Groove 1, 2009

-

Upload

trelleborg -

Category

Documents

-

view

129 -

download

1

Transcript of Groove 1, 2009

No. 1, 2009

groovein theTrelleborg Sealing Solutions

The world of seals and service

Controlled explosionOil & Gas

Exploring the options to reduce explosive decompression risk and extend seal life

Automotive

Extreme rotationProduct Feature

Mechanical Face Seals specifically engineered for difficult rotating environments

The optimum sealing materials for biofuels proven in tests

Sealing for a sustainable future

26

16

6

2

When engineers specify seals, biofuels present some significant challenges, as their chemical make-up can affect the sealing integrity of elastomers. Standard laboratory tests indicate that typical FKM and FVMQ compounds are compatible with biofuels. However, when sealing materials are tested in conditions reproducing those seen in service, it becomes evident that specialized formulations are required to ensure integrity and long service life.

Sealing for a sustainable future

contents

Automotive

Explosive Decompression (ED) is a major concern to the oil & gas industry as well as other sectors utilizing gas at high pressure. ED occurs when applied system pressure is released, causing absorbed gas to expand, damaging elastomer seals. We explore this phenomenon and discuss some of the principles to reduce ED risk and extend seal life in applications where ED may occur.

Controlled explosionOil & Gas

The new range of Mechanical Face Seals from Trelleborg Sealing Solutions is specifically engineered for rotating applications in extremely arduous environments. There they withstand severe wear and prevent ingress of harsh and abrasive external media.

Extreme rotationProduct Feature

Trelleborg Sealing Solutions in the groove No. 01/09

4

5

32

36

10

12

40

22

44

3

Pumped and ready to goSealing solutions for WEH hydrogen fuelling systems

On your bikeApplications for seals on cycles are numerous

Semicon on the webNew industry section on the website specific to semiconductor sealing solutions

Two Compounds Achieve NSF ListingTurcon® MF5 and MF6 conform to NSF/ANSI Standard

5S Success in ShanghaiTrelleborg Sealing Solutions Shanghai successfully starts its lean manufacturing program

Innovation

Low energy movementTrelleborg Sealing Solutions launches Turcon® Varilip® PDR. The optimum solution for high-speed rotating applications, it has exceptional low-friction characteristics, reducing torque. That cuts power consumption, contributing to lower equipment running costs and in the end, decreased energy bills.

Processing

A fair exchangeAs energy conservation becomes a focus for us all, the demand for Plate Heat Exchangers is booming. They are a fundamental part of many production processes and Trelleborg Sealing Solutions is one of the leading suppliers for gaskets fitted to these systems.

One application – Many solutionsTractor operators throughout the world rely on Trelleborg more than they can imagine. Our solutions seal vital components and ensure reliability, enhance driver comfort through sophisticated damping and protect the soil.

Plowing aheadHydraulics are used extensively on today‘s tractors. Each hydraulic device requires its own processor. In the search for a robust yet compact electronic control unit, manufacturers turn to one of the world’s leading specialists in the field of drive and control technologies: Rexroth.

Hydropower

The power of waterOn the Cowlitz River in the state of Washington sits the Mossyrock Dam, the Pacific Northwest United States’ tallest. Owned and operated by Tacoma Power, the dam is being overhauled to improve efficiency.

Compact performanceThe new Turcon® Roto VL Seal® is a high-pressure compact seal that is ideal for rotary applications where there is limited space or for installation into standard O-Ring grooves.

Service

Matchmaking onlineAlways trying to make the lives of engineers easier when they are specifying seals, we have developed some new additions online - a material search and chemical compatibility check. Both of these help match the optimum seal material to the requirements of specific applications.

News

Off-road

Rotary sealing

Trelleborg Sealing Solutions in the groove No. 01/09

4

Pumped and ready to goTrelleborg Sealing Solutions supplies seals for the new innovative TK17 fuel nozzle from WEH.

Whether refueling vehicles with natural gas or hydrogen, “nothing works without WEH.” The latest in a long line of patented systems from WEH is the single-handed TK17. It looks like a conventional gasoline nozzle but is completely innovative. The pressure-tight connection to the vehicle ensures that none of the gas, which is highly reactive, can reach the atmosphere.

To meet stringent operating requirements, the engineers at WEH worked closely with Trelleborg Sealing Solutions to choose a group of suitable seals, including O-Rings, Turcon® Stepseal® and Turcon® Glyd Ring®. These seals use standard materials as well as ones specially developed for this application, including some capable of withstanding temperatures as low as -40°C/ -40°F.

For a longer version of this article go to the News section on: www.tss.trelleborg.com.

+++ news +++ news +++ news +++ news +++ news news +++ news +++ news +++ news +++ news +++ news

Ever been to Shanghai, China? If you have, then you’ll know what it’s like to face an onslaught of bikes at rush hour. The same is true of Delhi, India or Taipei, Taiwan and many other cities in Asia, where the bike is a major form of transport.

You may not think so, but surprisingly, all of those two-wheeled vehicles need seals, and the applications are numerous. Seals from Trelleborg Sealing Solutions are found on front and rear shock absorbers, seat posts, as well as on brake levers and disks.

To support their participation in this market, the Trelleborg Sealing Solutions marketing company in Taiwan recently participated at the Taipei Cycle exhibition.

On your bike

Automotive

Cycles

Sealing solution for rear shock absorbers

Trelleborg Sealing Solutions in the groove No. 01/09

5

+++ news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++ news

Trelleborg Sealing Solutions In the groove, No. 1, 200999GBK9011EE0509© 2009 Trelleborg Group. All rights reserved® All trademarks are the property of the Trelleborg Group.The turquoise color is a registered trademark of the Trelleborg Group.

At time of publication the information contained in this literature is believed to be correct and accurate.

Editorial team: Mercedes Benjumeda, Donna Guinivan, Whitney Killip, Wendy Sack, Tobias Schmid, Sherry Sheng, Sandro Silverio, Robert Zahiri

Responsible under German Press Law: Robert Zahiri

Graphic Arts: dialogart gmbh, Stuttgart, Germany

Printing: W. Kohlhammer, Stuttgart, Germany

QUAD-RING® seal trademark of Quadion Corporation

Trelleborg Sealing Solutions Shanghai, China successfully started its lean manufacturing program with 5S implementation (Sort, Straighten, Shine, Standardize, Sustain) as the pilot project.

“All our efforts are driven by a desire to accomplish lean manufacturing. We want to achieve a safe and efficient operation to manufacture our products to the required standards of quality,” says Jim Wang, Production & Continuous Improvement Manager. “5S brings improvement in many aspects. Everyone feels more comfortable and efficient in a better working environment. The customers who visit our plant are impressed with our neat and well organized production areas.”

The 5S discipline will be followed by other lean manufacturing tool implementation such as Total Productive Maintenance (TPM), Standardized Work and Kanban.

5S success in Shanghai

Quality

A new and improved section on sealing in semiconductor applications can now be found on the Trelleborg Sealing Solutions website. The section outlines our capabilities in this challenging industry. In particular, we look at wet process applications, plasma systems, high-temperature situations, vacuum conditions and working with demanding chemicals. You will find details on recommended materials and products, along with a number of application examples.

Come explore our materials and products. Learn about our line of Isolast® Fab Range™ FFKM materials, which offer the ultimate in elastomer sealing. These high-performance materials demonstrate almost universal chemical compatibility, while operating in continuous temperatures up to +325°C/+617°F. Discover our wide range of products: the inflatable Airseal, bonded-to-metal seals, O-Rings, Wills Rings® metal seals, spring-

energized Turcon® Variseal®, Turcon® Varilip® PDR for rotary applications, V-Ring® for external media exclusion and FlexiMold™ giant seals.

www.tss.trelleborg.com

Semicon on the webSemiconductor

Trelleborg Sealing Solutions now has two compounds listed by NSF International as conforming to the requirements of NSF/ANSI Standard 51 - Food Equipment Materials. Turcon® MF5 compound has recently achieved this status, joining Turcon® MF6 in the listing.

