 - - - - -based high temperature alloys

5.2Heat resistant super alloys, cobalt or nickel

- - up to 900 15 - 35 - - - - -based, of a medium to hard nature to machine

5.3Heat resistant super alloys, cobalt or nickel

- -from 900

20 - 50 - - - - -based, of a hard or very hard nature to machine up to 1200

6.1 Copper - - up to 500 250 - 400 - - - - -

6.2 Brass (alpha - long chip) - - up to 800 200 - 400 - - - - -

6.3Brass (beta - short chip)

- - up to 800 200 - 800 - - - - -and soft bronze

6.4 High strength bronze - - up to 1200 50 - 120 - - - - -

7.1 Unalloyed: aluminium, magnesium & zinc - - up to 150 500 - 900 - - - -

7.2Aluminium alloys less than 5% Si

- -from 150

600 - 900 - - - - -magnesium and zinc alloys (long chip) up to 300

7.3 Aluminium alloys 5% to 10% Si - -from 200

300 - 600 - - - - -up to 500

7.4 Aluminium alloys above 10% Si (short chip) - -from 200

200 - 500 - - - - -up to 500

8.1 Thermoplastics - - - 300 - 700 - - - - -

8.2 Thermo-setting plastics - - - 300 - 500 - - - - -

8.3Reinforced plastics & composite

- - - 100 - 300 - - - - -materials

CU

TTIN

G TO

OLS

INDEXABLE MILLING CUTTERS

GROUP

139

Page292

Spares

SC1645C SC1630C

(ISO P10/M10/K10) Tin Coated Multi-purpose grade for general use, can cut the majority of ferrous and non-ferrous materials used in industry.

(ISO P20) Uncoated Grade for steel andstainless steel application.

(ISO K10) Uncoated Grade for cast irons,aluminiums, and non-ferrous materials.

Insert Grade Description

Hole Chamfer

Spotting

Edge Chamfer

SCM1045C

Inserts

Vee Groove Milling

Hole Chamfer

Vee Groove Milling

Speed & Feed Recommendations for Multi-Pro

Multi-Pro Spot Drills & Chamfer Mills

A spotting drill with all the advantages ofindexable inserts - reduced tool maintenancetime, increased performance, lower inventorycost and no regrinding requirements. The insertclamping method ensures accurate and securelocation with quick change-over times. Multi-prohas a unique geometry which allows cuttingover the centre line, using carbide, withoutchipping of the cutting edge. This versatile toolmay be used to ‘spot’ holes prior to drilling, asa means to guide the drill and keep the holestraight, to keep size and accurately position,relative to the datum.NB. The 118° inclusive tool is recommendedfor ‘spotting’ prior to drilling with 118° pointdrills. Countersinks may be produced prior todrilling to provide a corner break on a drilledhole, a chamfer conforming to drawingspecifications, a lead in for a subsequenttapping operation, or a full countersink toaccommodate a screw head. Corner chamferson edges, contours and bores can be machinedas light de-burring operations or full depthchamfers. Multi-pro may be used to producevee grooves for fluid channels, locations forround components and grip pattern orserrations on jaws and clamp pads.

Insert ScrewOrder Code OfferIND-107 Price/1

To suit SCM1045C -3249K £3.18To suit SC1645C & SC1630C -4800K £3.40

Designation Grade To SuitOrder Code List OfferYML-122 Price/1 Price/1

C22 GUX QM10 Multi-Pro Mini -0080N £23.18 £17.62C32 GUX QS20 Multi-Pro -0102P £18.67 £14.19C32 GUX QC10 Standard -0100N £18.67 £14.19

DesignationCutting Overall Included Shank Weight Order Code List OfferDiameter Length Angle Diameter each IND-139 Price/1 Price/1

SC 1645C 13mm 110mm 90° 16mm 174g -8545K £210.36 £126.22SC 1630C 16mm 110mm 118° 16mm 184g -8530K £210.36 £126.22

‘Multi Pro Mini’ - Uses C22 GUX Inserts

‘Multi Pro Standard’ - Uses C32 GUX Inserts

DesignationCutting Overall Included Shank Weight Order Code List OfferDiameter Length Angle Diameter each IND-139 Price/1 Price/1

