Greg Hinged Accessible Extruder visual instructions

-

Upload

rinceventgf -

Category

Documents

-

view

3.535 -

download

0

description

Transcript of Greg Hinged Accessible Extruder visual instructions

eMotion Tech

http://www.reprap-france.com

eMotion Tech

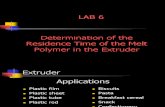

Greg's accessible hinged Wade's

geared extruder

Emotion Tech Greg's accessible hinged Wade's geared extruder

Insert 608zz bearing on the 2cm threaded rod, than insert it in the idler, see picture below.

Fasten the idler to extruder body with the 3cm screw.

Emotion Tech Greg's accessible hinged Wade's geared extruder

Put two 608zz bearings on each side of the extruder, see picture below.

Prepare your hobbed bolt as illustrated below. Adjust the number of M8 washer to face the hobbed

part to the passage of the wire into the extruded (two are enough).

Emotion Tech Greg's accessible hinged Wade's geared extruder

Place the big wheel and bolt on hobbed, add a washer and a nut, then a self-locking nut.

In both holes put two nuts M3 (a hammer may be necessary to drive correctly the nuts)

Emotion Tech Greg's accessible hinged Wade's geared extruder

Prepare two M3 screws 60 mm with a washer and a spring as shown below.

Attach the pulley to the motor with a smmal 3mm screw.

Emotion Tech Greg's accessible hinged Wade's geared extruder

Attach the motor using 10mm screws m3 (it may be advisable to perform this step after mounting

the carriage and hotend x).

Emotion Tech Greg's accessible hinged Wade's geared extruder

Place the hotend on the X carriage.

Screw two nuts and two washers on the rods of hotend, position the X carriage, position the

extruded through the holes indicate by arrows, secure with a washer and nut.