Turcon® MF5 and MF6 are part of the Turcon® MF range of materials specifically engineered for demanding processing environments, including food

and beverage production. Based on ultra-clean technology, these proprietary compounds are manufactured from high-purity PTFE grades and additives. Their smooth finish, with high gloss and low porosity, avoids the risk of contamination buildup and reduces particle shedding. Each batch of MF material is manufactured using high-purity material only and can be issued with a certificate of conformity.

www.nsf.org/international/

Two compounds achieve NSF listing

Food and Beverage

Trelleborg Sealing Solutions in the groove No. 01/09

6

Product Feature

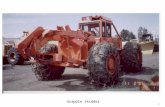

ExtremeThe new range of Mechanical Face Seals from Trelleborg Sealing Solutions is specifically engineered for rotating applications in extremely arduous environments. There they withstand severe wear and prevent ingress of harsh and abrasive external media.

Launching Mechanical Face Seals

Engineered for extremely arduous rotating environments

Cost-effective steel bearing option gives flexibility in design

Manufactured at Trelleborg Sealing Solutions Modena in Italy

The Mechanical Face Seal catalog is available for download from www.tss.trelleborg.com

In short...

rotation

What are Mechanical Face Seals?

The Mechanical Face Seal consists of two identical metal sealing rings mounted in two separate housings face-to-face on a lapped seal face. The metal rings are centered within their housings most commonly by O-Rings or otherwise by elastomers with a diamond-shaped cross section. One-half of the Mechanical Face Seal remains static in the housing, while the other half rotates with its counter face.

The elasticity of the O-Rings or elastomer rings generates a uniform axial face loading for the metal rings and these O-Rings act as static seals on the inner and outer diameter. They also prevent any contrarotation of the metal seal rings within their housings and ensure that all the relative rotary motion occurs at the dynamic interface between the seal rings.

Trelleborg Sealing Solutions in the groove No. 01/09

�

Mech

anica

l Face S

eals

Selecting the right Mechanical Face Seal

Cast iron or roller bearing steel?

The metal part of the Mechanical Face Seal is available in a choice of two different types of material, a special heat treated high-alloy corrosion-resistant mold cast iron or a forged roller bearing steel. Selection of material depends on operating conditions. Cast iron will operate in speeds up to 3 m/s/ 10 ft/s with oil lubrication, while for rotational speeds up to 2.2 m/s/ 7.2 ft/s, bearing steel is adequate.

Bearing steel provides cost savings andflexibility

Up to 2.2 m/s /7.2ft/s the bearing steel option, due to lower process and material costs, can offer significant savings, especially for medium to large size Mechanical Face Seals. In addition, there is more flexibility in design, allowing the seals to be custom-engineered for specific housings.

Elastomers to suit the application

Temperature resistance depends on the type of elastomer used within the seal. A choice of Acrylonitrile Butadiene Rubber (NBR), Hydrogenated Nitrile Butadiene Rubber (HNBR), Fluoroelastomer (FKM) or Silicone (VMQ), provides an operating range between -40°C to +200°C/ -40°F to +392°F. These compounds also give chemical compatibility to virtually all media encountered in applications where Mechanical Face Seals are used.

Trelleborg Sealing Solutions in the groove No. 01/09

�

An agricultural economybecame industrial

The economy of Italy has changed dramatically since the end of World War II. From an agricultural base, it has become an industrial country, the world’s seventh largest economy in USD exchange-rate terms and tenth largest in terms of purchasing power parity (PPP)*. Italy’s major exports are precision machinery, motor vehicles, including the iconic scooter, chemicals and electrical goods.

Italian fashion

* World Bank, IMF and the CIA World Fact book

Food, drink and style

Food is still an important product for Italy. It is the third largest producer of wine in the world, the most famous ones of which are probably the Tuscan Chianti and Piemontese Pinot Grigio. Italy is also known for its style and fashion houses including such famous names as Versace, Valentino, Fendi, Gucci, Prada, Dolce & Gabbana, Benetton and Armani.

Product Feature

Trelleborg has a strongpresence in Italy

There are numerous Trelleborg Group manufacturing facilities in Italy. Automotive parts are produced in Turin, while Milan is the home of printing blankets, used on presses that produce our newspapers and books the world over. Alongside them is the related technology of coated engineered fabrics. They supply everything from chemical and heat-resistant materials for protective clothing to the fabric for escape slides on aircraft. Trelleborg Wheel Systems is headquartered at its main production facility, just outside Rome, near Tivoli. Trelleborg Sealing Solutions has three plants in Italy: Livorno, near Pisa, Modena and Turin.

Mechanical Face Seals expertise in Modena

Mechanical Face Seals are manufactured at the Trelleborg Sealing Solutions plant in Modena, Italy. Originally known as GNL, the company was acquired by Trelleborg Group in 2008. Combining the expertise in this type of product from the original Modena site and that of Spilamberto close by, manufacturing has been consolidated within a state-of-the-art facility employing 60 people.

Source: Wikipedia

Trelleborg Sealing Solutions in the groove No. 01/09

9

Mech

anica

l Face S

eals

For further information on Mechanical Face Seals check out our comprehensive catalog. You can download it from the services area at

tss.trelleborg.com

● Heavy duty rotating applications such as rollers, front idlers and final drives of tracked vehicles

● Graders, shovels, plows and scrapers on tractors

● Off-highway trucks, drilling machines

● Hydraulic excavators

● Conveyors

● Concrete mixers

● Asphalt plants

● Mining and crushing equipment

● Mowers

● Hay balers

● Wind turbines

● Axles, gearboxes, mixers and stirrers

Where are Mechanical Face Seals used?

Trelleborg Sealing Solutions in the groove No. 01/09

10

Off-road

many solutionsOne application

Tractor operators throughout the world rely on Trelleborg more than they can imagine. Our solutions seal vital components and ensure reliability, enhance driver comfort through sophisticated damping and protect the soil.

Protection and power

Tractors are becoming more powerful all the time. Traveling increased distances both on road and in the field, where they now use heavy multifunctional tools, demands are high on both the vehicle and its tires. Trelleborg supplies Original Equipment Manufacturers (OEMs) with a wide range of tires, including the advanced TM900, one of the largest available. Its longer footprint effectively transmits traction to respect and protect the soil, while providing driver comfort.

A central role

Trelleborg Wheel Systems not only supplies the tires, but is also a provider of rims. The company is experiencing increased demand for its wheel and tire combinations.

Trelleborg Sealing Solutions in the groove No. 01/09

11

many solutionsOne application

Customer success

Trelleborg is the supplier of choice for agricultural radial tires to large tractor Original Equipment Manufacturers (OEMs), such as Massey Ferguson, Claas and Fendt.

Electronic controls

To maximize their effectiveness, tractors are increasingly utilizing high-tech controls. Electronic control units on hydraulic systems ensure a constant plowing depth, compensate for load differences and even position the vehicle as it works its way up and down the field. These highly sensitive devices require specialized sealing that can only be offered by a custom-engineered molded product.

Damping vibration

The Multi Directional Snubbing (MDS) mount from Trelleborg Industrial AVS, part of Trelleborg Engineered Systems, is designed to provide a high degree of isolation, while controlling the motions from large shock inputs experienced in severe off-road applications. It has become the solution of choice for tractor-cab mounting applications.