SCM 1045C 8mm 105mm 90° 10mm 78g -8050K £207.02 £124.21

RockwellRecommended

CuttingType of

Feed/Rev

Group Materials HardnessGrade

SpeedOperation

Pro Mini Pro Standard Pro Mini

HRC M/min 105mm 110mm 165mm

1.1 to Alloy Steels from 36QS20 80~100

Spot Drilling 0.020 0.026 0.013

1.3 and castings up to 45QM10

Chamfer Milling 0.050 0.070 0.040

1.4 to Tool and from 45QS20 QM10 55~65

Spot Drilling 0.012 0.016 0.008

1.6 die steels up to 55 Chamfer Milling 0.030 0.050 0.020

2.1 to up toQS20 QM10 70~90

Spot Drilling 0.020 0.026 0.013

2.3Stainless steels

36 Chamfer Milling 0.040 0.060 0.030

3.1 toQC10 QM10 100~120

Spot Drilling 0.034 0.045 0.022

3.4Cast irons -

Chamfer Milling 0.050 0.070 0.040

6.1 to Copper alloysQC10 QM10 120~150

Spot Drilling 0.034 0.045 0.022

6.6 brass and bronze -

Chamfer Milling 0.050 0.070 0.040

7.1 toQC10 QM10 120~150

Spot Drilling 0.034 0.045 0.022

7.4Aluminium alloys -

Chamfer Milling 0.050 0.070 0.040

Application Range

QS20 QS20

QM10 QM10

QC10QC10

CU

TTIN

G TO

OLS

Page293

INDEXABLE MILLING CUTTERS

GROUP

139

Indexable End Mills - Mill 1-10End Mills Weldon Shank• 10mm depth of cut capability.• Aggressive ramping rates.• Generates superior finish.• Mill true 90 walls.• High RPM capabilities.

Productivity at your fingertips

Cutter Dimensions (mm) Max. Max. Order Code OfferDesignation øD Z L2 L Ap1max Ramp Angle RPM KML-139 Price/1

16A02R025B16ED10 16 2 25 74 10.1 9.5° 50,100 -1671B £144.0020A03R028B20ED10 20 3 28 79 10,1 6.0° 44,800 -2060P £161.0025A03R032B25ED10 25 3 32 89 10,0 4.0° 40,000 -2446A £168.50

End Mills Weldon Shank

EDCT Inserts

Insert Size Grade

Order Code List OfferEDCT KML-113 Price/1 Price/1

10T308PDERLD KC725M -5350E £12.40 £9.92

Insert Size Grade

Order Code OfferHNGJ KMT-113 Price/1

0905ANSN-GD KC725M -6020K £15.80

Product Cutting Dimensions (mm)

Number Edges Ll W S BS Rε hm

EDCT10T308PDERLD 2 12.06 6.73 3.75 0.49 2.00 0.06

Excellent Insert Economy - 12 True Cutting Edges Per Insert

Kennametal’s Dodeka™ Face Mill Program is specifically engineered to deliver consistent performance in demanding rough and finishing face milling applications!• Use less horsepower — and gain up to 30% in productivity.• Up to 50% longer tool life.• Easy-to-use — one screw enables fast, accurate indexing.• 12 true cutting edges lower your cost per edge.• Run at higher speeds and feeds — with higher metal-removal rates.• 4.5mm depth-of-cut capability.• Available in diameters from 40 - 315mm. Full range details on request.• Through-coolant standard.

Dodeka™ Indexable Shell Mills Dodeka™ 45° Inserts - Grade KC725M

More True Cutting Edges for Greater Productivity per Insert

Product D1 Z D D1 D4 D6 L Weight Max Order Code OfferNumber mm mm max mm mm mm kg RPM KML-139 Price/1

KSHR50A04RS45HN09 50 4 22 61.0 n/a 38 40 0.3 12700 -9512M £286.00KSHR63A06RS45HN09 63 6 22 74.0 n/a 50 40 0.6 10100 -9514P £371.00KSHR80A06RS45HN09 80 6 27 91.0 n/a 60 50 1.1 7900 -9516R £401.50

Coarse Pitch - Metric

KC725M (ISO M15-M35, P15-P35, K15-35) A Multi-layer PVD AlTiN

coating with a tough 11.5% cobaltsubstrate designed primarily to beused in general and heavy machining.General purpose medium-speed gradefor steels. Good resistance to thermalshock. Suitable for wet and drymachining applications.