Hydraulic sealing

A typical tractor has a minimum of five different pumps and motors that control the hydraulic systems. For these, Trelleborg Sealing Solutions provides an extensive range of seals. Each of these pumps and motors is fitted with some form of oil seal, with mineral oil being the most common fluid that requires sealing. Other applications include static seals in the tank, couplings, pumps and motors. There are also dynamic seals in the cylinders that work the hydraulic actuators.

Trelleborg Sealing Solutions in the groove No. 01/09

12

Off-road

Plowingahead

Seals are integral to the Rexroth EHS2 electro-hydraulic control unit for tractors.

Trelleborg Sealing Solutions in the groove No. 01/09

13

Modern-day tractors rely heavily on hydraulics. These are used to ensure a constant plowing depth, compensating for load differences, bundling hay bales and even positioning the vehicle as it works its way up and down the field. Each hydraulic device requires its own processor. In the search for a robust yet compact electronic control unit, manufacturers turn to one of the world’s leading specialists in the field of drive and control technologies: Rexroth.

German manufacturer Rexroth developed a compact electro-hydraulic unit for controlling the hydraulics in tractors.

The company involved Trelleborg Sealing Solutions from product concept in meeting their stringent sealing requirements.

The combined expertise of the two partners resulted in the smooth and economical production of an extremely reliable electro-hydraulic control unit for modern farm machinery.

In short...

aheadDeveloped by Rexroth at its plant in Schwieberdingen, Germany, the EHS2 fulfills the need to integrate a number of functions in one central, space-saving electro-hydraulic control unit. Depending on the amount of hydraulic equipment to be installed in a tractor, each EHS2 is composed of three to seven SB33 hydraulic valve slices

supplied with compressed oil from a central pump. Each of these slices is responsible for a certain task, whether rotating, tilting, lifting or compressing. While this is now a best-selling product for Rexroth, the team of developers first had to overcome several hurdles – especially in terms of sealing.

Trelleborg Sealing Solutions in the groove No. 01/09

14

No easy task

To begin with, agricultural machinery is exposed to extreme conditions 365 days a year and often around the clock. The control unit has to withstand operating temperatures of up to +120°C/ +250°F, as well as possibly an ice-cold soaking when the tractor drives through water. In addition, the unit has to remain watertight despite the partial vacuum inside. All this makes heavy demands on seals.

The task is further complicated by the need for the seals to protect the control unit against oil, detergents, manure, high-pressure steam jets and even acidic lubricants. At the same time, the aluminum EHS2 control unit has to be perfectly sealed off from the SB33 hydraulics housing made of cast iron. A simple solution to sealing two metals with different thermal expansion coefficients is the use of a larger sealing cross section. However, this was not possible in this case, since the unit was specifically designed to be slim line.

Fortunately, the team had expert partners on hand at Trelleborg Sealing Solutions. Norbert Gläser, Key Account Manager, explains, “As the long-term partner for Rexroth we already knew their high demands regarding quality and tolerance levels by heart. Otherwise we might have underestimated the requirements a little bit.”

Tailored to requirements

The initial talks between the two partners made it clear that a special sealing solution would be necessary, designed to meet the demands of the application. Hermann Zöllner, Manager Engineered Products at Trelleborg Sealing Solutions, recalls that it was not easy to find the optimal mixture for the molded seal that fulfilled the requirements in terms of chemical and thermal resistance, while keeping the manufacturing process technically and economically viable.

This obstacle was overcome thanks to both partners displaying a willingness to collaborate beyond the factory gates. Dr. Ulrich Müller, who heads Engineering Mobile Electronics Hydraulics at Rexroth, explains, “The interaction between our developers and Trelleborg Sealing Solutions was perfect. Everyone worked over and above corporate restrictions. This joint expertise led, for example, to the optimum design of the aluminum casing for the control unit.”

Early involvement

Christoph Jochum, Manager Engineering Mobile Electronics – Sensors, Hydraulics at Rexroth, confirms, “The partnership showed me how important it is to integrate the seal manufacturer at an initial stage of development. This is especially the case as Trelleborg Sealing Solutions is not only an expert in seals and related materials, but also has wide-ranging experience with surface finishes at mechanical interfaces. This was extremely useful in terms of the different thermal properties involved here.”

Thanks to the use of computer simulation and the combined talents of Rexroth and Trelleborg Sealing Solutions, the team was able to reach its target without undue trial and error. This was evident, for example, in the small number of immersion tests that needed repeating, as well as the minimum amount of time spent experimenting on the elastomer formulations.

As a result, clients in the agricultural machinery industry now have a new generation of modular electro-hydraulic control units available, which remain compact while allowing for increasingly complex systems. In turn, farmers benefit from a perfect control system that is virtually maintenance-free and unrivaled in its resistance to internal and external influences. After all, the crops will not wait for the tractor to be repaired.

Off-road

Electro-hydraulic control units from Rexroth are proving to be extremely reliable in today‘s farm machinery.

Trelleborg Sealing Solutions in the groove No. 01/09

15Trelleborg Sealing Solutions in the groove No. 01/09

4020

6080 100

120

140

160

2

0

46

8

BAR

16

Oil & Gas

explosion

Bill Allan Oil & Gas Segment Manager, Trelleborg Sealing Solutions Europe

Controlled

Trelleborg Sealing Solutions in the groove No. 01/09

40

20

6080 100

120

140

160

2

0

46

8

BAR

1�

explosion

Explosive Decompression (ED) is a major concern to the oil & gas industry as well as other sectors utilizing gas at high pressure. It occurs when applied system pressure is released, causing absorbed gas to expand, damaging elastomer seals. Here we explore this phenomenon and discuss some of the principles to reduce ED risk and extend seal life in applications where ED may occur.

“As a seal developer and manufacturer with a significant proportion of our business in the oil & gas sector, Explosive Decompression (ED) has been a key area of focus for us,” says Bill Allan, Oil & Gas Segment Sales Manager for Europe.

Concentrating on engineering seals that give optimum performance

“We have invested considerable amounts of development time and money on the quest to find Explosive Decompression Resistant (EDR) materials,” continues Bill. “However, it is somewhat misleading to describe a particular elastomer as ED-resistant. It’s more about relative resistance. All elastomers are liable to absorb gases when placed under pressure. When the pressure is released the gas expands and this can cause internal cracks within the elastomer, leading to mechanical breakdown in severe cases. So our aim is to concentrate on engineering seals that give optimum performance based on operating conditions.”

Trelleborg Sealing Solutions in the groove No. 01/09

1�

Oil & Gas

For more information about Oil & Gas Sealing Solutions please contact your local marketing company or take a look at the XploR™ flyers in the services area on:

tss.trelleborg.com

Trelleborg Sealing Solutions works with engineers to design their applications to minimize the risk and effect of ED. This is a complex matter. Numerous factors have to be taken into account. These include the elastomer, the housing, the contact fluids and gases as well as their solubility, any swelling of the seal due to absorption of fluid and the morphology of bubble formation.

Speed, cycles and level of decompression are significant factors affecting ED

“Explosive decompression is also a bit of a misnomer, as decompression does not have to be rapid to cause significant damage in elastomer seals,” Bill points out. “In fact it has been shown that a 30-minute decompression can cause as much damage as an instantaneous one. In general, though, the longer the decompression, the less likely damage is to occur.

“Another factor is that in operation, seals tend not to be subject to a single decompression but cycles. There may be no apparent damage to a seal after a single decompression, but after several more cycles you can see the damage. The level of pressure in cycling tends not to be as important as the size of the pressure differential. A drop from 15 MPa/ 2,200 psi to 5 MPa/ 725 psi would probably be more damaging than, from say, 20 MPa/ 2,900 psi to 15 MPa/ 2,200psi.”

Work with the experts to maximize seal life

“Overall I’d always recommend talking to the experts,” says Bill. “A company like Trelleborg Sealing Solutions has the experience to help come up with the optimum seal groove design, configuration and material to ensure maximum seal life.”

Trelleborg Sealing Solutions in the groove No. 01/09

19

Explosive Decompression – How it occurs

Gas or gas mixtures in contact with elastomer surfaces can be absorbed under pressure. At high pressure absorbed gas is in a compressed state. When external pressure is reduced, either rapidly or over a relatively short period of time, the compressed gas rapidly expands within the elastomer. This can lead to crack

initiation within the body of the elastomer. These cracks propagate internally and this can cause void formation or cracks to appear on the elastomer surface.

When is there a higher risk of Explosive Decompression?

In dry gas applications where system media is mostly gas

When service pressures are 3,5 MPa/ 510 psi or higher

Where system pressure is not constant

If the differential between varying pressures is high

When pressure variations are rapid

At elevated or sub-zero temperatures

Factors to consider when designing equipment to minimize ED risk and effect

Application parameters· Gas pressure· Type of gas· Number of decompressions· Rate of decompression events· Pressure differential between cycles· Operating temperatures

Seal material · Chemical resistance· Thermal capabilities· Modulus · Tear strength

Seal design· Seal section· Groove fill

Seal and housing design tips to improve Explosive Decompression Resistance (EDR)

Keep seal section diameter as small as possible at 5.33 mm/ 0.2 inch or lower

Make initial squeeze as low as possible around 10-15 percent

Ensure tear strength of the elastomer is as high as possible

Design the seal groove combination to give close to 90 percent groove fill; this limits the potential area into which voids can expand

Use rigid anti-extrusion rings on both sides

Fact

s

Trelleborg Sealing Solutions in the groove No. 01/09

40

20

6080 100

120

140

160

2

0

46

8

BAR

20

Oil & Gas

Each material demonstrates unrivalled Explosive Decompression Resistance (EDR) within its material type

Temperature resistance over a broad range

Exceptional mechanical performance

Low long-term compression set

Very good chemical compatibility

Isolast® XploR™ J9513 gives almost universal chemical compatibility

Long life in aggressive media, including hydrocarbon and aqueous media, common within oil & gas applications

High modulus, high strength

Materials compliant to NORSOK M-710

XploR™: Features & benefits Fact

s

Trelleborg Sealing Solutions in the groove No. 01/09

40

20

6080 100

120

140

160

2

0

46

8

BAR

Mat

eria

l R

ange

21

The XploR™ range from Trelleborg Sealing Solutions is a suite of advanced elastomers especially developed for oil & gas applications. The portfolio includes compounds in HNBR, FKM and Isolast® Perfluoroelastomer (FFKM), each of which demonstrates best-in-class Explosive Decompression Resistance (EDR) for its material type.

The first FFKM on the market to meetNorsok M-�10 RGD test conditions

In independent tests, materials within the XploR™ range were able to satisfy both the Norsok M-710 sour service and Rapid Gas Decompression (RGD) test conditions. XploR™ J9513 is the first perfluoroelastomer on the market to meet the requirements of this stringent RGD test.

Best-in-class elastomers specially engineered for optimized EDR

Elastomer Base

Hardness

Color

Specific Gravity

Tensile Strength

Elongation at Break

Modulus 100%

Compression Set(72h/ 200°C/ 392°F)

TR10 Point

Service Temperature

DIN ISO 1629

DIN 53 505

DIN EN ISO

1183-1

DIN 53 504

DIN 53 504

DIN 53 504

DIN ISO 815 Type B

ASTM D 1329

g/cm2

MPa N/mm2

psi

%

MPa N/mm2

psi

%

°C

°F

°C

°F

XploR™H9T20

XploR™ V9T20

XploR™ J9513

Compound Number

XploR™:

In addition to the elastomers presented in this article, Trelleborg Sealing Solutions also offers a number of thermoplastic sealing materials with certificates of compliance to NORSOK M-710. These include Turcon®,

our proprietary range of PTFE based compounds, and PEEK™ materials. Turcon® demonstrates excellent EDR inherently due to the high crystallinity, low gas solubility and granular morphology of PTFE based materials.

Turcon® and PEEK™

HNBR

90 +/- 5

Shore A

Black

1.25 +/1

0.03

34.8

5,000

204

16.6

2,400

-23

-9

-30 to +175

-22 to +350

FKM

90 +/- 5

Shore A

Black

1.84 +/-

0.03

25.5

3,700

186

13.2

1,915

-15

+5

-20 to +230

-4 to +440

FFKM

95 +/- 5

Shore A

Black

1.92 +/-

0.03

18.6

2,700

68

N/A

35

-3

+27

-10 to +260

+14 to +500

Trelleborg Sealing Solutions in the groove No. 01/09

22

Rotary sealing

Turcon® Roto VL Seal® is developed from the proven Turcon® VL Seal®, and like this consists of an L-shaped Turcon® seal that is energized by a static O-Ring. Its non-symmetric single-acting seal design optimizes sealing performance under various pressure and surface velocity conditions.

“A unique feature of the new Turcon® Roto VL Seal® is that, due to its compact design, it can be fit into much smaller spaces than traditional rotary seals,” says Thomas Sandholdt, Product Manager for Trelleborg Sealing Solutions Helsingør, Denmark, where the product is manufactured. “It is also an excellent choice where standard O-Ring housing grooves are preferred.”

CompactThe new Turcon® Roto VL Seal® is a high-pressure compact seal that is ideal for rotary applications where there is limited space or for installation into standard O-Ring grooves.

performance

Turcon® Roto VL® Seal is ideal for a wide variety of applications. These include tractors, forestry equipment and injection molding machines.

Trelleborg Sealing Solutions in the groove No. 01/09

23

Elastomer O-Ring• High flexibility to satisfy hardware tolerances• High static sealing function eliminates fluid flow in the

groove• Elastomer materials available to meet a wide variety of

service conditions

Stabilizing Wing• Keeps the O-Ring in the correct position when not

pressurized• Assists pressure transfer from O-Ring to seal lip• Stabilizes the seal profile

Circumferential Lubricating Groove• Increases lubrication of dynamic contact area• Reduces contact area to lower friction

Rear Chamfer• Prevents extrusion of seal material into the radial clearance

Pressure Relieved Sealing Lip• Optimized sealing lip position for high sealing efficiency• Short dynamic contact area for low friction and torque

Contoured O-Ring Contact Zone• Stabilizes the O-Ring position in the seal groove• Secures optimal pressure transfer to dynamic sealing lip• Prevents O-Ring nibbling

Stabilized Groove Contact• Strong seal profile with full groove wall contact for stable

seal position• Prevents premature extrusion of seal material into the

radial clearance

Turcon

® Roto V

L Sea

l ®

Features and benefits of Turcon® Roto VL Seal®:

Trelleborg Sealing Solutions in the groove No. 01/09

24

Turcon

® Roto V

L Sea

l ®

Operating conditionsMovement: Rotary, intermittent or oscillating service Velocity to 2 m/s/ 6.5 ft/s

Pressure: Up to 30MPa / 4,350psi 40 MPa / 5,800 psi for short durations or when static

Temperature:

Turcon® materials: -40°C to +120°C/ -40°F to +248°F +200°C / +392°F static according to O-Ring material

Zurcon® Z52: -40°C to +80°C/ -40°F to +176°F +100°C / +212°F short durations or static according to O-Ring material

Zurcon® Z80: -40°C to +60°C/ -40°F to +140°F +80°C / +176°F short durations or static according to O-Ring material

Media: Hydraulic fluids, water-based fluids, air and gases depending on seal material

Tech

nica

l D

ata

Method of operationAs with other O-Ring based Slipper Seals, the initial squeeze of the O-Ring in Turcon® Roto VL® Seal ensures sufficient contact pressure between seal surface and mating surface to provide tightness at low pressure. With increasing system pressure, the O-Ring and the seal body direct pressure down on the sealing surface to ensure sealing efficiency at all pressures. At very high pressure, the contact area with the mating surface is increased so excessive stress in the seal and mating surface is avoided.