KC725M

CU

TTIN

G TO

OLS

INDEXABLE MILLING CUTTERS

GROUP

139

Page294

Series Cutter Dimensions (mm) Weight Order Code OfferDesignation ØD Dia. R Ød1 Ød2 L L2 L4 each DIJ-123 Price/1

BNMS - 060030T S10 6 3.0 10 5.4 80 30 15.0 80g -2301A £126.68Short BNMS - 080035T S12 8 4.0 12 7.2 92 35 18.5 81g -2302B £106.08

BNMS - 100035T S12 10 5.0 12 9.0 92 35 21.0 82g -2303C £98.87BNMM - 080053T S12 8 4.0 12 7.2 110 53 18.5 101g -2102B £92.69BNMM - 100053T S12 10 5.0 12 9.0 110 53 21.0 149g -2103C £102.99BNMM - 120053T S12 12 6.0 12 10.0 110 53 22.0 176g -2104D £82.39

Medium BNMM - 160063T S16 16 8.0 16 14.0 123 63 28.0 192g -2105E £92.69BNMM - 200075T S20 20 10.0 20 17.0 141 75 34.0 388g -2107G £102.99BNMM - 250090T S25 25 12.5 25 21.0 166 90 41.0 612g -2109J £108.14BNMM - 300106T S32 30 15.0 32 26.0 186 106 49.0 1037g -2110K £127.71BNML - 100075T S12 10 5.0 12 9.0 132 75 21.0 130g -2003C £114.32

Long BNML - 250135T S32 25 12.5 32 21.0 215 135 41.0 -2009J £121.66BNML - 300160T S32 30 15.0 32 26.0 240 160 49.0 1287g -2010K £134.67

Straight Neck

Series Cutter Dimensions (mm) Weight Order Code OfferDesignation ØD Dia. R Ød1 Ød2 L L2 each DIJ-123 Price/1

BNMM -120053S S12 12 6.0 12 10 110 53 107g -2054D £88.57

Medium BNMM -200075S S20 20 10.0 20 17 141 75 -2057G £97.84BNMM -250090S S25 25 12.5 25 21 166 90 -2059J £102.99BNMM -300106S S32 30 15.0 32 26 186 106 -2060K £121.53BNMS -120026S S12 12 6.0 12 10 83 26 24g -2204D £72.09

Short BNMS -200038S S20 20 10.0 20 17 104 38 321g -2207G £98.87BNMS -250045S S25 25 12.5 25 21 121 45 -2209J £99.90

Inserts

To Suit Weight Order Code OfferCutter Dia per 20 IND-140 Price/1

8 7g -0600K £16.4510 9g -0610K £16.4512 13g -0620K £16.4516 28g -0630K £16.4520 44g -0640K £17.2425 80g -0650K £20.1330

180g -0660K £26.1632

Screws

Mirror BallCutters

A range of cutter bodies and inserts for finishing the profiles of dies and moulds. Inserts areprecision ground to ensure accurate workpiece form and high quality surface finish, which minimisessubsequent polishing. The DZ coating provides for maximum tool life and edge durability whencutting at high speeds. Should be held in a roller lock type chuck.

Taper Neck

To Suit Designation Weight Order Code List OfferCutter Dia. BNM

Gradeeach DIJ-122 Price/1 Price/1

6 060 JC5015 20g -2060J £23.51 £17.40

8080 JC5003

24g-2080F £23.51 £17.40

080 JC5015 -2080J £23.51 £17.40

10100 JC5003 -2090F £25.48 £18.86100 JC5015 -2090J £25.48 £18.86

12120 JC5003

44g-2110F £26.45 £19.57

120 JC5015 -2110J £26.45 £19.57

16160 JC5003

80g-2120F £32.82 £24.29

160 JC5015 -2120J £32.82 £24.29

20200 JC5003

150g-2130F £36.73 £27.18

200 JC5015 -2130J £36.73 £27.18

25250 JC5003

340g-2140F £47.02 £34.79

250 JC5015 -2140J £47.02 £34.79

30300 JC5003

457g-2150F £68.59 £50.76

300 JC5015 -2150J £68.59 £50.76

Insert Grades(P01-P10/M10/K01-K10)Die-mould applications in

hardened material at high cuttingspeeds. Micro grain substrate withDZ coating for steels up to 55HRCand across a wide range ofmaterials.

(ISO P10-M10-K10)Grade for finishing

operations using small depths of cuton low to high carbon steels,stainless steels, cast irons, copper,aluminium alloys, hardened die steeland materials up to HRC55.

(P10-P30/M25-M35/K20)PVD coated grade.

General purpose milling applications.