A multitude of applicationsTurcon® Roto VL® Seal is primarily intended for constant service in demanding situations where there are rotary, swiveling or helical movements at medium to high system pressure.

Some applications where the new Turcon® Roto VL Seal® would be found are:

• rolling mills• machine tools• hydraulic swivels• injection molding machines• valve spindles• food processing (blenders and mixers) • hydraulic steering units • forestry machines and cranes • rotators for handling devices • vane actuators/motors• hydraulic motors • hydraulic pumps • propeller thrusters • ROVs (remotely operated vehicles)

Rotary sealing

Turcon® Roto VL® Seal is available in a broad range of sizes.

Trelleborg Sealing Solutions in the groove No. 01/09

Trelleborg is a global engineering

group creating high-performance

solutions that seal, damp and

protect in demanding industrial

environments, all over the world.

Find out more about our world

at www.trelleborg.com.

At Trelleborg, we aim high. Not only with our high-performance polymer

solutions, but also with our people. Our world is challenging and

demanding, which often results in pioneering developments. To stay

world leading, we need talented people. Are you Trelleborg potential?

Trelleborg. Where talents grow.

Solutions Securing Values™

Some call you talented.We call you Trelleborg potential.

080909_Studentannons_T-time.indd 1 08-10-28 17.08.29

26

Automotive

Fulfilling all our energy needs from oil while reducing our CO2 emissions will become increasingly difficult.

Biofuels present a short-term sustainable option, but much controversy has focused on the real environmental benefits of first generation fuels.

Sealing in biofuels, especially the next generation ones developed to have less environmental impact, is challenging.

Trelleborg Sealing Solutions has undertaken substantial research, which means that we can recommend the optimum sealing solution for biofuel applications.

In short...

Sealing for a sustainable

future

Trelleborg Sealing Solutions in the groove No. 01/09

2�

It seems more and more likely that the use of fossil fuels is heading down a dead-end street. Global warming, yo-yoing oil prices and an overwhelming dependency on oil make these fuels a less than viable option for the future.

As an energy source for transportation, biofuelswill play a future role

Car manufacturers consider sustainable biofuels an essential part of an integrated approach to reducing CO2 emissions. They have invested in engine modifications to accommodate current biofuel blends and future fuel mixes with higher biofuel content.

“The second generation of biofuels,” says Gordon Micallef, Technical Director, Trelleborg Sealing Solutions Malta, “is likely

to play an increasingly important role as an energy source for transportation in the near future. These biofuels are made from non-edible feedstock and have increased yields.”

Biofuels can deteriorate the properties ofelastomer seals

However, these biofuels present new challenges in many areas, from production, to the service station, to the vehicle.

“O-Rings are the most commonly used seal in fuel systems and the effect biofuels have on the elastomers they are made of is critical in ensuring sealing integrity. For instance, a blend ratio of 25 percent alcohol in gasoline can cause major deterioration in the properties of elastomers.”

When engineers specify seals, biofuels present some significant challenges as their chemical make-up can affect the sealing integrity of elastomers. Standard laboratory tests indicate that typical FKM and FVMQ compounds are compatible with biofuels. However, when sealing materials are tested in conditions reproducing those seen in service, it becomes evident that specialized formulations are required to ensure integrity and long service life.

Trelleborg Sealing Solutions in the groove No. 01/09

2�

By 2050, the world needs to double its supply of energy while cutting CO2 emissions in half. As the global population heads for nine billion, supplies of conventional oil and gas will not keep up.

Biofuels are the only short-term alternative

The introduction of biofuels such as ethanol and biodiesel, with their inherent potential to reduce CO2 emissions significantly, appeared to be the sustainable solution. But eco-euphoria gave way to alarming reports about the side effects of biofuel production. They have been blamed for everything from destroying the environment to starvation in the developing world.

However, some experts supporting the technology say that criticism against biofuels is exaggerated or just plain wrong. For example, 98 percent of the palm oil production

that is widely blamed for the destruction of the Malaysian rainforest and the orangutans that live there is used for food and cosmetics, not biofuels. These experts argue that biofuels, as the only short-term renewable alternative to oil in transport fuels, have an important role to play now – subject of course to environmental safeguards on how they are produced.

New sources of biofuel focus on sustainability

Since widespread criticism of first generation fuels, research is focusing on utilizing sources that do not compete with food, threaten rainforests or undermine communities creating biofuels. These include cellulosic ethanol from straw, synthetic biodiesel from woodchips and gasoline made directly from sugars. Producers are also looking at maximizing use of by-products, minimizing waste.

For example, most biomass fuel production will have a protein by-product, which can be used for animal feed. There may also be residue of the biomass itself, which can be used for power. Cellulosic ethanol has by-product chemicals such as xylitol, which is used in a range of food products.

Another concern is whether biofuels take more energy to create than they give back. It is believed that in almost all situations this is not the case. Corn-based ethanol, for example, emits around 10 to 30 percent less CO2 than gasoline on a well-to-wheels basis. Ethanol made from Brazilian sugar cane emits up to 90 percent less.

And biofuels are getting better all the time, more energy efficient, lower in CO2 and more sustainable. Algae, another future source, is expected someday to absorb more CO2 than is later emitted during the production and combustion processes combined.

Testing and compound development for theoptimum sealing solution

Trelleborg Sealing Solutions is working on safe alternatives for all types of combustion engines, collaborating with fuel producers and dealers – as well as with customers and original equipment manufacturers. Through testing and compound development, the company is comparing the effects of biofuels on various elastomeric sealing compounds in search of optimal formulations.

“Recently,” Micallef says, “we evaluated the compatibility of typical automotive fuels for both diesel and gasoline engines with various fuel system compounds focusing on hardness, stress-strain and volume swelling. As newer gasoline engines operate at high pressures, the combined effects of high pressures and biofuels were also studied.”

Standard seal formulations may not giverequired integrity

Standard laboratory tests suggested that typical elastomers of Fluorocarbon (FKM) and Fluorosilicone (FVMQ) were compatible

with commonly used biofuels. However, going one step further, testing was conducted to reproduce service conditions.

“This presented a different picture,” Micallef says. “Water contamination in biodiesel is highly probable and can lead to nonreversible degenerative effects on certain FKMs.”

It is crucial to select the right compound

“In high-pressure gasoline applications,” he continues, “the risk of rapid decompression failure, where gas captured within the seal can cause the seal to split, is increased by the addition of ethanol. In our tests, non-optimized compounds cracked sub-surface. This dramatically reduces the integrity of the seal, while being difficult to detect.”

Tests by Trelleborg Sealing Solutions have proven it crucial to select the right compound for the various seals used in fuel applications. “Research and development is essential,” says Micallef. “It is the only way we can ensure we have the optimum seal for the job.”

Fact

s

Fuel for thought

Automotive

Trelleborg Sealing Solutions in the groove No. 01/09

29

Helping bring in the cropTrelleborg Sealing Solutions is not the only part of Trelleborg Group helping make biofuels a reality. Trelleborg Wheel Systems is doing so as well.

Approximately 50 percent of the cars currently on Brazilian roads are fueled by ethanol produced from sugar cane, and the country is now the world’s second largest producer of ethanol and its number one exporter. Brazil’s seven million-plus hectares/ seventeen million-plus acres already under sugar cane are projected to double by 2020.