JC5010

JC5003

JC5015

CAT - 849 - 2298A

See the Dijet UK Catalogue for a complete range of Dijet products• Handy size format: 170 x 245mm

• 288 pages, including: INDEXABLE TOOLING

INDEXABLE INSERTS

DRILLS

END MILLS

TECHNICAL INFO

CAT - 849- 2299A

CU

TTIN

G TO

OLS

Page295

INDEXABLE MILLING CUTTERS

GROUP

139

Face Milling Copy Milling Pocket Milling Helical Milling Shoulder Milling

Dimensions (mm) Applicable InsertsWeight Order Code Offer

Designation R ØD L ØD1 MD W each DIJ-123 Price/1

MBN-160-M8 8 16 23 15 M8 12 BNM/RNM 160... -4820D £71.06MBN-200-M10 10 20 30 18.5 M10 17 BNM/RNM 200... -4822F £81.36MBN-250-M12 12.5 25 35 24 M12 22 BNM/RNM 250... -4824H £102.99MBN-300-M16 15 30 43 29 M16 22 BNM/RNM 300... -4826K £123.59MBN-320-M16 16 32 43 29 M16 22 BNM/RNM 320... -4828M £120.50

Product Dimensions (mm) Order Code List OfferNumber R A B T DIJ-122 Price/1 Price/1

BNM-100-S 5.0 10 8.5 2.6 -2094Q £24.38 £18.04BNM-160-S 8.0 16 12.0 4.0 -2124Q £31.41 £23.24BNM-200-S 10.0 20 15.0 5.0 -2134Q £35.16 £26.02BNM-300-S 15.0 30 22.5 7.0 -2154Q £65.63 £48.57BNM-320-S 16.0 32 23.5 7.0 -2164Q £65.63 £48.57

Product Dimensions (mm) Order Code List OfferNumber R A B T DIJ-122 Price/1 Price/1

BNM-160-AAA 8.0 16 12.0 4.0 -2115J £40.99 £30.33BNM-200-AAA 10.0 20 15.0 5.0 -2125J £45.89 £33.96BNM-250-AAA 12.5 25 18.5 6.0 -2135J £58.73 £43.46BNM-300-AAA 15.0 30 22.5 7.0 -2145J £85.66 £63.39BNM-320-AAA 16.0 32 23.5 7.0 -2155J £85.66 £63.39

JC5003

Insert Grades(P01-P10/M10/K01-K10)Die-mould applications in hardened

material at high cutting speeds. Micro grainsubstrate with DZ coating for steels up to55HRC and across a wide range of materials.

(P10-P30/M25-M35/K20)PVD coated grade.

General purpose milling applications.

Mirror Ball Indexable Ball Nose End Mills

MBN Modular Head for high speed cutting.

BNM Inserts

JC5015

BNM-S Inserts for Carbide Mirror Ball Body BNM Super Precision Inserts

MSN Carbide Shank Straight Neck HolderFor high productivity and high rigidity. Through coolant hole. Carbide shank.

Combination with carbide shank gives high efficient machining for deep applications.

MSN Carbide AdaptorM__ Head

CARBIDE SHANK

Dimensions (mm) Applicable Heads

DesignationØD I1 L ØD1 MD Order Code Offer

DIJ-123 Price/1

MSN-M8-40-S16C 40 95 MBM & MRN-160-M8 -5840A £109.17MSN-M8-80-S16C 16 80 135 15.5 M8 MDH 3160 & 4160-M8 -5842C £129.77MSN-M8-120-S16C 120 175 -5844E £150.37MSN-M10-40-S20C

2040 100

19.5 M10MBM & MRN-200-M10 -5858V £168.91

MSN-M10-90-S20C 90 150 MDH -420 & 5200-M10 -5860X £160.67MSN-M12-55-S25C 55 120 MBM & MRN -250-M12 -5874Q £164.79MSN-M12-105-S25C 25 105 170 24 M12 MDH -5250-M12 -5860A £211.14MSN-M12-155-S25C 155 220 MSH -2025-M12 -5864E £262.64MSN-M16-55-S32C

3255 120

29 M16MBM & MRN -320-M16 -5892K £200.84

MSN-M16-155-S32C 155 220 MSH -3032 & 3035-M16 -5878V £324.44

Grade JC5003 Grade JC5015 To Suit Designation R A B T Order Code Order Code List Offer

Cutter Dia. BNM DIJ-122 DIJ-122 Price/1 Price/1

16 160 8.0 16 12.0 4 -2120F -2120J £32.82 £24.2920 200 10.0 20 15.0 5 -2130F -2130J £36.73 £27.1825 250 12.5 25 18.5 6 -2140F -2140J £47.02 £34.7930 300 15.0 30 22.5 7 -2150F -2150J £68.59 £50.76

CU

TTIN

G TO

OLS

•••••••••••••••••••••••••

•••••

••••••••••••••

••••••••••

PROMO KIT BOX

SPECIAL GUARANTEE CARDSupplied in the kit boxValid until end of 2014Activation required to validate

INDEXABLE MILLING CUTTERS

GROUP

139

Page296

CU

TTIN

G TO

OLS

AdvantagesHigh machining volume, even on lower performance machinesNew soft cutting insert design with 3D chip breaker geometryHigh reliability due to stable insert, cutter and large chip pocket design14-edge indexable inserts for lower overall tooling costsIdeal for steel and cast iron milling applications

••••••••••••

••••••••••

Efficient and Economical Milling

New 14 corner inserts for steel andstainless steel machining.KIT INCLUDES:1 x Face Milling Cutter + 10 Inserts

Page297

INDEXABLE MILLING CUTTERS

GROUP

139CU

TTIN

G TO

OLS

General purpose multi corner insert Face Milling Cutter

Right hand tool holder only (clamps and wrench included)

Light Alloy Cast IronCarbon and

Hardened Steel Stainless SteelAlloy Steel

*Special prices are only available while promotional stocks last

Product Dimensions (mm) Coolant No. of Mass Max. Depth Type Order Code List OfferNumber D1 D2 L1 D9 L7 D8 D12 W1 L8 Hole Teeth (kg) of Cut ap (mm) (Fig.) PRO-139 Price/1 Price/1

AHXS063-AR 63 75.6 50 22 20 11 50 10.4 6.3 • 5 0.6 6 1 -0080K £516.22 £179.99AHXS080-AR 80 92.6 50 27 23 13 56 12.4 7 • 6 1.0 6 1 -0081K £584.91 £189.99AHXS100-AR 100 112.6 50 32 32 45 78 14.4 8 • 7 1.6 6 2 -0082K £653.57 £239.99AHXS125-AR 125 137.6 63 40 42 56 89 16.4 9 • 8 3.0 6 2 -0083K £742.46 £274.99AHXS160-AR 160 172.6 63 40 29 56 120 16.4 9 • 10 5.2 6 3 -0084K £940.41 £354.99

Efficient and Economical Milling

KIT INCLUDES:1 x Face Milling Cutter + 10 Inserts

NNMU200708ZEN-MP 14 Edge Insert

Designation GradeOrder Code List OfferMTS-122 Price/1 Price/1

NNMU 200708ZEN-MP VP15TF -6266X £17.28 £14.69

Insert Grade Descriptions(P15-P35/M15-M35/K15-K30) PVD‘Miracle’ CoatedMilling Grade. Offers increased heat resistance and adhesion

strength. For all steels, cast irons and some stainless steel.

VP15TF

Insert Grade Descriptions(M30) New Multi-layer coated grade providing superior wearand fracture resistance needed for milling stainless steel.

Special tough cemented carbide substrate giving excellentperformance.

MP7030

*Special prices are only available while promotional stocks last

Product Dimensions (mm) Coolant No. of Mass Max. Depth Type Order Code List OfferNumber D1 D2 L1 D9 L7 D8 D12 W1 L8 Hole Teeth (kg) of Cut ap (mm) (Fig.) PRO-139 Price/1 Price/1

AHXS063-AR 63 75.6 50 22 20 11 50 10.4 6.3 • 5 0.6 6 1 -0085K £516.22 £179.99AHXS080-AR 80 92.6 50 27 23 13 56 12.4 7 • 6 1.0 6 1 -0086K £584.91 £189.99AHXS100-AR 100 112.6 50 32 32 45 78 14.4 8 • 7 1.6 6 2 -0087K £653.57 £239.99AHXS125-AR 125 137.6 63 40 42 56 89 16.4 9 • 8 3.0 6 2 -0088K £742.46 £274.99AHXS160-AR 160 172.6 63 40 29 56 120 16.4 9 • 10 5.2 6 3 -0089K £940.41 £354.99

NNMU200712ZER-MM 14 Edge Insert

Designation GradeOrder Code List OfferMTS-122 Price/1 Price/1

NNMU 200712ZER-MM MP7030 -6268M £17.28 £14.69

KIT INCLUDES:1 x Face Milling Cutter + 10 Inserts

NEW