Sugar cane harvesting is the core business of Trelleborg Wheel Systems in South America. Extra-wide tires it developed for the forestry industry in the 1960s are ideally suited to sugar cane. Their extended width means less compaction of the soil, which in turn leads to improved nutrient absorption and a reduction in the need for fertilizers.

Trelleborg Sealing Solutions in the groove No. 01/09

30

Biofuels are liquid fuels made from organic matter, typically crops. Bioethanol begins with the fermentation of plants containing sugar, such as sugar cane, sugar beet or corn. A series of reactions caused by yeast or bacteria convert this sugar to ethanol. Biodiesel is produced via base-catalyzed transesterification from oilseeds such as rapeseed, oil palm or others. Triglycerides (fat/oil) react with alcohol to form mono-alkyl ester (biodiesel) and glycerol.

These can be blended in relatively small quantities with existing fossil fuels for use in unmodified internal combustion engines, making them an immediately viable option for the transportation industry.

First generation biofuels are being superseded by second generation ones. Derived from the whole plant, they include biomass to liquid (BTL) and cellulosic ethanol. Both contain a higher CO2 avoidance potential than the first generation methods and increased yields, plus there are no direct interferences in the food chain.

Under pressureA practical example of sealing in biofuel applications is this high-pressure pump. In this application, there was engine oil on the drive side and fuel on the pump side. A three-part seal in between them prevents the two from mixing. The seal has sealing lips in both directions made of Turcon® PTFE based material along with two O-Rings in a specially formulated elastomer that act as pre-stressing elements. This solution provides a good wiping effect, high resistance to wear, the ability to function at temperatures down to -40°C/ -40°F and stability in the presence of biofuels.

Fueling researchTrelleborg Sealing Solutions has been working with automotive manufacturers since biofuel technology was in its infancy. Recognizing the issues in finding the right seals for biofueling systems, we conducted in-depth research on the suitability of sealing formulations in biofuel mixtures. From this research, we can recommend the optimum material for biofuel sealing applications including diesel and gasoline fuel connectors and injectors, either high or low pressure, as well as diesel pumps.

For full details of our biofuel research read “The optimum sealing compounds for biofuels” in the news area on

tss.trelleborg.com

What are biofuels? Fact

s

App

licat

ion

Automotive

Fermentation Esterification

Fruit / Seed

Gas

olin

e

Die

sel

Enzymaticdecomposition

GasificationFT-Synthesis

Ethanol Bio Ester

CelluloseEthanol BTL

1st Generation Biofuels

2nd Generation Biofuels

Biomass,organic residues

Trelleborg Sealing Solutions in the groove No. 01/09

31

Read the article? Now see the movie!Why not take a look at the Trelleborg Sealing Solutions movie on sealing in biofuels? You can order it from your local marketing company now.

The Turcon® alternativeResistant to virtually all media, Turcon®, the Trelleborg Sealing Solutions proprietary PTFE based sealing material, is an ideal option for dynamic and rotary biofuel applications. The material, is available in a variety of geometries, energized either with an elastomer element or with a spring.

For more details, please contact your local Trelleborg Sealing Solutions marketing company. For contacts go to

tss.trelleborg.com

Trelleborg Sealing Solutions in the groove No. 01/09

32

Innovation

“Currently there is a big push by industry in general to reduce power consumption and our carbon footprint,” says Stuart Moares, Product Manager for Trelleborg Sealing Solutions Bridgwater, UK, one location where Turcon® Varilip® PDR is manufactured. “Apart from showing responsibility for the environment, it has the benefit of lowering ever-increasing energy bills.”

“lowering ever-increasing energy bills”

Taking a specific example from the semiconductor sector, tests show that Turcon® Varilip® PDR requires only around 50 percent of the torque of a radial oil seal when running in Fomblin® oil, commonly used in vacuum pumps. This meets designers’ objectives for lower power consumption, a critical success factor in this type of equipment.

A cost-effective option for virtually any rotatingapplication

Based on the substantial experience of Trelleborg Sealing Solutions in supply of custom-designed metal-bodied rotary shaft seals, the new range offers customers a wide choice of standard parts in various corrosion-resistant materials and lip geometries. These will meet the requirements of virtually any rotating application in numerous industries including chemical processing, oil & gas, semiconductor, automotive, motor sport, marine, machine tools and power transmission. As no specific tooling is needed in manufacturing, they prove a very cost-effective option.

Trelleborg Sealing Solutions launches Turcon® Varilip® PDR. The optimum solution for high-speed rotating applications, it has exceptional low-friction characteristics, reducing torque. That cuts power consumption, contributing to lower equipment running costs and in the end, decreased energy bills.

movementLow energy

Turcon® Varilip® PDR is ideal not just for processing systems. It has been successful in motor sport applications too.

Trelleborg Sealing Solutions in the groove No. 01/09

33

Turcon® PTFE based sealing lip• Low-friction to facilitate reduced power loss and friction-

induced heat• Unique self-lubricating hydrodynamic feature further

reduces friction• Advanced geometries engineered to give excellent

performance in almost every high-speed rotary situation • Multiple lip configurations to address most sealing needs• Material compatible with virtually all media• Available in FDA-compliant grades

Metal body• Durability in harsh environments• Effective sealing on static outer diameter• Resistance to thermal cycling• Choice of high-quality metals including Stainless Steel,

aluminum and other specialized metals such as Hastelloy® or Titanium

• High corrosion-resistance• Superior precision-machined finish for improved sealing on

the static interface

Overall Turcon® Varilip® PDR seal• Contributes to a reduction in power consumption of

equipment• High speed capability up to 100 m/s / 19,680 ft/m• Wide operating temperature range from -60°C to +200°C/ -76°F to +392°F• Options available for dry-running applications and for soft

shafts• Retrofits in radial oil seal grooves• Unlimited shelf life with no special storage requirements

Benefits of Turcon® Varilip® PDRinclude:

Turcon

® Varilip

® PD

R

Trelleborg Sealing Solutions in the groove No. 01/09

80 / 265

70 / 230

60 / 200

50 / 165

40 / 130

30 / 100

20 / 65

10 / 35

8000

7000

6000

5000

4000

3000

2000

1000

0 40 /1.60

80 /3.15

120 /4.50

160 /6.30

200 /7.90

34

Turcon® Varilip® PDR gives superior surface speed capability compared to elastomeric shaft seals.

services area.

Download the Turcon® Varilip® PDR catalog from

tss.trelleborg.com

Long service life in rotary applicationsTurcon® Varilip® PDR (Performance, Durability, Reliability) rotary shaft seals are constructed from one or multiple Turcon® PTFE based sealing elements which are mechanically retained in a precision-machined metal body. The metal body gives a robust static seal against the housing, preventing thermal cycling, while the Turcon® sealing element provides positive dynamic sealing on the shaft, leading to excellent performance at high rotary speeds. Characterized by low friction and stick-slip-free running, the seal reduces temperature generation, permits higher peripheral speeds and lowers power consumption. This results in a long-service life, with maximized mean time between planned maintenance and greater productivity.

Pro

duct

info

rmat

ion

High speed performance

Innovation

Turcon® Varilip® PDR

Fluoroelastomer

Polyacrylic

Nitrile

RP

M

Sur

face

Spe

ed m

/s /

ft/

s

Shaft Diameter mm/in

Trelleborg Sealing Solutions in the groove No. 01/09

+300°C / +572°F

+250°C / +482°F

+200°C / +392°F

+150°C / +302°F

+100°C / +212°F

+50° / +122°F

0°C / +32°F

-50°C / -58°F

-100°C / -148°F

35

Turcon

® Varilip

® PD

R

Turcon® Varilip® PDR provides outstanding high and low operating temperature performance.

Turcon® Varilip® PDR has been successfully tested in 20 percent fluorine gas, used in semiconductor fabrication applications, at temperatures in excess of +250°C/ +482°F.

Wide temperature range

Turcon®

Silicone

Fluoroelastomer

Polyacrylic

Nitrile

Leather

Trelleborg Sealing Solutions in the groove No. 01/09

36

Processing

“It’s hard to tell you all the applications for Plate Heat Exchangers or PHEs, as they are affectionately known,” says Jonas Jerleus, Trelleborg Sealing Solutions Global PHE Coordinator. “Originally they were used in the sterilization and pasteurization of dairy products, mainly milk. Now though you’ll find them on ships, feeding heating systems for buildings and in almost every processing plant.”

The demand for Plate HeatExchangers has doubled

PHEs for liquid beverages used to take the lion’s share of the market. This sector has diminished as the other sectors have expanded. In the early days, the number of PHEs sold was relatively small. Then demand started growing, and driven by a desire to manage energy better, in the last ten years the market has doubled.

“Heat is generated in all types of processing,” says Jon Cutler, Trelleborg

Sealing Solutions Material Development Manager for PHE gaskets. “In richer and less environmentally aware times heat was just pumped out of the processing system and wasted. That wasn’t good for energy conservation or the atmosphere.

“PHEs ensure efficient energyuse by recycling heat”

“Think of a power station. Why get rid of all the steam used for energy production when it can be diverted into heating offices and homes? On a ship, just like the function a car’s radiator performs, but on a larger scale, PHEs mean heat from combustion engines is used for air-conditioning and heating. While in processing plants, PHEs ensure efficient energy use by recycling heat. When they are employed within a system the overall heat loss can be extremely low.”

“Wander around a processing plant and you’ll see PHE up to five meters/ 16 feet in height,” adds Jonas. “The largest plate

A fair

As energy conservation becomes a focus for us all, the demand for Plate Heat Exchangers is booming. Not only are they a fundamental part of many production processes, they also facilitate the use of what otherwise would be wasted heat. Trelleborg Sealing Solutions is one of the leading suppliers for gaskets fitted to these systems.

exchange

Trelleborg Sealing Solutions in the groove No. 01/09

3�

Plate Heat Exchangers are used for heating and cooling.

Depending on the process, heat is recycled in various ways to conserve energy.

Applications are numerous, from liquid beverage production to district heating systems.

Trelleborg Sealing Solutions produces the critical gaskets that allow PHEs to function successfully.

In short...

exchange

Trelleborg Sealing Solutions in the groove No. 01/09

3�

width is one and a half meters/ five feet, and length is four meters/ 13 feet. This is restricted by the maximum size to which strip steel can be produced. They will range from this size down to about 280 millimeters/ 11 inches long and 100 millimeters/ four inches wide.”

Gaskets preventing liquids mixing orleaking are critical in PHEs

The plates are sealed with a rubber gasket that prevents the two liquids within the PHE leaking out or mixing. “Gaskets are critical elements within a PHE and potentially their weakest link,” continues Jon. “We’ve been making them for more than 25 years and customers rely on our material expertise.”

Sealing in PHEs is not easy. Temperatures are at extremes from –45°C to +200°C/ –49°F to +392°F, while chemicals are some of the most aggressive processed. As the liquids are pushed through a large PHE with maybe 200 plates, pressures are also high. These are generally between 0,5 and 1.5 MPa/ 72 and 218 psi but sometimes even up to 3.5 MPa/ 508 psi.

“we are able to guarantee meetingthe OEMs’ tight tolerances”

“We’re taking gasket compounds to the limits of their performance,” says Jon. “Great efforts have been made to ensure gasket material longevity at high temperatures and pressures. An advantage we have is that applications are static. Materials can also be engineered with both high modulus and excellent deformation resistance.”

Trelleborg Sealing Solutions works very closely with its customers, and quality is key. “If there is one thing we pride ourselves on more than any other,” Jon points out, “it is the initial fit of our gaskets. Probably better than any other manufacturer we are able to guarantee meeting the OEMs’ tight tolerances in gasket length control.”

As OEMs expand productionworldwide, a supplier’s global reach is important

Jonas emphasizes that service is also important. “Timing can be critical, especially when a ship is being fitted out. We may be given one specific day that the gaskets can be delivered, and there can be no excuse if they are not ready on time.”

An emerging trend is that the PHE original equipment manufacturers, who have predominantly manufactured in Europe up until now, are expanding production globally. “That’s where our global reach is important,” says Jonas. “In Europe we manufacture in Poland and demand from the Americas is fulfilled from our facility in Tijuana, Mexico. With manufacturing in Asia increasing, we have now transferred gasket technology to our plant in Shanghai, China.”

Processing

Fact

s

Heat exchanger plate and gasket

Plate heat exchangers are used in a wide variety of sizes.

How a Plate Heat Exchanger worksThe design concept for all PHEs is the same. Between two metal end plates there is a series of thin metal plates close to each other. The liquid to be processed is pumped into one side of the plates while the liquid facilitating heating and cooling is pumped into the other. The key to the process is that both liquids come into contact with the maximum plate surface area to rapidly exchange heat from one liquid to the other. Plates are produced in a variety of metals, primarily strip Stainless Steel and for contact with seawater, in titanium. The main gasket materials for plate heat exchangers are Nitrile Butadiene Rubber (NBR), Ethylene Propylene Diene Rubber (EPDM), Fluoroelastomer (FKM), Chloroprene Rubber (CR) and Hydrogenated Acrylonitrile-Butadiene Rubber (HNBR) with other compound types being used for specific applications.

Trelleborg Sealing Solutions in the groove No. 01/09

39

Food and beverage processingPHEs were originally developed for the pasteurization and sterilization of dairy products. Their use has extended to all types of liquids in food and beverage processing.

Chemical processingLarge PHEs are used in many chemical manufacturing processes for controlled heating and cooling.

Pulp and paper millsWaste heat is effectively recycled in pulp handling and paper production.

Industrial refrigerationFor ice and snow production, PHEs often have refrigerants on one side of the exchanger and coolant on the other.

Power industryNumerous PHEs are utilized for cooling, pre-heating and waste heat recovery in all types of power stations.

Marine Below deck a variety of PHEs might utilize heat generated from engines for various functions, including heating and air-conditioning, as well as cooling the engines themselves.

Biofuel productionPHEs are an integral part of the extraction and processing of ethanol from vegetable matter.

Building Heating Ventilating and Air-Conditioning (HVAC)District heating systems where PHEs allow the use of steam from power stations to heat or air-condition apartment buildings, factories and public buildings

PHE gaskets range in length from 280 millimeters/ 11 inches up to four meters/ 13 feet at a maximum of one and a half meters/ five feet wide. The smallest thickness is two millimeters/ 0.08 inches up to 20 millimeters/ 0.8 inches for gaskets used in evaporation and condensation processes, such as ethanol production.

App

licat

ionsPlate heat exchanger applications:

Fact

s

Plate Heat Exchanger construction

1 Fixed cover/end plate2 Movable cover/end plate3 Carrying bar4 Guiding bar5 End support6 Plates/ gaskets� Tightening bolt� Connection port

2

1

3

4

56

�

8

Trelleborg Sealing Solutions in the groove No. 01/09

40

Hydropower

On the Cowlitz River in the state of Washington sits the Mossyrock Dam, the Pacific Northwest United States’ tallest. Owned and operated by Tacoma Power, the dam is being overhauled to improve efficiency. When completed, Riffe Lake reservoir, formed by Mossyrock, will power 78,000 homes with electricity. That’s 30,000 more than it powers currently.

powerwater

Theof

Trelleborg Sealing Solutions in the groove No. 01/09

41

After over forty years of service, hydroelectric turbine units on the Mossyrock Dam were not as efficient as they once were, with repairs and maintenance becoming more and more expensive. Eventually, without replacement, failure due to mechanical fatigue would take place, meaning very costly repairs. To avoid this, Tacoma Power decided to upgrade the two largest 150 megawatt units and install one additional unit before any problems could occur.

ANDRITZ HYDRO Canada, a worldwide manufacturer of hydroelectric turbines, was awarded the contract to upgrade the Mossyrock Dam hydroelectric turbine units. The two 150 megawatt propeller units were originally built in 1968 and have had an extended service life of almost 40 billion kilowatt hours.

Complete Overhaul

Trelleborg Sealing Solutions Canada, working with ANDRITZ HYDRO Canada engineers, specified machined Orkot® TXMM hydro bearing materials for the upgrades. “We worked together

Two hydroelectric turbines are being replaced and an additional one fitted as part of an upgrade to Mossyrock Dam after forty years of service.

ANDRITZ HYDRO Canada will be undertaking this work.

Once completed, the dam will power 30,000 extra homes with electricity.

Trelleborg Sealing Solutions will supply hydro bearings and a variety of seals for the turbines.

In short...

water

to calculate and design the bearings for proper installed clearances and interferences,” says Tom Carew, Hydro Segment Manager for Trelleborg Sealing Solutions Americas, who worked closely with ANDRITZ through the whole project.

The wicket gate bearings, vertical and horizontal liners, operating rings and all linkage bearings on the turbines were all fitted out with Orkot® TXMM bearing materials. In addition, Variseal® VR seals, using an elastomeric energizer and Zurcon® Z80 jacket, were incorporated into all intermediate and lower wicket gate bearing designs. These seals are specially designed by Trelleborg Sealing Solutions Broomfield for hydro bearing applications.

Partnership Formed

Trelleborg Sealing Solutions Canada is now a preferred supplier for ANDRITZ HYDRO, with Orkot® TXMM hydro bearings being the recommended product for specification on all future projects, where required.

The new, upgraded turbines will be fabricated and installed in 2009. In addition to also replacing the wicket gate seals and bearings with Trelleborg Sealing Solutions product, ANDRITZ will complete the project by replacing the exciters and generator stator, refurbishing the rotors and modernizing the governor with a new digital control system.

Orkot® bearings are used on numerous

hydropower applications.

Trelleborg Sealing Solutions in the groove No. 01/09

42

Mossyrock Dam is the Pacific Northwest United States’ tallest at 185 meters/ 606 feet. Owned and operated by Tacoma Power, the dam is being overhauled to improve efficiency. After this has been done, Riffe Lake, the 34 kilometers/ 23 mile long reservoir formed by Mossyrock, will power 78,000 homes with electricity.

The reservoir serves multiple purposesbesides power generation. It is a popular recreation destination, particularly in the summer and fall. During winter and spring the level of the reservoir is lowered to provide space to help manage down-river flooding. During the summer months water is gradually released to provide supplemental river flows for the benefit of the fish habitat.

Fact

s: T

he d

am

Hydropower

Trelleborg Sealing Solutions in the groove No. 01/09

43

Hydroelectric SpeakGross Head – the true vertical distance from intake to turbine and the resulting pressure at the bottom

Net Head – the pressure at the bottom of a pipeline when water is flowing to the turbine

Exciter – controls the magnetic field in the generator system and controls the output voltage and/or current

Generator Stator – stationary part of the rotor system, as is in an electric generator

Governor – electronic system that controls the speed on the turbine

Mossyrock Dam: Generating power since 1968On October 13, 1968, Tacoma City Light’s Mossyrock Dam on the Cowlitz River in eastern Lewis County generated electricity for the first time. The two generators within its powerhouse with net head of 105 meters/ 345 feet, each generate 150,000 kilowatts of electricity for Tacoma.

His

tory

Defi

nition

s

Pictured are the tops of the generators. Each of these generators is powered by its own turbine unit, located below the generator floor.

Trelleborg Sealing Solutions in the groove No. 01/09

44

Service

Matchmaking

Trelleborg Sealing Solutions prides itself on the best-in-class tools it has on the web. Always trying to make the lives of engineers easier when they are specifying seals, we have developed some new additions online - a material search and chemical compatibility check. Both of these help match the optimum seal material to the requirements of specific applications.

online

Trelleborg Sealing Solutions in the groove No. 01/09

45

Quick and user-friendly way of finding the level of resistance of elastomer material groups to a broad range of media, both fluids and gases

Simple symbols indicate resistance

One or multiple media can be selected in a single search

Chemical compatibility check

Simple to use It’s really easy to find the optimum material type for your application!

1. Select the media seals will come into contact with in your application from an A to Z list covering all common process and cleaning fluids and gases. You can select more than one at a time.

2. Click ‘Show compatibility.’

3. The result is a table with symbols indicating if sealing material types have very good, good or limited suitability, or if the material type is unsuitable.

4. From the table the optimum material type can be selected. As the results are only a guide, then it’s time to email or pick up the phone to contact your local marketing company to select the best compound for the job.

5. Or go to Material Search to find out more information on specific materials

Trelleborg Sealing Solutions in the groove No. 01/09

46

Detailed data at the click of a mouse Use this tool to identify the optimum sealing

compound from the hundreds of elastomers listed.

Material searchFind material properties searching by elastomer material type or trade names quickly and easily

Identify compounds that meet specific property requirements such as operating temperatures or hardness

Identify formulations that comply to specific approvals or standards

1. If you select ‘Search by Material Name and Properties’ on the first screen you have the choice of searching for compounds by material group, common trade names, the Trelleborg Sealing Solutions name, temperature in Celsius or Fahrenheit, hardness and approvals.

Service

Trelleborg Sealing Solutions in the groove No. 01/09

4�

to access all our online services.

Trelleborg Sealing Solutions believes that it now provides more widely available online services than any other sealing supplier.

The new material search and chemical compatibility check join the already well-established O-Ring calculator, electronic catalog and CAD service. All are available in the Members Area free-of-charge. Go to

tss.trelleborg.com

2. A good starting point is to add the lower and upper temperature range of your application. The result will give you all the compounds that can theoretically operate within those limits.

3. You can then more closely match your requirements by selecting hardness, a specific material type or an approval that needs to be met.

4. The alternative of searching by product type allows you to narrow your criteria down to recommended materials for O-Rings, QUAD-RING® and V-Ring®.

5. Again, the suitability of materials resulting from the tool is only a guide. So make sure you contact your local marketing company to complete the specification process.

Trelleborg Sealing Solutions in the groove No. 01/09

Your Partner for Sealing Technology

Trelleborg Sealing Solutions

www.tss.trelleborg.com

A complete selection of the nest seals...available from Trelleborg Sealing Solutions – your one-stop-shop.

Trelleborg Sealing Solutions offers an outstandingly comprehensive sealing portfolio –

a one-stop-shop providing the best in elastomer, thermoplastic, PTFE and composite

technologies; our solutions are featured in virtually every application conceivable within

the aerospace, automotive and industrial industries.

TSS Imagead Quality general.indd 1 23.04.09 11:23

Your Partner for Sealing Technology

Trelleborg Sealing Solutions

www.tss.trelleborg.com

A complete selection of the nest seals...available from Trelleborg Sealing Solutions – your one-stop-shop.

Trelleborg Sealing Solutions offers an outstandingly comprehensive sealing portfolio –

a one-stop-shop providing the best in elastomer, thermoplastic, PTFE and composite

technologies; our solutions are featured in virtually every application conceivable within

the aerospace, automotive and industrial industries.

TSS Imagead Quality general.indd 1 23.04.09 11:23

A complete selectionof the finest seals...

![Grua Groove RT600[1]](https://static.fdocuments.in/doc/165x107/54fdd96d4a7959422b8b49c7/grua-groove-rt6001.jpg)